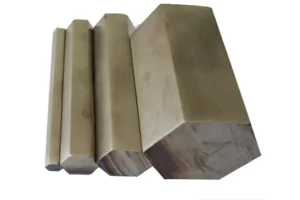

Stainless Steel Hexagonal Bar

Short Description:

The stainless steel hexagonal bar is a section of hexagonal solid long bar made of stainless steel. Due to its wear resistance, corrosion resistance, and good toughness, stainless steel hexagonal bar is widely used in oceanic, chemical, construction, and other fields.

Stainless Steel Hexagonal Bar Details:

Size:

3mm-200mm, 1/8″ to 8″

Standard:

GB1220, ASTM A 484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Grade:

201,304 ,316,316L,310s,430,409

Finish:

Black,N draw

General Description Standards about Stainless Steel Hexagonal Bar:

In terms of stainless steel bar rolling standards, the US, UK, Germany, France, Russia, Japan and international standards are more advanced, and the US standard size tolerance is the most stringent. The latest standards for national stainless steel hot-rolled profiles are: ASTMA276 “Standard Specification for Stainless Steel and Heat-Resistant Steel Bars and Profiles”; American ASTM 484/A484M “General Requirements for Stainless Steel and Heat-Resistant Steel Bars, Billets and Forgings”; German DIN17440 “Technical Conditions for Delivery of Stainless Steel Sheet, Hot Rolled Strip, Wire, Drawn Wire, Steel Bar, Forging and Billet”; Japan JlS64304 “Stainless Steel Rod”.

In the early 1980s, China combined the standards of the United States, Japan, Germany, the former Soviet Union and the International Organization for Standardization (ISO), and focused on the Japanese JIS stainless steel rod standards, and formulated the national standard GB1220-92 for stainless steel bars, with reference to foreign countries. Standards, the national standard GB4356-84 for stainless steel wire rods has been formulated, which makes the steel series more perfect, and adopts internationally-used brands such as the United States and Japan.

Some stainless steel grades in China correspond to American standard grades, as shown in Table 1. At the same time, it retains the commonly used grades in China, which is basically consistent with the stainless steel grades of developed countries such as the United States, and has greater versatility. Compared with developed countries, the gap between the standards itself has shrunk a lot, but the surface quality and dimensional tolerances are poor, and the difference in physical level is large.

Stainless Steel Hexagonal Bar – Production Process

Bar production line process: billet acceptance → heating → rolling → double shearing → cooling → shearing → inspection → packaging → metering → storage.

Small bars are produced by small mills. The main types of small mills are: continuous, semi-continuous and horizontal. At present, most of the world’s new and in-use small continuous rolling mills.

Today’s popular rebar mills have a universal high-speed rolling rebar mill and a 4-segment high-yield rebar mill. The billet used in the continuous small rolling mill is generally a continuous casting billet, and its side length is generally 130-160 mm, 180 mm×180 mm, the length is generally about 6-12 meters, and the billet weight is 1.5~3 tons.

The rolling lines are mostly arranged in a flat-upright manner, achieving full-line non-torsion rolling. The number of racks is determined by the principle of rolling one rack together. The rolling mills are mostly even-numbered passes. There are 18, 20, 22 or even 24 small mills for different blank sizes and finished sizes, and 18 are the mainstream. Speed-adjustable, micro-tension and tension-free rolling are the distinguishing features of modern all-continuous small mills.

Part of the rough rolling and medium rolling frame is controlled by micro tension. The part of the medium rolling and the finishing mill are tension-free to ensure the dimensional accuracy of the product. Continuous mills generally have 6 to 10 loopers, and even up to 12 loopers.

Bar rolling is the easiest to implement in all rolled materials and can be done in a variety of ways. From three-roller to to-twist, from semi-continuous to full-continuous, bars can be produced, but their yield, dimensional accuracy, finished product, and pass rate are quite different. The rigidity of the three-roll mill is low, and the fluctuation of the heating temperature will inevitably lead to serious product size fluctuations.

In addition, the slow speed of the course and the long rolling time lead to an increase in the temperature difference between the head and the tail of the rolling stock, the size is inconsistent, and the performance is uneven. The output is very low, the quality fluctuates greatly, and the quality rate is extremely low. Full-continuous rolling mills generally adopt flat and alternate, the rolling parts are not twisted, the accidents are small, the output is high, and large-scale professional production and structural performance control can be realized.

At the same time, the rolling mill adopts high rigidity, the control degree is high, and the dimensional precision and The pass rate has been greatly improved, especially the yield rate has been increased, and the waste of steelmaking in the return furnace has been reduced. At present, bar rolling is mostly carried out by step-type heating furnace, high-pressure water descaling, low-temperature rolling, headless rolling and other new processes. Rough rolling and medium rolling are developed to adapt to large billets and improve rolling precision. Finishing mill Mainly to improve accuracy and speed.

Compared with ordinary carbon steel hot rolling, the rolling technology and process of stainless steel are mainly reflected in the inspection and cleaning of ingots, heating methods, roll hole design, rolling temperature control and on-line heat treatment of products.

Why Choose Sino Stainless Steel?

As a leading supplier of Stainless Steel Hexagonal Bars across the world, Sino Stainless Steel provides customers with high-qulity Stainless Steel Hexagonal Bars at a very competitive price.

Previous: Stainless steel Channel Bar

Next: 316L316 Cold Rolled Stainless Steel sheets(0.2mm-8mm)

Stainless Steel Hexagonal Bar

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com