As a seasoned expert in the field of metal materials from Sino Stainless Steel, I have encountered numerous types of metallic forms, each serving its unique purpose in various industries. Among these, sheet coils and plates are two commonly used forms, but there exist significant differences between a sheet coil and a plate. This article aims to provide a comprehensive and authoritative comparison between sheet coils and plates.

What are the differences between a sheet coil and a plate?

Let’s start with sheet coils. A sheet coil, as the name suggests, is a continuous strip of metal that has been rolled or coiled into a circular shape. Typically, sheet coils are made from thin sheets of metal, such as steel or aluminum, and they are often used in applications where a flexible, continuous source of metal is required. The main advantage of sheet coils is their versatility. They can be easily unwound, cut, and formed into various shapes and sizes, making them suitable for a wide range of applications.

Sheet coils are commonly used in the construction industry, particularly in roofing and cladding. Their flexibility allows them to be easily installed over irregular surfaces, and their durability ensures long-lasting performance. In the automotive industry, sheet coils are used for the production of body panels and other components, where their ability to be formed into complex shapes is highly valued. Additionally, sheet coils find applications in the packaging industry, where they are used to create metal containers and cans.

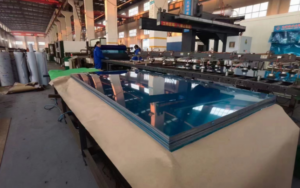

On the other hand, plates are a different form of metal material. Plates are typically thicker and more rigid than sheet coils, and they are usually produced in flat, rectangular shapes. Plates are made from a variety of metals, including stainless steel, carbon steel, and aluminum, and their thickness can range from a few millimeters to several inches. The thickness and rigidity of plates make them suitable for applications that require structural support and strength.

Plates are widely used in the construction of bridges, buildings, and other large-scale structures. They provide a solid foundation and support for the entire structure, ensuring its stability and durability. In the oil and gas industry, plates are used to construct pipelines, tanks, and other equipment that need to withstand high pressures and temperatures. Additionally, plates are also used in the manufacturing of heavy machinery and equipment, where their strength and durability are crucial.

The manufacturing processes of sheet coils and plates also differ significantly. Sheet coils are typically produced through a rolling process, where a large block of metal is passed through a series of rollers to achieve the desired thickness and width. This process allows for the continuous production of long strips of metal, which can then be coiled for ease of transportation and storage.

On the contrary, plates are produced through a variety of processes, including hot rolling, cold rolling, and forging. These processes involve the shaping and compressing of metal into the desired thickness and shape. The type of process used depends on the material, thickness, and desired properties of the plate. For example, hot rolling is commonly used for thicker plates, as it allows for the metal to be shaped and compressed while still hot, resulting in a more uniform grain structure and improved mechanical properties.

In terms of mechanical properties, plates and sheet coils also exhibit differences. Plates, due to their thicker cross-sections, tend to have higher tensile strength and yield strength, making them more suitable for structural applications. Sheet coils, on the other hand, may have lower strength but offer greater flexibility and formability, allowing them to be easily shaped and formed into various configurations.

Moreover, the surface finishes of plates and sheet coils can also vary. Plates can be produced with a variety of finishes, including polished, brushed, and sandblasted, depending on the desired aesthetics and functional requirements. Sheet coils, on the other hand, are typically produced with a smoother, more uniform surface finish, suitable for applications where a clean and consistent appearance is desired.

Conclusion

In summary, the difference between a sheet coil and a plate lies in their characteristics, applications, manufacturing processes, mechanical properties, and surface finishes. Sheet coils offer versatility and formability, making them suitable for applications where flexibility and continuous metal sources are required. Plates, on the other hand, provide strength and structural support, making them ideal for applications that demand high levels of durability and stability.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between a sheet coil and a plate. If you are looking for stainless steel coil and stainless steel plate suppliers and manufacturers online now, we would advise you to visit Sino Stainless Steel.

As a leading supplier of stainless steel products from Shanghai China, Sino Stainless Steel offers customers high-quality stainless steel coils, stainless steel plates, stainless steel strips, stainless steel decorative sheets, stainless steel tubes, stainless steel pipes, and stainless steel bars at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com