Does stainless steel rust?

Have you ever looked at a shiny piece of stainless steel, having such a question: does stainless steel rust? You’re not alone. Despite its reputation for being corrosion-resistant, many people still question whether stainless steel is truly immune to rust. The answer, as with many things in life, is not a simple one. To truly understand how stainless steel resists rust, we need to dive into the science behind its composition and explore the various factors that can contribute to corrosion. So buckle up and get ready to learn all about stainless steel and its rust-resistant properties.

The answer for the title question is yes. Stainless steel is known for its corrosion-resistant properties, which make it highly resistant to rust. This is due to the high levels of chromium present in the steel, which creates a protective layer on the surface of the metal that prevents rust from forming. However, if the stainless steel is exposed to certain environmental conditions, such as high levels of salt or acidic substances, it can still be susceptible to rust. Additionally, poor maintenance or cleaning practices can also contribute to rust formation on stainless steel. Overall, while stainless steel is highly resistant to rust, it is not entirely immune and requires proper care to maintain its durability.

With its popularity as a durable and versatile material for a variety of applications, it’s no wonder that people often wonder about the rust-resistant properties of stainless steel.This article will continue to discuss the stainless steel from the following aspects:

Table of Contents

What makes stainless steel resistant to rust?

Stainless steel is a popular material for various applications due to its excellent corrosion resistance properties, making it highly resistant to rust. The key to its resistance lies in its unique composition. Stainless steel is made up of a combination of iron, carbon, and other elements, such as chromium and nickel.

Chromium is a key element that gives stainless steel its resistance to rust. When exposed to oxygen, it reacts with it to form a thin, transparent layer of chromium oxide on the surface of the steel. This layer acts as a protective barrier, preventing oxygen and other corrosive substances from penetrating the steel and causing rust.

The amount of chromium in stainless steel determines its level of resistance to rust. Higher levels of chromium result in higher resistance to rust. Additionally, the presence of other elements, such as nickel and molybdenum, further enhances the steel’s resistance to corrosion.

Stainless steel also has a smooth, non-porous surface that inhibits the accumulation of dirt and other contaminants, which can contribute to rust formation. This makes it easy to clean and maintain, further enhancing its resistance to rust.

Overall, the unique composition of stainless steel, combined with its smooth surface and ease of maintenance, make it highly resistant to rust and an ideal material for a wide range of applications.

Stainless steel is known for its corrosion-resistant properties, but it is not completely immune to rust. Certain environmental conditions can still cause rust formation on stainless steel surfaces.

One of the most common factors is exposure to chloride-containing substances, such as saltwater, bleach, or cleaning solutions. High humidity and stagnant water can also create a corrosive environment for stainless steel.

Moreover, the presence of iron particles or other impurities on the surface of stainless steel can initiate rust formation. In outdoor settings, exposure to air pollutants and acid rain can also lead to corrosion. It’s important to note that the degree of rust formation depends on the quality and composition of the stainless steel, as well as the severity and duration of exposure to these environmental conditions.

Under what environmental conditions can stainless steel still rust?

Can poor maintenance or cleaning practices contribute to rust formation on stainless steel?

Absolutely! Poor maintenance and cleaning practices can contribute to rust formation on stainless steel.

For example, if stainless steel is not properly cleaned, contaminants like dirt, grease, or other organic matter can accumulate on the surface, leading to corrosion.

Similarly, if stainless steel is exposed to harsh chemicals or abrasive materials during cleaning, it can damage the protective layer and make it vulnerable to rust formation. It’s important to use the proper cleaning methods and materials for stainless steel, and to regularly inspect and maintain it to prevent corrosion. Neglecting maintenance or using incorrect cleaning practices can ultimately compromise the integrity of the stainless steel and lead to costly repairs or replacements.

When it comes to rust on stainless steel, there are a few common culprits to blame. One of the most significant causes is exposure to chloride-containing substances such as seawater, which can break down the protective layer on the steel surface.

Additionally, harsh cleaning agents containing chlorine or other corrosive chemicals can also damage the stainless steel’s protective layer, leaving it vulnerable to rust formation. Another common cause of rust on stainless steel is contamination from iron particles, which can occur during fabrication or installation if proper precautions are not taken.

Finally, poor maintenance practices such as leaving standing water on stainless steel surfaces or failing to address surface damage can also contribute to rust formation over time. To prevent these common causes of rust, it’s essential to properly maintain and care for stainless steel surfaces and avoid exposure to corrosive substances.

What are the common causes of rust formation on stainless steel?

How can stainless steel be properly maintained to prevent rust and ensure longevity?

Stainless steel is a durable and versatile material that is widely used in various applications.

Proper maintenance is key to preventing rust formation and ensuring longevity. Regular cleaning with mild soap and water can help remove dirt and debris that may contribute to rust formation. Avoid using harsh chemicals or abrasive materials that can scratch the surface of the stainless steel, as this can create areas where rust can form.

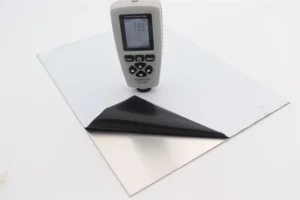

Applying a protective coating, such as a clear lacquer, can help to prevent rust and extend the life of the stainless steel. It’s also important to inspect the stainless steel regularly for any signs of corrosion or damage, and address any issues promptly to prevent further damage. With proper maintenance, stainless steel can provide long-lasting performance and aesthetics.

Conclusion

Stainless steel is a popular material due to its resistance to rust and corrosion, making it suitable for various applications, including construction, automotive, and medical equipment.

However, stainless steel can still rust under certain conditions, such as exposure to high levels of chloride or poor maintenance practices. Common causes of rust on stainless steel include contamination from iron particles, improper cleaning methods, and scratches on the surface. To prevent rust formation and ensure the longevity of stainless steel, proper maintenance practices such as regular cleaning with non-abrasive materials and avoiding exposure to harsh chemicals are crucial. Understanding the properties and environmental factors that can affect stainless steel’s resistance to rust is essential to maintain its quality and longevity. With proper care, stainless steel can provide durability and reliability for many years to come.

If you want to find a trustworthy supplier of stainless steel products, we’d advise you to visit Sino Stainless Steel. As a leading supplier of stainless steel products across the world, Sino Stainless Steel provides customers with stainless steel strips, stainless steel coils, stainless steel plates, stainless steel sheets, stainless steel bars, and stainless steel wires at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

dapoxetine priligy Event 2 Anastrozole was as effective as tamoxifen to treat postmenopausal women with HR breast cancer