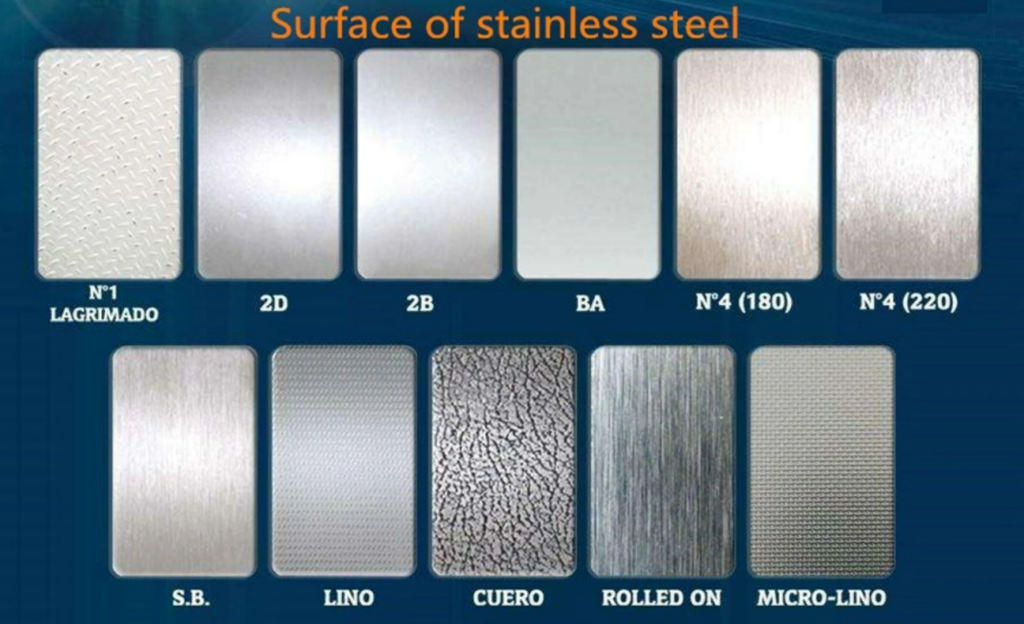

Stainless steel is a widely used metal material. Due to its excellent corrosion resistance and beautiful surface quality, it is widely used in construction, furniture, kitchenware, medical equipment, and other fields. There are many different methods of stainless steel surface treatment, including 2B, 2D, 4B, BA, and NO. 4 surface treatment methods. So, 2B vs 2D vs 4B vs BA vs NO.4 surface finishes – what’s the difference? Below we will introduce them in detail.

2B vs 2D vs 4B vs BA vs No.4 Surface Finishes – What’s the Difference?

2B vs 2D vs 4B vs BA vs No.4 Surface Finishes – I. 2B Surface Treatment

2B surface treatment is a common surface treatment method, with high surface quality, silver-white color, and good luster and mirror finish. It has good rust resistance and corrosion resistance, and also possesses certain fingerprint resistance. It is commonly used in occasions that require high luster and smoothness.

2B vs 2D vs 4B vs BA vs No.4 Surface Finishes – II. 2D Surface Treatment

2D surface treatment is a more rugged surface treatment method, with a non-lustered gray or black appearance. The advantage of 2D surface treatment is its strong fingerprint resistance and rust resistance, and it is relatively low-cost. It is commonly used in structural parts and supports that require high strength and durability.

2B vs 2D vs 4B vs BA vs No.4 Surface Finishes – III. 4B Surface Treatment

4B surface treatment is a more advanced surface treatment method, with extremely high surface quality, extremely high luster, and mirror finish. It is suitable for occasions that require excellent surface quality and luster, such as high-end tableware and luxury buildings.

2B vs 2D vs 4B vs BA vs No.4 Surface Finishes – IV. BA Surface Treatment

BA surface treatment is a special surface treatment method, also known as “super polishing”, with a silver white or gray appearance, and extremely high luster and mirror finish. It is suitable for occasions that require excellent surface quality and luster, such as high-end decoration and luxury buildings. At the same time, BA surface treatment also has strong fingerprint resistance and corrosion resistance.

2B vs 2D vs 4B vs BA vs No.4 Surface Finishes – V. NO.4 Surface Treatment

NO.4 surface treatment is a more common surface treatment method, also known as “sand” or “satin”, with a non-lustered gray or black appearance. The advantage of NO.4 surface treatment is its strong fingerprint resistance and rust resistance, and it is relatively low-cost. It is commonly used in occasions that require certain rust resistance and luster, such as ordinary buildings and furniture. Additionally, NO.4 surface treatment also has a certain decorative effect, able to bring warm and comfortable visual feelings to people.

Conclusion

In summary, the 2B, 2D, 4B, BA, and NO.4 surface treatment methods of stainless steel have different characteristics and applications. When selecting the surface treatment method of stainless steel, it needs to be based on the specific application and requirements to achieve the best use effect and appearance effect. At the same time, attention should also be paid to the impact of different surface treatment methods on the performance and service life of stainless steel.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between the 2B, 2D, 4B, BA, and NO.4 surface treatment methods. If you want to learn more about surface treatment methods, we would advise you to visit Sino Stainless Steel.

As a leading supplier of stainless steel products across the world, Sino Stainless Steel provides customers with high-quality colored stainless steel sheets, stainless steel pipes, stainless steel strips, stainless steel coils, stainless steel plates, stainless steel sheets, stainless steel bars, and stainless steel tubes at an extremely competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

Hypogonadism is an increasingly common finding in aging men, those treated for prostate cancer or other diseases involving hormone therapy or chemotherapy, and men with erectile dysfunction buy nolva and clomid uk

Unfortunately, whereas the overhead press does activate the

aspect delts, it’s not enough to create that spherical

shoulder shape. When most people discuss shoulder coaching, they’re

referring to the deltoids, which have three completely different heads

– the anterior (front), medial (side), and rear delts.

These three heads are the prime movers of the shoulder

joint and upper arm in varied instructions. The shoulder muscle is doubtless considered one of the

most attention-grabbing anatomically as a end result of each head has its personal insertion point

and may work independently from the other

heads.

Regardless of why it happens, a stronger shoulder can deal with the abuse far more successfully than a weak one.

Massive, broad shoulders are some of the defining

options in relation to men’s aesthetics. After the routine, we’ll undergo everything else

you have to know, including important programming suggestions, training variables, and ways to

proceed progressing.

Then, when you start your workout you want to start some high-rep

units of the first exercise utilizing very mild weights, and even no weights

in any respect. This will get the shoulder used to

the actions it’s about to take action you’re not beginning your first set

chilly. Simply like lateral raises, you’ll want

to go on the lighter aspect of things for the weight! Going too heavy means you may find yourself

using momentum to ‘swing’ the load up, instead

of fulling using the anterior delts to drive the weight up.

The hottest method to perform frontal raises is utilizing a pair of dumbbells, either together or one arm at a time, alternating reps between arms.

The lateral deltoids are located on the facet of your upper arm.

The side delts are answerable for shoulder abduction, which is the arm raised to the

physique’s facet [1]. This muscle creates a broader look of the higher

physique and is the primary focus for wide shoulders.

The half-kneeling landmine press combines horizontal and vertical actions to ensure you make your shoulders stronger.

On high of that, if you’ve experienced any shoulder harm recently,

this train can be used as a modified overhead press.

One of the reasons guys do not prepare shoulders, especially the overhead press, is it tends to

be a fairly weak motion sample and muscle group for most lifters.

To do this we’re going to do a tri-set with cable machine raises.

We’ll do variations for the front delt, the center delt, and the rear delt.

Pull the band apart together with your right

hand, as if pulling a bow, squeezing your again and shoulder

muscle tissue and bending your elbow as

you do that. When it comes to coaching frequency, there are heaps of

variables to take into account. For instance, your age, your recovery routine, diet, and the

intensity of your session all impacts how your physique will react,

recover and rebuild.

Some examples of variations embody single-arm raises, chest-supported side raises, and dumbbell lateral to-front raises.

It’s a variation of the standard overhead press, however with a impartial grip as an alternative of a pronated (overhand) or supinated (underhand) grip.

The dumbbell shrug is a superb exercise for building shoulder energy, bettering posture, and relieving neck and shoulder pain. There are many variations

of bent-over lateral elevate you could add

to your workout routine, and all have their own unique advantages.

They are performing the train whereas the seated shoulder press is a stricter version than standing

and prevents dishonest the weight upward using momentum generated by the

legs.

Lifting to get wider shoulders requires attacking the facet

delts. The broad physique is a combination of a large

higher again and lats with a smaller waist through reduced physique fats.

In my experience, nothing will grow your higher again like the snatch grip high pull

from the blocks. When we dive into the analysis, we see probably the most important activation of the aspect delts is during the lateral increase train in comparison with any other

exercise [1,2].

Elevate your shoulders as high as you can, then lower them again down and repeat.

Teres major is a small muscle that is positioned on the underside of the

upper arm. It Is typically referred to as ‘lat’s little helper’

because of its partnership with the latissimus dorsi. The latissimus dorsi muscle is likely considered one

of the largest muscles in your again and is partially lined by the trapezius.

Growing your ‘lats’ will make it simpler for you to manage your personal bodyweight.

This motion targets the entire shoulder advanced while enhancing shoulder stability and mobility.

Here’s your go-to routine for increase massive, respectable

shoulders.

Isolating these posterior shoulder muscular tissues means much less weight is required to build strength and measurement inside the

goal muscle tissue. You can perform the landmine press from a standing or half-kneeling place.

Each are effective shoulder workouts, but the kneeling place provides better stability

and places less pressure on the lower again for those who wrestle

with again issues. Skilled lifters know that shoulders

develop well with some high-rep pump work within the mix.

It can be nice by itself, or as a second shoulder day seventy two

hours after one centered extra on free weights and

presses.

Lengthen your arms out to your sides and draw them down, rotating your palms to face

the ceiling. Continue till the back of your palms touches the small of your again. We’ve compiled the information and expertise of ourentire team to

create these three Free E-books that can helpyou lose fats and re-build your body from the ground up.

Testosterone is critical to develop a stronger and more muscular physique as well as improving your physical efficiency.

There have been numerous studies on carried out creatine on effective it is enhancing physical performance in addition to positive aspects in fat/bone-free mass.

Extensive grip chin ups are almost second to none

in phrases of increasing shoulder girdle girth and creating as a lot area as possible between shoulder ends.

Made for the elite athlete and the strong-willed our products

were designed to gasoline your athletic efficiency. Rotate out of

your shoulder and the middle of your again, not your

lower back.

The shoulders are some of the active muscle teams, as they assist nearly all actions

of the upper arms. Due to how energetic the shoulders are for push movements,

folks typically will train them with triceps or chest.

People typically blast the traps on the finish of their shoulder exercise with a few shrugs.

Shrugs have a really quick vary of movement, so swap to higher reps in the range quite

than going heavy for low reps. One of my favorite workouts,

the Arnold Press, hits all three heads of the shoulders in a single movement.

Although it’s not the best train to hit the lateral delts, it still does.

Whereas sure, utilizing challenging weights will help

set off growth, you’re additionally extra likely to make

use of different muscle groups to get the burden moving, which leads us to our subsequent mistake.

There are 4 muscular tissues in your rotator cuff, 5 in your

shoulder girdle, and three deltoid heads. That Is so much that can go incorrect when you don’t make sure everything is primed and ready to go.

It targets a different part of the deltoid than the

frontal elevate. The medial deltoids are the side a part of

the shoulder muscle and are specifically worked during

the lateral elevate.

Reverse curls force your brachialis and forearm muscle tissue to do

extra of the work. In addition, they’re a great way to boost your grip strength.

The front, or anterior, deltoid begins from the outer portion of the clavicle and attaches

to the deltoid tuberosity, located on the high

of the upper arm. This part of the muscle participates in any motion during

which the upper arm is pulled forward and/or upward.

While this train won’t do a lot for the scale of your shoulders, it may help enhance shoulder joint

health. Most chest and tons of shoulder workouts contain medial or

inward rotation. This can cause imbalances inside

the rotator cuff, which is a group of small muscle

tissue that stabilize and control the finer actions of the

shoulder joint.

I usually do reps of single-arm raises on each side to coach my lateral delts effectively.

The dumbbell upright row can be utilized to focus on your shoulders or

traps, relying on how wide or slim you retain your elbows

through the movement. One of the most effective

ways to put on some severe shoulder mass and get full, dense shoulders is by doing

dumbbell shoulder workouts. Beginners and superior

lifters use dumbbells to construct a powerful basis of power.

Even when you don’t enhance the quantity of sets you carry out, you’ll still discover that you’re capable

of carry out more reps, at heavier weights leading

to large growth. For a few of us, there’s nothing higher

than placing heavy stuff overhead. This old-school free-weights-only shoulder exercise starts off with heavy, powerful push-presses, then pumps up your

lateral and rear delts with dumbbells. The secret to the Cable Face

Pull’s effectiveness lies in the combination of exterior rotation and horizontal pulling.

This movement engages the rear deltoids intensely, along with the muscle tissue of

the higher again. The constant rigidity offered by

the cable ensures that the rear delts are engaged throughout

the complete vary of movement, making this train a comprehensive rear delt builder.

As you pull your body upwards, the rear deltoids are

referred to as into motion to regulate and execute

the motion.

The motion required for the dumbbell entrance increase is identical to

the lateral raise; the one difference being the plane by which

the arm strikes. This time, begin with the dumbbells on the entrance of the

thighs and look to lift straight arms directly up till approximately aligned with the

shoulders. As the name suggests, this isolation exercise places probably the most demand on the anterior head of the delt.

Building robust arms and shoulders requires the proper

mixture of exercises. A good workout should include movements that

focus on the biceps, triceps, deltoids, and supporting muscles.

Every of these workouts hit some unique muscle fibers in the goal

muscle.

But there are some issues you are capable of do to make every train more practical.

Put Together to maximise your features with our unique 12-week

hypertrophy training program. Select between a four

or 5 day training cut up and achieve 2-12 kilos of muscle over 90 days…

Whereas they share some similarities, there are variations between the hammer vs. biceps curls.

For example, as a substitute of using a supinated grip

(palms going through up), you’ll use a impartial grip.

These dumbbell arm workouts are one of the best in the enterprise for building every muscle of the higher arm.

Bounce up on two parallel bars or gymnastics rings along with your palms going through inward and

your arms straight (A). In this text, we cover seven of the most effective bodybuilding again workouts that can allow you to construct mass,

strength, and definition. Whether you’re a beginner or

an experienced lifter, these exercises will provide the

muse for a well-rounded again workout. In my work with skilled

baseball teams over the past twenty years, I’ve seen firsthand how well-intentioned

stretching can generally do extra harm than good. But over time,

mobility experts realized this stretch was making the shoulder joint excessively loose and

unstable, growing harm danger quite than preventing it.

After your first week, the app begins coaching you every exercise,

ensuring you’re progressing with out overdoing it.

But if you would like much more growth from this exercise, if your machine lets you, lean again as you carry out it.

Hip thrusts have been shown to develop the glutes

simply as a lot as squats and, in this study, even led to almost double the glute development when added to a leg

exercise (9.1% vs 5.9%). On your last set, push past failure by doing as many half-reps as you presumably can within the stretched position to maximize development.

It isn’t harmful to coach with muscle soreness, however if it is more like “Ouch, I can’t move” somewhat than “Hmm, I really feel the final workout,”

take another day to recuperate. You can add resistance by holding a weight plate, a dumbbell,

or even your cat to your chest as you crunch away.

The tricep pushdown is the ideal beginner’s triceps train. It’s straightforward to be taught, and you can really feel it

hitting the right muscle tissue.

Another instance of why workout times will vary is

your schedule. To wrap issues up, let’s reply a quantity of frequently asked questions relating to exercising 5 days every week…

You should be ingesting about half your bodyweight in ounces of water.

So, if you weight 200lbs, you need one hundred

ounces of water per day (or 3 liters). The concept of recovery is easy and easy, but for lots of people,

it’s onerous to follow via.

If there’s one half where most fail at bodybuilding it’s the food regimen. Now,

this publish is extra about the eight week bodybuilding exercise program (the weight training part), so I’m not going to go

in depth with diet. These are our coaching guides for each major

muscle group in the physique. In these guides, you’ll study about the muscles’ anatomy, effective workouts to

coach them, and a sample energy coaching workout. Too typically, individuals

skip weights in favor of cardio—especially women, a few of whom could fear about building bulky muscles.

You’re capable of maximize your time in the health club as you will be working multiple muscles at once.

This lets you burn more energy and target different muscle

teams quicker than with other kinds of training.

According to science, muscular tissues develop the most when they’re stimulated each

forty eight hours. A full body exercise with weights takes this into

consideration by hitting all muscle teams a number of occasions over the course of a number of days.

This program is designed to build muscle and

strength, so ideally, you will be in a caloric surplus.

We suggest starting with a 300-calorie surplus after which monitoring and assessing it after a couple of

weeks.

It’s time for the ultimate train of the first exercise within the newbie energy coaching program.

We’re ending the session with an stomach exercise, either

the crunch or the hanging knee elevate. Choose whichever you get pleasure from,

or swap it up every other exercise for variety.

The neatest thing about strength coaching is that

it’s for everyone. No age restrictions exist, and it’s never

“too late to start lifting.” On the opposite, the older you may be, the extra important it is to include regular strength exercises in your life.

The saying “age is just a number” won’t be totally correct,

however resistance exercise is the closest thing we have to an elixir of youth.

You can change it around a great deal to meet whatever your particular

person wants are, ensuring you get what you’re in search of out of your workout program.

This is another extraordinarily intense training program so

you have to at all times monitor recovery between classes.

Related to the 5 x 5, when you’re planning on doing a lot

of further exercise with this program – sports coaching,

cardio, or otherwise, you might run into some problems.

You should be difficult yourself to get fitter and stronger every time.

It also will help the lifting weight not

seem so heavy by slowly progressing up to it. This is to maximise power

improvements and muscle progress. You ought to look to extend the weights by 2lbs – 5lbs every workout, relying on the exercise.

The new workouts will construct on what we started in Workout

1 while nonetheless maintaining the full physique exercise program simple and effective.

If you’re like Max and struggle to squat deep, strive

elevating your heels on plates. Working out 5 days a week is greater

than enough to build muscle. You can unfold out the volume

of your coaching throughout the week, which lots of people find easier to manage

than 3-4 days of high volume training.

A beginner’s set of adjustable weight dumbbells starts at about $50, but the

worth will increase as you add extra weight.

Many gyms or health facilities supply introductory coaching classes at little or

no cost, or they’ve trainers available in case you have questions.

Additionally, there are tons of private trainers who train purchasers on-line, via video platforms.

Gaining 10 kilos of muscle in 12 weeks is usually thought-about unrealistic.

However, substantial muscle development can still happen with a

well-structured exercise and vitamin plan in 12 weeks.

Change legs with each step and focus on controlling the descent —

your back knee should hover just above the ground

at the backside of each rep. The wider bar forces your elbows to flare out, participating more of your upper and outer back

muscles. It’s additionally easier in your joints, decreasing the chance of overuse

injuries from repeating the identical actions.

Various tools have been used by the authors of SR‐MAs to evaluate the standard of

original studies. Amongst the seven SR‐MAs that offered an general rating of examine high quality, the

median (range) percentage of unique research with “good” or “high” high quality was 23 (0

to 100)%. As A Outcome Of teens can progress so shortly without supplements,

reap the benefits of this and do it as supplement-free

as you can. Then, as quickly as positive aspects begin to stall out, begin trying totally different dietary supplements.

As a teen with plenty of energy, it can be tempting to crush it in the fitness center and go too onerous.

Assuming you (or your teen) has gone by way of puberty, here is the perfect training plan to observe.

This article is designed to cut by way of the nonsense and set you

on the proper track with the perfect exercise for

novices. One of the most effective ways to keep up an exercise behavior within the early days is by discovering an accountability buddy.

My greatest advice is to break this cycle as soon as you presumably

can by forcing your self to do the following exercise.

If lacking exercises turns into a habit, it’s a

really tough one to interrupt. The reason squats are first for each exercise is

that you’re more likely to skip the squats if you leave them to the end.

However you can go from an empty bar to 175lbs

of weight in beneath 5 minutes like this.

Since it nonetheless allows enough rest over the complete

week and breaks the physique up so each exercise

is barely much less tense, it is a good place to begin. However you’re going to

notice that your reps are going to extend during this phase.

Your first 4 weeks are going to be all about constructing a stable foundation of mass and energy.

Whether Or Not you’re new to bodybuilding or you’ve been on this recreation for some time, these workouts will simply allow you to pack on some serious

size. This is one of my personal 8-week exercise programs for gaining mass.

And you may be doing some heavy lifting on this bodybuilding exercise.

Some of our coaching programs, particularly the strength-focused ones, prescribe training weights based on percentages

of your 1RM.

Three workouts give you higher outcomes than two, however it’s a comparatively

slight difference, unlike going from one weekly exercise to two.

When you’re feeling ready on your subsequent set, you likely are ready.

Weight training is amongst the greatest issues you can do for your physique.

This strength-based routine for males over 50 is

your best fitness center exercise alternative but to make some modifications and throw

away the rule guide. Help your gym workouts with 3-5 minute every day

mobility drills. Whether Or Not it’s ankle circles, trunk twists or shoulder

rolls – keeping supple is great for useful longevity.

You don’t want to get all 3 sets; simply add weight and proceed.

Most of your energy and nutrition need to come from actual meals.

You can’t stay on dietary supplements and extremely refined meals products, if you need to build

essentially the most muscle mass. In this text, you’ll be capable of see the programming for the primary 4 weeks.

The aim is to stay with the same movements so it is easy to trace strength increases from week one to week twelve.

The isolation exercises change every 4 weeks and shall be

a combination of resistance machines, dumbbells,

and cables. The main aim of our powerlifting programs is to extend your strength within the squat, bench press, and deadlift.

And if you’re a member of my new app BuiltWithScience+, simply

open up the digicam on your telephone and scan this QR code to get this

full physique workout program at no cost. So, to make up for it, just like we did with the again workouts throughout the week,

on the end of your final set do as many half reps as you’ll be able to in that

each one essential stretched place. To end off the quads for the week, we’re doing

3 sets of reps of leg extensions. This is BuiltWithScience+, my

new app, and it’s designed to do all the heavy lifting for you — besides the actual weights, in fact.

Alright, that wraps out Workout 2 of our full physique

workout routine.

Bullmastiff is a base-building energy program created by Alex Bromley at Empire Barbell.

The major goal of this system is develop your base energy in the 4 huge lifts (squat, bench press, deadlift, overhead press) after which use that wider base to attain greater peak power.

Whereas you’re coaching every muscle group 3x a week, you’ll still have enough restoration time between periods as you’ll only perform

a number of exercises per muscle group per day.

I’d recommend beginning every lift with 3-4 warm-up units, slowly progressing

in weight to your working units. Earlier Than puberty,

youth and teenagers can raise weights, but the goal ought to be on studying actions and rising health somewhat than raising heavy weights and building muscles.

Youth can’t placed on mass before puberty, as they have not

yet had their hearty dose of muscle-building hormones,

like testosterone and other development hormones,

dumped into their bloodstream. You can do cardio after your workout, on your rest days, or

in the morning or evening separated out of your weightlifting sessions.

If it was up to us, we’d say do cardio in the morning and weightlifting within the night.

Your muscular tissues are strongest in the night because your physique is hotter.

For most individuals, they’ll get one of the best power exercises in later on within the day.

After all, how often have you seen something like this, bench press for 3 units of 8-10

for a number of weeks, or even months with

no change. For this beginner energy coaching program, your progression might be in the type of increasing the weight when you presumably can.

That’s when you must up the problem and trick these lazy muscular tissues into improving once more.

You can try this in several methods, like lifting heavier

weights as you get stronger, do more sets per workout, or relaxation shorter time between units.

If you’re aiming for the most effective energy gains, consider your set

rest as your finest health club buddy. You’ll need to relax

for about 2–3 minutes between units. As A End Result Of your muscular tissues and nervous system want time to

get well for you to perform your greatest.

As we discussed earlier, not everyone has sufficient time to stick to a 6-day

workout schedule religiously. However, this doesn’t indicate that you just

cannot achieve the specified physique form. Sure, you’ll have the

ability to construct the physique of your goals even when you work out for 3-days every

week. A 3-day entire physique workout routine is the perfect method to target all muscle teams effectively.

Lifting issues over your head is a day-to-day move for hoisting

groceries or lifting your child, grandchild, or little cousin into

the air. Squats are a superb way to strengthen your lower physique muscles, particularly your

glutes and quads. These muscle tissue are the powerhouses of your body, and improving their energy and energy interprets to higher efficiency in almost

all everyday actions and sports. Warming up before

lifting is crucial because it prepares your physique for the action-packed workout you’re about to embark

on, like preheating your oven before baking a batch of muscle muffins.

Utilizing BCAA for men results in higher performance within the

fitness center and an increase in muscle growth. The

process of taking a BCAA for girls will also lead to muscle growth and fewer muscle

fatigue. BCAAs assist prevent muscular injury in notably tough coaching sessions.

Analysis reveals that a BCAA complement can scale back soreness and the

decrements in strength and efficiency that observe a heavy

eccentric lifting protocol.

With 5 grams of pure BCAAs, and only three grams of carbs, in addition to natural stimulants

and antioxidants, your well being and wellness simply got a critical increase alongside with your performance.

Zero sugar, and calories makes this conducive to any food plan and

price your money to advance your vitality ranges and positive aspects.

Nutricost BCAA provides a comprehensive mix of essential amino acids, promoting muscle development

and speeding up recovery post-workout.

Whey Protein, then again, is a whole protein source that incorporates

all of the important amino acids, including BCAAs. If you’re seeking to support your overall protein intake and have a more well-rounded post-workout

restoration, Whey Protein might be the higher possibility for you.

The three branched-chain amino acids are leucine, isoleucine, and valine.

But recent research set this worth as high as a hundred and

forty four mg of BCAAs per kg (65 mg/lb) of body weight. Ladies should devour at least 9 grams of

BCAAs day by day while men need a minimum of 12 grams (46).

A daily minimum of 34 mg of BCAAs per kg (15 mg/lb) of body weight used

to be really helpful by the World Well Being Group (45). I looked at Apollon Vitamin, NutraBio, Redcon, Transparent Labs, ASC Supplements, and Performax,

brands I trust, to help get an image of what goes right into a “typical”

EAA supplement. Chemix is always doing one thing totally different with its

dietary supplements and challenging the standard knowledge of what a

complement “should” include.

Nonetheless, individuals with specific health issues,

especially these regarding liver or kidney function, should consult a healthcare

supplier before starting BCAA supplementation. One

Other main factor is the extra components included

within the formulation. Some BCAA powders may incorporate other

performance enhancers like citrulline, beta-alanine, or caffeine, which may further support

endurance and power levels. In addition to enhancing efficiency, BCAA pre-workout powders may also assist in lowering fatigue

and psychological cloudiness during intense exercise.

By incorporating these powders into your pre-workout

routine, you can maximize your endurance and achieve your health objectives more effectively.

Not only is it designed to sharpen focus and drive, but it also promises enhanced endurance

and restoration, fostering a powerful mind-muscle connection for athletes seeking to excel.

With pure energizers, antioxidants, and important vitamins and

minerals, this advanced formula is ideal for training and performance.

Whereas these dietary supplements will all help with performance,

having one specifically designed to optimize your objectives is large.

With revolutionary formulas, these products like Pro Contest can seriously

boost your positive aspects. For fighting soreness and

selling recovery, taking BCAAs before training appears to be better.

This is especially true if you’re doing eccentric train and for these doing resistance train.

BCAAs have been found to extend endurance throughout

exercise and workouts on the gym. A study published

in Sports Science & Drugs notes that supplementation of BCAAs

might help improve endurance train efficiency.

BCAAs dietary supplements are designed to help athletes and health fanatics throughout

exercises.

Take one dose in the morning, one dose either before, after,

or throughout your workout, and one dose within the night or maybe even before bed.

The purity and ease of Sheer Energy Labs BCAA make it an attractive choose if capsules are what you’re

on the lookout for. We review published medical analysis in respected scientific

journals to arrive at our conclusions a couple of product or well being topic.

Women who are pregnant or breastfeeding ought to avoid

supplementing with extra BCAA, as ought to individuals earlier than surgery.

In addition, medical situations that may preclude using BCAA supplements include branched-chain ketoaciduria,

diabetes, and liver illness. BCAA supplements must be saved in a cool, dry place, away from moisture and direct daylight.

If you hit the gym on an everyday basis and you’re

aiming to get stronger and more muscular, you

want to in all probability add a BCAA complement to your health program.

However, if you are simply mixing your BCAA powder into water, it

can be better to have a sweetener and flavoring agent within the mix—however, you don’t essentially need too much

in the way in which of sugar. We had a robust preference for BCAA powders that use noncaloric sweeteners as

opposed to sugar. BCAAs can be very useful in case you are

trying to get a concentrated dose of muscle-repairing compounds

while preserving your overall caloric consumption low.

Some BCAA supplements may contain synthetic components or

dietary allergens that would potentially cause digestive points for

sure individuals. Nevertheless, when choosing the proper BCAA supplement,

these digestive points can be prevented, permitting for optimal

progress of muscle mass and recovery. Nevertheless, it appears that BCAAs will

not be appropriate supplements for people with diabetes, sure psychiatric situations, and liver issues.

As analysis into these supplements’ security is ongoing,

it’s always greatest to consult with a medical skilled

earlier than taking them. They will be able to advise you on whether or not an amino

acid supplement like BCAA will go properly with you. BCAA supplements will not be safe

for all individuals, so make positive to speak with a healthcare

skilled before taking any of the products listed above.

Hold in thoughts that dosing and frequency change depending on what the BCAA supplement is being used

for.

Branched-chain amino acids (BCAA’s) are the essential amino

acids which encompass Valine, Leucine, and Isoleucine.

Taking a BCAA powder or supplement helps sustain muscle, enhance vitality, and

struggle off muscle fatigue during long workouts. Amino acids are naturally

discovered in many meals, especially these that are excessive in protein.

They promote sturdy muscles and make it easier to take care

of a wholesome weight. This is just one of many reasons

why so many skilled athletes take these supplements.

One of essentially the most vital advantages of amino

acids is that they assist stop the breakdown of muscle

tissue. Branched-chain amino acids or BCAAs stimulate a process

generally recognized as protein synthesis.

At an inexpensive value point, Cellucor’s BCAA Sport may be a worthwhile funding

for triathletes seeking to maximize their recovery.

In addition to that, they provide a science-backed five-gram dose of glutamine,

an amino acid that can help promote muscle upkeep and immunity.

To top it off, their formulation offers 1,000 milligrams of coconut water

powder, a high electrolyte-containing compound. For athletes who’re bored of the subpar flavored supplements available on the market, an option similar to Clear Labs

BCAA Glutamine is definitely worth trying. Collectively, these essential amino acids gas your performance and guarantee

faster restoration instances.1st Phorm BCAA Powder is secure

and effective for anybody seeking to improve their workouts.

With zero sugar, it’s perfect for these managing weight or pursuing lean muscle targets.

Designed for each men and women, it supports endurance during cardio and strength training whereas promoting hydration.

BCAAs, or branched-chain amino acids, are a group of three

EEAs-leucine, isoleucine, and valine. Arguably the most important important amino acid

to spice up muscle progress is leucine. Plant Aminos accommodates all

9 of the essential amino acids, three department chain amino acids, and 9 other non-essential amino acids to assist

muscular tissues repair and facilitate higher brain function. Plant Aminos is USDA licensed organic,

vegan friendly, and uncooked in the kind to adhere to the very best standards of purity and quality.

To take this intra-workout complement on coaching days, combine one

scoop of the important amino acids in ounces of water.

Nutrafirst suggests its users to take profound care of

their health through BCAA especially when their indulgence is more

in physical exercise. Physique loses lots of power through the strategy of constructing muscle because

of which athletes or bodybuilders usually find yourself fatigued.

Dietary supplements are important for everybody, particularly for people who should suffer energy-draining days on account of hectic work schedule.

Improvement in the general health could be attributed to taking BCAA bodybuilding complement.

The reduction in DOMS (Delayed Onset of Muscle Soreness)

and faster muscle restoration are added benefits that runners can take pleasure in from taking their BCAA dietary supplements.

Understanding the significance of one of the best bcaa powder can be a game-changer, especially for those eager on health or muscle-building.

These supplements promise to fill dietary gaps, making them a subject of interest for athletes and health enthusiasts.

According to Darby, one draw back of BCAAs is that they include only three of the nine important amino acids.

Kaged Muscle Pre-Kaged is the ultimate word pre-workout nice for those

seeking to increase vitality, enhance endurance, enhance muscle

pumps, and improve mental readability and

focus. Third celebration examined with no heavy metals, banned substances, you possibly can trust

this absolutely disclosed label and method is working for you.

With science-backed components and a fully loaded

formula, you’ll be able to trust this supplement will take your gains to new heights.

Moreover, it echoes the brand’s dedication to safety and efficacy,

providing a swift transformation within 30 days without the legal and health

dangers of traditional anabolic steroids. This product can additionally be

third-party tested and Knowledgeable Choice certified, meaning that merchandise

are examined monthly for contaminants and banned substances.

But it’s formulated with synthetic sweeteners sucralose and acesulfame potassium.

If you’re making an attempt to avoid these components, you may wish to choose a product that makes use of a natural sweetener, like stevia.

Still, it’s price noting that there are some downsides

to taking BCAAs as capsules.

Monitoring your body’s response to BCAA consumption is

significant to ensure it enhances your fitness

objectives without antagonistic effects.

Since you’ll be consuming this powder often, a nice style and good solubility in water

are crucial for long-term adherence. Additionally, researching buyer evaluations and choosing

products from reputable brands will help you ensure that you’re selecting

a powder that has been examined for quality and efficacy.

What sets Optimum Diet apart is the brand’s commitment to quality and transparency.

Each scoop delivers 5 grams of BCAAs, together with no synthetic colours or

flavors. Coupled with its affordable pricing, this product is

a favorite among both amateur and professional athletes seeking to maximize their training without breaking the

financial institution. One necessary issue to hold in mind is that the majority of those cons of BCAA supplementation occur because of excessive intake of those amino acids.

One such is Transparent Labs BCAA Glutamine, which comes in 5 appealing

flavors. The well being and safety of ACTIVE.com’s readers is of the utmost significance to us.

To ensure your well-being when consuming supplements, we prioritize products which are independently tested by a third get together.

As for the price, first, it’s needed to say that powders

are cheaper than capsules for a similar dosage per serving.

This supplement’s green tea extract, L-carnitine powder and green coffee bean promote pure

and rapid weight reduction. It is a superb selection for these who need to

lose excess body fat as shortly as potential.

The 9 essential amino acids are histidine, isoleucine,

leucine, lysine, methionine, phenylalanine, threonine, tryptophan, and valine.

It’s formulated with isoleucine, which aids within the

manufacturing of power during workouts and the remainder of the time.

It additionally includes useful electrolytes which assist with hydration and recovery.

As you discover the choices highlighted in our critiques and shopping for guide, bear in mind the unique requirements of your

physique and coaching routine. Investing in high-quality dietary

supplements is not going to solely elevate your efficiency but also contribute to your long-term

well being and well-being. Select one of the best BCAA pre-workout powders that

resonate with you, and watch as your exercise

experiences transform for the better. Choosing the right BCAA pre-workout powder can considerably

improve your coaching efficiency and recovery.

Three of those essential amino acids; leucine, isoleucine, and valine, are referred to as branched-chain amino acids (BCAAs)

as a outcome of their chemical structure. Its unique blend of elements aims to enhance coaching endurance

and assist in faster recovery. The sugar-free

method provides a smooth taste without the bitterness typically found in comparable products.

BCAA supplements are used to boost muscle development and boost exercise efficiency.

Nevertheless, they might promote muscle growth, however in a lesser method than a complete protein supply can. Branched-Chain Amino Acids (BCAAs) are essential vitamins that play a key position in muscle restoration, reducing fatigue, and

promoting muscle development. Whether you

may be an athlete, fitness enthusiast, or simply trying to enhance your exercise efficiency, BCAA dietary supplements are an efficient way to assist your health targets.

The keto diet is a excessive fat, low carb diet that promises quick and effective fat loss so long as you are ready to maintain the metabolic state of ketosis (90).

As mentioned before, BCAAs are metabolized immediately within the liver and offer a fast supply

of energy. This means you get to begin off with an energy increase that makes you are feeling like a winner already (77).

When you are taking your BCAA supplement is most essential as they offer you a

wide selection of advantages that can be utilized efficiently if taken on the right time.

If the price is not an issue, then a mixture of BCAAs and whey dietary supplements is

the best choice as they complement each other. A single serving of a BCAA complement normally

incorporates about 3000 to 3500 mg of leucine while the amount of leucine you get from an EAA supplement tends

to be much lesser. Consulting your doctor or a nutritionist will help to

resolve on the right BCAA dose for your specific wants and targets.

Universal Diet is a New Jersey-based supplement firm that’s been in the complement business for round forty years.

Animal is certainly one of their most popular manufacturers that was created to fill the

needs and desires of pro bodybuilders. Genius BCAA

does not comprise any fillers or synthetic components, as an alternative choosing rigorously selected

scientific elements. It is even sweetened naturally with organic

stevia, monk fruit, and different pure flavors. If you’re

trying to keep away from synthetic components, then it’s worth noting that Large Aminos accommodates pure and artificial flavors.

There are two fantastic flavors, one being bomb popsicle and

the other Kiwi Blueberry. Clear Labs BCAA glutamine is a product

geared in the course of restoration and repairing muscle tissues.

The micronized particles within the powder guarantee fast dissolvability and fast absorption into the body to promote physical

advantages, as properly as improve the cognitive functioning of the brain. The other benefit to micronized creatine is that it blends extra easily

with water than commonplace powders, making this product very simple

to make use of. Particularly, the bloating comes from a

rise within the osmotic stress of muscle cells brought on by creatine monohydrate, which invites water from the

surrounding tissues to rush into these cells. As for our favorite creatine complement, we can’t deny the formulation know-how of Magnum Massive C Iso-Creatine Matrix,

which blends four types creatine to offset the water retention concern. The EcoWise brand has the advantage here with its micronized formulation, which increases

solubility by 59 times, helping your body absorb creatine

faster and more successfully. These Bageto creatine monohydrate gummies are selling like crazy—2,000 bottles this month alone

and rated 4.7 stars. In Distinction To the best general, which comes in each

mango and strawberry, this model keeps it simple

with only one taste.

Furthermore, the complement undergoes third-party

lab testing, guaranteeing its authenticity and potency.

With ten scrumptious flavors to choose from, as nicely as an unflavored variation, you’ve the flexibleness to tailor your complement experience to your taste.

BioPerine® takes the effectiveness of StrengthSeries Creatine HMB a step further

by rising the bioavailability and absorption of its key ingredients.

This means you’re getting essentially the most out of each serving, making certain that your efforts within the gym translate to tangible outcomes.

Creatine powder has been extensively studied for over 25 years and is considered to

be one of the safest and most generally studied dietary supplements available on the market.

Nonetheless, it’s important to seek the assistance

of with a healthcare skilled before beginning any new complement,

particularly if you have any pre-existing medical situations.

Earlier Than delving into the search for the best

creatine, it’s important to grasp why this complement is relevant for men within the 50 and above age group.

As we age, muscle mass tends to decrease, which can have

an effect on our strength and energy levels.

Due to varying medical tips regarding dosage, it is highly suggested to eat creatine as per the

instructions given by your healthcare supplier. Individual

wants can vary based mostly on components such as body weight, train depth, and targets.

Research has consistently studied the results of creatine,

deeming it secure in really helpful doses — notably creatine

monohydrate, which is commonly considered the gold normal.

Studies persistently present that both method boosts muscle creatine levels by 20–40% (albeit, at

totally different speeds), resulting in measurable gains

in energy, power output, and lean mass. Analysis additionally highlights its

safety, with decades of information exhibiting no important opposed effects on kidney or

liver perform in healthy people when taken at recommended doses.

When it comes to maximizing your workouts and reaching optimum muscle features, selecting the best

creatine complement is crucial.

A standout function of MuscleTech Platinum’s creatine

supplement is its efficiency, providing a potent dose of 5g of 100% pure, micronized creatine monohydrate.

This micronized type ensures higher solubility and sooner absorption in liquid, making it a super choice for individuals who favor easy mixing and consumption.

It Is sometimes beneficial to take creatine dietary supplements with a meal or after a workout to boost absorption. However,

particular timing could vary based on individual preferences and targets.

Creatine is available as powders or tablets and could be purchased

domestically or online without a prescription. It’s all the time greatest to talk together with your major care doctor in case you have any questions

or concerns about whether or not or not creatine

(or some other supplement/product) might be safe

for you. Extra severe weightlifters in bulking phases will usually take creatine both before and

after a exercise. You won’t discover any groundbreaking improvements right here,

but if you simply want pure creatine to do its factor reliably and

at a aggressive price, Thorne is a stable pick.

We contemplate Magnum Huge C to be one of the best creatine complement in the

intervening time, and positively the best creatine tablet.

This post contains hyperlinks via which we could earn a small

fee must you make a purchase from a brand. This by no means impacts our

capability to objectively critique the products and brands we

review.

Alternatively, protein supplementation could additionally be extra helpful for people who exercise

regularly, as they may have higher protein requirements.

This can help help the growth and shedding of the uterine lining, which is

a vital a half of the standard menstrual cycle. Analysis states that creatine increases estrogen manufacturing in females, a

key hormone in the menstrual cycle. Therefore, will increase in estrogen levels can help regulate

the menstrual cycle, cut back PMS, and improve overall hormonal stability.

This signifies that an unbiased lab checks the product to ensure the

accuracy of labeling and ingredients.

It’s always best to seek the advice of with a healthcare supplier if you

have pre-existing kidney situations earlier than starting any

supplement. Creatine is saved in the muscular tissues as phosphocreatine

and used during activities that require fast bursts of energy, similar to lifting weights or sprinting.

By supplementing with creatine, you presumably can enhance your phosphocreatine stores, permitting you to perform at higher intensities for longer durations.

They are available both unflavored and blue raspberry versions, and contain your tried-and-true five grams of

creatine monohydrate in each stick. If you’re taking creatine to

enhance your workouts and enhance muscle development, you may surprise wheth…

For in any other case wholesome people, when taken as suggested (such as by way of the instructions on your complement or a suggestion from a

registered dietitian), there ought to be no antagonistic results from

creatine.

Creatine is a naturally occurring substance discovered in the body used

to make ATP, which your physique uses for power. Supplementing with creatine

has been proven to extend power endurance and

help build lean muscle mass. With so many advantages, it’s no wonder creatine is commonly hailed as the

best creatine supplement for muscle progress.

Analysis backs up these claims, exhibiting

vital improvements in muscle mass, strength, and general athletic efficiency for many who incorporate creatine

into their routine. One Other way to decide one of the

best creatine for men’s muscle progress is by taking a look at potential synergy with different dietary supplements.

For occasion, combining creatine with protein powder, branched-chain amino acids

(BCAAs), or beta-alanine could additional support muscle features and workout efficiency.

Creatine has long been celebrated as one of the most efficient and

research-backed dietary supplements for enhancing strength, energy, and muscle measurement.

As with energy bars, I suggest a dedicated Oly bar should you train with specificity towards these lifts.

Olympic weightlifting bars are identified by single weightlifting rings, a thinner diameter shaft, and infrequently, needle bearings.

Eleiko is known for having extraordinarily high-quality Swedish steel that performs great and looks flawless.

This bar presents a 28mm shaft and 215k tensile energy, which is on the upper end of the

spectrum. It’s not meant for use as a training bar with excessive reps or volume since

the knurling is extra aggressive.

Late in the competitors, Nassiri wanted to clean and jerk a world document 150kg (330.5 lbs) to beat Hungary’s Imre Foldi.

After roaring “Ya Ali” four instances – three before the attempt and once during — Nassiri accomplished a profitable lift to assert gold.

Atlanta, The 64kg (141 lbs) competition started with Turkey’s two-time defending champion Naim Suleymanoglu taking the

lead over his Greek rival Valerios Leonidis.

Turkey and Greece have a protracted history of battle, and every lifter’s supporters took positions at opposite sides of the venue, exchanging taunts.

Many of the steps to learning the snatch besides that the catch might be carried out above your

head with arms prolonged rather than within the rack place.

From right here, shortly flip the bar whereas dropping beneath it and pulling your elbows up.

The clean and jerk consist of four primary sections plus the set-up.

The Get RXd quick bar has one of many longest sleeves of our greatest short barbell

picks. One of our ‘must have’ standards for these bars was that they’re ‘rackable’.

Because these imperfections aren’t as vital as with different bars in its value vary.

The E.T. Energetic is one of the few Oly bars in this worth bracket that’s

definitely price the cash. This means it won’t rust or corrode even when ignored

within the rain (although don’t do that obviously!) But it does mean should you stay

in a moist surroundings this bar shall be completely

fantastic.

Regular weightlifting with proper kind ends in vital increases in each flexibility and joint stability.

In Accordance to USA Olympic Weightlifting related sports activities have been practiced since

historic occasions, as there are data of power competitions

in Greece and Egypt. Since then, the sport has slowly gained in recognition,

and in 2000, women joined the competition on the Sydney Olympic Video Games.

Weightlifting is unbeatable for growing muscular power, power, stability, mobility, and explosiveness.

These advantages switch over to different sports, enhance overall fitness, and help in harm

prevention.

Above all, she prioritizes constructing a supportive group inside our gym where every member leaves coaching feeling valued and heard.

Originally from Southern California Megan grew up in the weight room together with her Dad.

This quickly evolved into playing any sport she could entry and finally touchdown on collegiate basketball.

As you’ll see, there’s a a lot bigger variance in phrases of oxidation resistance.

Barbell finishes tend to really feel good general, however utilized coatings tend to feel inferior in comparability with conversion coatings

or no coatings in any respect.

At the same time, you’ll additionally hyperextend your ankle slightly

to come up in your toes. When it involves studying the clear and jerk, we’re actually going to

interrupt the clean and jerk into two separate movements. Then, of course, you’ve all the opposite terms corresponding to “bodybuilding” or “powerlifting”.

This might contain transferring up or down in weight while maintaining or improving their strength-to-weight ratio.

We have spent over 120 hours of research and examined

over a hundred barbells. Once I had chosen the 191 barbells to

match for this guide I made an enormous spreadsheet and collected all the info.

This is the sort of bar I’d recommend for most people with a home gym as

they’re very versatile.

Relying on the aims of coaching, coaches and athletes can set a selection of targets.

The quadriceps, glutes, hamstrings, core, and posterior

chain of body are all targets of the back squat coaching regimen. The athlete extends his toes in a backward-forward stance, performing an athletic specific

lunge after pushing the weight up.

70918248

70918248

70918248

70918248

70918248

70918248

70918248

70918248

70918248

Peter has garnered multiple health certifications, together with

private coaching and sports activities vitamin credentials.

Some of the opposite unwanted effects embody loss of hair, headaches,

giddiness, allergic reactions on the pores and skin, zits, oiliness on the face, or decreased intercourse drive.

Post-cycle syndrome impacts both women and men, manifesting

as sexual dysfunction, diminished libido, fatigue, and melancholy.

Total, Anavar has turn out to be an integral part of bodybuilding, helping people not solely to reshape

their our bodies but also to improve their overall training effectiveness.

Simply to quickly recap… anabolic steroids are synthetic substances much

like the male intercourse hormone

testosterone. Though docs do prescribe them to patients, after they do it’s

to assist people with sure kinds of anaemia and for men who don’t produce enough pure testosterone.

Anavar’s top-of-the-line steroids for maintaining your natural testosterone levels as excessive as potential after a cycle.

Nonetheless, Anavar nonetheless has the potential to scale back your male hormone production, even if it’s to

a small degree. Now Anavar was originally produced through the early

60s for medicinal use to treat patients affected by muscle-wasting situations.

Anavar and Turinabol are two popular anabolic steroids among bodybuilders, however they’ve some variations when it comes to

effects and unwanted effects. Anavar and Winstrol are two popular anabolic steroids amongst bodybuilders, but they’ve some differences when it

comes to effects and unwanted effects. For females, the Anavar dosing range is often decrease than for males, with a spread of 5-10mg per day.

Bear In Mind, a accountable method towards steroid use includes the phases before, throughout, and importantly, after

the cycle. Correct restoration could make all the difference in your bodybuilding expertise.

Many bodybuilders profit from the elevated ability to lift heavier weights

or carry out extensive routines. This amplified energy is a direct

result of the steroid’s impact on muscle contraction and short-term power output.

Anavar benefits women by growing lean muscle mass, enhancing

fats loss, and enhancing energy without vital androgenic effects.

What makes Anavar different from most other anabolic steroids is their seemingly non-existent androgenic results.

They carry a comparatively low risk of masculinizing unwanted effects,

whether or not deepening voice or rising too much body hair.

This way, Anavar stays a safer selection for girls trying to

develop their physique with out dropping their femininity.

For occasion, if you wish to reduce, you probably can stack Anavar with Winstrol or

Trenbolone.

A test can be used to determine whether or not Anavar

is present in a substance. Extra purity exams can be utilized

to determine Anavar dosage, allowing you to determine whether or not the drug is

true to label or has been undercut. Just remember that the most effective time

of day to take Anavar would nonetheless depend upon the elements

above. Be sure to seek the guidance of your

doctor earlier than deciding to be able to identify which time of the day

is best suited to you. Oxandrolone is a steroid that might be dissolved

in liquid, ideally consuming water.

Anavar cycles sometimes range between 6 to eight weeks, guaranteeing that your physique

receives sufficient time to adapt and reply to the compound.

Throughout this time, users typically expertise elevated vitality ranges, enhanced muscle pumps, and improved muscle definition. It’s essential to notice that Anavar is a mild steroid, making it appropriate for

both women and men. In the world of bodybuilding and health, reaching superior body

composition is the last word goal. Anavar, also identified

as Oxandrolone, is a extensively known performance-enhancing drug that is favored by each men and women for its ability to advertise

lean muscle growth and burn fat. Many feminine bodybuilders and athletes have

used Anavar and shared their optimistic outcomes.

For example one recreational bodybuilder reported vital fats loss and lean muscle gain with minimal unwanted effects over a 6 week cycle.

IGF-1 is used by medical doctors to detect potential cancer risk and tumor progress in sufferers.

We have additionally seen HGH having cardiovascular benefits when used in the therapy

of sufferers poor in endogenous growth hormone (5), having

a paradoxical effect and inflicting cardiac atrophy. HGH additionally increases cognitive

capability as a result of growth hormone receptors being expressed in brain areas, together

with the cerebral cortex, choroid plexus, and hippocampus (2).

Children who haven’t experienced a regular development spurt applicable for

their age may be prescribed HGH by a pediatric endocrinologist.

We have seen this speed up growth and considerably enhance

their quality of life.

Nevertheless, if a person predominantly wants to burn fat on Anavar, then a small

calorie deficit could be applied to speed up fat loss while aiding muscle

retention. Cardiovascular train, or HIIT (high-intensity interval training),

may be utilized to speed up a user’s metabolism while providing

cardiac advantages. Alcohol has a adverse effect on cortisol levels (35); thus, fat-burning might become inhibited.

Anavar is a very popular oral steroid as a result of its side effects

are incredibly low. It was developed quite late in comparison with other Steroids and has

due to this fact been altered to have the least amount of Androgenic

unwanted side effects possible. There appears to be a “big-boys-only” club around information (and

documentation) about women and equipment. There are so many random

gear boards online with faceless women speaking

about their cycle experiences.

Moreover, her total weight has really increased, indicative of muscle acquire.

Thus, outcomes on Anavar should not be monitored with scales (due to simultaneous fat-burning and muscle-building), however as a substitute visually.

One means Anavar burns fats is simply by producing exogenous testosterone, a fat-burning

hormone that will increase lipolysis. Nevertheless, we’ve additionally discovered Anavar to enhance T3 (triiodothyronine) ranges, a potent thyroid

fat-burning hormone that also has positive results on the metabolism.

The acquisition of Anavar for cosmetic purposes additionally poses hazards

to users, as we now have discovered counterfeiting to be common with this steroid.

It will increase muscle endurance and power by growing phosphocreatine synthesis in muscle

tissue, so athletes can work more durable during high

depth workouts and get well quicker. Alcohol must be averted when utilizing

oral anabolic steroids, as we have discovered it to exacerbate liver values.

Regardless Of a modest dose, we find Winstrol continues to provide important anabolism and fats loss because

of the efficiency of the compound. We commonly observe this type of cutting stack when bodybuilders are preparing

for a competition, attempting to reduce back physique fats and protect muscle

tissue. Our lipid profiles point out that testosterone is cardiotoxic,

though less so than different anabolic steroids. Furthermore, testosterone is not particularly hepatotoxic, as

it’s an injectable steroid. Hepatic and cardiac

health are the 2 main issues we now have when somebody is using

anabolic steroids.

Combining these factors, customers can work towards bettering their general fitness and well-being.

The beneficial dosage of Anvarol is three capsules per

day, taken with water roughly 15 minutes after your workout.

You must look no additional than Anvarol by CrazyBulk if

you’re looking for a safer and more healthy alternative to Anavar for women. The majority of those effects are caused when you abuse,

take excess dosage or have an underlying/hidden medical situation. It’s

all the time finest to talk to your physician earlier than starting any kind

of supplement routine. If you expertise any severe side effects whereas

taking Anavar, you need to cease taking the medicine and

discuss to your healthcare provider right away.

Analysis has also proven it to possess safety in long-term medical settings

(9). Check your blood sugar often as directed and share the outcomes together with your physician. Tell your physician instantly in case you have signs of low blood sugar, such

as sudden sweating, shaking, fast heartbeat, starvation, blurred vision, dizziness, or tingling hands/feet.

Your doctor might have to regulate your diabetes medicine, train program, or diet.

Remember that this treatment has been prescribed because your physician has judged that the profit to

you is greater than the risk of unwanted effects. Anavar is

a modified by-product of DHT (Dihydroteststerone), and possesses a

quantity of modifications that alter its activity in numerous methods.

Regardless Of being one of many most secure anabolic steroids today, Anavar can nonetheless trigger some problems in your body, primarily

because Anavar is a hormone. Solely time whenever you don’t want a PCT after an Anavar cycle is when cycles

last lower than 4 weeks and with low doses. Anavar is a well-liked alternative for males who want to build lean muscle mass and enhance energy.

It is a gentle steroid that is well-tolerated by most men, and it

can be utilized in each cutting and bulking cycles. Anavar can additionally

be identified for its capacity to extend vascularity and promote

a more outlined physique. It Is difficult to pinpoint the exact results that one

will obtain via utilizing oxandrolone, especially relating to lean muscle gains.

Generally men will not experience huge muscle features, however

most of what they do earn stays after a cycle as a end result of there isn’t any water retention involved.

Alternatively, they might resolve to stack the above steroids along side Anavar.

Oxandrin remains to be sold right now, but under the current firm name

Savient. Generic Anavar is now produced and bought, with the orphan drug designation expiring,

dismantling BTG’s monopoly. Nonetheless, due to this earlier elevation in worth, in addition to

high demand for Anavar and only a few labs in the

world producing it, Anavar nonetheless stays expensive right now.

We know it to be the highest-priced pharmaceutical steroid,

along with Primobolan. BTG was granted orphan drug designation for treating rare muscle-wasting illnesses

and conditions corresponding to AIDS, Turner syndrome, and muscular dystrophy.

This gave BTG seven years of market exclusivity, leading to a pharmaceutical monopoly.

Anavar is a comparatively mild steroid, in comparison with different AAS

similar to trenbolone or anadrol. Nevertheless,

anavar’s a banned substance and is illegal to purchase in lots of international locations – with no prescription (including US

and UK). #2 Experience – if you’ve never been to the fitness center and are very inexperienced then it’s

not essential to jump to performance enhancing medicine.

Rent a personal coach and tidy up your nutrition and

you’ll discover improvements. If a newbie takes Anavar though they

could notice some enhancements they likely wont see the same improvements as someone who’s been coaching for 5+ years and has thousands of hours

lifting experience. One problem some athletes/bodybuilders can experience when in a calorie deficit is muscle loss.

You’ll be lifting heavier weights and may discover your lifting action improves with that energy boost.

You can anticipate superb results without water retention with

this cycle. The finest testosterone esters are Testosterone Enanthate or

Testosterone Cypionate, with once-weekly injections.

It is not really helpful to stack Anavar with different steroids during

your first cycle. This steroid could cause an increase in LDL levels of cholesterol,

which can increase your risk of coronary heart disease.

To help fight this facet impact, it’s important

to take care of a nutritious diet and train often. One of the unique traits of Anavar is

its relatively brief half-life. The half-life of Anavar is approximately 9 hours,

which suggests it stays in your system for a brief

time period.

Circulating testosterone as the hormonal foundation of intercourse

variations in athletic efficiency. Results of oxandrolone on plasma lipoproteins and the intravenous fat tolerance in man. Moreover, if a

person has skilled gynecomastia, this is a sign that the substance is Dianabol (42).

These are some of the points bodybuilders who visit our clinic face when buying UGL Anavar.

Equally, using Anavar all yr round on a lower dose in comparability

with administering a better dose within the short time period, the particular person is less likely to discover results.

However, a better dose in a short six-week cycle shall be extra evident.

Nevertheless, skilled athletes might be susceptible to such detection.

Take Anavar on the identical time each day to get the

most profit and cut back the risk of unwanted effects.

At All Times comply with your doctor’s directions

on when and tips on how to take Anavar. Throughout this

time, the person takes Anavar day by day in a selected dosage – more on this instantly beneath.

The amount of testosterone creates the next anabolic to decrease the androgenic ratio, where there could be more male tissue growth in the body that’s larger than the

final male characteristics. This means extra muscular tissues, one thing athletes, and bodybuilders

need as a result of it doesn’t put much stress onto the relaxation of the body.

Men utilizing Anavar might experience several particular side effects associated

to their hormonal stability and reproductive well being.

One of the main concerns of Anavar for men is the suppression of natural testosterone production.

However if you absolutely need to make use of

Anavar, you need to be conscious of the potential risks.

Moreover, should you’re a man with low testosterone levels, Anavar can be a good

option. Nevertheless, should you resolve to make use of it, monitor your blood strain closely and discontinue use if you

start to expertise any signal of it. Anavar can increase your blood’s

LDL levels of cholesterol (the “bad” cholesterol). If you expertise any changes in your

skin shade while taking Anavar, you must report them to your physician.

No, it isn’t recommended to use Anavar whether

it is previous its expiration date. It is important to verify the expiration date before use and to discard any expired medicine.

Despite the pressure to be good, it’s essential to

keep true to private moral values. By following the

following tips and storing properly, you’ll hold your compounds efficient for longer.

Chemical composition may have changed, upping the probabilities of side effects like

liver injury or toxicity. There could also be heart points,

hormonal disturbances, and extreme withdrawal symptoms.

In truth, it’s true that a loss of muscle mass is inevitable after quitting any steroid.

Fortunately, this impact may be minimized by adequately utilizing PCT

with Anavar. The first thing they acknowledged was that Anavar was in all probability the most secure anabolic

steroid on the market and one of many least problematic for individuals to make use of for prolonged durations.

In abstract, strategy your Anavar journey with an knowledgeable and discerning mindset.

Prioritize authorized and secure acquisition, keep

dedicated to your fitness objectives, and remain consistent in your efforts.

By doing so, you set the muse for a balanced and

accountable strategy to incorporating Anavar into your fitness routine.

As you start your journey with Anavar, it’s important to maintain in mind that components similar to availability, pricing,

and perceived advantages can differ considerably.

Winstrol is likely to trigger virilization effects in ladies, together with voice

hoarseness30, acne, adjustments in menstrual durations, and growth of facial hair.

Females would need to use very low doses of Winstrol to avoid these effects, in the 4mg to

10mg every day vary. We could compare Anavar with an extended list of AAS

and other PEDs if you’re making an attempt to choose the best compound on your next cycle.

By decreasing water retention and selling fat loss, its injection helps to

reveal underlying muscle definition and create a leaner look.

It could be particularly helpful during chopping phases, where athletes aim to

minimize back body fats while preserving muscle mass.

The main mechanism of motion of Anavar entails its ability to reinforce

protein synthesis throughout the muscle cells. Protein synthesis is the method by which the physique builds new proteins, together with muscle

tissue. By growing protein synthesis, it promotes muscle growth

and helps people acquire lean muscle mass.

Males typically take doses in the vary of eighty to a hundred mg per day,

whereas girls might opt for 20 to forty mg per day.

Combining Anavar with other anabolic steroids is frequent throughout bulking cycles to synergize the effects.

Like any performance-enhancing substance, injectable Oxandrolone could carry potential

unwanted facet effects. Some potential unwanted aspect effects of injectables

embrace hormonal imbalances, lipid profile modifications,

pimples, hair loss, virilization (development of masculine traits in females), and cardiovascular pressure.

It is essential to observe for these side effects and

promptly consult with a healthcare skilled if any opposed reactions happen.

Implementing correct cycle support, post-cycle remedy, and maintaining

a accountable strategy to dosage and period

can help reduce the danger of unwanted facet effects.

However, it’s important to notice that there is not any one-size-fits-all dosage,

as individual responses can range primarily based on elements similar to

age, gender, general health, and fitness goals.

Anavar is a well-liked selection for lots of bodybuilders because it is an efficient way to construct muscle and cut fat.

If you’re a bodybuilder, the really helpful dosage of Anavar is 25-50mg per day.

6 weeks of Anavar combined with a routine of exercises, wholesome eating, and a low-sugar food regimen ought to assist muscle mass improve and weight