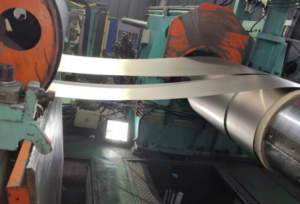

Stainless steel, a ubiquitous metallic material, finds extensive applications across various sectors such as construction, food processing, and healthcare. Enhancing the reliability and durability of stainless steel is crucial to meet the diverse application requirements of these sectors. Among the various metalworking techniques, the hot rolling process significantly influences the properties of stainless steel during its manufacture. In this article, we will take a closer look at the advantages of hot rolling process in stainless steel manufacturing.

Advantages of Hot Rolling Process in Stainless Steel Manufacturing:

Firstly, regarding the elimination of structural defects. The hot rolling process in stainless steel manufacturing effectively mitigates defects inherent in the ingot casting process, including bubbles, cracks, and porosity. This refinement of steel grains results in a more compact microstructure, thereby enhancing the overall performance of stainless steel materials.

Secondly, hot rolling enhances mechanical properties. It promotes distinct grain boundary migration and recrystallization within the stainless steel structure, facilitating the formation of strengthening precipitates. Consequently, this process strengthens the mechanical strength and ductility of stainless steel. However, non-metallic inclusions like sulfides and oxides within stainless steel can cause microstructure coarsening at high temperatures, potentially degrading mechanical properties. Thus, rigorous control over hot rolling temperatures is essential.

Furthermore, hot rolling improves workability. During the process, the stainless steel’s microstructure undergoes adjustment, resulting in a more uniform structure with finer grains. This reduction or elimination of casting defects enhances the workability of stainless steel. Additionally, hot rolling optimizes material properties, reduces surface hardness, and facilitates easier shaping and processing.

Moreover, hot rolling contributes to energy savings. Leveraging the principle of thermal expansion and contraction, stainless steel is heated to a specific temperature before rolling, capitalizing on its high plasticity and low deformation resistance at elevated temperatures. This approach not only decreases energy consumption during rolling but also enhances material plasticity, reducing the number of processing steps and time, thus lowering overall processing costs. Furthermore, the adoption of large ingots and heavy reductions in hot rolling enhances production efficiency.

Summary

In summary, the hot rolling process plays a pivotal role in stainless steel manufacturing, addressing issues such as eliminating structural defects, enhancing mechanical properties, improving workability, and reducing energy consumption. However, it can also introduce delamination within stainless steel, disrupting internal stress balance and affecting stability. Therefore, strict control over raw material quality and careful selection and regulation of hot rolling parameters are imperative to ensure superior stainless steel performance.

Why Choose Sino Stainless Steel?

Thank you for reading our article and we hope it can help you to have a better understanding of the advantages of hot rolling process in stainless steel manufacturing. If you are looking for suppliers and manufacturers of stainless steel, we would advise you to visit Sino Stainless Steel.

As a leading supplier of austenitic stainless steel, Sino Stainless Steel offers customers high-quality stainless steel coils, stainless steel sheets, stainless steel strips, stainless steel tubes and stainless steel wires at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

https://www.pgyer.com/apk/apk/rox.casino Rox.casino скачать приложение для Андроид

https://www.appcreator24.com/app3402860-8rusyn Vodka.casino скачать Андроид

https://telegram.botlist.ru/12079-crypto-bot.html CryptoBot это Телеграм бот, позволяющий безопасно и анонимно купить, продать и хранить Toncoin (токены блокчейна TON) и другие крипто валюты.

Informacje Rolki freeskate to także sprzęt do wykonywania różnorodnych sztuczek. Do jazdy między pachołkami oraz gwałtownych skrętów i skoków produkuje się rolki slalomowe. Najważniejsze jest, aby były one idealnie dopasowane do stopy użytkownika. Ma to ogromne znaczenie, ponieważ tricki czy wariacje fanów jednośladów wymagające zazwyczaj szczególnej precyzji, nie zawsze są bezpieczne. Te pliki pozwalają nam na dokonanie analiz dotyczących naszego sklepu internetowego, co może przyczynić się do jego lepszego funkcjonowania i dostosowania do potrzeb Użytkowników. Te pliki są niezbędne do działania naszej strony internetowej, dlatego też nie możesz ich wyłączyć. Te pliki są niezbędne do działania naszej strony internetowej, dlatego też nie możesz ich wyłączyć.

https://bordeaux.onvasortir.com/profil_read.php?sportowerolki

Rolki dla osób początkujących lub jeżdżących rekreacyjnie. Wyposażone w kauczukowe łożyskowane kółka, wentylowane buty zapewniające wysoki komfort jazdy użytkownikowi, z możliwością regulacji rozmiaru. W prawym bucie znajduje się hamulec, który w razie potrzeby można zdemontować i przepiąć do buta lewego. UWAGA Dla najmłodszych proponujemy trzykołowe rolki dla dzieci dla zapewnienia stabilności. Dużą zaletą regulowanych rolek jest możliwość regulacji o aż 3 cm. Rolki Rollerblade Apex dostępne są w trzech wariantach rozmiarowych. Każdy z nich posiada zakres regulacji w ramach 4 pełnych rozmiarów: EU 29-32; EU 33-36; EU 37-40. Zwykle maluchy w wieku od trzech do czterech lat biegające już po domu są gotowe do nauki jazdy na rolkach. Mądrze jest wprowadzać dzieci w ten sport, zapisując je na zajęcia. Mogą nauczyć się bezpiecznie i skutecznie jeździć na rolkach pod okiem profesjonalnej osoby dorosłej.

iuD0zPePmFF

AqI4zfmNkXW

2O9Awtyllch

xcx8CDa0r7a

08cw1lAicEl

vinY7Vc38Ii

AIDpO0y3IOW

ZXyl8Re9pxw

fW6Mm0vyXnd

Bf606LgUVjB

PP1ZiHezDc5

APaBSO4B4T5

OGOK6AKNxGA

rLou9DKOEOz

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Drop sets are whenever you attain muscle failure with a weight then you definitely immediately seize a

lighter weight and carry out the identical train to

exhaustion. Then you seize a good decrease weight and

repeat the cycle until you get the specified effect.

Often 3 to 4 drop units at the end of an exercise is enough to absolutely tax

the muscle. You don’t have to push you training max every exercise however you should be pumping and sweating onerous.

Nonetheless, go too light or cease each set too early and you won’t

enhance. The key’s to cease one full rep before failure – what’s referred to as a ‘one rep in reserve’ or 1RIR.

In this second pull workout of the week you’ll be going as heavy as possible for triples

and fives. This method can work wonders for building and

shaping your muscular tissues, resulting in excessive definition (as long as your

diet is right!). That’s because you’re stunning your muscles into development by making them do one thing they’re not used to.

Coaching every muscle as quickly as a week can and will make that muscle larger.

However, for most individuals a minimum of, it’s

most likely the least effective method to train.

Greatest Physiques is the number 1 destination for one of the best wanting our bodies on the planet.

We cover professional athletes, fashions and even social media stars to

deliver you the perfect, up to date data in our profiles.

Examine out our greatest rated testosterone boosters to extend energy, muscle, power and libido.

Do this for 6-8 weeks consistency and we assure you’ll be a

special person altogether. The goal is to observe

every exercise day precisely as it’s presented right here.

I do recommend that you simply do some sort of

cardio 3-4 times every week. Of course, how a lot, what type,

and the way lengthy each length depends on where you may be presently,

and what your objectives are. Glutamine is also identified to contain immunity-boosting properties.

It encourages proper digestion and provides reduction from indigestion and

heartburn symptoms. Throughout an intense workout, your glutamine shops will be quickly used up, so it’s important to take earlier than,

during, and after your exercise. Unlike any of the splits we’ve lined, the bro break up involves dedicating

a whole workout to each muscle group.

From the selection of workouts, together with the means to order your

program for maximal positive aspects. Whatever it is you want to

really feel like your old self once more, we’ve obtained you lined.

For minimalist coaching I usually favor an upper lower cut up for a quantity of reasons.

One, you are less likely to get overuse injuries, since all the

actions which stress the identical joints/connective tissues are typically hit on the same days.

This will help you break up your exercise and can enable alternating muscle groups extra relaxation. Sometimes what’s

really helpful is a calorie surplus, the place you’re gaining weight and eating extra energy than your physique wants

on a regular basis. Perform about 50% of

these sets with either lengthened partials

instead of full range of movement reps, or with lengthened partials done

after your regular set. If you attempt to do full body 5x per week training all to failure, all with 20 plus units per week,

without deloading, you know that something has to offer.

Some folks consider you need to take your units to all-out failure, the point

the place your muscular tissues can not lift the weight.

So, we ran a examine to try to see whether rising reps or rising in load was better

for muscle development.

So I would say after that, actually you simply must focus perhaps all or nearly all of

your effort on the facet delts. And for these, I really like dumbbell lateral

raises, seated or standing with very good control.

Plus, after all, a variety of cable laterals are all the time really great.

As A End Result Of of the massive position stretch performs on hypertrophy, doing bicep curls from a stretched place of the biceps is a good idea.

That’ll embrace cable, baynesian curls, and behind-the-back incline

dumbbell curls. For triceps, it’s going to be overhead movements

as these really stretch, particularly the lengthy head.

On non-training days he should reduce this by 200 to 3,822.

For quality mass gain, always make small modifications to vitality intake over time.

You can comply with this 8-week bodybuilding exercise program religiously, but when you don’t give your muscle tissue what they should recover, they simply is not going

to develop.

This is usually carried out in your final set and towards the end of your workout.

If you want to maintain your physique guessing and, in flip, hold your metabolic

price up, then you would alternate your days between ingesting a

high and low quantity of carbohydrates. Most athletes

are probably to have their high carb days during the more

intense training days (like leg day), alternating between these two phases helps maintain an accelerated metabolic fee.

While most of your vitamin might be coming from

complete foods, it is important to take a multi-vitamin in order to fill in the gaps.

The stress of bodybuilding on the physique can’t be overstated.

If you aren’t ready with the best vitamins, then your

body will succumb to overtraining. Be sure to purchase a quality multi-vitamin to take with breakfast.

Jump out of bed the following day with pleasure, figuring out that you

will smash your exercise. As you head out the door,

your mental intensity stage ought to be at about 7 out

of 10. Driving to the fitness center, see yourself efficiently

finishing your max lifts again, and dial it as a

lot as a 9.

But if you’re ready to do this transfer, it’s

great for adding measurement to the delts.

That said, we advise you turn the order of squats each week—in week 2, for instance, do

common squats first, and in week three, begin off with Smith machine squats.

This will ensure a well-balanced leg protocol by way of the course of four weeks.

At a look this may appear counterproductive for building muscle.

You need energy to construct muscle and gas your workouts; many plant-based foods usually are

not very calorie dense. That’s nice on a minimize, however it can make

gaining weight and adding mass difficult.

There is definitely no harm in eating carbs after training, although.

It might improve restoration after high-intensity periods,

even though doing so is unlikely to boost long-term muscle progress.

These advanced training techniques ought to

be used only at times, however when used sensibly, they might help you

enhance workout depth and bust through a bodybuilding plateau.

In fact, the men were capable of crank out, on average, three additional reps on the leg extension machine when they did leg curls instantly,

30 seconds or 60 seconds earlier. The face pull targets each the aspect and rear delts, along with various muscular tissues in the upper again. While there are many different ways to do cable face pulls, depending on the muscular tissues you’re attempting to work, this

is the means in which I prefer to do them. Train quantity 4

is the seated leg curl, which is a knee flexion exercise

for the hamstrings. If you don’t have access to a leg curl machine, one of these leg curl options will do an analogous job.

The wide grip entrance lat pulldown hits the again and biceps.

Use a daily V deal with, hold the elbows near the body, and pull

your palms in the path of the lower a half of the stomach,

close to the stomach button.

As A Substitute, contract your glutes, brace

your abdominal wall to achieve stability, and use a full vary of motion from beneath your chin as much as

straight arms. Nonetheless, for hypertrophy coaching,

you need to carry out the squat in a managed method, keeping pressure in your muscles throughout

the set. If establishing a good mind-muscle connection means less weight on the bar,

don’t hesitate to lower the load. Remember, your muscles develop whenever you rest them through the 24–48 hours following

your training session, not while you’re really lifting.

As you acquire coaching experience, taking two to 3 minutes

to get well between sets lets you carry heavier and do extra reps for

probably barely better gains over time.

If you’re aiming to see actual features in power and

muscle, it’s essential to coach not just onerous, but good.

This means walking into the gym with a transparent plan each time.

Your intensity and energy during every set are as essential as the

rep vary. You should take every set close to failure (leaving one to 2

reps within the tank) and use a weight that allows you to hit

that mark while utilizing good form. As Quickly As you feel like you’re a rep shy

of not with the ability to do another rep with good method, stop the set, relaxation, after which do your subsequent set.

One approach to progress is to add one rep to all of your units (or

even just one exercise) from week to week. So, should you can press 70-pound dumbbells for an average of 10 reps across

three units, start there.

They can give attention to proper kind on the bench

press, dumbbell presses, varied squats and deadlifts and so on. This is crucial as these

are the actions that are likely to trigger harm down the highway as one gets stronger if correct type is not learned early on. Recovery is one of the most important parts of an effective program,

and a full body workout plan ensures you do not overtrain.

There is little to no proof that these supplements will aid your bodybuilding efforts.

Examples of potentially useful bodybuilding supplements embrace vitamin D,

omega-3 fatty acids, multivitamins, and important amino acids.

As A Substitute, control your energy with your food plan and steadily introduce cardio.

Other dietary supplements like fat burners, BCAAs, and others claiming to

“boost” your hormones, are normally a waste of cash during

a bodybuilding minimize. Dietary Supplements

shouldn’t be relied upon as a substitute for a balanced diet during a bodybuilding

reduce, however they can be helpful when you’re trying to get shredded.

If you’re already an skilled bodybuilder, you have a headstart

over all your same-age peers. However when you’re consuming in a caloric surplus to achieve muscle, don’t be afraid to treat yourself from time to time.

Along with doing too many exercises, most people don’t train exhausting sufficient on them.

Not that you just need to rush by way of your exercises,

but you need to have the identical depth degree as a sprinter.

For those that say, “No ache, no gain,” I say, “No ache, no brain.” You don’t need to feel sore and exhausted by the top of your training session to see optimal results.

Like the opposite exercises, you’ll start with a heavy compound train.

Quite, I’m going to offer you 5 bodybuilding training splits.

And on the end of this publish, I’ll show you the way you to

alternate all of these coaching splits to alter up your routine.

Use a coaching log to track weights, units, and reps.

Modify based mostly on efficiency. Even although you don’t increase the load on every set, the cumulative impact of your reps will

make each set progressively harder. However, it is important that you are strict on each

your rest time and your exercise type for each single one

of those 36 reps. On your first three units, you do 8-10 reps,

going as heavy as you can with correct form.

To lose physique fats, you should eat fewer calories than you burn. With Out a calorie

deficit, it does not matter the way you train or what your diet appears like.

Sooner or later, you’ll need to go on a cutting food plan to make your muscle tissue visible and show

the fruits of your labors in the health club. Going for 2.2 g/kg/day guarantees

you get enough to help muscle growth and restore during the bulking

season. A good bodybuilding food plan is the same as a wholesome,

balanced diet for anybody else, only emphasizing muscle-building

nutrients like protein. Pre-exhaustion training can effectively increase a workout’s general depth and volume, and you would use it during a high-volume training cycle.

Each alternate options work nicely and haven’t any

reported side effects. Getting sufficient sleep is important for general well

being, muscle restoration, and development. Sleep is an often-overlooked facet of chopping for

bodybuilding. The only must-do for a profitable reduce is to eat a high-protein diet.

If you’re a newbie, this workout will beat you up huge time.

The volume, frequency and intensity might be too much so that you

just can cope with, and chances are you’ll either get injured or push past your limits far

too fast. If you’ve been power coaching regularly for the final

yr or so and already have a decent base of health, this information will catapult you into the stratosphere

of great physiques. Throughout this 7-day exercise plan we’ll guide you thru every

little thing you should completely remodel the way you

look. 7 full days of training is sufficient to construct sturdy foundations.

It’s sufficient to ramp up quantity and smash via a training plateau

that’s left you lagging for weeks now.

The effort for each set should feel the same—that you

can do two extra reps earlier than you name it quits—but the number

of reps you can do with the identical intensity decreases as your muscle tissue fatigue.

If you can do three units of 12 reps for all of your sets from the leap, you’re

in all probability not challenging your muscular tissues sufficient.

One of probably the most renown energy gaining workouts

packages is the 5 x 5 routine. This is also most

likely the most feasible workout routine for coaching three days per

week. This is essential, as you don’t want to battle to make

it to the top of the set and do the exercises with out proper type, as this could lead to damage.

Plus, it’s a good way to trace your progress, as you’ll be succesful of adjust up as you get stronger, according to progressive overload training.

The size vary is huge — from XXXS to 5XL — and

so they even have approval from the Worldwide Powerlifting Federation (IPF) and the Worldwide Weightlifting Federation (IWF).

If you do weightlifting, CrossFit or powerlifting, having a pair

of the best knee sleeves is a crucial weightlifting accessory in your health

club bag. As your training becomes more intense and your lifts get heavier, you’ll have to put cash into the best equipment to get the most out

of your coaching and help your physique.

This is particularly necessary when you attain heavier weight thresholds or are working toward your one-rep max (1RM).

The added stability helps forestall hyperextension or collapse,

which might result in injury. If you’ve never heard

of SBD when it comes to weightlifting, where have you ever been? The model has been the sponsor for the World’s Strongest Man competition for years and is loved by athletes.

These knee sleeves have been made with 7mm neoprene for

optimum assist and bolstered seams for longevity (don’t anticipate any ripping right here or poor

quality).

Backside line, whether you probably can wear a

knee brace every day is decided by your distinctive situation and

what the consultants say. So, play it protected and have that chat along

with your healthcare go-to earlier than strapping in. Orthopedic specialists and bodily therapists are the go-to

of us right here. They’re Going To give your knee a good once-over

and figure out whether common brace use is the way to go.

Ligaments are fibrous connective tissues in the body that join bone to bone.

Made from a highly tuned 4-way stretch material, the PowerLix Knee Sleeve

offers a comfortable but delicate fit for full knee mobility whereas decreasing damage threat.

Our team reported a snug fit and reliable positioning throughout numerous workouts, attributing this stability to the high-quality elastic

band. Knee sleeves are sometimes produced from neoprene, a type of

synthetic rubber that offers glorious flexibility and sturdiness.

They are obtainable in various sizes and thicknesses, designed to suit snugly

around your knee.

Knee sleeves present a cosy, compressive layer that enhances stability and comfort around the knee joint.

This help is especially useful when squatting with heavy weights, as it helps preserve knee alignment and reduces the danger of twisting or lateral movements that can result in injury.

The heat from the compression additionally aids in preserving

the joints lubricated and prepared to carry out.

Squatting is a fancy motion that requires proper approach, kind, and stability,

particularly in the knees. Knee sleeves can present support, heat, and compression, which might enhance efficiency and scale

back the danger of injury.

Also, some reviewers say that the durability of the sleeve is lacking.

Nevertheless, in case you are a beginner on the lookout

for a comfortable wrap at an inexpensive value, then the Bear KompleX is a great

choice. The Bear Komplex Knee Sleeve is an ideal knee sleeve for newbie squaters.

It is made out of a rubber material that’s fairly flexible

and lets you get your full range of movement during

a squat.

Titan makes severe powerlifting gear, from squat suits to

lifting belts to knee wraps. At less than half the value of some of the premium knee sleeves on evaluate, this product is ideal for newbies who aren’t certain if they want or want knee sleeves.

Anatomically shaped for consolation, these knee sleeves are especially

well-suited for beginners. Nordic lifting 7 mm Neoprene

Sleeves is our top pick for health fanatics and heavy lifters who need to protect their knees at an affordable price – for

under $40. If Rehband knee sleeves have a drawback,

they are bought singularly and not in pairs.

With so many models on the market, it may be hard to

know which knee sleeves to determine on. According

to studies by the American Faculty of Sports Activities Drugs, squats dramatically improve

decrease body energy, practical mobility, and

even bone density.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

70918248