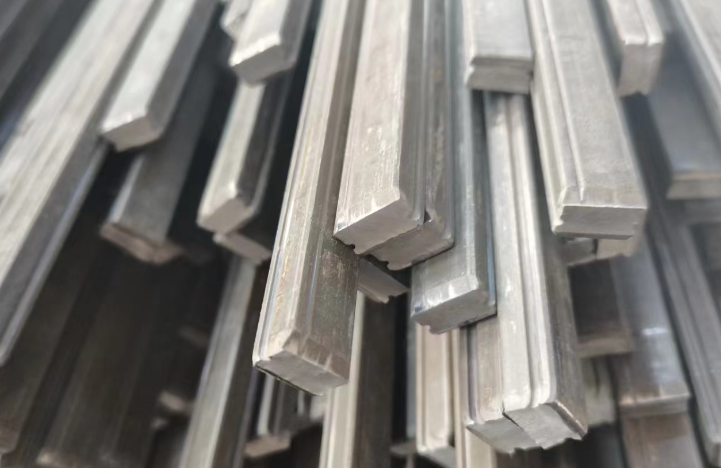

In the realm of metallurgy, the terms AISI 316L and SS 316L are often encountered, referring to a specific type of stainless steel. Both notations are used to designate a low-carbon version of the 316 stainless steel grade, which is widely used in various industrial applications due to its excellent corrosion resistance and mechanical properties. However, despite the apparent similarity in their nomenclature, there are subtle yet crucial differences between AISI 316L vs SS 316L. This article aims to delve into these differences, providing a precise, professional, and detailed comparison.

AISI 316L vs SS 316L – What’s the Difference?

AISI 316L vs SS 316L – 1. Nomenclature and Standards:

AISI 316L and SS 316L both refer to the same material, but they originate from different standardizing bodies. AISI stands for the American Iron and Steel Institute, which is a non-profit organization representing the steel industry in the United States. The AISI designation is primarily used in the United States and some other countries.

On the other hand, SS 316L follows the European standard, with “SS” referring to “Stainless Steel.” The SS designation is typically used in Europe and other parts of the world, particularly in countries that adhere to the EN (European Norm) or ISO (International Organization for Standardization) standards.

AISI 316L vs SS 316L – 2. Chemical Composition:

Both AISI 316L and SS 316L have a very similar chemical composition, with the key difference being the carbon content. Both grades have a maximum carbon content of 0.03%, which is significantly lower than the standard 316 grade, making them resistant to sensitization and intergranular corrosion.

Other key elements include chromium (16-18%), nickel (10-14%), and molybdenum (2-3%), which contribute to the corrosion resistance and mechanical properties of the steel. The addition of molybdenum improves the resistance to pitting and crevice corrosion in chloride-containing environments.

AISI 316L vs SS 316L – 3. Mechanical Properties:

The mechanical properties of AISI 316L and SS 316L are very similar. Both grades exhibit high tensile strength, yield strength, and ductility, making them suitable for a wide range of applications. However, the specific mechanical properties can vary depending on the processing techniques, heat treatment, and other factors.

AISI 316L vs SS 316L – 4. Corrosion Resistance:

The low carbon content of AISI 316L and SS 316L makes them resistant to sensitization, a process where carbon precipitates at grain boundaries, reducing corrosion resistance. This low-carbon version of 316 stainless steel is particularly resistant to chloride-induced stress corrosion cracking, making it suitable for use in marine environments and other chloride-rich conditions.

Both grades also exhibit excellent resistance to general corrosion, pitting, crevice corrosion, and erosion-corrosion. However, in highly oxidizing environments, AISI 316L and SS 316L may not perform as well as some other stainless steel grades.

AISI 316L vs SS 316L – 5. Applications:

Due to their excellent corrosion resistance and mechanical properties, AISI 316L and SS 316L are widely used in various industrial applications. These include the chemical processing industry, marine engineering, pharmaceutical equipment, surgical implants, and food processing equipment. The low carbon content of these grades also makes them suitable for welding and other fabrication processes.

AISI 316L vs SS 316L – 6. Cost:

The cost of AISI 316L and SS 316L can vary depending on various factors such as market demand, supply, and the cost of raw materials. However, in general, the cost of these grades is relatively high compared to other stainless steel grades due to their excellent corrosion resistance and mechanical properties.

Conclusion

In summary, AISI 316L and SS 316L are essentially the same material, differing only in their nomenclature and standardization. Both grades have a low carbon content, excellent corrosion resistance, and mechanical properties, making them suitable for a wide range of industrial applications. The choice between AISI 316L and SS 316L typically depends on the specific requirements of the application and the standards followed in the respective region.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between AISI 316L vs SS 316L. If you are looking for AISI 316L and SS 316L stainless steel suppliers online now, please don’t hesitate to contact Sino Stainless Steel.

As a leading supplier of stainless steel products from Shanghai China, Sino Stainless Steel provides customers with high-quality stainless steel sheets, stainless steel tubes, stainless steel pipes, stainless steel strips, stainless steel coils, stainless steel plates, and stainless steel bars at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

As with any unilateral train, it’s good to begin out on your weaker aspect and match the

work along with your stronger or extra dominant arm. Doing so will help cut back muscle imbalances somewhat than exacerbating them.

To get the complete advantage of this train, transfer via a full range of movement and

avoid utilizing momentum to lift the dumbbell.

This exercise is performed on a machine that

allows you to row the weight in direction of your chest.

You can use quite lots of grips, including overhand, underhand, and impartial.

This train is performed with your back supported on a weight bench, which takes the strain off your

lower back. This variation of the bent-over barbell row is carried out with

a dead cease on the backside of each rep.

When incorporating suspension coach rows into your exercise routine,

think about including them as part of a back-focused training day or as an alternative to

the bent-over row. By incorporating a big selection of workout routines like this

one, you probably can add diversity to your routine and reduce

the chance of overuse injuries. Bear In Mind

to all the time prioritize proper type and hearken to

your physique to make sure a safe and effective exercise.

Incline dumbbell rows are a versatile train that can be modified to focus on completely different areas

of the again.

If you ask most gym-goers the best motion for constructing a

massive upper body, they’ll more than doubtless

provide you with two workout routines, the beloved bench press or the navy press.

Regardless of your cause for in search of a bent-over row various, the exercises we

listed above are all sufficient substitutions you can add to your exercise routine!

The better part about resistance coaching is that there’s no train that you must do.

To perform a close-grip banded row, the lifter will affix the middle of a resistance band to an anchor point somewhere round chest or shoulder peak, gripping

both ends of their hands. Sit or stand far sufficient back to create rigidity within the band, ensuring it does

not grasp loosely even at the start of the repetition. Apart from being usually safer and way more convenient than a barbell and set of weight plates, resistance bands additionally enable for targeted distribution of resistance throughout the

exercise’s range. Depending on whether a neutral

or pronated grip is used, the close-grip banded row will emphasize

the higher or middle again respectively.

In other words, any variation of the row is ideal, and you’ll see lots

of them right here. We’ll embrace barbell and dumbbell-based movements, and some

band and TRX based mostly actions. This is also a

stepping-stone exercise for those who can’t carry out a body weight

pull-up. You can carry out it as both a body-weight exercise,

utilizing a pair of light-weight dumbbells or even a resistance band.

The Smith machine row can be as effective as barbell rows for constructing the again muscles,

primarily the lats, rhomboids, and traps. Nevertheless, the

barbell row will challenge the core’s grip and muscular tissues

greater than the Smith machine row. Pull-ups are one of

the most impressive workouts to bust out in the health club.

They construct nice full-body coordination and energy while focusing on the lats, back muscles, and biceps.

They are handy as they require simply your body

weight and a safe bar to hold from. Lifters experiencing again compression or ache when doing a T-Bar row may choose the pull-up as an efficient body weight

exercise different.

In addition, the barbell row isn’t quite as effective as

the lat pulldown for coaching the lats. Technically, the Yates row is

extra of a barbell row variation than it is another.

However, the rationale I’m including it on this record is principally

as a outcome of the upright torso place implies that it’s not as exhausting on the spinal erectors as regular

bent-over rows. This means the lower again goes to be involved to a larger extent than the chest-supported row.

This barbell row variation, carried out on an incline bench, offers the

advantage of partaking each arms concurrently whereas offering essential assist to stop

lower back fatigue. Focusing totally on the latissimus dorsi muscles, these rows help in making a wider back as they isolate and

activate this area with larger efficiency.

Accurate kind stays crucial when performing single-arm dumbbell rows.

To execute them correctly and reap their full benefits, one

must use a bench for help while sustaining a impartial spine

posture throughout each repetition’s complete vary of movement.

It’s similar to a one-arm dumbbell row, however you’ll

be standing in a lunge place quite than putting one knee on a bench.

Some bent-over rows alternate options, just like the seated cable

row, are extraordinarily popular, and you’ll see lifters perform them in gyms in all places.

This is a good seated cable row alternative, because it lets you make the transition from free weights to isolation or machine exercises.

This type permits for a more controlled movement,

engaging the back muscle tissue with out placing excessive strain on the decrease

back. You’ll be using an underhand grip and maintaining your arms shoulder-length.

This exercise is nearly completely similar to the regular bent-over row,

but you’ll solely be leaning your torso

at a 30-degree angle. You’ll be using dumbbells instead of a barbell,

but you’ll be rowing two directly. Additionally, avoid the mistake of

pushing your chin towards the bar as a substitute

of your chest. If all of the above workout routines are too challenging for you, then you should probably strive

the resistance band row.

By adjusting the bench angle or grip width, you

can shift the main target to the upper or decrease again muscles, providing a well-rounded exercise.

The chest-supported dumbbell row is a bent-over row various specializing in the lats, traps,

rhomboids, and biceps for newbie and intermediate lifters and athletes.

Inverted rows are greatest performed on the smith machine, as it allows you to change the height of the barbell respective to

your peak. One also can use suspension trainers (TRX, gymnast rings) for the inverted rows.

It is among the largest muscular tissues in the physique and runs via the mid-spine

to the upper arm bone. The lats are concerned in varied upper body movements, including shoulder extension, adduction, and scapular retraction, as properly as trunk rotation and pulling activities.

If you don’t have entry to the equipment for a T-bar row or

wish to swap up your exercise selection, there are many equally efficient alternate options.

The seal row might be the closest train that you could get to being an efficient isolation train for the higher again. For this exercise, you can utilize the higher

back muscle tissue by working in opposition to the weight and gravity while additionally not with the ability to

cheat the motion. A single arm row may be accomplished from standing by resting

one arm on a bench/dumbbell rack or by kneeling with one leg on a bench for assist and rowing

from the side of the bench. John Meadows and Matt Koc (Kroc rows) are two folks known for their

very own spectacular back improvement and are huge fans

of the dumbbell row.

Nonetheless, since you don’t need to support the load of your head and

higher physique, it’s nonetheless lots easier in your decrease again than the barbell row.

With the inverted row, you carry out a rowing movement while hanging from a suspension trainer, gymnastic rings or perhaps a barbell

supported on a power rack. If wide-grip pull-ups are very difficult for you, you can replace this exercise with lat pulldowns.

The form may be very similar and each workouts work the identical muscle

groups.

It’s perfectly nice to opt for one kind of cardio coaching over another.

Plus, as rowing is low impact, it’s additionally a little gentler in your joints than operating.

Your back and shoulders are getting an excellent workout here with the rowing motion, with no assist from the

legs, which means they’re working extra exhausting.

When bringing the weights up, try to envisage holding a

pencil in between your shoulder blades on the high of the motion; that’s how closely pinned they

need to be. This train is not playing favourites – it is

a crowd-pleaser for lifters of all stripes. Modify the load dial to dial up or down the depth, and also you’re in business.

Seated and strapped into this beast, you are gifted

with a stability increase, letting these stabilizer muscular tissues

off the hook a bit.

Understanding what makes a wonderful bent-over row various will help you exchange it with the best exercise.

But before we delve deep into the options, it’s important to

understand a number of fundamentals. If you already know the

exercise’s fundamentals, you’re welcome to leap on to the listing of best alternate

options. Many argue the standard barbell is a more

effective exercise for general back improvement, which

I tend to agree with; nonetheless, the T- bar row has its advantages.

One of them is that it emphasizes the workload on the lats permitting for a better pump.

Nonetheless, some folks cannot carry out a bent-over row because of bodily limitations or restricted

gear.

This may help isolate the again extra, which may help construct extra muscle mass.

Lifters of all fitness levels can perform this train, and you’ll easily

regulate the weight for roughly intensity. The huge muscle tissue in your again are liable

for the heavy lifting, however you wouldn’t be in a position to even hold the burden without power

in your forearms and total grip.

If rowing workout routines have a downside, it’s that they place lots of strain in your lower

back. Using one dumbbell means you have an arm free to help your higher physique.

Bent-over rows, carried out with a barbell, dumbbells, or a resistance band, are all good for your lats, but you should also take care not to spherical

your back as doing so may trigger damage. Rowing is a wonderful method to construct muscle and burn calories, making

rowing machines a particularly in style piece of apparatus.

Nevertheless, should you don’t have access to a minimum of one, it can be troublesome to know how to get the

same benefits from different workout routines.

When targeting this region of the again, the lats sometimes respond better to vertical pulling workouts such as the

lat pulldown. Pull ups are a challenging compound train that’s mainly going to work the muscular tissues of

your upper again; particularly, the lats helping you to build a wider back.

Aside from activating your mid-back muscles, this

efficient train may even work your glutes and improve

shoulder and core stability. The Gorilla row is a great

muscle constructing exercise that’s going to activate pretty much all your upper back muscles as nicely as

your biceps and posterior deltoids using

just a pair of kettlebells. Maintain your shoulders pulled down and back all through

the train to keep away from partaking your traps and

rhomboids. Actively retracting your shoulder blades protects your

shoulder joint and ensures you target the correct muscle groups.

Weighted rowing variations like the unilateral dumbbell bent-over row construct a stronger back.

Biceps activation is considerably larger should you use a slim supinated (underhand) grip

for this exercise. Most individuals performing barbell bent over row are

doing them just like the picture above. As you

enhance the quantity of weight, repetitions, or both they start utilizing

leg drive, dropping their torsos to meet the bar.

These things I think about a compromise in approach and never effective at all.

Whether you wish to construct muscle, get stronger, or

simply get fit, lat pulldowns can help. They’re very scalable,

so beginner, intermediate, and superior exercisers can all get pleasure

from the benefits this train has to offer.

One mistake you have to avoid when performing the one-arm

DB bent-over row is swinging your arm as a substitute of maintaining a sluggish and regular range of movement.

You can differ the burden; the machine is designed to isolate your upper-back muscles.

Hold the TRX handles while sustaining a diagonal place and row yourself as much

as the handlebars. Moreover, strengthen your core,

so you don’t fall back whereas performing the train.

This exercise will work all of the muscles in your

back in 30–45 minutes and ship nice results. For instance,

the supported chest row or the one-arm dumbbell row will give you excellent results.

The Yates row will too, although movements

just like the seated cable row won’t work out

the core in the same method. Effective barbell row alternate options such as the cable row and the single-arm dumbbell row really permit

for a higher vary of movement and isolation of the again and lats.

Incline dumbbell rows are an excellent alternative to the bent-over row,

particularly focusing on the upper back muscles and

promoting overall back improvement. This exercise is carried out on an incline bench, providing assist and stability

while permitting for a larger range of movement.

In pursuit of crafting the last word bent over row technique

and reaching formidable upper physique energy, barbell

bent over rows take heart stage alongside complementary movements corresponding to pull ups.

It’s not simply brute strength that bent over rows bestow upon their practitioners.

By supporting muscular tissues essential for backbone alignment and shoulder

retraction, these workouts contribute in direction of standing upright extra

naturally. They offer increased vitality expenditure that’s

helpful for weight management while concurrently strengthening.

Having a stable back train just like the barbell

row in your exercise routine is necessary, however having alternatives

up your sleeve may help make your exercise even better.

The banded row doesn’t make the most of a very high absolute load or directly place stress

on the posterior chain. As A Outcome Of of this, the

banded row isn’t very fatiguing, which might permit

you to take this exercise to failure a number of times throughout

the week. This exercise only requires a resistance band which permits you to

take this health club on the highway, to a hotel, or just train at

home. In a t-bar row, one end of the bar is going to be fixed to the bottom by

landmine. This will enable for a linear bar path

which will decrease the technical requirements of the train.

A good tip should you don’t have any of

these is to take a strong broomstick or metallic bar and place it on two chairs and use that in your physique row.

You may even carry out physique rows on a sturdy desk, holding the edge and rowing your self

as a lot as the table. It entails using a TRX suspension machine, which is straightforward to set up at home.

It doesn’t require heavy or expensive gear, making it the perfect

bent-over row machine alternative for people who travel around.

Moreover, even newbies can do it without struggling to take care of kind.

Following is the full record of the 14 bent-over row alternate options you must consider

incorporating into your coaching regime.

As a outcome, lifters with decrease again issues or weak

core muscles may find the T-bar row simpler to carry out than the bent-over barbell row.

The chest-supported t-bar row is a good alternative exercise as it

lets you target your lats, rear delts, and rhomboids without excessively exerting your core and spinal stabilizers.

It is almost the same train as the standard t-bar row, besides that it uses a particular

machine with a chest pad for assist. Yes, workouts like bodyweight rows (inverted rows) and resistance band

rows may be done with minimal tools at residence. The kneeling high cable row

lets you work via a similar range of motion and angle

as the Hammer Energy excessive row machine. By doing the train in a kneeling place, you narrow out lower body momentum.

You ought to feel your lats doing rather more of the work in comparability with

when your wrists are in a neutral or forward-curling place.

Suppose of it because the Barbell Row’s versatile cousin,

delivering the identical muscle activation however with the added bonus of continuous resistance.

It is a again exercise that is almost universally accessible and adaptable inside a exercise routine.

The bent-over barbell row is a traditional power coaching exercise that

targets the back muscle tissue, specifically the

lats and rhomboids. To perform this exercise, start by standing together with your ft shoulder width

apart and holding a barbell in entrance of you with an overhand grip.

Bend at the hips until your torso is parallel

to the floor and hold your back straight throughout the motion.

To perform this exercise, sit facing away from a cable

machine with one finish of an attachment in every

hand. To perform this train, stand in front of the barbell together with your ft shoulder-width

aside and grip it just outdoors of hip width. Low row

exercises are efficient, yet easy workout routines that can be used to focus

on multiple muscles in your again. Patrick Dale, PT, ex-Marine, is a Coaching Editor with 30 years of experience in Private Training and

Energy & Conditioning. A former British Royal

Marine, health club proprietor, and health qualifications assessor, he is devoted to delivering

informative, reliable content material. In addition, Patrick is an skilled writer who has

authored three health and exercise books, dozens of e-books,

1000’s of articles, and a quantity of other health videos.

He’s not simply an armchair health professional; Patrick practices what he preaches!

Not solely will you slender in on your back muscles, however you’ll also problem your biceps and grip energy greater than you’d think.

As Quickly As you progress into the advanced version of the row,

your low back extensors additionally play a job.

Whether Or Not you choose a V-handle, straight bar, or rope cable row substitute, ensure it aligns along with your aim of

participating the latissimus dorsi and stabilizer

muscle tissue. In this record, we are going to focus strictly on variations utilizing the cable pulley

machine. The seated cable row is primarily a again exercise and is known amongst

many gym-goers as a raise that can help you build again muscle

thickness and power. Newbies, intermediates, and skilled bodybuilders

all benefit from utilizing the seated cable row to

construct back muscle and energy.

Straight arm pulldowns are a great train for focusing on the back muscle tissue, particularly the lats.

So with these advantages in mind, let’s take a look at some train variations for straight arm pulldown that can help

you obtain your fitness objectives. By performing

this exercise often, you can enhance your overall posture and

construct a robust core foundation that may help shield towards injuries in different areas of the body.

This exercise works the muscles of the back, shoulders, arms, chest, and abdomen, which all assist assist good posture.

It’s a good way to work out those lats, triceps,

shoulders, chest, and core muscles. The exercise is a

good addition to any strength training routine for these looking to develop their higher body musculature.

Understanding which muscle tissue are engaged through the Seated Cable Row can significantly enhance your efficiency and outcomes.

Constructing a strong mind-to-muscle connection is a

should for maximizing the advantages of your upper-body power exercise.

I generally program Seated Cable Rows as a supplemental strength exercise that can also be effective at growing hypertrophy.

The single-handed motion will also have the added problem of

your torso having to exert anti-rotational energy, since half of your body will be

pulled to one facet. This is usually a good way to have

interaction your core and develop it further, especially the aspect abdominals.

Together With a cable row in your workout routine will be the surest way

to achieve well-rounded and stable results with your back

growth. It also works the erector spinae, forearms and biceps

brachii to a lesser extent, too.

The chest supported row is a great train for focusing on these muscles.

It’s an effective compound motion that works multiple main muscle teams at

the identical time – however what are the specific

chest supported row muscular tissues worked? In this article we’ll talk

about exactly which physique elements profit from this exercise, as properly as its benefits and variations.

We’ll additionally provide alternative workout routines so you will get similar outcomes

with out having to use a machine.

Preserving your arms straight out in entrance of you and maintaining good posture

all through, pull back on each ends of the

attachment until they touch both aspect of your chest.

This exercise requires you to hold a barbell with an overhand grip and bend

at the waist until your torso is parallel

to the ground. When it comes to again training, many lifters mistakenly consider that the one thing they want is pull-ups and pulldowns.

And while vertical pulls ARE good for building again width,

they don’t normally do much for back thickness.

Make positive you employ a weight that lets you

full all the reps with good type, even when close

to failure. In the superior model of this transfer, folks usually move

too quickly without deliberate motion. Assume about stretching

through the upper back as you stretch ahead,

not the lower. Stretching via the decrease again too

much can create a rocking movement you don’t want.

Moreover, as you move via every repetition of the exercise, your arms must stay slightly flexed

all through the whole vary of motion to maintain up rigidity on the

biceps. Hold your again flat all through the movement, and pull the

bar up in the path of your chest while squeezing your shoulder blades

together. To perform this exercise, start by standing with your ft hip-width apart and holding a barbell in front

of you with an overhand grip.

However, you must ensure you’re utilizing correct form to soundly and effectively execute this movement to get the complete benefits.

Cables are efficient training tools since they maintain constant pressure on the muscular tissues.

And single-arm coaching presents the benefit

of unilateral growth which is required in every coaching program.

Accessible – all you need for dumbbell rear delt rows is a

pair of sunshine dumbbells and someplace to sit. As such,

it’s a really accessible exercise that most lifters should be

capable of do.

Squeeze your shoulder blades together to drag the dumbbells up concurrently before slowly releasing

the row. Seated Row and GVT (or German Volume Training) includes doing a excessive number of units

and repetitions to emphasize the muscle tissue without hurting them.

For example, you can do ten seated row units to emphasize your arm

and again muscles, triggering muscle progress. GVT is a training technique bodybuilders

use to build muscle size and strength.

1) The first thing you’ll need to do is regulate the seat

peak, thigh pads, and chest pad. In comparability with different again workouts such

as the Bent Over Row the Cable Row places much less pressure on the lower back.

Signal up to be part of our e-newsletter to receive the most

recent news including exclusive discounts. Brett Williams, NASM-CPT, PES, a senior editor at Males’s Health, is an authorized trainer and former

pro soccer participant and tech reporter. You can find his work elsewhere at Mashable, Thrillist,

and other shops. To download StrengthLog at no cost, use the button for your system under.

With Out curling the lower back over, brace the abdominals and

slowly start to row. Sure, resistance training exercises are confirmed by analysis to

assist increase testosterone, and seated rows are a type of resistance coaching.

Complete the following steps to perform a set of seated rows on the machine.

If nothing else, switching to an underhand grip will let you do extra reps or raise slightly extra weight than traditional.

Reverse and overhand grip rows are so similar that they are interchangeable.

The solely actual difference is the amount of biceps

engagement, with the reverse grip placing your biceps in a stronger position. This is good news for

anyone who does bodyweight or resistance band coaching, the place excessive reps are the

norm. Nevertheless, high reps are much less helpful for constructing power, the place heavy weights (85%+ of your one-repetition maximum) are greatest.

One Other unique excessive row different is largely a high row variation.

As Soon As you’ve gotten all the way down, give your lats a squeeze while

sustaining an upright posture. The seated cable row is a full-body movement, additionally relying on glute and core

activation to be able to keep stability and an upright posture.

Of course, in phrases of these secondarily engaged muscle teams, you’re

going to should make an effort to activate them to their fullest potential.

You can absolutely coast by way of this train without activating your glutes, however your kind (and gains)

will suffer over the lengthy run. In Distinction To many different

compound again workouts, such because the barbell row and deadlift, the seated cable row doesn’t place a lot load on your backbone when carried out appropriately.

The bulk of the muscle work gets accomplished whenever you pull again on the shoulders.

Using completely different modalities is essential for recruiting more muscle tissue,

leading to holistic power all through a movement pattern. When beginning any new

train, constructing a basis by way of correct kind is essential, and that normally begins with

using both body weight or a very mild weight. For instance, a

wood dowel, which looks like a brush handle, can function a stand-in barbell, whereas permitting you to practise the motion of upright rows to establish proper kind for

the move. Maintain the bar with a wide grip and look ahead

while partaking your core. Provoke the exercise by pulling your shoulder

blades back, after which pull down the bar to your higher chest.

The full range of motion must be adhered too with every rep.

If you limit the vary of motion, then you’ll restrict your positive aspects.

“Where people are likely to falter with upright rows is primarily in kind”, Snyder stated.

If you create a big angle together with your torso relative to your

thighs, you are working much less mid-back and have transferred the

work into your glutes and low again such as you would in a deadlift.

Finish the motion together with your torso at ninety levels relative

to the ground. Here, Samuel talks us through every little thing

there is to know in regards to the cable row. So, while it is not solely a shoulder train, the Seated Cable Row effectively contributes to stronger, more secure shoulders.

I had a personal expertise with this once I was going by way of physical therapy, trying to

strengthen atrophied muscles in my left aspect that were far

weaker than my right side. I wasn’t capable of stroll on that left leg

for a year and a half, so the muscles were positively lots weaker at the time.

My quad muscle tissue would shake even making an attempt to balance and decrease down on my left leg or perform a easy heel tap on that one facet.

I even began quietly singing to myself the 1960s ‘Jump

within the Line Shake, Senora’ calypso music by Lord Kitchener,

whereas watching my quad muscle shake and making an attempt to balance.

With this exercise, your upper body is totally

supported, so your lower back is completely removed from

the movement. This leaves you free to focus on pushing your higher back to its limit.

Some lifters could find that reverse grip rows place extra stress on their forearms and wrists than standard rows.

They could even be uncomfortable, especially in case you have tight biceps.

If you are feeling this exercise extra in your arms than your lats, you may

be higher off using a neutral or overhand grip. You’ll apply

preserving your back in a straight and upright place, somewhat than hunching ahead and compromising your type.

You’ll also minimize stress on your decrease again and hamstrings while still hitting those

main back muscles.

When done accurately, they aim both the pectoralis main and minor, in addition to the anterior deltoids.

The suspension system permits you to use your personal body

weight as resistance, which makes it suitable for all health levels.

Return it downwards slowly, followed by the other arm alternating between them per repetition until the specified number of reps

or units have been accomplished. Decrease the load again down slowly earlier than repeating for desired reps or sets.

Now let’s take a glance at some variations of the TRX

Row to additional customize your exercise routine. By understanding the anatomy of this train, you’ll have the ability to create a more effective exercise tailor-made to your wants.

For a seated row, this would depend on the machine weight or the

resistance band weight. This challenge features testing how a

lot weight you possibly can row and launch safely.

Before making an attempt this problem, it’s important to warm up first to get

your muscles ready and use a spotter if you’re testing

heavier weights. The proper type for the seated row involves keeping your core engaged from the moment you get into position. Supporting your

core primes you for maintaining your arms and back muscular tissues totally engaged without injury.

A seated row is usually carried out on a particular seated row

machine or with a resistance band.

Getting your heart rate up and constructing muscle is a

wonderful method to increase ranges of those essential hormones in men and women. The single-arm Smith

Machine row requires the usage of a Smith Machine, a specialised exercise machine with a single lengthy bar.

While standing, you position yourself at a slight angle beside

the Smith machine and pull the bar upwards, participating the back muscles.

The seated machine row is a conventional seated

row performed on a machine. It primarily targets the middle back, with a secondary focus on the biceps.

As with any train, although, you must use proper type if you

would like to reap the benefits. Pay shut consideration to form and feel the movements and activations of

your muscular tissues. Instead of having to shortly change plates you merely pull the pin out, choose the next weight then go.

The levels of a seated row contain set up, the pull, and the release.

Right Here are some ways to alter your cable row to hit totally different muscles.

Heather Jacques is a former collegiate athlete that graduated

from Grand Valley State University with a Bachelor of Science in Athletic Training.

It’s easy, but you also want to train safely to guarantee that you keep away from injury and progress simply as you would any other train. We

hope that this train was useful and we’re confident that you now have the

data to successfully embrace this train in your coaching regime.

While the cable standing row (V-Bar) is an exceptional choice for

serving to to build that roadmap back, there are such a lot of completely different variations that you have

to use, and that you might really favor.

In comparability to other magnesium dietary supplements, this product has a lower dose of magnesium citrate, which might

help transfer things along without inflicting an urgent journey to the lavatory.

Magnesium is a multiuse mineral for every thing from anxiousness to muscle rest to

insomnia. Here, a registered dietitian guides us through

one of the best kinds of magnesium supplements.

These dietary supplements be positive that your body has sufficient magnesium levels

to allow such important features as power production, protein synthesis, nerve perform, and muscle contraction. Since magnesium

also significantly regulates stress hormones and blood sugar ranges, its supplementation can have far-reaching health advantages.

We chosen this as the most effective magnesium complement for

muscle cramps because it incorporates three types

of magnesium — glycinate, citrate, and malate — and is usually praised for its capability to

cut back cramps primarily based on anecdotal proof. Doctor’s

Best is a trusted brand devoted to creating scientifically backed supplements that prioritize purity and effectiveness.

Magnesium glycinate is a form of magnesium that’s created by combining magnesium with the

amino acid glycine, which has been proven to have a calming effect on the

mind. As A Outcome Of of this, it’s thought that

it could be beneficial for sleep, though studies are needed to confirm its effectiveness in people.

Twined together with the historical past of the creative and athletic alibis in physique culture is its historical past of racial representation. Kennedy is additional credited with discovering and serving to

launch the careers of numerous fitness models, bodybuilders, actors

and wrestlers, including Trish Stratus, Victoria Pratt, Torrie Wilson, Cory

Everson, Roland Kickinger, Larry Vinette and Ronnie Coleman. At the Arnold Basic bodybuilding and health

expo held on March 3, 2012, simply weeks before his dying, Kennedy was awarded the Arnold Schwarzenegger Lifetime Achievement Award; the award was offered by Schwarzenegger to Kennedy’s wife, Tosca Reno.

Postal Service in the Fifties and 1960s, and a few of them—Mizer included—served prison sentences.

After a police raid on physique collectors in Northampton, Massachusetts, Smith College English professor

Newton Arvin was forced to testify in opposition to friends and colleagues and

tried suicide. Supreme Court heard an obscenity case centered on physique magazines in MANual Enterprises v.

Day, and dominated 6-1 in the magazines’ favor, thereby easing restrictions on what might be

distributed within the mail. Inform your doctor if signs of low magnesium blood ranges (such as muscle cramps, tiredness,

irritability, depression) last or worsen.

Chest Pump Exercise Working on the chest is certainly one of the hardest of all of the muscle tissue within the

physique. Our mission is to be your go-to life-style resource for building a

fit physique, wholesome mind, and full financial

freedom. We’ll convey you exclusive interviews, useful hacks, and content you can’t find wherever else.

We welcome photographs, articles, reviews, interviews, commentary, upcoming events, etc.

The suggestions form on this page can be used to report content material that’s not correct, up-to-date or questionable in any manner.

We follow a strict editorial policy, particularly

associated to the sources we use. Our articles are resourced from respected online pages, with research

drawn from tutorial institutions and peer-reviewed research.

At age 62, “Massive Bill” shares his knowledge to dominate one of many ultimate energy marks.

We do NOT intend for the data offered by way of our articles to exchange the medical relationship with a certified physician,

nor does it represent specialized recommendation. We’re unable

to supply private health advice, however we’ve partnered with

JustAnswer who presents on-demand docs to answer your medical questions 24/7.

Discuss online now with a health care provider and get

fast 1-on-1 answers from the comfort of your sofa.

Magnesium influences muscle contraction and release, related to many

physiological processes, from your heart to physical performance and post-performance restoration. According to Dr Jomova, an skilled in food sciences and know-how at the Thinker College in Nitra, magnesium

is a cofactor in more than 300 enzyme-related reactions.

An hour-long DVD can be included, containing 18 movies made

by Bob Mizer between 1954 and 1968, in black-and-white and colour, all edited specifically for this e-book.

Mizer’s take on Dr. Frankenstein’s monster, in posing straps, is a standout.

In 1951 Mizer launched Physique Pictorial, America’s first indisputably gay magazine, bringing his photographs of top bodybuilders to grateful readers

worldwide. In 1957 he revealed a catalog that includes all his males, titled one thousand Mannequin Directory.

A second one thousand Mannequin Directory followed in 1968, with the lads photographed in the intervening years.

The little 98-page books grew to become prompt collectibles, however the photos were so small, 12

to a page, that they had been as frustrating to view as they have

been titillating. Bob Mizer started taking photographs of strapping young men on Muscle Seashore in L.A.’s Venice

Seashore back in 1945.

Jim and Champ hit it off directly and the photographer proceeded

with the first of 21 separate photo periods with the boy.

These images shortly turned him into the primary (and still most enduringly

popular) homosexual icons of all time. Stryker was recent out of high school when he met photographer Walter Kundzicz (a.k.a.

Champion) in the summer of 1952. In search of latest topics for a rising portfolio of young male models,

Champ traveled particularly to a rural swimming gap to meet the beautiful blonde youth.

Upon arrival, he was greeted with the breathtaking sight of a completely bare 18-year-old in a tree, laughing

uproariously as he urinated on a friend standing under.

Spinach is normally a good supply of magnesium,

as one cup (180 g) of cooked spinach accommodates around 158 mg of spinach, or 37% of the Day By Day Value.

Our Mag wheels are perpetual merchandise that serve every enthusiast with style and expertise.

Recognized as The Unique Muscle Automotive Wheel, the S/S line is our most popular custom chrome wheel design. Signal in by coming into the code we

despatched to , or clicking the magic link within the e mail.

Tissue Salts are absorbed into the body through the blood vessels in the mouth, chewing the tablets quite

than swallowing entire is preferred.

Earlier Than taking a magnesium supplement, tell your doctor or pharmacist if you are allergic to

it; or if you have any other allergy symptoms. This product might comprise inactive ingredients, which can trigger allergic reactions or different issues.

The film’s story centers on a rebellious high school pupil, Michael Harlan (Stockwell),

whose interest and expertise working on muscle vehicles far

exceeds his efficiency in school.

Whether you’re a beginner, intermediate, or superior athlete, you’ll discover every little thing you have to succeed here.

Build Muscle Mass & Add Bulk To Your Legs The best workouts

for increasing leg muscle mass. Muscle and Well Being participates

in affiliate internet marketing applications, which implies we

may receives a commission commissions on editorially chosen merchandise purchased by way of our links to retailer sites.

Make legday each effective and efficient with this underutilized piece of kit.

We will dispatch your order within one – two business days from our Warehouse in Shrewsbury.

Your order tracking number will be emailed to you once launched by Royal Mail.

This can take up to forty eight hours after dispatching from our Service Centre.

It is the remedy which relieves cramps and aches and dietary supplements the action of Kali Phos.

Mag Phos is quick to relieve pain, especially cramping, capturing, darting

or spasmodic pain. It relieves muscular twitching,

cramps, hiccups, convulsive fits of coughing and people sudden,

sharp twinges of ache which are so distressing. Buyer Reviews,

including Product Star Ratings assist prospects to study extra

about the product and determine whether it’s

the right product for them.

However because of the Covid-19 pandemic, they stopped print

publication in 2020 and stuck with digital content material for apparent reasons.

Magnesium is very useful in controlling stress and anxiety; it helps regulate the hormones associated to emphasize, including cortisol.

Cortisol commonly rises by way of persistent stress and may have damaging effects on the body after

a while. Magnesium helps counteract this by promoting relaxation and reducing the physiological

results of stress. Mag Genin™ includes magnesium glycinate,

probably the greatest magnesium glycinate supplements, recognized for its excessive absorption and minimal digestive discomfort.

Magnesium has been proven to play an important function in serving

to your muscle tissue relax. That’s why insufficient magnesium intake is thought to trigger some

muscle cramps.

Deciding On essentially the most appropriate type of magnesium, as well as

the suitable dosage, is an important step in selecting the best product for you.

In a time the place sexuality was repressed in the mainstream, Hearth Island came to

symbolize a spot of mystery and a homosexual haven for so much of.

Whereas a lot about Jim Stryker stays unknown, his blonde beauty towards the liberated setting of Hearth Island stays a

snapshot in time of a refuge for younger homosexual boys of

the time. Do not flush medications down the toilet or pour them right into a drain until

instructed to do so. Correctly discard this product when it’s expired or not needed.

Matthew is an ACE (American Council On Exercise) certified health skilled who has had a ardour for health since elementary school and continues to research and discover methods to build muscle

successfully by way of coaching and food plan. He additionally loves to help others

to achieve their fitness objectives and unfold the information where

needed.

Magnesium supplements might help fill this gap and support better well being.

Here’s a listing of a few of the greatest

magnesium dietary supplements available right now. Magnesium supplements

are dietary aids that help one regain magnesium within the physique.

They are out there in various types of magnesium, every having its properties and benefits.

For example, magnesium glycinate is said to have calming results, whereas magnesium citrate is used for digestive well being and

to remedy constipation. Some forms of magnesium supplements

are also better absorbed than others. For example,

magnesium citrate is much better absorbed than magnesium oxide and may be extra environment friendly

at enhancing low magnesium levels in the physique.

By the 1930s some of the situations for a print-based, gay physique culture have been in place, though

its infrastructure was not yet discernibly gay.

Bodybuilding and gym-based weightlifting were becoming more popular.

Energy and Health magazine, linked to the York Barbell Firm in York, Pennsylvania, started publishing on this interval, and the

primary Mister America bodybuilding contest was held in 1939.

Right Here and there, homosexual photographers like

Al Urban started up regional mail-order companies for his or her pictures

of muscular younger males, but nobody had but thought of assembling pictures right into a journal format.

Magnesium glycinate is a extremely bioavailable magnesium bonded with the

amino acid glycine. A study by researchers Derek Case,

et al, share within the Journal of Molecules notes that this constituent is a calming mineral salt that is normally beneficial for people underneath a lot stress,

nervousness, or disturbance of sleep. In Distinction To most of its other forms, it is

light to the stomach and suitable for sensitive digestive methods.

He also created a health clothing line (Faremon) and complement line (Formula 1).

Most of the stores had been ultimately closed, whereas the clothing and

supplement line was sold or discontinued to focus on the core enterprise of guide

and magazine publishing. Verify the labels on all your

prescription and nonprescription/herbal

merchandise (such as antacids, laxatives, vitamins) as a end result

of they might comprise magnesium. If either of those effects last or get worse, inform your physician or pharmacist promptly.

Take every dose with a full glass (8 ounces or 240 milliliters)

of water until your physician directs you in any other case.

Frequent mineral tablets corresponding to magnesium or calcium have related

properties, but they merely refill the body’s mineral reserves.

Tissue Salts don’t need to be damaged down within the digestive tract before being assimilated, which allows them to be extraordinarily effective.

Tissue Salts are minerals which help the healing processes within the

body by regulating mineral ranges in the cells.

They are the 12 vital minerals that the physique needs daily

to assist cell metabolism and be positive that the minerals which the body

ingests are evenly distributed.

A host of powerful new engines was provided, and all of them could be mated to

a buyer’s choice of handbook or automatic transmissions.

While on an uncommon date together with his nerdy classmate,

Ellie Sawyer (von Zerneck), Michael trespasses onto an deserted Air Force base that years before housed an alien craft recovered from Roswell, New Mexico.

There, he stumbles upon the engine from that ship, a

compact, plasma globe-esque piece of apparatus,

and absconds with it, pondering that it could be the reply to his

science project dilemma. Enhancing Your Bench Press – Weight lifting program

for muscle mass and bench press energy. Preserving match has turn out to

be common to most individuals because it has been linked to various advantages.

EXPRESS Transport is £3.99 for all orders over £39.99 throughout

the United Kingdom. All parcels for STANDARD

delivery throughout the Uk are despatched via Royal Mail

48 Hour Tracked Service. Transport charges are charged primarily based on a

flat fee of £4.ninety nine per order. Shipping is FREE for

all orders over £39.ninety nine within the United Kingdom.

One factor that set Kundzicz other than other photographers of the time,

was that he didn’t pretend to see his fashions only as stunning photographic subjects.

He displayed them clearly as sex objects and sometimes even engaged in romantic and sexual relationships with them.

With a great rise in reputation, folks seek supplements for their well being assist.

Referred to because the “miracle mineral,” magnesium is vital in tons of of bodily processes,

starting from vitality manufacturing to muscle rest.

The ruling in MANual Enterprises opened the door for

the physique magazines to become more open in regards to the erotic lure of physique

photographs as nicely as the specifically homosexual sexuality

they had been addressing. Slowly over the course of the

Sixties, physique photography grew extra overtly

sexual as artists depicted their models nude and chose youthful, slimmer men—and boys—to photograph.

Although Mizer’s pictures retained their 1950s atmosphere of playful,

boyish romping, most different photographers shortly moved to take benefit of what they noticed as both extra expressive and more worthwhile sexual nudes.

Mean peak concentrations and area underneath the curve (AUC) have been significantly larger with CPY (17 and 14%,

respectively) compared to CM. The small variations in kinetics are unlikely to have any clinically related

effects on muscle creatine elevation during times of creatine loading.

A follow-up examine together with muscle biopsies would be

required to conclude if the bioavailability of this specific creatine salt

was indeed larger (Fig. 8). Creatine supplementation is renowned for its ability to considerably

enhance athletic performance by improving power, energy, and endurance in high-intensity exercises.

Beyond its quick results on physical efficiency,

creatine additionally contributes to increased muscle mass.

Second, although there’s a development towards elevated 15-s work relative to

FFM with creatine supplementation, this pattern did not attain statistical significance.

As described by Mader and Heck [4], lactate distribution area is

a fraction of FFM. Subsequently, as FFM increases, the

lactate distribution space additionally expands proportionally [4,22].

This enlargement signifies that the identical total quantity of

lactate produced is extra diluted, theoretically leading to decrease

concentrations of capillary blood lactate. Buffered Creatine is marketed as the one kind of creatine with a pH above 12.

It is claimed that this forms a more secure molecule that enters the

muscle cell in its entirety and doesn’t result in the formation of creatinine, which will increase bioavailability and

makes it superior to creatine monohydrate.

When it comes to the bioavailability of creatine supplements, Creatine Monohydrate is mostly thought-about to have larger

bioavailability as in comparability with Creatine Nitrate.

In praxis and theory, creatine monohydrate and HCl produce comparable advantages.

Creatine HCl is an acid salt type of creatine that has

been reacted with hydrochloric acid. And if Cr digestion is slower for meals than it is from a complement then keeping your

shops topped up with a good-quality pre exercise will result in more energy for intense train and

excessive efficiency physical exercise. The energy your physique uses for on a daily basis

duties comes from a molecule known as adenosine triphosphate (ATP).

Rooster is the most typical sort of poultry amongst all

the home fowl which is eaten, on the earth.

It is a superb supply of lean meat (meat with

out a lot fat), which is excessive in protein and creatine (5).

AlzChem AG (Trostberg, Germany) offered funding for this study

by way of a research grant to Texas A&M University. All researchers concerned independently collected, analyzed, and interpreted the outcomes from this study and

have no monetary interests concerning the outcome of this investigation. Data from this study

have been presented on the Worldwide Society of Sports Activities Diet Annual meeting and have not been submitted for publication to any other journals.

Creatine dietary supplements enhance the physique’s retailer

of phosphocreatine, which is used to provide ATP, the primary energy foreign money of the cell,

during quick bursts of high-intensity train. This can result in improved efficiency in activities such as sprinting,

weightlifting, and different explosive movements by growing the duration that high-intensity exercise could be sustained.

While creatine monohydrate is more generally used and researched, creatine phosphate is another form

that some athletes and fitness fanatics consider.

It is important to know the variations in absorption, efficacy, and safety

between these two types of creatine. Creatine HCL may be thought of higher for slicing by some due to its potential for inflicting less water retention compared to Creatine Monohydrate.

If you select to not do a loading phase, you should devour between 3-5 grams of creatine every day.

Throughout a creatine load, you’ll eat a considerable

amount of creatine in a short period of time.

We would suggest that an individual who chooses to make use of

dietary dietary supplements confirm that their producer of alternative supplies ample

proof that their supplements are effective, adhere to cGMP tips,

and have some type of third celebration batch testing in place.

If you’re looking for dietary dietary supplements that exceed these criteria, we do produce

a small line of evidence-based supplements which are rigorously examined.

General, creatine supplementation most likely doesn’t increase the chance of male pattern baldness in males without any type of

genetic predisposition to the condition. However in case your aim is

to take care of lean mass or enhance endurance performance, Kre-Alkalyn is the way

to go. With Kre-Alkalyn, you’re going to get about 10% extra absorption than monohydrate,

however it’s going to also have much less of a adverse effect in your stomach.

Both ingredients do not include creatine as such, since they’ve been chemically altered.

While it’s assumed that the human physique will transfer these molecules

into creatine upon intake, there are not any published data available to base firm conclusions.

Creatine crystallizes from water as monoclinic prisms holding one molecule of water of

crystallization per molecule of creatine.

Continued drying of CM ends in a loss of

the water of crystallization at round 100°C, yielding anhydrous creatine.

As a result, creatine can solely form salts with robust acids,

having a pka value of less than three.98. Creatine forms

salts by the protonation of its guanidine moiety (see Fig. 1).

Initially, it increases the water content material of

the muscular tissues, making them appear larger. Concerning combinations with carbohydrates,

protein, and/or caffeine there isn’t much in the way

of long term knowledge exhibiting a difference in muscle creatine content

material when taken with or with out these co-ingredients.

It is unlikely any of those components alter muscle or total physique levels of creatine significantly with supplementation. Similarly,

there are not any security studies in pregnant women, although some preclinical

trials in animals present there could additionally be some benefit if oxygen provide to the fetus is compromised.

[31] Outside of the analysis setting, supplementing creatine during pregnancy and whereas breastfeeding might be not

a fantastic thought. During these periods of time, small enhancements in muscular

power power adaptations are generally not worth the danger of supplementation.

As Soon As the physique absorbs COP, it might take up to seven days before any results may turn out to be noticeable.

However if you see no change, change the dose accordingly or as directed by a doctor.

Moreover, creatinol-O-phosphate powder doesn’t include any fillers of

any type and is free of sugar, soy, dairy,

yeast, gluten, corn and additives.

This compound is among the main power transmitters and it’s involved in the synthesis of proteins, among other things.

Nevertheless, some research has demonstrated that there

have been important positive aspects in fat-free mass for trainees using creatine HCL supplements

in comparability with topics which are utilizing creatine

monohydrate supplements. An extra research found that creatine placed in a highly acidic

state stabilized at a ph stage of 1.0. The creatine absorbed by the intestines elevated by 60% as a result of enhanced

solubility and elevated permeability under these circumstances (5).

Creatine HCL was developed to permit it to combine higher with liquids,

enhance absorption, and eliminate water retention and gastrointestinal issues

– the two most typical complaints with creatine monohydrate.

However — when purchasing creatine — it’s important to do not neglect that every creatine

supplement is totally different. There are also many sorts of creatine, with creatine HCL

and creatine monohydrate being the most well-liked.

Dietary supplements embody vitamins, minerals, botanicals, amino acids, and enzymes that are not supposed to treat or stop disease.

The majority of safety issues surrounding dietary supplements is as

a outcome of of contamination with unapproved components and/or mislabeled dietary supplements.

Instantly after the top of the supramaximal tests, the

members remained seated quietly for 10 min for measurement of EPOCfast.

The supramaximal efforts have been performed 4 occasions, the primary 2 efforts being used as familiarization and the subsequent 2 efforts after the placebo and creatine ingestion durations.

The ultimate familiarization supramaximal check was in contrast with the placebo

condition to guarantee that there was no longer any familiarization impact.

In the USA, a key determinant triggering the necessity for an NDIN to

FDA is whether or not or not an NDI which has been present

within the meals provide has been chemically altered (Federal Meals, Drug and Beauty Act 1938b).

One of the major roles of creatine is to act as a non-mitochondrial

vitality buffer, rapidly transferring power via a reversible reaction catalyzed by the creatine kinase enzyme (Gualano et

al., 2010). Creatine (N-(aminoiminomethyl)-N-methyl glycine) is an ingredient

generally found in meals, primarily in fish and meat, and is sold as a dietary complement in markets around the globe.

Its use as an ergogenic aid and attainable therapy for certain neuromuscular problems is nicely documented

in scientific literature (Buford et al. 2007; Kreider et al.

2010). In latest years, the recognition of creatine has risen dramatically, particularly among

athletes.

And if you’re after a boost in energy, athleticism and strength then there’s only one

choice. The sheer wealth of proof suggests that creatine monohydrate is a superior supplement when it

comes to a pre workout. Whilst some pharmaceutical firms claim

that Cr nitrate is more practical at boosting

explosive energy and power, these claims are unsubstantiated.

The wonderful thing about Creapure® is that it has been the go-to creatine used in dozens of

sports science and energy & conditioning studies for years, so its

effectiveness may be very well-documented.

On the other hand, 20 generic creatine monohydrate brands that had

been tested averaged a whopping 25 mg/kg of DHT,

over eight occasions the really helpful safety restrict.

As is my custom here on heydayDo, I will present hyperlinks to

all of the related sports science and medical assets,

medical research, & dietary data used on this article.

Although, some claims have led individuals to imagine that it provides further benefits as a outcome of

nitrate molecule.

Responders are marked purple when ΔLa decreased more than SWC or orange

when 15-s work elevated greater than SWC. ΔLa, distinction between resting and peak post-exercise capillary blood lactate ranges;

SWC, smallest worthwhile change. Creatine monohydrate is a broadly used nutritional

ergogenic aid amongst athletes, primarily to enhance muscular energy [25].

Predominantly stored in muscular tissues, particularly

kind II fibers [26], and usually sourced from animal meals, creatine

supplementation has constantly been shown to

increase intramuscular PCr shops [25,27]. This improve in PCr is taken into account the

principle mechanism for elevating anaerobic energy capacity [25].

The effectivity of creatine phosphate in vitality transfer is what units

it apart as a potential alternative to creatine monohydrate.

This is particularly important for people with pre-existing medical situations,

those taking drugs, or those that have particular

health considerations or objectives. The journey of creatine within the physique is a testomony to its organic prowess.

Creatine monohydrate is renowned for its excessive bioavailability, which refers again to the

proportion of the substance that enters the circulation when launched into the body and is thus able to have an lively impact.

Creatine phosphate, while much less studied, also performs an important function in the body’s vitality

techniques. Creatine phosphate, also recognized as phosphocreatine or PCr,

is a phosphorylated creatine molecule with 62.3% creatine and 37.7% phosphate.

Creatine Anhydrous Creatine anhydrous is creatine monohydrate

with the water removed. It provides barely extra creatine

than creatine monohydrate on a gram-per-gram basis, but

it has by no means been proven to be more practical.

According to the Journal of the Worldwide Society of Sports

Diet, two research had been carried out to evaluate the security and exercise performance benefits of

creatine nitrate (CrN) supplementation in comparability to creatine monohydrate

(CrM) and a placebo. In the early Nineties, EAS launched its original model of creatine monohydrate and thus sparked the first great revolution into

the sports diet market. Since the release of Phosphagen, Hi-Tech has

worked diligently to develop a creatine product that would symbolize the identical quantum leap in nutritional

know-how and consumer worth that EAS’ Phosphagen did.

Hi-Tech understood that to achieve this mission, it might have

to design a sophisticated creatine product that significantly superior the muscle-building potential

of the original Phosphagen. Moreover, Hi-Tech realized that the successful design of such a complicated creatine product could

take a decade or more of both in-house and unbiased research and experimentation. The aim of this study was to evaluate the

results of creatine monohydrate supplementation on morphology,

MyHC isoform expression, and myostatin pathway signaling in gastrocnemius (white

portion) and the soleus muscle tissue of rats submitted to resistance training.

Since the gastrocnemius muscle superficial

area (white portion) is characterised by the predominance

of fast-twitch fibers, whereas the soleus is a classical slow-twitch muscle, these muscle tissue were used on this examine.

Research reporting phosphocreatine and total creatine ranges in main depressive disorder.

Multiple sources of proof, from epidemiology, genetics,

biochemistry, and neuroimaging, indicate that bioenergetic

abnormalities contribute to the development of depressive signs in each MDD and bipolar dysfunction (BD).

Collectively, they counsel that compounds that might enhance mind power storage, like creatine, might contribute to the therapy of melancholy.

Human analysis on CreatT1 expression has been pretty limited to health and illness issues [16-19].

Nevertheless, some studies have examined how

Cr supplementation in humans affects CreaT gene expression in vegetarians [20], males

versus females [21], and between younger and aged people [22].

The research that didn’t report significant improvements principally report non-significant features.

1RM leg press significantly elevated in all subjects, and the studies didn’t discover differences between the groups.

Each groups additionally skilled decreases in fat and gains in fat-free muscle mass,

but the levels were more important in the creatine HCL group.

Creatine monohydrate is made up of a creatine molecule attached to a single

water molecule. It has been the most extensively researched creatine complement,

with numerous advantages. The physique doesn’t essentially have enhanced health or

performance ranges with the free ADP made obtainable from ATP

hydrolysis.

One parameter derived from these measurements, known as νLamax, is considered a surrogate

marker for the maximal glycolytic price. Both Creatine Monohydrate and Creatine HCL

offer distinct advantages for enhancing athletic efficiency.

Selecting the best creatine complement is decided by your particular health goals, private preferences,

and how your physique reacts to each type. By understanding the

creatine HCL benefits, in addition to the suitable creatine

monohydrate dosage, you presumably can maximize your exercise results and achieve your required outcomes.

While the exact reasons behind his departure stay unclear, speculations recommend that

it could presumably be as a result of private reasons or

a need to pursue other alternatives. CrossFit Regionals isn’t solely a

check of physical talents but additionally psychological energy.

In high-pressure conditions, staying calm and targeted

could make all the difference.

Sure, athletes who’re unable to carry out certain actions because of injuries or bodily limitations may select to complete another version of the

WOD or search a medical exemption. Nevertheless, it is ultimately as a lot as Crossfit’s discretion to permit such exemptions.

Due To This Fact, athletes who aspire to make it to this intermediate

competition have to be dedicated to their long-term aim of competing at the highest stage in Crossfit.

Prepare as a team – If you’re aiming to qualify with a group,

it’s crucial to train collectively and work on communication and strategy.

Practice with function – Every workout should have a particular objective behind it.

CrossFit Regionals is an annual competitors that brings

together elite athletes from around the world to compete for a spot within the CrossFit Games.

It serves as a qualifying occasion where athletes showcase their expertise, endurance, and strength by way of a

collection of intense workouts. Crossfit is a high-intensity fitness program that

has gained immense recognition lately. This program focuses on useful

movements performed at a high intensity level, and aims to enhance overall bodily fitness and strength.

Crossfit competitions take place at various ranges, together with native,

nationwide, and international events. Amongst these competitions are the Crossfit Games, which function the final word check of fitness for athletes worldwide.

It takes a novel combination of skill, dedication, and technique to make it to Regionals,

and on this article, we’ll dive into the necessities and strategy of qualifying.

Whether Or Not you’re a seasoned CrossFit athlete or just getting started, understanding the highway to Regionals can provide you a brand new degree of motivation and inspiration for your health

journey. So let’s lace up our Nanos and prepare to discover tips on how to qualify for CrossFit Regionals.

Inside each region, there are several training zones the place athletes can compete.

These coaching zones are sometimes positioned in major cities or metropolitan areas within each state.

To qualify for regionals, people must determine their goats early on and work to improve them.

This may involve looking for professional coaching or programming

specifically tailor-made in path of enhancing these abilities.

Neglecting your goats could be detrimental to your efficiency at regionals.

The first step in the direction of qualifying for

Crossfit Regionals is taking part in the annual Crossfit

Open competition. The Open is an online competition that lasts for five

weeks, with a model new exercise being launched every week.

Athletes compete in opposition to each other by submitting their scores online or participating

in stay occasions organized by their local box (gym).

To begin, each athlete must first compete in the Open, which is a worldwide competitors open to anybody

who desires to take part.

Seek steerage from experienced rivals and coaches to optimize your chances of making it to the

CrossFit Video Games. Nonetheless, it’s estimated that across the high 10% of athletes in each region, based on their Open rankings, will advance to the Semifinals.

Be ready for intense exercises that will test your physical and psychological limits.

CrossFit Regionals are known for pushing athletes to their most

potential. The variety of groups from each area that advance to the CrossFit Games is dependent upon varied elements, together with the dimensions and competitiveness of the area.

Solely those that can stay centered beneath

stress will have an opportunity at qualifying for the CrossFit Games.

For novices seeking to enterprise into the world of CrossFit competitions, it’s essential to know the structure and necessities of these events.

The CrossFit Competitions for Newbies 2023 information offers a comprehensive overview of what to

expect, how to prepare, and ideas for fulfillment

in your first competitors. As such, the MVP Area will host the fittest athletes from all over the

world for three days from August 1-3. CrossFit held the East Regionals at MVP Area (then it was

called Occasions Union Center) years ago so there is history there, but I wanted to study extra concerning the new residence of the Video Games.

The variety of qualifiers varies primarily based on the region and the general number of

athletes competing. This means they must use a registered decide at an affiliate or submit

an official video submission. The Ten CrossFit Semifinal occasions are seeded with qualifying athletes from each continent.

Study the means to play on this year’s Open within the first ever adaptive athletes division.

Just Lately, CrossFit Games Head Decide and Competitors Director Adrian Bozman delivered competitors season briefs to Masters athletes

ahead of the CrossFit Games. The first weekend of the 2013 CrossFit Regionals gets underway Might 17, running

all the greatest way to June 9. For extra info on the workouts,

you possibly can try all the motion normal movies by clicking here.

There will be a prize purse of more than $3.3 million (USD) across the Particular

Person, Staff, Adaptive, and Masters divisions

spanning the Semifinals and CrossFit Video Games championships.

Continuing the precedent set on the inception of the CrossFit Video Games, feminine and male competitors will

obtain equal prize money for their respective ending

positions. For those events, if an athlete failed to fulfill the minimal work requirement, they might not be eligible to maneuver on to the following occasion.

The Open consists of 5 workouts over 5 weeks, with one exercise being launched each week.

These workouts challenge numerous features

of fitness similar to strength, endurance, and ability.

It takes dedication, onerous work and months of coaching to earn a spot

at this prestigious occasion. Every region has its own qualifying process, but all of

them follow comparable tips set by CrossFit headquarters.

Each WOD has a specific level system, and your complete score is calculated by adding up your

points from all of the WODs. Three-day passes will

be sold on-line until two days earlier than the

regional starts. Single-day passes shall

be bought at the gate, if any house remains, and may be subject to venue fees.

The top forty eight may have three days

to decide whether or not to simply accept or decline their individual invitations—April 9-12.

Areas might be backfilled from the 49th- to 60th-place finishers

within the area. Anybody who finished in the prime 60

in his or her area must submit video of Open Workout 14.4.

It takes a well-rounded athlete who can excel in a number of elements of fitness.

The high rivals not only have impressive numbers on their lifts and exercises, but additionally they

possess expertise such as gymnastics, Olympic weightlifting,