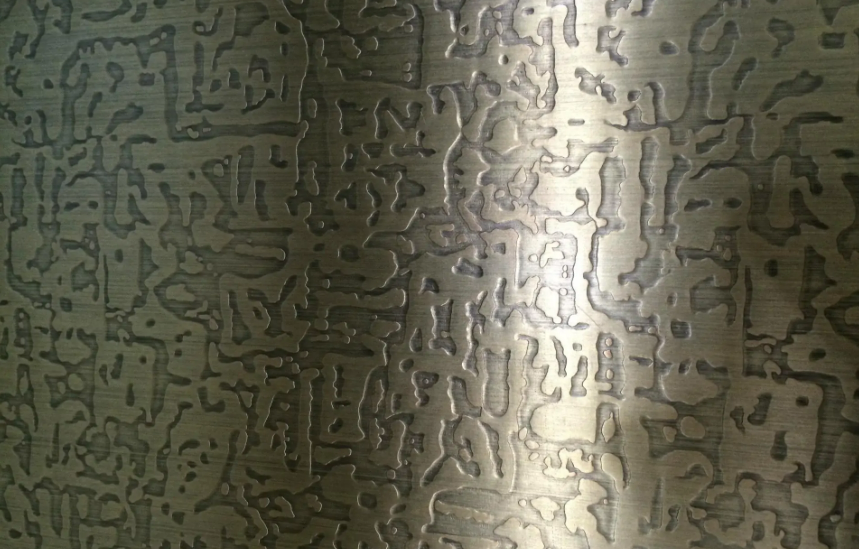

An etched stainless steel sheet is a patterned sheet with various patterns and designs corroded on the surface of stainless steel through chemical methods. Taking an 8K mirror sheet, brushing sheet, and sandblasting sheet as the base sheet, after etching treatment, the surface of the object is further processed by local and grain, brushing, gold inlaying, local titanium gold, and other complex processes to achieve a pattern of light and dark contrast and colorful effect. In this article, we’ll take a closer look at the characteristics of etched stainless steel sheets.

Characteristics of Etched Stainless Steel Sheet

- The etching decorative sheet is processed using a new etching process – the etching optimization version, which creates a three-dimensional effect with rich texture and graphics.

- Etching sheets come in a rich variety of patterns. Masterpieces such as famous paintings, posters, and essays can be produced through etching optimization versions. Similarly, common stainless steel door panel patterns and bathroom cabinet panel patterns in our daily lives can also be produced and processed using this process.

- Etched stainless steel sheets are reliable in quality. Using high-quality 304 stainless steel material, they will not rust or fade even in the atmosphere, rain, and humid environments, making them ideal decorative materials. Etching sheets are commonly used for decorative purposes such as hotel lobby ceilings, hotel gate frame edges, elevator door frames, and patterned handles.

Stainless Steel Etching Principle

The principle of stainless steel etching or corrosion is to use the strong oxidizing property of ferric chloride to corrode the surface of stainless steel, transforming the trivalent iron into a more stable divalent iron. The specific production process is: first apply a protective layer on the stainless steel surface to protect the parts that need to be protected, then put it into a waterfall line spraying with ferric chloride. After the corrosion is complete, wash off the protective layer to form patterns.

Installation method of etched stainless steel sheets

Colorful stainless steel etching sheets for decoration are generally made of 0.6-2mm of different thicknesses of 201 or 304 materials. According to the thickness and decoration parts of the stainless steel plate, the installation method can be divided into two types: with frame and with base plate, and without base plate. The former is mostly used for indoor wall columns or moisture-proof waterproof locations, such as door decorations without rainwater exposure. The frame adopts a wood frame, angle steel welding frame, and light steel frame. The latter is mostly used for outdoor wall decoration, the frame adopts an angle steel welding frame, a light steel frame.

The construction process is basically the following steps:

- Install the frame: The installation process of the base frame can be referred to as the construction process of wooden or light steel frames, and the perpendicularity and flatness should be repeatedly checked.

- Fix the base plate: The base plate is generally made of 5-12mm thick plywood. The construction method and requirements are the same as for ordinary wooden veneer construction, but when the frame is made of light steel or angle steel, holes should be drilled into the frame with a power drill, and the base plate should be fixed on the frame with self-tapping screws, with the screw heads not protruding above the surface of the base plate.

- Fix the faceplate: Before installing the colored stainless steel plate, it should be made into a finished shape according to the design size and shape requirements. If there is a base plate, apply waterproof sealant to the base plate and the back of the stainless steel plate, and gently paste the prepared stainless steel plate onto the base plate. If there is no base plate, fasten the pre-processed stainless steel plate onto the light steel frame with stainless steel screws or weld directly onto the frame.

- Edge treatment: For joints or corners between stainless steel plates, use sealing glue or stainless steel slots to seal and decorate.

- Use a soft dry cloth to clean the colored stainless steel surface and peel off the protective film on the surface.

Conclusion

Thank you for reading our article and we hope it can let you have a better understanding of the characteristics of etched stainless steel sheets. If you want to learn more about the characteristics of etched stainless steel sheets, we would like to advise you to visit Sino Stainless Steel for more information. As one of the top suppliers of Stainless Steel Wire, sheets, Strips, and Stainless Steel Plates, Sino Stainless Steel provides high-quality etched stainless steel sheets at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com