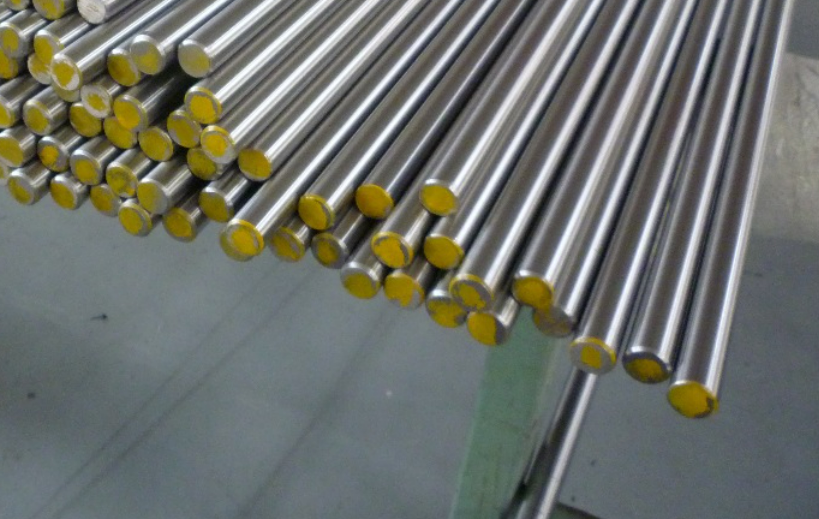

446 stainless steel is a high-temperature stainless steel, also known as AISI 446 stainless steel. It is a ferrite stainless steel with good resistance to high-temperature oxidation and corrosion resistance, especially in oxidizing environments. 446 stainless steel contains elements such as chromium, molybdenum, and aluminum, which can improve its high-temperature resistance and corrosion resistance. In addition, 446 stainless steel also has good mechanical properties and processing properties, and can be used to manufacture high-temperature equipment and chemical industry equipment. In this article, we’ll take a look at the properties and applications of 446 stainless steel.

Chemical Composition and Elemental Analysis of 446 Stainless Steel:

446 stainless steel is a high alloy stainless steel that is resistant to high-temperature corrosion and its chemical composition is critical to its performance. Here is an analysis of its main elements:

- Carbon (C): Carbon content is less than 0.20%, which helps improve corrosion resistance.

- Silicon (Si): Silicon content is less than 1.00%.

- Manganese (Mn): Manganese content is less than 1.50%.

- Phosphorus (P): Phosphorus content is less than 0.040%.

- Sulfur (S): Sulfur content is less than 0.030%.

- Chromium (Cr): Chromium content is between 23.00% and 27.00%, which is the main contributor to its high-temperature resistance.

- Nickel (Ni): Nickel content is allowed to be added, with a minimum of 0.60%.

- Nitrogen (N): Nitrogen content is less than 0.25%.

- Copper (Cu): Copper content is allowed to be added, with a minimum of 0.30%.

- Other elements: There are no other significant alloying elements besides the above.

Properties of 446 Stainless Steel:

- High corrosion resistance: Due to the high proportion of chromium, it can form a dense oxide chromium protective film, effectively preventing the erosion of oxygen, water and other corrosive media, and has excellent corrosion resistance.

- High-temperature resistance: It can maintain structural stability and mechanical properties in high-temperature environments up to 1082℃, making it particularly suitable for high-temperature processes and equipment manufacturing.

- High strength: It can withstand large forces and pressures, making it suitable for various engineering and structural applications.

- Magnetic: This means that this stainless steel can be attracted by magnets.

- Good processing performance: It has good mechanical properties and processing performance, and is easy to process operations such as cutting, bending, and welding.

- Cannot be hardened by heat treatment: This means that it cannot increase its hardness or strength through the process of heating and cooling.

- Wide application fields: Due to its excellent performance, 446 stainless steel is widely used in many fields such as petroleum, chemicals, electricity, construction, aerospace, and so on.

Applications of 446 Stainless Steel:

Grade 446 stainless steel is mainly used in the manufacturing of industrial equipment and parts in high-temperature environments. It has excellent high-temperature resistance and can maintain good mechanical properties and corrosion resistance at high temperatures. Specific application areas include:

- Boilers and Heat Exchangers: 446-grade stainless steel can be used to manufacture pipelines, baffles, flanges, and other components of high-temperature and high-pressure boilers and heat exchangers.

- Gas Burners: 446-grade stainless steel can be used to manufacture burner combustion chambers, nozzles, flame shrouds, and other components.

- Glass Molds: 446-grade stainless steel can be used to make glass molds because its thermal expansion coefficient at high temperatures is similar to glass, reducing thermal stress between the mold and glass.

- Furnace Linings and Furnace Accessories: 446-grade stainless steel can be used to make high-temperature furnace linings and furnace accessories, such as annealing boxes, kiln linings, industrial mufflers, etc.

In summary, 446-grade stainless steel has excellent corrosion resistance and heat resistance at high temperatures, making it widely used in the manufacturing of various high-temperature industrial equipment and components.

Corresponding Grades of 446 Stainless Steel in Various Countries:

- China: The digital grade in GB-T standard is S12550, and the new grade is 16Cr25N.

- US: The corresponding grade in ASTMA standard is S44600, and in SAE standard it is 51446.

- Japanese: In JIS standard, its corresponding grade is SHU446.

- European: The corresponding grade in EN standard is x8cr28.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the properties and applications of 446 stainless steel. If you want to learn more about stainless steel, we’d advise you to visit Sino Stainless Steel for more information.

As a leading supplier of stainless steel products across the world, Sino Stainless Steel provides customers with high-quality stainless steel products such as stainless steel coils, stainless steel plates, stainless steel sheets, stainless steel bars, and stainless steel wires at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com