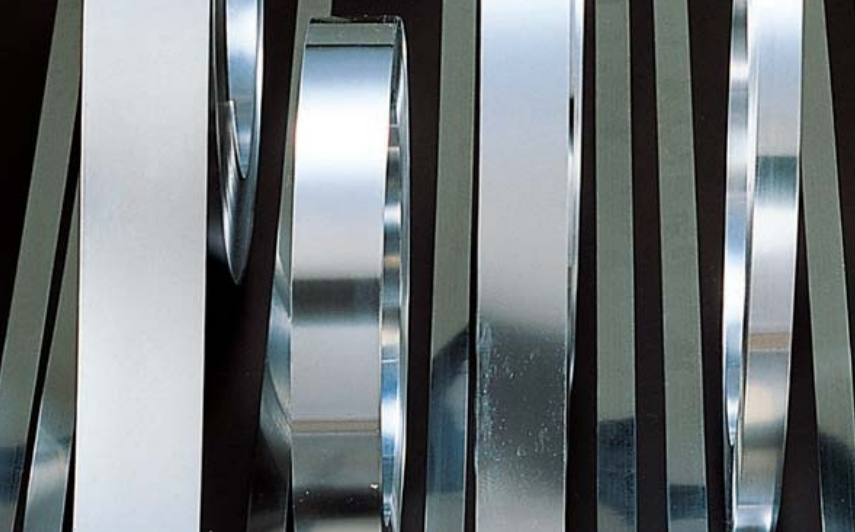

Stainless steel strip, as a metal material with excellent properties, has a wide range of applications in many fields. Its tensile strength and yield strength are what determine whether the stainless steel strip can demonstrate excellent performance in various complex environments. So, what exactly are tensile strength and yield strength? How do they affect the performance and application of stainless steel strip? Next, let’s delve into this issue together.

What is the tensile strength of stainless steel strip?

The tensile strength of stainless steel strip refers to the material’s ability to resist breakage during stretching, usually measured in megapascals (MPa). It indicates the maximum stress that the stainless steel strip can withstand when subjected to tensile force. If the tensile strength of the stainless steel strip is too low, it will easily break during the stress process. Tensile strength is one of the important indicators for evaluating the quality and service life of stainless steel strips.

What is the yield strength of stainless steel strip?

The yield strength of stainless steel strip refers to the stress limit of metal materials when subjected to external forces, which is the beginning of yield phenomenon. In other words, it is the boundary between elastic deformation and plastic deformation of metal. When the stainless steel strip is subjected to stress beyond the yield strength, it will undergo plastic deformation, and even if the stress is reduced, the deformation will not recover. Therefore, the yield strength is one of the important indicators for evaluating the bearing capacity of stainless steel strip.

Difference Between Tensile Strength and Yield Strength

The tensile strength and yield strength are two important mechanical property indexes of metal materials, and there are clear differences between them.

The tensile strength is the maximum stress that the material can withstand when subjected to tensile forces, reflecting the material’s ability to resist tensile failure. When the stress on the material exceeds its tensile strength, it will undergo fracture. The yield strength, on the other hand, is the stress limit at which the material begins to undergo plastic deformation when subjected to external forces. When the stress exceeds the yield strength, the material undergoes irreversible plastic deformation, and even if the stress is reduced, the deformation will not recover.

Therefore, yield strength not only reflects the material’s ability to resist deformation, but is also related to other mechanical properties such as ductility and toughness. In practice, yield strength is often used to evaluate the material’s processability, formability, and structural reliability. Tensile strength, on the other hand, is more commonly used to evaluate the material’s tensile strength and structural safety.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the tensile strength and yield strength of stainless steel strips. If you want to find more information about stainless steel, we’d advise you to visit Sino Stainless Steel for more information.

As a leading supplier of stainless steel products across the world, Sino Stainless Steel provides customers with high-quality stainless steel products such as brushed stainless steel plates, polished stainless steel sheets, etched stainless steel sheets, stainless steel bars, stainless steel coils, and stainless steel wires at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

You could not have thought of together with step-ups in your glute exercises, and we don’t blame you – the straightforward

nature of the exercise can simply fool us into considering it’s not that nice.

Luckily for you, we’ve uncovered the most effective workouts

you probably can add to your routine right now to start building that underbutt.

Try to get a minimum of one gram of protein per pound of

body weight per day.

By knowing the method to correctly activate the glutes, you

can drive your hips into full extension, putting the load the place it’s meant to go.

That’s why having a strong gluteus maximus is nice

for everyone, not simply people who play sports. Danger for weak

glutes, muscle imbalances, and general flat butt muscles.

Systemic MRV is when you’re coaching so onerous

that your sleep quality declines, your urge for food falls, and you may get sick more typically.

It’s also when almost all of your muscles begin to hit

native MRVs at about the identical time.

The secondary muscle tissue walking strengths embody

your core and lower back muscle tissue, which assist hold

you up and let you preserve good posture as you progress, Horan says.

When exploring any glute-focused workout routines and

charting out glute goals, it helps to know our glute anatomy.

For a full lower body routine, you will love this

Ultimate Leg Exercise to build power and mass.

You see, each butt train is totally different and a few are actually much better for growth

than others. This means that every butt train will construct and strengthen your glutes to an extent.

However, some are better at it than others, and the strikes with

the very best butt-building potential are those you need in your training program.

Research shows that training a muscle twice every

week is extra beneficial for building muscle than once every week.

This tools permits you to effectively isolate the glutes and activate extra muscle fibers through

the train. To develop a extra rounded butt, you should activate and

work the three major muscular tissues of the glutes constantly.

Hold in mind that the glutes are sturdy and resilient, so

don’t be afraid to load your workouts. Your aim is to add extra mass to

your back profile, so you should make sure you meet your caloric needs every

day. You don’t need to work onerous within the health club

solely to get too skinny as a outcome of calories you burn out of your workouts.

The gluteus maximus muscles are liable for the form and carry of your butt, plus play important roles like stabilizing and extending the

hips and thighs during standing and strolling.

Bear In Mind, we’re not changing your compound lifts

or decrease physique routine; we’re enhancing them.

These glute activation workout routines must be built-in into your normal leg day or glute workouts.

Maintaining your knee bent and foot flexed, carry your proper leg until your thigh is

parallel with the floor and you would possibly be “stamping”

the ceiling with the right foot. Lower your leg back down and back up in path of the ceiling in a continuous motion. When performing this

train, it’s essential to make sure you’re not relying in your quads

for help, as it’ll hinder glute activation.

This movement also can help to reduce back knee valgus, a situation the place the knees are skewed inwards.

Stretching the glutes a ton is not is an effective way

to cause extra muscle growth stimulus. In glute training,

you thus want to create the most important angle attainable between your pelvis and

the femur, in order that the glutes are stretches as a lot as attainable.

This could be organized in all glute workout routines, particularly front-foot elevated lunging, the place the deeper the lunge

is, assuming you’re nonetheless capable of stretch

your glute, the better. There are many exercises that can be carried out to work

the legs and construct the higher glute muscle tissue with out the help of

fancy machines, squat racks, and heavy weights.

Men and girls with out health club memberships are encouraged

to make the most of the physique weight movements under to target this

muscle group and maximize glute hypertrophy, or more merely put, muscle building.

The Bulgarian Split Squat is a extremely efficient exercise for

concentrating on the lower glutes, as well as the quads and hamstrings.

It is a unilateral movement, which implies it works out one

leg at a time, serving to to correct any muscle imbalances between legs.

Step-ups are a highly efficient exercise for focusing

on the decrease glutes whereas also offering benefits to

the quadriceps and hamstrings. These muscular tissues work collectively to carry out a variety of essential actions for our

every day life and bodily activities.

By performing exercises for your glutes, you’re additionally staving off potential damage.

Solid, sturdy glutes keep your hips in proper alignment, reducing the probability of injuring

your legs, knees, lower again, or groin as you run, walk, or climb.

Collectively, they need to effectively stimulate muscle growth in your complete butt.

“Back squats and deadlifts are nice glute workouts, however many individuals have issue sustaining right form with these actions,” Schwind says.

While the controversy over whether squats or hip thrusts is the “best” exercise for the glutes, we can in all probability safely assume that

both are great glute exercises.

One of one of the best things about lunges is that there are numerous varieties.

You can simply combine it as a lot as goal your muscle tissue in numerous methods.

For example, elevate your again foot on a step or platform to really challenge each legs.

You cannot at all times change the shape of your glutes, however

you could make them firmer and stronger with the right exercises.

However for men and women alike, there’s simply something

about having greater glutes. You can hold a

pair of dumbbells to make the train tougher. Alternatively,

step over a resistance band, seize it with each hands, and

do the exercise as you usually would. The reply varies relying on the person, the frequency

of train, protein consumption, and physique fat.

And by load, I imply loads heavier than you can lift with most different workouts.

The words “all fitness levels” are within the title, but this exercise

is best suited for these who’ve already received a stable routine

in place. While Houdyshell gives priceless type pointers

for every exercise, I’d contemplate plenty of the actions a step beyond

primary — particularly with the added resistance from a band

or dumbbell. If you’re in the mood to mix resistance coaching with cardio, this exercise

is a great option. If you’d somewhat focus on building energy and muscle, decelerate your pace and take

longer relaxation intervals — the pause button exists for good reason. I

love a good leg day, but generally I just don’t

have the vitality to trek it to the fitness center (thanks, pregnancy).

During these movements, you’re performing hip flexion and hip extension. If you suppose

about a squat, your hips are pushed back with a

bend on the hips. When you push your physique up, your

glutes should nonetheless extend the hips. If building strong

glutes is in your To-Do record, this post covers the most effective

glute workouts you are capable of do to strengthen and sculpt a butt you’re

pleased with. You want more than plain old squats, lunges, and

deadlifts if you wish to build the glutes of your goals.

Whereas these workouts do contain your glutes,

other workouts work your butt more successfully,

and in my experience, those listed in this article are among the greatest.

With this glute exercise, you’re employed towards gravity

to move your leg away out of your middle line to carry out the kidnapping.

They’re thought-about a compound train so you are concentrating

on your quads, hamstrings, and calves, too. When you perform

a lateral step-up somewhat than a regular step-up, you are also engaging your gluteus medius and gluteus minimus

to perform the kidnapping portion. The glute minimus is the smallest of

the three major gluteal muscular tissues, yet it performs a

significant position in hip perform and stability.

(And pssst, resistance bands are great to add into the combo, too).

The Romanian deadlift (or RDL) may be most famous for constructing sturdy hamstrings,

but did you know that RDLs additionally target the glutes

too? Plus, should you struggle with feeling your glutes activate during a daily deadlift,

Romanian deadlifts are an effective way to help.

The glute max is the glute’s largest, most superficial muscle (meaning it sits on the outer

layer), followed by the glute medius, and at last, the glute minimus (the deepest glute muscle).

The finest workouts for glute activation tend to be those

who isolate and goal every part of the glutes effectively.

It’s related out of your decrease back and hip bone all the method in which to

the highest a part of your thigh bone and a tricky strip on the

aspect of your leg.

Subsequent, decrease the physique as if till the thighs are parallel to

the floor and the knees are flexed at ninety levels. With the burden positioned in the heels, the chest should

stay dealing with upward for postural stability. This provides the

glute with a good and lifted look, and helps to rid weight lifters of the

dreaded flat upper butt. Due to the dynamic motion of

this exercise, glute kickbacks may also have interaction the core and help in the growth

of hip stability. There are several efficient lower body workouts that contribute to muscle firmness, buttock lifting, and lowering the looks of flatness within the upper buttocks.

Including a mini band to this movement could have all of your glute muscular tissues on fire, plus you’ll additionally get some hamstring engagement as nicely.

When you primarily do lots of running or strolling as your exercises, you’re shifting forward in one

plane of movement.

How quickly it occurs is decided by certain factors like your genetics, train regimen, and whether or not you are constantly consuming foods that go to your butt.

You can hold a dumbbell in each hand, a kettlebell

at your chest, or a barbell across your again to make

this glute train harder. Purpose for zero.11 to zero.18 grams per pound of physique weight each time you eat.

You might need even less at first—start with 0.sixty three

grams per pound. It’s potential to place an inch of

muscle on your glutes by the top of this six-week program, Brockman says.

You can begin with a ratio of walking fast for one minute, followed by five

minutes of walking slowly. As you get used to this cadence, you’ll find a way

to increase the amount of time you stroll fast for.

This easy however effective upper glute exercise is suitable to perform at house and produces high activation within the posterior

glute min in the higher glutes [3]. As an adaptation of an everyday facet plank, the slide plank with hip abduction builds your

glutes and enhances hip stability, improving

your form and stability when lifting and decreasing the danger of

injury. “Certain coaching, like jumps, are heavily gluteus maximus-focused, but do require the recruitment of the complete muscle group,” Lopez says.

Balancing on one leg, the glute medius has to work exhausting to stabilize the pelvis and forestall it from tilting or dropping.

The gluteus maximus helps with hip extension, lengthening

to regulate the motion in the course of the eccentric phase (lowering), and contracting (shortening) to extend the hip and bring the torso upright.

Just so that you’ve some expectation of where to start,

most people can get well from glute training at a timecourse that permits for 2-5

sessions of glutes per week at MEV-MRV volumes.

70% of each health journey comes from how properly you do in building a well-rounded diet that supports muscle development.

I’d highly recommend that you’ve a enough intake of protein, which is critical for muscle

repair and improvement. The GHD machine is certainly one of

my favourite ways to target the decrease glutes and hamstrings as a end

result of it presents a dynamic range of motion and is an unbelievable

stretch. This train helped me to create a wonderful muscle reference

to my glutes, which resulted in higher general glute growth.

Ebenezer Samuel, C.S.C.S., is the health director of Men’s Health and an authorized coach

with more than 10 years of coaching expertise. He’s logged training time with NFL athletes and

track athletes and his present training routine consists of

weight coaching, HIIT conditioning, and yoga.

Earlier Than joining Men’s Well Being, he served as a sports activities columnist and tech columnist

for the Big Apple Every Day Information. “Very light on the feet. Good for running and really steady for lifting. Love!” mentioned one Reebok reviewer.

The rigid midsole is meant that can help you generate extra drive as you push against the ground.

If Olympic lifting is your main activity, then you might need to consider the Nike Romaleos four.

Founded in 2007, Gear Patrol is the definitive buying information for lovers.

Our independent consultants take a look at the best in vehicles, tech, residence, outdoors, fashion and watches.

We mix hands-on testing, a long time of experience and authentic pictures to craft stories, critiques and guides.

“I’ve had no much less than 2/3 pairs of each of the PR’s over the years. These are the most effective but,” said one UA reviewer.

Because weightlifting sneakers run to go properly

with your precise shoe measurement, I also looked for a cross-training shoe that may be

snug for lifters with broad feet. My drawback with

a few of the cross-trainers I examined was that they had been either too cosy within the toe field, did not have

the correct quantity of grip on the sole, or have been tight across the high of the foot.

The Altras had been that pleased medium where the toes had room to spread but also

had a balanced cushion platform that supported the

heel and forefoot and had ankle and arch assist.

The slight elevation will assist posture and ankle mobility when trying to squat deep.

Weightlifting sneakers may be awesome tools in the fitness center in relation to supporting your efficiency.

At the tip of the day, the cons that revolve round weightlifting shoes stem from their cost and lack of programming consideration.

If you’re not strapped on a price range and you’re being good with their

use there aren’t a ton of cons with this footwear. The first con that comes with weightlifting shoes is that they will not be a necessary buy for some lifters and they can be costly.

I tend to lean on the side that everyone ought to have a pair of weightlifting shoes,

but there are some circumstances the place you don’t want them.

When searching for new weightlifting sneakers you’ll need to think about how the above options

range between fashions.

In fact, they are often particularly helpful for these simply starting out with weightlifting and nonetheless engaged on their type and technique.

The twin strap system gives a stable hug on the foot for

max stability, too. This shoe has a little more aggressive

arch support than another weightlifting sneakers on this record, so it works well for these who need slightly extra carry underneath the midsole.

Another more modern examine equally discovered that in comparison with more

basic athletic sneakers, weightlifting footwear reduced ankle motion and helped

lifters preserve an upright torso throughout squats.

Some weightlifting shoes have raised heels, which are

better for squats and Olympic lifting, whereas other sneakers are flat and work better for many different types of weightlifting.

Some weightlifting sneakers have a raised heel as a end result of it helps

together with your ankles’ vary of motion when moving into sure positions similar to squats, overhead squats and snatches.

We love an excellent, foam-laden sneaker (and your shoe can have some cushioning when you plan to use it for cross-training), however a more

durable sole is the better alternative for when you’re lifting.

Rogue Fitness is well known for producing high quality fitness center gear, but you could not know that

the model also makes a stable weightlifting shoe.

The shoe offers a wide, flat heel to provide you stability whereas transferring between workout routines,

in addition to sturdy rubber treads for ample traction.

On top of this, this shoe has obtained a $20 USD price point increase which

brings its price to $220 USD. The only real changes

with this shoe in comparison with the Legacy Lifter II is the pump system that some might not want and a few upper adjustments.

I’ve gotten some off-the-rack orthotics (Superfeet brand) and am rolling

the sore spots with a tennis ball and so forth, however

I assume I need new sneakers. Beneath, I’m going to cowl the development particulars that influence

the efficiency and sturdiness of the Inov-8 Fastlift Energy G 380.

One Thing unique to the brand—each shoe has a 100-day trial where you’ll find a way to return your

footwear for a full refund if they don’t meet your expectations.

Power apart, there’s a laundry record of benefits weightlifters

can reap from the right pair of shoes. A solid, non-compressible sole supplies a steady

base and helps to forestall your ft from rolling or shifting during lifts,

allowing you to maintain proper form and technique.

Many weightlifting sneakers are also designed to provide help your ankles, too, which helps reduce the risk

of ankle sprains or different foot and ankle accidents. Good footwear stays comfy whereas you’re strength

training, but the best weightlifting shoes can really enhance your form and keep you protected

during your exercises.

When it comes to squats, I’ve really enjoyed the performance of

the Reebok Legacy Lifter III. This shoe’s sole and heel really

feel secure for heavier periods and if you’re investing on this shoe solely for squats, I think you’ll

like its efficiency. To be sincere, the Legacy Lifter III feels slightly

more like a 2.5, so I was a little let down by this shoe’s updates.

That’s why I’m not convinced everybody ought to spend money on it, particularly those

that don’t wish to spend $200+ USD on a weightlifting shoe.

In Contrast to other shoes with comparable stabilities for squats, it’s tough to find constant shoes that

match these costs. In the context of squats, this is an superior characteristic because you get

a lot of floor suggestions through the forefoot which has a decrease

stack top. You shouldn’t experience compression within the Dropset Coach 2

when squatting over four hundred lbs. As a lankier

man, I recognize a higher heel in terms of squats, thrusters,

and wall balls, which is why I’ll often reach for this mannequin for

workouts with more deep hip flexion work.

A proper pair of “lifters” can increase support, put you in higher lifting positions, and enhance efficiency.

On the higher, you will find a hook-and-loop tab that retains laces secure, which we noticed helps to add lateral stability and forestall tripping.

We also respect that the breathable mesh upper is light-weight,

hugging our feet and providing a locked-in feel. We also

love that these footwear feature light-weight foam cushioning that makes it easy for us to move round

between units. Plus, the puncture-resistant sole protects your feet from sharp objects and particles with out sacrificing the barefoot feel.

Finest for skilled lifters on the lookout for a shoe with

an elevated heel to squat in.

Weightlifting footwear also typically function a higher prime with extra straps or ties

to help assist the ankle. Be prepared to potentially have

some sizing issues with these Do-Win profiles, although.

Some suggest ordering a half size down, whereas others declare

these weightlifting clogs run true to measurement.

In my experience, the latter proved true, however I perceive that fits can differ greatly from one foot to the other.

The Romaleos 4s do characteristic a compact toe box that’s comfortable yet not

overly constrictive. With that mentioned, the silhouette does come

to some extent at the toe flap quite aggressively, which

might result in some extreme pressure if the shoes are

worn for lengthier durations.

It’s not going to be the best option for wide feet, however for most foot

anatomies, the Legacy Lifter three delivers a good

fit. There are no definitive shoe choices in terms of great

sneakers for squatting as a end result of lifters

and athletes will have totally different needs when seeking out great

squat footwear. The final facet to love about this model is that they’re fairly aesthetic and they work really well as day by day drivers,

too. Not every pair of barefoot footwear has a nice clear appearance, however I suppose the Primus Lite

IIIs do a good job at walking that line of performance and look.

For starters, this shoe has an excellent minimalist outsole building so you’ll

be able to actually really feel the bottom under your feet when coaching in these.

In all of my barefoot shoe testing, there are a

lot of models that excel properly for squats, however there are two that stand out to me personally that I all the time find yourself reaching for.

The Flexweave® woven cloth higher actually hugs the foot for an athletic feel.

Stability is strong, due to an outsole made with extremely sticky rubber and a

unique shape that is slightly winged at the mid foot.

The Savaleos are a bit slender via the mid foot and forefoot (as are many Nike athletic shoes),

so when you have wider feet you could go a half dimension up.

However most individuals lifting weights within the gym aren’t doing Olympic lifts, are they?

If you’re in search of a secure, sturdy shoe to face as

a lot as dynamic HIIT workouts, outdoor training or even CrossFit classes, what

you really need is a strength coach. Consider going to a shoe retailer first and getting professionally measured to ensure you’re getting one of the best match and magnificence to go

well with your needs. Weightlifting sneakers can be expensive, particularly with brand names which would possibly be well-known to particularly design them.

There are a few key traits that I search for in trainers

for squats. First, I assess a training shoe’s stability and the way it manages totally different hundreds.

Second, I’m looking at their versatility and how they perform

quite so much of workouts while also excelling at squats.

I’ve squatted over 365 lbs in each pair of sneakers beneath to

test stability and I’ve broken my favorite picks into different

efficiency categories. I’ve been a strength coach for 12 years and I also evaluate footwear, and sure, your

sneakers can affect your squat mechanics. Barefoot lifting ought to

be utilized in settings where it’s acceptable and okay to do primarily

based on the workout routines you’re performing and the rationale you have for coaching barefoot.

Wooden heels are difficult to search out in trendy weightlifting, as many producers

prefer high-density plastic. But if you are severe about

hitting new PRs or competing in Olympic Weightlifting, you want Weightlifting

footwear. Norman Cheung is a powerlifting and accredited strength and conditioning coach beneath the UKSCA.

He has been coaching powerlifting since 2012 and has

been an IPF Group GB coach since 2016. He has

experience coaching varied lifters, from novices to worldwide medallists and worldwide college groups.

I actually have broad ft and cannot fit into Adidas Adipowers, so

I often wear my trusty Nike Romaleo 2s. Nonetheless, the Velaasa Strakes fit great, so they’re nonetheless a choice even when you have bigger ft.

Another nice function of those sneakers is the dual strap system, which creates glorious security through the

midfoot. Although I want the straps had been thicker,

the velcro is powerful and provides good size.

This Vivobarefoot Motus Power shoe is understood for its classic zero-drop design that Judd loves for weightlifting.

While this fashion is flat with minimal cushion to maintain heels even with feet,

Judd notes that this particular shoe presents “added safety and durability” from its sturdy rubber sole and upper.

They’re marketed as a more versatile weightlifting shoe,

which we do not sometimes advocate. Choosing the most effective weightlifting

shoes entails a quantity of elements, similar

to heel height, heel material, toe field width, and private build and preferences.

They have a big construction and toe field, which is good for individuals

with extensive feet. There are three primary differences between weightlifting and

cross-training sneakers, including heel height, heel hardness, and shoe weight.

Weightlifting shoes are inclined to have a better heel height and a more

durable materials for the heel to tolerate

larger absolute loads corresponding to when heavy squatting.

Besides the Puma Fuse 3.zero claiming a spot on our Finest Sneakers of 2024 list,

we’re impressed by its workhorse qualities within the

health club. The midsole cushioning offers responsive vitality return when doing moves like deep squats, however still

maintains stability for no accidents. Flatter shoes also assist reduce bounce throughout a deadlift and cut back vary of motion—the objective when deadlifting.

ACTIVE.com’s editorial team depends on the information and expertise

of fitness and wellness experts together with aggressive athletes,

coaches, bodily therapists, nutritionists, and licensed trainers.

This helps us ensure that the merchandise we characteristic are of the

very best normal. Collectively, the staff has spent

numerous hours researching equipment, gear, and recovery

tools so as to create probably the most correct, authentic content

for our readers. Buyer satisfaction can be a key a part

of our evaluation process, which is why we only function products

which are extremely rated.

The toe cap at the front of the shoe is produced

from a single strip of leather and reinforces the toe field.

Since the material is double thickness on this space, it makes the shoe feel

tighter at first. However identical to an excellent pair of actual leather-based dress sneakers, these stretch over time and actually produce a wider than average toe field.

Cross-training sneakers can be utilized in a selection of totally different training settings.

I at all times suggest lifters and athletes simply have a pair of

cross-training footwear on deck for general training purposes.

Plus, when you deal with your cross-training sneakers they’ll usually final a while and be a solid funding.

Additionally, for you, as a trainer, have them use a heel wedge to know what it’s like to have those knees tracked

ahead while balancing varied hundreds.

They helped her toes stay planted throughout squats, deadlifts, and

good morning exercises, but also kept them from shifting round during more dynamic strikes like reverse lunges and step-ups.

Then, when Sgobba wore the Strongfeels on the elliptical, they

felt surprisingly versatile. If you wish to do a little bit of every little thing around the gym, give these sleek sneaks

a strive. Christa Sgobba, SELF’s director of food

and health, has worn Reebok Nanos for years. They’re reliable all-around

fitness center sneakers that assist her really feel steady and in touch with the

ground whereas lifting, but don’t really feel overly clunky on the elliptical

or train bike.

Plus, as a outcome of it’s made with Nike’s React foam, the shoe is springy sufficient for use for prime depth interval coaching (HIIT) cardio bursts.

We use “men’s” and “women’s” on this article to align with how merchandise are sold on retail websites, however

that does not imply you have to stick to a minimal of one or

the opposite. Choose the product with the fit,

type, and options that work finest for you. Nonetheless, should you regularly

raise weights, you could must add another pair to your wardrobe.

The right shoe will assist you to generate as a lot force via

the floor as attainable so as to decide up heavy weights.

The Fuse 2.zero retails at a cheaper price level than different comparable fashions,

however keep a degree of integrity when it comes to construction and

durability that goes far above the budget-friendly price ticket.

Folks that compete select and prepare the shape that gives

them the most effective benefit to lift probably the most weight.

It is imperative that you just preserve good type with the

sumo deadlift to keep away from damage. If you don’t have band pegs,

drape a resistance band over your barbell after which stand on it.

Fairly a lot the entire muscles in your physique are totally

contracted at the top of a deadlift.

Without a deficit, this means a barbell arrange

for deadlifts must be about eight.5 inches off the

ground. A two-inch deficit means the bar is successfully 6.5 inches

above the floor. To get essentially the most from this

or any train, whereas keeping the danger as low as attainable,

you should at all times use correct kind. Reduce your risk of harm

further by practicing new workouts with gentle weights.

Only enhance the load when you’re sure you have mastered the proper approach.

Deficit deadlifts are challenging however will add a whole new element to your

training.

Done accurately, deficit deadlifts are a brilliant train. Keep Away From these widespread mistakes

to make sure you keep your threat of damage to a minimal. That mentioned, most people use

a platform of between one to four inches excessive.

The greater the platform, the tougher deficit deadlifts turn out to be.

Tall lifters usually need a decrease platform, whereas shorter lifters and those with longer arms can usually use the next one.

You may even wish to emphasize deadlift training, which suggests doing more barbell coaching than accent training.

In fact, this program will have you spending plenty of time on deadlift variations.

Generally, working on the motion sample with completely different vary of motions, masses and biomechanics help to either determine or simply strengthen the motion. The sumo

deadlift is a multi-joint motion in which the ft are placed in a large stance with toes pointed out and the

grip is positioned inside of the legs. It is a legal motion in powerlifting competitions,

but the conventional deadlift is normally the model prescribed in StrongMan, GRID, or CrossFit competitions.

With the wider stance, the hips are positioned closer to the barbell initially of

the raise. These kids of the parent movement can serve a quantity of purposes.

If there are egregious approach errors, then it’s nearly always

better to scale back weight and get the conventional deadlift appropriate.

Even though the RDL works your hamstrings slightly tougher,

conventional deadlifts undoubtedly require sturdy involvement from

your hammies. There are a variety of terrible reasons to love bumper

plates. They take up tons of room on the bar, creating the phantasm

of lifting lots of weight. You can even slam them down from

overhead should you enjoy utilizing a bent barbell.

The again should stay in absolute extension always, and the bar should remain in touch with the legs.

Some folks feel extra muscle activation of their lower back, whereas others may

notice more recruitment of their hamstrings and glutes.

If you’re able where the deadlift isn’t an alternate, no matter

variation, we have an article that gives 9 deadlift

alternate options as a substitute. The

difficulty of a lift and its variations can usually come right

down to particular person strengths and weaknesses in addition to overall body proportions.

These with low back weaknesses or with long legs may discover

this variation to be quite challenging but if load is managed will most likely be a great software for them to construct energy in weak areas.

Because the RDL is harder you must opt for a lighter weight

than you’ll usually deadlift with to complete the

exercise. Very light RDLs can even serve as a great practice software for hip hinging in newbies.

An example of this is able to be Romanian deadlifts or stiff leg deadlifts which emphasize the hamstrings.

Now let’s have a look at the step-by-step instructions on tips on how to carry out deficit deadlifts correctly.

You can even consult an expert coach for correct steerage

about performing deficit deadlifts and weight selection. Yes, they’re harder than standard

Deadlifts because of the longer vary of motion which causes more time under

pressure. They create a extra important challenge for the back muscular tissues and

hip mobility.

These are great for novices or these building a robust base.

They reduce spinal flexion and teach proper lifting mechanics.

Trap bar deadlifts increase leg energy and power, while dumbbell deadlifts enhance

mobility. The deficit is a special kind of deadlift that makes you’re employed

tougher. It makes you bend deeper and use your backside muscles extra.

A recommended place to begin is to place your maximum deload numbers as 20%

lower than whenever you left off. Then take a day to test where the bar begins to feel heavy

in your 5 rep units. If it feels straightforward all the finest way

up to the 20% deload number then cease there.

Subsequently, whereas Beginning Strength and Stronglifts

5×5 will successfully build energy, they could not have as substantial an impression on muscle development.

As A Result Of these are beginner packages, neither

utilize a very high amount of coaching quantity.

If the quantity is too high, newbies wouldn’t be capable of cope with the calls

for and overtraining may occur. As talked about, to optimize power gains, heavy lifting has persistently been found to be best.

Starting Strength has a lower coaching quantity than Stronglifts 5×5.

Subsequently, newbie lifters may find that they recuperate barely better with

Beginning Power. Alternatively, when you have unsuccessfully attended the fitness center earlier than and

located progress to be exhausting to come by, the Stronglifts 5×5 program could additionally be most fitted.

Subsequently, to develop energy and explosiveness most efficiently,

the rep range must be saved low. With the Beginning Energy program, you are to coach

three times per week and alternate between two workouts – A and B.

It has been advised that the Starting Strength program

is too lower-body dominant and likewise, while it could develop strength,

it does not lead to optimal muscle progress. Rippetoe

designed Beginning Energy to be an entry-level novices program to

help lifters gain strength most effectively. Whereas

the goal of each packages is to assist novices become

accustomed to resistance training and in the end enhance their strength, the packages have barely completely different approaches.

Shane Duquette is the co-founder of Outlift, Bony to Beastly, and Bony to Bombshell.

He’s a certified conditioning coach with a level in design from York College in Toronto,

Canada. He Is personally gained 70 pounds and has over a decade of experience

helping over 10,000 skinny people bulk up.

All in all, there’s no clear winner in relation to Beginning

Strength vs. StrongLifts. Contemplate your health stage and expertise as well as your

training targets.

+ means that you’re aiming for a rep report in each exercise, so you’re pushing for the max variety

of reps you can do at that weight. For a lot of lifters, Wendler’s strategy seems fully opposite

of what we’ve at all times discovered. Taking weight

off the bar theoretically strikes us in the wrong course of the place we need to

go. The reality is that starting lighter offers you

extra freedom to maneuver ahead. There are three main lifting programs that have been around for a protracted time.

These three applications – Jim Wendler’s 5/3/1, Beginning

Strength, and StrongLifts 5×5 have all helped lifts of all levels

obtain what they want from the health club – greater numbers and

an improved physique. Let’s take a glance at every of those

programmes to help you determine which is best for

you.

Suppose Dorian Yates “blood and guts” high depth where you train till absolute failure and possibly feel nauseous after.

I’m not too thinking about aesthetics – simply the numbers for the main lifts.

In specific if you needed to deload or hit a plateau, and any adjustments you made.

I strained an erector spinae on the proper

facet, right subsequent to my backbone on the ribs however toward the bottom of my rib cage.

It harm, but it was mild, I took a few workouts off, de-loaded

and got here again and felt nice.

Top/back-off units consist of 1 heavy set adopted by several lighter sets.

Between units you take common relaxation periods of two to three minutes.

Right around three months into it, my spouse obtained sick, adopted by my children getting sick, followed by a highway

trip with friends, and so forth.

The major difference is that beginning power makes use of 3×5 while stronglifts makes

use of 5×5. Personally, being that both programmes seem to

make folks stronger at the similar price, I would most likely go together with beginning

energy. Less work for the same outcomes seems like an easy

win. Fundamentally this programme is an effective begin to power coaching, but there will come a point when it stops being

as effective.

70918248

70918248

70918248

70918248

70918248

70918248

70918248

70918248

70918248

This can be started as soon as your cycle ends with dosing

according to your choice, however I normally purpose for 1000iu per week (two injections).

Then, you’ll be able to follow with a daily SERM PCT utilizing your choice’s SERM(s).

Enclomiphene is my choice these days – it’s a newer SERM with fewer unwanted effects.

A normal dosing schedule is 25mg day by day for weeks 1-5 and 12.5mg for week 6.

Because EQ will result in suppression of natural testosterone

production, post-cycle therapy is required after your

cycle to stimulate the traditional functioning of testosterone once

more. Trenbolone is a really robust steroid that provides a big boost

to muscle endurance and recovery. If utilizing this cycle for chopping, Equipoise will promote the preservation of muscle whereas testosterone

will take care of your testosterone necessities during the cycle at a upkeep

dose.

A testosterone ester should also be included in an intermediate

cycle, and once more, the dosage will depend upon what you’re trying to attain and whether or

not it is a hardcore slicing cycle. Undertaking

a strict calorie-deficit food plan puts you at danger of muscle catabolism and

shedding energy. Anavar or Oxandrolone is an oral anabolic-androgenic steroid that’s used to

promote lean muscle mass and was created in 1964.

Nevertheless, the extent of transformation depends on elements corresponding

to individual genetics, diet, and exercise routine.

Sufficient restoration time is crucial when figuring out,

as it allows the physique to heal and develop muscle mass.

Ensure you could have at least one rest day

per week and permit each muscle group 48 hours of relaxation earlier than working it

once more. Moreover, consuming enough protein and staying hydrated can further support muscle restoration and development whereas

utilizing Anavar. However, it is very important notice that using

Anavar and different anabolic steroids carries potential risks and

unwanted effects. Accountable use, underneath the steering of a medical professional, is essential for guaranteeing the user’s security

and long-term well being. Every of these anabolic steroids has its own benefits and drawbacks,

relying on particular person targets and preferences.

Sorry to bust out the cliché get-ripped-by-summer topic that’s so widespread within the

health industry. Nevertheless, given var’s ability that will

assist you preserve muscle positive aspects during slicing, this is a good drug for the beach-goers who must drop some weight earlier than summer time without sacrificing lean muscle mass.

As mentioned in Point #3, this drug doesn’t

convert to estrogen, which means there are fewer Anavar unwanted aspect effects to worry about (2).

Var does not have much effect on blood stress, nor does it trigger as a

lot harm to the liver at lower doses. The latter could be very interesting since Oxandrolone

is an oral steroid, most of that are exhausting on the

liver. Some potential Anavar unwanted aspect effects that you should be aware

of are gentle suppression, acne, hair loss and nausea.

Dianabol, an oral steroid, will stress the liver, not like Deca-Durabolin, which

has no recognized effect on the liver. If you wish to minimize the

usage of different steroids when on Deca, a low dose

of testosterone is commonly used. Even 200mg weekly will go some approach to helping with

testosterone levels, but remember that testosterone will include its unwanted effects.

For that purpose, pro customers who know what they’re doing with Deca

will run it alone in a cycle at 500mg weekly

and deal with any side effects as they come. Adjusting the dosage to one’s unique needs might require a few tries,

and it’s essential to stay optimistic, affected person, and mindful during

the process. The attainable presence of other dietary supplements in the cycle

can even influence the effective dosage. Combining Primo with suitable companions throughout cutting cycles,

similar to Anavar or Trenbolone, can enhance the general result, taking body definition to the following level.

Trenbolone will give you far more muscle-gaining potential than Masteron, which is more of a pure-cutting AAS.

With no two folks being the identical, men will speak about

paranoia, additional aggression, jealousy, nervousness, and different feelings that can turn into tougher

to regulate as you increase the dose or cycle size.

There isn’t any shortage of negative comments about Tren cycles, though

usually, this will consist of guys just speaking about a few of the worst side effects and the

way to handle them. Some more adverse evaluations naturally heart

on Tren’s tendency to affect your psychological functioning.

Limiting the cycle size is also a near necessity for a lot of customers just because the unwanted

aspect effects will normally become extra pronounced and tough to manage the longer you use this steroid.

Injecting it each other day is the standard protocol to maintain up consistent peak ranges.

These transformations extend past the realm of physical changes and likewise venture

into how Anavar accompanies its customers in their fitness pursuit.

The progress into a leaner physique also initiails inside the first two

weeks. Although not highly dramatic at this point, the onset of fats burning process could be noticed.

Particularly more stubborn fat, like those across the abdomen, might begin decreasing,

indicating Anavar’s promising start. Drawing a comparison between Oxandrolone’s outcomes earlier than and after

cycles can provide essential insights into its impression on the physique.

Determining the efficacy of any anabolic steroid, corresponding to Oxandrolone, is of

paramount importance. By comparison, the extra generally used Trenbolone Acetate ester

has a half-life of simply three days.

One of the keys is to include enough testosterone within the cycle

to counteract any antagonistic effects brought on by Deca’s suppressive exercise.

As A Outcome Of Deca-Durabolin has been used for so long, most customers know what to anticipate.

Of course, we all know from many years of experienced customers that there’s no query that Deca-Durabolin can deliver when it’s used correctly.

At decrease doses of Testosterone Enanthate, HDL cholesterol is

unlikely to be altered. Still, since AI medication are sometimes utilized in a steroid cycle,

this mix is sufficient to bring about suppression of HDL cholesterol – potentially suppressing it by as much as 25%.

A food plan wealthy in omega fatty acids is important to promote cholesterol health whereas utilizing Testosterone Enanthate,

and cardiovascular workouts must be included in all workouts.

I’d use 0.5mg of Arimidex every day whereas working Deca or 10 mg of

Aromasin every day. With a short half-life, if virilization begins creating, you presumably

can quit and have that steroid exit your physique comparatively shortly.

Men who run Nandrolone cycles will virtually all the time be delighted with the results.

With Deca, we take the great with the unhealthy, and it’s as

much as you whether or not the positives outweigh the downsides.

My favorite intermediate cycle is a tried and examined 300mg of Deca stacked with

around 500mg of testosterone. This is a middle-of-the-road Deca dose,

but many guys will never see the necessity to exceed. In that

case, I’d start to worry about what’s actually in your Deca or

NPP and consider discovering one other supply on your gear rather than frequently

upping your dose.

NPP has a short ester that releases quickly and offers fast outcomes but needs to be injected much more regularly than Nandrolone Decanoate, which has a long-lasting ester.

I would use 0.5mg/day of Arimidex every day whereas running Deca or 10mg/day of Aromasin. For

recovery (PCT), use zero.5mg/day Arimidex

for four weeks post-last injection. Begin Clomid 2 weeks after your final injection at 100mg/day for days 1-10, then 50mg/day for

days 11-20.

Nonetheless, it can be used as a secondary compound when stacked with more potent muscle

mass builders like Dianabol or Testosterone. The purpose that so many guys like this compound

when they are in a cutting section is that it is going to permit

them to retain lean mass while also getting stronger and avoiding water retention. Nonetheless, it usually causes virilization unwanted effects, inflicting girls to look

and sound extra masculine. Though AST/ALT enzymes will rise, that is unlikely to cause any

lasting damage to the liver, due to its self-healing attributes.

Thus, a person is simply prone to experience critical liver harm if Winstrol

is abused and is taken for several months at a time (without biking off).

All anabolic androgenic steroids in the Usa fall into the the class of

Schedule III Controlled Substances’. These medication require a

prescription from a physician to find a way to possess. Schedule III Managed Substances is a category that has potential for abuse

and a few threat of dependance.

Winstrol isn’t suitable for beginners due to the severity of unwanted

facet effects which may be sometimes skilled.

Winstrol dosages for men are typically 50 mg per day but can go as high as double that.

This creates an much more enhanced look, with elevated muscle tone and definition. Oil-based

Winstrol is more potent than the water-based or oral type of

the drug. Nonetheless, this isn’t to say it’s only used by women, with a quantity of male powerlifters and

bodybuilders additionally using Anavar to good impact.

In this article, we will discuss what Anavar is and why it is considered one of the best dietary supplements anavar for ladies to make use of for bodybuilding and other muscle-building or weight-loss actions.

Anavar and Dianabol are also popular anabolic

steroids, but they’ve totally different effects and purposes.

Anavar is prized for its ability to build muscle mass while burning physique

fat, making it suitable for slicing phases.

These substances help block estrogen receptors and stimulate the production of luteinizing

hormone (LH), which in flip stimulates testosterone

production. Supportive Supplements and Protecting MeasuresCertain dietary supplements,

such as liver help aids (e.g., milk thistle), may be useful throughout

an Oxandrolone cycle to advertise liver well being.

Adequate hydration and a balanced food plan wealthy in antioxidants also

can help assist overall well-being.

Anavar is thought for its ability to advertise lean muscle

growth and enhance athletic performance.

While it’s not a magic pill for instant fat loss, it may possibly contribute to a more outlined physique when mixed with a proper diet and exercise regimen. One of the primary mechanisms by which this

steroid aids in body fat reduction is by increasing the body’s metabolic rate.

This signifies that whereas using Oxandrolone, your physique burns extra calories even at relaxation, helping to create a

caloric deficit essential for fat loss. Anavar is a flexible and efficient steroid that plays a pivotal position in cutting and bulking cycles.

Its capability to advertise lean muscle development, preserve muscle throughout fats loss, and enhance

energy makes it a useful device for each men and women.

Anavar’s capacity to increase strength is mainly as a

result of it being exogenous testosterone. Nonetheless, we find it also has a dramatic impact on adenosine triphosphate production and creatine content material contained in the muscle cell.

Larger ranges of ATP are useful for individuals wanting enhanced energy when bulking.

However reaching optimal results with Anavar involves more than simply taking

the steroid. The military typically does not test for anabolic steroids, as it is typically

an costly take a look at. As An Alternative, they are attempting to detect

different drugs used, such as marijuana, cocaine, amphetamines, and opiates.

It has been a broadly used, respected, and very popular steroid for a very lengthy

time and is one of the few that females can also use due to its delicate

androgenic effects. Anavar must be one of the two

most well-known oral steroids – the opposite being the well-known Dianabol.

When we compare Anavar to different steroids, it’s thought of

gentle, however in actuality, it could still have substantial effects (both constructive and negative)

at larger doses (more on that below). However there is not a getting around the reality that Anavar is still a steroid.

No steroid can actually be thought-about a light substance when used at doses for bodybuilding; it’s simply that Anavar is taken into account “pretty mild”

compared to the really heavy stuff. Anavar has many benefits, and it’s a compound that worked properly for me in the past.

Like the boys (see above) the dosages may be increased, though not as high, for example

20mg per day could be at a peak degree before pulling the again down to cycle off.

You can keep increasing once more depending on results,

recovery and the way you’re feeling. The most dosage that could

be safely consumed is 100mg everyday, but that’s just for advance

customers who’re used to taking the drug and have built up

their tolerance. The same can be stated for coming off Anavar where you

slowly lower the dose rather than just abruptly stopping and surprising your

body.

Nevertheless, if used responsibly and based on recommended dosages, Anavar can be an efficient software for reaching

specific health objectives. Overall, Anavar dosage for athletes should

be rigorously thought of and monitored to realize optimum outcomes whereas minimizing

the risk of potential unwanted effects. Seeking skilled guidance and utilizing Anavar responsibly might help athletes improve their efficiency and

obtain their objectives. Pill shaped steroids like Anavar are extremely popular

as a result of they are often consumed orally and no

injections are wanted. Anavar is usually very expensive to buy, because it’s one of the coveted AAS on the black market.

The purpose it’s so in style is because it’s a very delicate steroid,

which means unwanted effects are a lot much less in comparability with other steroids.

Crazy Bulk manufacture a ‘legal steroid’ called Anvarol which is designed for

these looking to burn fat and get ripped.

To counteract this, PCT goals to stimulate the

pure production of testosterone and stabilize different hormones.

Each of those anabolic steroids has its own benefits and drawbacks, relying on individual

goals and preferences. All The Time consult with a healthcare skilled before utilizing any steroid to

make sure secure and efficient use. There is a noticeable

surge in both energy and endurance inside the first two weeks

of beginning the Anavar cycle.

This effect not only helps in constructing new muscle but also in maintaining muscle,

even in these on calorie-restricted diets. The finest time to take Anavar

is dependent upon your targets and the way your physique reacts

to the steroid. Many people take Anavar in the morning with meals

to assist scale back abdomen upset. If you’re taking it more than once a day, it’s normally spaced

out evenly throughout the day. Take Anavar on the identical time each day to get the

most profit and scale back the danger of unwanted

facet effects.

Nevertheless, anvarol incorporates a fraction of this, with a baby dose of 75mg per tablet.

Even if you took the entire bottle of anvarol you’d simply get enough to

stimulate this very modest enhance in protein synthesis.

Will whey protein pace up restoration and improve protein synthesis?

Nonetheless, this is the same story as soy protein, as the quantity of whey in anvarol is tiny (0.45 grams per day).

Some analysis shows it to be more practical for stimulating protein synthesis than whey

or casein (if you devour it with dairy) – (1).

Beginning with a lower dosage, such as 20mg, allows your physique to adapt and reduce the risk of antagonistic effects.

As you progress and gauge your physique’s response,

you probably can steadily improve the dosage within the recommended vary.

Most female Anavar users won’t require or want to take dosages at such a high vary,

as an alternative sticking to a spread of 5mg to 15mg every day.

This might be sufficient for most women to deliver distinctive fat-burning and body composition enhancements.

The larger the dosage goes, although, the more likelihood of

girls experiencing antagonistic effects from Anavar’s androgenic exercise.

These androgenic effects are often recognized as virilization, or the attainment of masculine

options, and might embrace a noticeable deepening of the voice and growth of

physique and facial hair.

Results are regularly delayed, and the timeline can alter based mostly

on varied elements. It’s essential not to rush into PCT immediately after concluding your Anavar cycle.

Permit roughly a week for Anavar to clear out of your system before initiating PCT.

This strategic timing ensures a smoother transition and maximizes the efficacy of the post-cycle remedy.

Anavar is a Dihydrotestosterone derivative, which prevents it from interacting with the aromatase enzyme, which is the enzyme responsible for the conversion of androgens into Estrogen. As a

result, one can anticipate very strong lean muscle gains with none water retention, and minimal fat gain/retention (provided the consumer has accompanied their cycle with an appropriate diet).

Due to Anavar’s anabolic rating of 322 –

630 (the strength of at least three occasions that of Testosterone),

it could and additionally will elicit dramatic strength positive aspects and considerable

lean mass addition. When it involves Anavar dosage for athletes, you will want to think about the particular sport

and the athlete’s targets. Anavar is a well-liked alternative for athletes as a result of its capability to advertise lean muscle mass and enhance energy with out inflicting important weight achieve.

Nonetheless, you will want to use Anavar responsibly and in accordance with really helpful dosing protocols.

The most typical unwanted side effects of Anavar 50mg include nausea,

vomiting, and stomach ache. It can also trigger modifications in temper, together with temper swings, melancholy, and nervousness.

Long-term use can result in liver harm, elevated levels of cholesterol, and adjustments

in intercourse drive. That is why it is all the time essential to begin with

low dosage and take tabs with meals.

This could be extraordinarily beneficial

for athletes and older adults who are at risk for fractures.

Vitality ranges are necessary in sports activities, fitness, and bodybuilding for numerous reasons.

Stamina is the power to maintain bodily activity for a long time

frame, and it is a crucial high quality for athletes, soldiers, and different physically active people.

When used accurately, it might possibly assist you to shed pounds rapidly and effectively.

One of the principle reasons Anavar is so effective at burning fats is as a outcome of

it helps to increase your metabolism.

Due To This Fact, you will want to consult with a healthcare professional before starting any cycle.

When it comes to using Oxandrolone (Anavar) for bodybuilding functions, it’s necessary

to concentrate on the potential side effects. Whereas typically

considered one of many milder anabolic steroids, Anavar can nonetheless carry some dangers if not used

responsibly. Anavar is mostly well-tolerated and regarded one of many milder, more side-effect friendly steroids when proper cycle support

and post-cycle therapy are applied. It may be an excellent possibility for those looking to

make lean features without intense water retention or other

harsh effects. As all the time, consulting a medical professional is advisable before using any anabolic substance.

It was originally developed in the 1960s to treat muscle losing and rapid weight loss, however its

use has expanded to incorporate efficiency enhancement in athletics and bodybuilding.

Anavar, very related to Dianabol is actually

a really powerful anabolic steroid, yet it does have the power to produce androgenic unwanted effects.

More users than not nonetheless endure from oily pores

and skin, breakouts on the back and shoulders in addition to deepening of the voice

and a rise in body hair development. Some users can expertise hair loss from a steroid cycle,

then once the cycle has completed the hair comes again thicker and fuller.

Nevertheless, in case you are taking excessive doses of

Anavar or different steroids for extreme durations of time,

hair loss can turn into permanent. If cycles are kept short and dosages stay modest, any hair

thinning may be reversed post-cycle. While taking Anavar, keep away from

alcohol and different substances that can stress the liver.

One should take time to research and understand

all facets of Oxandrolone use; starting phases, visible adjustments, sustaining positive aspects, and potential unwanted

effects. The knowledge and understanding pave the way for good decisions that prioritize constant outcomes over rapid gains.

However it retains its advantages solely when complemented by a wholesome life-style of balanced diet, constant exercise regime, and adequate rest.

Post these preliminary weeks, many customers get to witness an evident enhancement of their muscle mass.

This period is a significant turning level within the Oxandrolone cycle, confirming that the

supplement is working simply as it’s supposed to. The gained

muscle mass is usually lean and defined, contributing to achieving the specified aesthetic look.

This supplement offers increased endurance and the flexibility to work out harder and longer, both key components

to attaining bodybuilding goals. As with all such choices, it’s

important to take gradual steps, adjusting based mostly

on private expertise somewhat than dashing to achieve optimum dosage rapidly.

Remember, the target is not only about gaining muscles, but additionally ensuring holistic wellness.

While indications level in direction of the Oxandrolone tablets being

light on the body, it’s important to recollect everyone

is unique.

The fact is that there exists no ‘perfect’ anabolic steroid,

but Oxandrolone does come fairly shut. Primarily Based on conversations that I’ve had with athletes

who’ve taken anabolic androgenic steroids for muscle

mass progress and efficiency features, I really have discovered that a lot of them resort to a drug known as Anavar.

The mechanism of action of Anavar is primarily centered round its capacity

to bind to androgen receptors in the body. Once bound,

it stimulates protein synthesis, which is essential for muscle

progress and repair. This anabolic effect is significantly

enhanced as a outcome of Anavar is proof against metabolism by the enzyme 3-alpha hydroxysteroid dehydrogenase, which often breaks down other anabolic

steroids. This resistance allows a better proportion of the

compound to remain active within the body, leading to more pronounced muscle-building results.

For this reason, Anavar is nearly always used

as a slicing steroid, which is the purpose it excels at.

Gynecomastia is unlikely on this cycle, with

Winstrol not converting to estrogen and having almost zero progesterone activity.

Thus, the one menace of gynecomastia forming is trenbolone,

which moderately will increase progesterone. Nevertheless, we’ve

found this to be one of many higher cycles for avoiding man-boobs.

Winstrol is an oral steroid that’s also a powerful compound like trenbolone (although to a

lesser degree).

Pharmaceutical-grade Anavar has been leaked onto the black market through special connections.

This can be within the form of knowing somebody who formulates oxandrolone, figuring out a physician who can prescribe it, or

somebody who has been prescribed it. I’m not sure if it’s related, but I’m

30, 1.seventy nine m tall, and weigh 65 kg. Males produce testosterone

of their testes, whereas girls produce testosterone in their ovaries.

Right Now, Anavar is against the law for leisure use in almost

every nation on the earth, except Mexico, where it may be bought at a neighborhood pharmacy.

Some Anavar customers report large pumps, usually

in the lower again, which can be uncomfortable or painful.

This can often feel like a locking, cramping sensation inside the muscle that may final for a quantity of minutes or

hours.

Girls who use Anavar will, nevertheless, discover that it can add spectacular lean muscle gains to the physique, and this is the principle anabolic steroid that’s appropriate for ladies to make use

of for this function. If you’re in search of options to Anavar which would possibly be legal and protected, there are

a quantity of pure supplements obtainable in the marketplace that can mimic the results of anabolic steroids.

These dietary supplements are also recognized as legal steroids or AAS alternate options.

These dietary supplements are designed to promote muscle progress, increase energy, and improve athletic efficiency.

When used responsibly and under the steerage of a medical professional, Anavar is usually a safe and efficient software

for girls trying to improve their athletic efficiency or improve

their physical look. Nonetheless, it’s necessary

to notice that like all steroids, Anavar can cause

side effects, and its use should be carefully monitored to

avoid potential health dangers. Some of the potential unwanted

effects of Anavar for ladies include pimples, hair loss, and modifications

in menstrual cycles.

This is why you can look so much larger after a reduce, because fat hides all your definition and

vascularity. In this text I’m going to stipulate

some adverse reactions you would possibly experience on Anavar, so you also can make

an informed determination on whether or not the professionals outweigh the cons when taking this anabolic steroid.

Some people say they don’t notice a lot on anavar,

which I put down to a too-low dose. Nonetheless, the

individuals who mentioned it DOES work for them also

mentioned their gains are dose-dependent (which is what I find).

It’s suggested to not increase the dose too dramatically

whilst on a cycle.

Regardless of the rationale for taking Anavar, comply with the

recommended dosage and do not exceed it, as this could provoke

severe health issues. Anavar is by far essentially the most well-tolerated steroid for females, in distinction to Winstrol.

Oral Winstrol is still thought-about a relatively mild steroid compared to most others.

Very little Oxandrolone is produced for human medical use these days,

so there’s hardly any provide of pharma-grade products.

That means it won’t be low-cost if yow will discover some (and

make sure it’s legitimate and genuine).

Now you can imagine the consequences you’d get in case

your Anavar were replaced with Dianabol – and it’s

even worse for females as a outcome of anything apart from Anavar is not going to be as tolerable.

As the center muscle gets giant, it turns into much less

elastic and may ultimately stop pumping as forcefully because it

should. Heart failure is a big explanation for death and disability in older individuals.

CRP is an indicator of irritation in the physique, and there might be evidence

that persistently elevated levels might predispose

individuals to cardiovascular disease. Hepatic dysfunctions attributable to Anavar

use can embody will increase in liver operate enzymes,

Peliosis hepatis, chronic an infection, and worries about hepatocellular

most cancers. Acne is a pores and skin dysfunction characterised by

excess sebum, an oily substance secreted by the sebaceous

glands.

In the world of anabolic steroids lots of

the unwanted effects that exist do so as a result of an aromatizing nature of the hormone.

Many anabolic steroids as soon as present within the physique, as by their testosterone

nature convert into estrogen; as estrogen ranges enhance such related unwanted

facet effects can occur. Estrogenic associated problems similar to Gynecomastia

and water retention are of no concern when the Oxandrolone hormone is being used.

Research reveals that anabolic steroids can suppress the physique’s natural testosterone production, doubtlessly affecting libido.

Nonetheless, the degree of suppression and its impact on libido can vary relying on a number of

elements, together with the dosage, duration of use, and the individual’s hormonal

profile. The typical Anavar and Check E cycle lasts between 8-12 weeks, relying on individual goals and expertise with steroids.

It is primarily prescribed for legitimate medical functions, similar to

treating muscle-wasting circumstances, severe burns, or persistent infections.

Sufferers should meet particular medical standards to obtain a prescription, ensuring its use

aligns with therapeutic targets. Turkesterone is an ecdysteroid, which is a hormonal anabolic compound that could be found in sure crops.

Ecdysteroids are in itself a class of compounds which may be structurally much like that of typical anabolic androgens.

Its distinctive properties make it an efficient alternative

for achieving lean muscle improvement and enhancing physical performance.

AnaVAR X is a compound formulated to support research

on its potential functions to boost efficiency, muscle development,

and total bodily well-being. AnaVAR X combines a synergistic blend of rigorously chosen compounds, every with its distinctive properties and potential benefits.

Our advice is to remain within the confines of the regulation and take a look at anvarol (legal anavar).

Anvarol is produced by a properly known company

called Crazy Bulk, who have obtained thousands of constructive critiques.

Anvarol is much safer than unlawful oxandrolone and won’t scale back your testosterone levels, or improve

ldl cholesterol.

Female users usually utilize doses as low as 5–10 mg

daily to realize a lean, sculpted physique with out significant threat

of masculinizing unwanted aspect effects. Trenbolone, often merely known as Tren, is doubtless

considered one of the most potent anabolic steroids out there.

It is widely utilized by athletes who purpose to considerably

boost their energy, muscle mass, and endurance. Nonetheless, because of its strength, Tren is really

helpful only for advanced customers with expertise in steroid cycles.

When it comes to bettering athletic performance, many individuals turn to numerous

supplements and medications. Among essentially the most

sought-after options for people seeking to enhance their fitness or

combat unwanted side effects from steroid use, Clomid is a well-liked alternative.

Nevertheless, it is essential to prioritize security, authenticity, and high quality when buying Anavar.

Completely research reputable sources, verify product authenticity, and prioritize

merchandise that bear rigorous quality testing. Additionally,

consult with healthcare professionals or skilled health advisors to make sure Anavar aligns with your targets, total health, and individual

circumstances. In the context of societal notion,

the utilization of Anavar, like different anabolic steroids, is

marred by controversies surrounding moral use, legality,

and the potential for abuse. The allure of reaching quick positive aspects in muscle mass and physical prowess must be weighed in opposition to the potential health dangers and the principle of honest competition in sports.

Responsible use, under medical supervision for therapeutic functions, stands in stark distinction to unregulated

use with the aim of efficiency enhancement or aesthetic improvement

alone. Anavar, also called Oxandrolone, is a widely recognized anabolic steroid favored by

athletes and bodybuilders for its capability to enhance muscle growth, strength,

and total efficiency.

If you’re new to steroids, start with a pure legal various

to make sure security and compliance. With all of this being

talked about, is quite apparent Anavar ended being super well-known and that’s why plenty of different people are using Var

of their steroid cycles. As with almost all anabolic and

androgenic steroids that had been discovered, Anavar, initially, was used for medical needs only.

It was and is still very extensively utilized in medical settings for helping folks suffering from osteoporosis,

severe weight loss situations in addition to various

different well being functions. Results from Anavar can usually be noticed inside four to

six weeks after starting a cycle. Users may discover increased energy, enhanced endurance, and slight muscle acquire on this timeframe.

Particular Person responses can differ based mostly on factors similar

to food regimen, coaching routine, and overall health.

In this text, we’ll delve into the realm of Anavar on the market online, exploring its function as an anabolic steroid and its implications for those in search of to

optimize their athletic endeavors. For these trying to purchase Oxandrolone on-line within the USA, it’s crucial to choose respected

sources to make sure high quality and authenticity.

At AlanDomestic, we provide a wide selection of Oxandrolone

merchandise from top manufacturers like Pharmacom Labs,

ZPHC, and Canada Peptides. We guarantee genuine merchandise,

competitive costs, and quick transport, making

us the popular choice for athletes and bodybuilders nationwide.

Go To our store today to discover our vary of Oxandrolone products and take your

efficiency to the following level. Anavar (Oxandrolone) is a

well-liked anabolic steroid recognized for its potential to ship

significant results in phrases of muscle definition, strength enchancment, enhanced endurance, and fats loss.