In terms of manufacturing, steel is one of the most widely used and versatile materials in the industry. Over the years, a type of steel that has become popular is Cold Rolled Steel Strips. This material boasts a unique set of characteristics that make it an ideal choice for various applications ranging from automotive components to household appliances. But what exactly are these characteristics? In this blog post, we will explore the advantages and disadvantages of cold-rolled steel strip, its production process, and its numerous applications in different industries. So, let’s delve into the world of cold-rolled steel strips together!

What is the cold rolled steel strip?

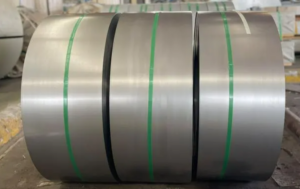

The cold-rolled steel strip is a type of steel that has undergone a cold-rolling process, which involves passing the material between rollers at room temperature. Compared to hot-rolled steel, this process produces a product that is thinner but stronger.

The thickness of cold-rolled steel strips typically ranges from 0.5 millimeters to 6 millimeters, making it ideal for applications that require precise dimensions and strict tolerances. It also boasts excellent surface quality due to its smooth finish and lack of oxidation or rust.

Unlike hot-rolled steel, cold-rolled steel strip is not heated during the production process. This means there is no deformation or warping caused by high temperatures, resulting in more consistent material properties throughout the entire material.

Cold Rolled Steel Strips can be made from various grades of carbon and alloy steels, providing manufacturers with a wide range of options depending on their specific needs. Additionally, this material can be further processed through annealing or tempering processes to further enhance its mechanical properties.

Cold-rolled steel strip has many advantages compared to other types of materials, including higher strength, dimensional consistency, and surface quality. These characteristics make it an attractive choice for industries such as automotive manufacturing, construction equipment manufacturing, and consumer goods production, among others.

Advantages of Cold Rolled Steel Strip

The Cold Rolled Steel Strip has become a popular material in various industries due to its numerous advantages. One of the main advantages is that compared to hot-rolled steel, it improves dimensional accuracy and surface finish. This means that manufacturers can produce parts with stricter tolerances, making them more precise and reliable.

Another advantage of cold-rolled steel strips is their strength. The cold-rolling process increases the material’s strength and hardness while maintaining its ductility, allowing it to be bent or shaped without cracking or breaking.

In addition, cold-rolled steel strip has excellent formability, weldability, and machinability. It can easily be formed into different shapes without losing its structural integrity, making it an ideal choice for production runs with complex designs.

An important feature of cold-rolled steel strips is their clean surface finish without rust or oxidation due to the lack of heat treatment in the manufacturing process; this makes it suitable for applications that require a visually appealing appearance, such as automotive exterior panels.

Due to the fewer steps in the cold-rolling process compared to hot-rolling, production costs are lower. The large-scale production of cold-rolled steel strips is even cheaper because they require less energy consumption during the processing steps.

These advantages make cold-rolled steel strips an attractive choice for many industries that prioritize precision engineering and cost-efficiency.

Disadvantages of Cold Rolled Steel Strip

Despite its many advantages, Cold Rolled Steel Strip also has some disadvantages. One of the main drawbacks is that cold rolling can reduce the ductility and toughness of the steel. This means that the steel may be more prone to cracking or breaking under pressure.

Another disadvantage is that cold-rolled steel strips may have a rougher surface texture compared to hot-rolled steel. This may make them less suitable for applications that require a smooth finish, such as automotive body panels or appliances.

Cold rolling can also increase the hardness of steel, which may make it more difficult to process in subsequent processing steps, such as bending, forming, or welding. In addition, cold rolling can cause residual stresses in the material, which over time can affect its properties.

Producing high-quality cold-rolled products requires specialized equipment and processes, which can result in higher production costs compared to other manufacturing forms.

Despite these drawbacks, cold-rolled steel strip remains an excellent choice for many applications because it has unique characteristics and advantages over other materials.

Applications of Cold Rolled Steel Strip

Due to its unique characteristics, cold-rolled steel strip has a wide range of applications. Its excellent dimensional accuracy and surface finish make it an ideal material for many industries.

One of the most common uses of Cold Rolled Steel Strips is in automotive manufacturing. It is used to produce various parts such as door frames, engine components, and transmission gears due to its high strength-to-weight ratio.

Another industry that benefits from cold-rolled steel strips is the construction industry. It is used in building bridges, roofs, pipes, and other structures because it provides durability and strength without sacrificing flexibility.

The home appliances industry also heavily relies on cold-rolled steel strips because they can resist rust or corrosion caused by moisture or humidity. Refrigerators, washing machines, dryers, and other appliances are made using this metal due to their long-lasting performance.

In addition to the aforementioned industries, there is no doubt that the versatility of cold-rolled steel has increased demand in many areas, including electronics where it can be found in computer cases and phone housings; packaging materials such as cans and bottles; aerospace components such as aircraft engine and turbine parts; and power generation equipment like wind turbine blades, just to name a few examples!

Steps Involved in the Production of Cold Rolled Steel Strip

The production of Cold Rolled Steel Strip involves multiple steps to ensure the quality of the final product. The first step is pickling, which removes the surface rust or oxides from hot-rolled steel. This is achieved by immersing the steel in an acid solution before rinsing it with water.

After pickling, the steel undergoes a process called rolling. In this stage, the steel is passed through a series of rolls, which compress and shape it into a thinner strip of steel. The rolls also improve the surface finish and straightness.

Next is annealing, where the steel strip is heated above its recrystallization temperature to eliminate any stresses created during the rolling process. This ensures uniformity and improves formability.

After annealing, leveling rolling is performed as part of the refining process. The thin plate is subjected to slight elongation without changing its thickness; improving strength and smoothness properties while significantly reducing material costs.

Depending on its intended use, a coating can be applied to provide additional protection against corrosion or other environmental factors.

These processes contribute to the production of high-quality cold-rolled steel strips, which feature excellent dimensional accuracy and smooth surface finishes suitable for various applications in industries such as automotive manufacturing.

Why Choose Sino Stainless Steel?

Thank you for reading our article, we hope it can help you to have a better understanding of the definition, advantages, disadvantages, and applications of Cold Rolled Steel Strips. If you are looking for suppliers and manufacturers of Cold Rolled Steel Strips online now, we’d advise you to visit Sino Stainless Steel.

As a leading supplier of cold-rolled stainless steel products across the world, Sino Stainless Steel provides customers with high-quality Stainless Steel Angles, Stainless Steel Channels, 201 Stainless Steel Strips & 304 Stainless Steel Strips, 409 Stainless Steel, 316 and 316L Stainless Steel, Stainless Steel Hexagon Bars, Hot-rolled Stainless Steel, Colored Stainless Steel Sheets, Stainless Steel Perforated Sheets, Cold-rolled Precision Stainless Steel, Stainless Steel Wire, and Embossed Stainless Steel Plates.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com