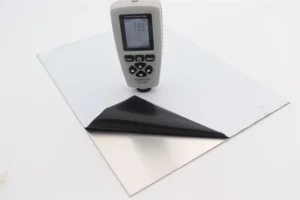

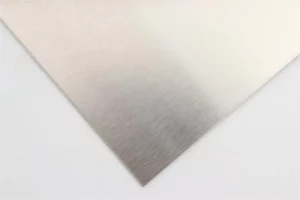

Polished Stainless Steel Plate

Short Description:

Polished Stainless Steel Plate is a precision-processed stainless steel product with a high surface finish, exhibiting a bright and shiny metal appearance and a reflective effect. This processing technique typically involves mechanical polishing or chemical electropolishing to polish the surface of the stainless steel to achieve a certain gloss and smoothness.

Description:

- Finish: No.3, No.4, No.5, SB, Color coating, #3, #4, #8,Hair Line(HL)

- Film: PVC,PE, PI, Laser PVC, 20um-120um

- Thickness: 4.0mm – 100mm

- Width: 300mm – 3300mm, the narrowed products pls check in strip products

- Length:500mm-12000mm

- Grade: 304 ,316L ,201, 202, 430, 410s ,409, 409L, 310, 2205, 321

Surface:

#3 / No.3 – (0.4 ~ 3.0mm) 100 # ~ 130 # (line discontinuous, coarse sand)

#4 / No.4 – (0.4 ~ 3.0mm) 150 # ~ 180 # (line discontinuous, fine sand)

#5 / No.5 – (0.4 ~ 3.0mm) 320 # (finer than No. 4)

HL /hair line – (0.4 ~ 3.0mm) 150 # ~ 320 # (line continuous, commonly known as straight hair, hair silk surface, the general use of 240 # grind)

Polished Stainless Steel Plate Applications:

It has a wide range of applications in various fields, including building decoration, home appliances, automobiles, medical devices, and more. Its excellent corrosion resistance and beautiful surface quality make it an important material in modern manufacturing.

During the production of polished ss plate, multiple processes and precise processing techniques are required to ensure the surface quality and precision. Additionally, to meet the needs of different applications, polished stainless steel plate is available in various specifications and thicknesses.

In summary, polished stainless steel plate is a high-gloss, high-smoothness, and highly corrosion-resistant stainless steel product that is widely used in various fields.

Why Choose Sino Stainless Steel?

If you are looking for polished stainless steel plate suppliers and manufacturers online now, we would advise you to visit Sino Stainless Steel.

As a leading supplier of stainless steel products across the world, Sino Stainless Steel provides customers with high-quality stainless steel products like Polished Stainless Steel Plates, Hot-rolled Stainless Coils, Cold-rolled Stainless Steel Coils, Polished Stainless Steel Coils, Stainless Steel Wires, and Precision Stainless Steel Sheets at a very competitive price.

Polished Stainless Steel Plate

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com