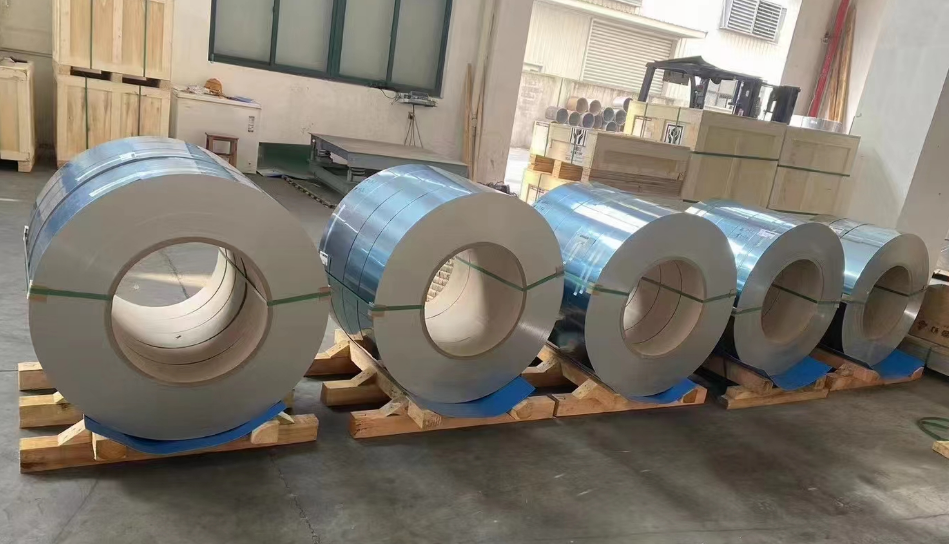

In today’s diverse industrial applications, stainless steel materials are favored for their unique corrosion resistance, strength, and aesthetics. Among them, cold rolled stainless steel coil, as an important metal product, plays an indispensable role in various fields. It meets a variety of demanding application requirements with its unique physical and mechanical properties. Next, we will delve into the characteristics, uses, and production processes of cold-rolled stainless steel coils.

Cold Rolled Stainless Steel Coil: Characteristics, Uses, and Production Processes

I. Characteristics of Cold Rolled Stainless Steel Coils

Cold-rolled stainless steel coil is a metal material that has been processed by the cold-rolling process. Compared with hot-rolled stainless steel coil, it has the following characteristics:

- High precision: Cold-rolled stainless steel coils have high dimensional accuracy and thickness accuracy, smooth surface, and good flatness and verticality.

- Excellent mechanical properties: Due to the refinement of the internal grains of the metal during the cold rolling process, the cold-rolled stainless steel coil has higher strength and hardness, as well as good plasticity and toughness.

- Strong corrosion resistance: Cold-rolled stainless steel coils have a smooth surface and are not easy to adhere to impurities. They have good corrosion resistance and can adapt to various harsh environmental conditions.

- High aesthetics: Due to its excellent surface quality and appearance, cold-rolled stainless steel coils are widely used in construction, decoration, furniture, and other fields.

II. Uses of Cold Rolled Stainless Steel Coils

Due to its excellent characteristics and wide adaptability, cold-rolled stainless steel coils are widely used in various fields. Here are its main uses:

- Construction field: Cold rolled stainless steel coils can be used to manufacture exterior wall panels, doors, windows, railings, stairs, etc. of buildings. Its excellent corrosion resistance and aesthetics can greatly improve the quality of the building.

- Home appliance field: In home appliances, such as refrigerators, washing machines, air conditioners, etc., cold-rolled stainless steel coils are mainly used to manufacture exterior parts and internal structural parts. Its excellent mechanical properties and corrosion resistance can greatly extend the service life of the product.

- Kitchenware field: Among kitchenware products, such as stainless steel pots, bowls, ladles, basins, etc., cold-rolled stainless steel coils are one of the main raw materials. Its excellent corrosion resistance and aesthetics can ensure the long-term use of the products.

- Automobile field: In automobile manufacturing, cold-rolled stainless steel coils are mainly used to manufacture automobile parts, such as automobile body panels, automobile wheels, etc. Its excellent mechanical properties and corrosion resistance can greatly extend the service life of automobiles.

III. Production Process of Cold Rolled Stainless Steel Coil

The production process of cold-rolled stainless steel coils mainly includes the following steps:

- Steelmaking: The steelmaking process is the first step in producing stainless steel coils. Various raw materials need to be melted in a blast furnace to obtain stainless steel molten steel. During the steelmaking process, appropriate amounts of chromium, nickel, and other alloying elements need to be added to improve the corrosion resistance and other properties of the steel.

- Continuous casting and rolling: The molten steel obtained after steelmaking needs to go through two steps: continuous casting and rolling. In continuous casting, molten steel is poured into a crystallizer, and after cooling and solidification, a stainless steel slab is obtained. Then multiple passes of rolling and annealing are carried out through the rolling mill to obtain cold rolled stainless steel coils with the required thickness and flatness. The temperature, rolling force, and annealing conditions need to be precisely controlled during the rolling process to ensure product performance and quality.

- Surface treatment: In order to improve the aesthetics and corrosion resistance of cold rolled stainless steel coils, surface treatment is required. Common surface treatment methods include polishing, spraying, electroplating, etc. These treatments can make the surface smoother and more beautiful, and form a protective film to prevent corrosion and oxidation.

- Quality inspection and packaging: After surface treatment, quality inspection is required to ensure that the product meets relevant standards and customer requirements. Quality inspection includes appearance inspection, dimensional measurement, mechanical property testing, etc. Qualified products will be packaged and shipped from the factory for transportation and storage. Packaging is usually made of moisture-proof and rust-proof materials to protect the product from damage and corrosion.

Conclusion

Thank you for reading our article, and we hope it can help you to have a better understanding of the characteristics, uses, and production processes of cold rolled stainless steel coils. If you are looking for cold rolled stainless steel coils now, please don’t hesitate to contact Sino Stainless Steel.

As a leading supplier of cold rolled stainless steel coils from China, Sino Stainless Steel provides our customers with high-quality cold-rolled stainless steel coils, colored stainless steel sheets, stainless steel pipes, stainless steel strips, stainless steel plates, stainless steel sheets, stainless steel bars, and stainless steel tubes at an extremely competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com