As people’s awareness of health and safety continues to grow, the demands for the performance and quality of food, medical, and household hygiene equipment have also intensified. Certain types of stainless steel, due to their exceptional antibacterial properties, meet these heightened safety and hygiene requirements during equipment manufacturing, thus enjoying widespread applications in modern life. In this article, let’s take a closer look at the antibacterial properties of stainless steel.

Antibacterial Properties of Stainless Steel:

The antibacterial effect of stainless steel stems from the addition of metallic elements with antibacterial characteristics, such as copper, into specific grades. These metallic elements can release antibacterial ions that disrupt bacterial cell membranes, leading to bacterial death and ensuring a lasting antibacterial effect.

However, it’s crucial to note that not all stainless steel possesses antibacterial properties; only specific types of antibacterial stainless steel exhibit this capability. According to tests conducted by the National Institute for the Control of Pharmaceutical and Biological Products, these stainless steels fully comply with national technical standards in terms of toxicity and human safety.

Furthermore, they demonstrate a killing rate of over 99% against Escherichia coli and Staphylococcus aureus, while also exhibiting significant efficacy against other bacteria like Candida albicans and Fusarium oxysporum. Remarkably, even after surface wear, they maintain their antibacterial properties, highlighting their excellent durability.

Additionally, incorporating specific quantities of antibacterial metallic elements like silver, cobalt, and zinc into regular stainless steel, while rigorously controlling the smelting, casting, forging, rolling, and heat treatment processes, can endow the material with biocompatibility, broad-spectrum antibacterial properties, and long-lasting antibacterial effects. For instance, the inclusion of silver ions inhibits the growth of most pathogens on the surface, preventing bacterial proliferation. Similarly, cobalt and zinc also contribute to antibacterial performance, with the specific effects depending on the elemental composition ratio.

These antibacterial metallic elements precipitate uniformly within the stainless steel matrix in specific sizes and shapes, not only preserving the mechanical properties and corrosion resistance of regular stainless steel but also enhancing its antibacterial properties. Depending on the antibacterial material used, antibacterial stainless steel can be classified into surface-coated, composite, surface-modified, and alloy-type (with added antibacterial metallic elements) varieties.

Conclusion

In conclusion, as a novel alloy material, antibacterial stainless steel not only retains the structural, functional, and aesthetic qualities of regular stainless steel but also boasts excellent antibacterial properties. With the escalating demand for hygienic and safe antibacterial stainless steel due to improved living standards, high-quality and cost-effective copper-containing antibacterial stainless steel has achieved large-scale applications.

Why Choose Sino Stainless Steel?

Thank you for reading our article and we hope it can help you to have a better understanding of the antibacterial properties of stainless steel. If you are looking for suppliers and manufacturers of stainless steel products, we would advise you to visit Sino Stainless Steel.

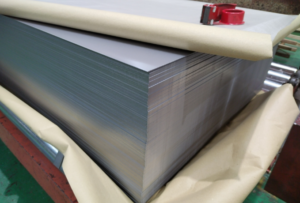

As a leading supplier of stainless steel from Shanghai China, Sino Stainless Steel offers customers high-quality stainless steel coils, stainless steel sheets, stainless steel wires, and stainless steel tubes at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

9qPR1sVT3Bg

wF77zGRiFdU

HrOxeBFhtW4

oXmOG01AaYx

JDpwch4vdX9

OE59JvcCWlo

CqurJviiJT9

LIR0YY3V7Hz

Bv9nKXYpvsv

igs1lyB3TDx

WqUdxIdrY6W

YSNFY972uYQ

Y6hQ2wZd4EF

QS2AV9pPnAN

K8GFAHzGh9I

Mg73yzqfV2R

GG2vQuG9qDc

VBXJhaO43MZ

joqNBdjtGtT

3Ye19k7W8Pg

nZJ3u0XYn6Q

pLxr9XEal20

M4LYmpQe5A5

Vxb6eoNTjdN

Er3piyLYXMF

6OAqB9xXYTr

XdeJ7QPXGOK

uykvDBkaZZU

bY7RhSkN9wD

lk8Zhlx1WOv

Op8VNclKo3T

tWhMJ44Ws0Z

UxJM6dkAF3f

BdK2XgxpACH

Vix9gAscnoM

e5nS6hBmG6w

zqPicEz1NxC

JHVt8cFTjPj

bpH8wAbmRmB

UsiL9KDLqMa

8u3Y6Pt9zaQ

sDTUqTU7UHy

Ytg8KCh3Egp

BdipttFOqPB

dRUYRniR7Gh

mJ1FzL6zEM0

Your article helped me a lot, is there any more related content? Thanks!

In basic, chin ups are nice for your grip power because you must

maintain onto the bar. The shut grip additional

improves that by activating your forearms and biceps more.

Levrone’s again had impressive thickness, especially via his traps and upper lats, but he additionally maintained a level of

refinement and aesthetic enchantment that made him stand out.

He holds a Master’s diploma in Train Science from Rutgers University and is a

Licensed Power and Conditioning Specialist. Andrew is dedicated to offering

informative, reliable recommendation on bodybuilding, training, and workout applications.

Most of us have one facet that’s weaker than the other and harder to

develop. Some use an overhand grip, others an underhand grip, with the approach ranging

from leaning forward until parallel to virtually standing upright.

Most individuals prefer utilizing free weights, while some like the soundness

of a Smith machine.

To optimize your back exercises, begin with a proper warm-up and select the proper

weight for every train. Focus on sustaining correct type throughout each motion and incorporate selection into your routine to focus on different muscle groups effectively.

By utilizing a slender grip on the Smith machine, you can isolate these particular back muscles extra intensely

in comparison with wider grips. This motion promotes better scapular retraction, which helps in reaching a thicker and stronger back.

Transitioning from the Barbell Bent Over Wide Grip Row to the Barbell Reverse Grip Incline Bench

Row, this exercise targets the upper back and lats while additionally engaging the biceps.

His back’s density was extraordinary, giving him an imposing presence

even among taller competitors. The compact, muscular look made his again stand out in poses like the rear double biceps.

Heath’s standout pose was the rear double biceps, where his deeply etched decrease lats and the overall 3D impact

of his back have been on full display.

It permits you to depress the scapula and keep your shoulders down, which helps better engage

the decrease lats. Doing the seated row with a band retains your lats beneath constant pressure.

To hold the emphasis on the lower lats, remember to externally rotate your shoulders together with your scapula slightly depressed and your chest up.

Whereas you’re doing the train, think about engaging the lower lats

somewhat than the trapezius.

Regardless of which you prefer, the pull-up and

the lat pulldown are your go-to choices for a wide, muscular

again. A thorough warm-up routine will increase blood move to your muscles, enhances focus and suppleness, and readies your physique for the upcoming exhausting work.

As A Outcome Of the again is amongst the more advanced body components, composed of a quantity of muscles,

all essential for each visual appearance and performance, you wish to hit it from many angles and use a wide rep

vary.

With Out the platysma, it would be harder to show emotions through facial movements.

Be positive to do high-rep dumbbell rows every every now and then, but what you really need

to give attention to most of the time is getting stronger on this

exercise. Notably, it isn’t attainable to completely isolate the decrease lats while training.

That’s because all latissimus dorsi muscle fibers have the identical insertion point on the

higher arm. However, you can higher activate

the lower portion of the lats by modifying your exercise form and coaching technique.

You work the identical muscular tissues at the endpoints however at

weaker lengths and in positions that might harm the joints.

Some vary of motion does appear necessary though to allow negative work and other

effects revealed when inspecting types of muscle contraction. This calls

into question the need for so much of exercises to develop the upper back.

Shoulder melancholy, which occurs on vertical pulls, subtracts or lessens the contribution from many of those muscle

tissue however still involves the latissimus dorsi. The lower total contribution isolates the lats more so,

with isolation always resulting in problems. It does require a larger range of movement for them, however this isn’t essentially a great thing.

This exercise also places extra emphasis on the biceps than the standard barbell bent-over row.

The dumbbell ought to start under your shoulder and finish at your hip, identical to in the

previous train. “As you initiate the pull, imagine driving your elbows down and back, as if attempting to the touch them to your back pockets,” cues

Saini.

Variety can be introduced by changing up the kinds of rows, including in pull-ups or chin-ups, incorporating completely different grip positions,

and including isolation exercises for smaller muscle groups.

Preserve proper type throughout every train to forestall

injury and maximize the effectiveness of your back exercises.

Focus on preserving your again straight, shoulders pulled again, and core engaged.

It’s also important for rising movement efficiency, especially with pulling and twisting

movements. Your back is the one muscle that can make you look big from all angles,

not just the entrance. Once More, don’t neglect workout routines for width (this is why lat

pulldowns are included in your back workout above).

Barbell rows (some call them bent-over rows) are the only most effective

exercise for building back thickness. In truth, if you only had time for one again train, this must be it.

Constructing muscle is as much about restoration resource-intensive as it’s concerning the actual workouts.

It should be famous that the behind the head lat

pull-down can potential course harm or strain to the rotary cuff

if not carried out with correct type and technique.

Your lats work with the teres major and pectoralis main muscles to adduct,

rotate, and extend your arms. Its primary operate is moving

the arms towards the body’s middle, as seen in exercises like chin-ups and lat pulldowns.

He focuses on detailed muscle contractions to develop the striations and graininess that outline

his physique. Bannout’s back growth was a results of his strict consideration to form.

He emphasized the importance of posing apply in growing muscle element,

especially in the lower again. By specializing

in excessive repetitions and squeezing the muscle tissue throughout every rep, Bannout was capable of carve out some of the most detailed again muscles in historical past.

Regardless Of typically competing part-time, Levrone maintained

an elite physique by sticking to the fundamentals of heavy training, proving that consistency was extra important than frequency in his success.

Arnold believed in constantly changing his exercises to avoid hitting plateaus.

This approach, alongside with his emphasis on volume and variety,

was key to his distinctive again growth.

This exercise targets your mid-back and lats while reducing pressure in your wrists and elbows because of

its neutral grip. Hold the bar with an overhand grip, keeping your arms

prolonged straight out in front of you. With your toes flat on the floor,

lean again barely while maintaining a straight posture. Coaching your back leads not solely to visible enhancements but also will increase general muscle endurance and lifting capability throughout

totally different exercises. As you have interaction these muscle

tissue constantly, each hypertrophy and brute force amplify

– equipping you with the mandatory prowess for difficult exercises and day by day tasks alike.

As a private trainer with over three a long time of experience, I’ve

helped several athletes bring up their decrease lats using specific workouts.

This article lists 5 of the best decrease lat moves for building a

dense, broad back. To get the rear delts totally shortened, you

actually need to enter shoulder extension, the place the elbow comes as

far behind the body as potential, without the shoulder rolling ahead.

A supinated (underhand) grip will lend itself to keeping the arm path in close to the physique, which is in a position to are

inclined to bias the lats extra. A neutral grip tends to

do the identical, however can be used to hit the teres a bit extra.

An overhand grip disables the biceps and can irritate the forearm,

elbow, and wrist. This once again isolates the lats extra

by removing a muscle that tries to help.

Be Taught how to maximize this exercise for a thicker back by studying extra.

Building a strong and thick again comes with a number

of benefits, including improved posture, a more

balanced physique, increased energy, and the flexibility to achieve a

V-taper. These advantages can have a optimistic impression on your overall

bodily health and health. As well, for those who

can’t yet do a pull-up, this can be a great different.

A thick, well-developed again protects your spine and improves posture.

Our information dives into the ultimate back

exercises that will add serious thickness to your muscles, enhancing both type and function. In this text, we cover seven of the most effective bodybuilding again exercises that can assist you

to construct mass, energy, and definition. Whether you’re a newbie or

an skilled lifter, these workout routines will provide the foundation for

a well-rounded back exercise. If you need extra muscle-building information, we have a free muscle-building publication. If you want a full workout and diet program, including a 5-month customizable full-body exercise routine, a food plan guide,

a recipe guide, and on-line teaching, check out our

Bony to Beastly Program.

His back has a rugged look, with impressive detail

and muscle separation. Bannout’s back wasn’t the largest, nevertheless it was one of the most defined, with incredibly

detailed lower back development. His well-known “Christmas tree” muscle pattern turned the symbol of elite

conditioning, showcasing deep cuts and striations in his

decrease back. Wolf’s strategy was to emphasize excessive repetitions to carve out the width and detail that made his again so recognizable.

Wheeler had a background in martial arts, which contributed to his exceptional flexibility and muscle control.

This background allowed him to realize perfect posing and greater control over his physique on stage.

His philosophy was to train smarter, not longer, avoiding pointless quantity to stop overtraining and damage.

Totally Different machines present unique stretches and contractions

due to their lever or pulley configurations and the

positioning of the handles. These 13 bodybuilders showcased a few of the most remarkable backs in competitive bodybuilding history.

Their coaching methods and dedication function inspiration for aspiring bodybuilders and fitness fanatics alike, proving that with the proper technique,

a world-class again is achievable. Now it’s as a lot as you—apply these ideas to your individual routine and begin building

your personal legendary again. Franco Columbu was a world-class powerlifter, and his capacity

to deadlift huge weights tremendously contributed to his back’s density.

Seated cable rows are excellent for mid-back

development because they provide constant tension, making certain effective muscle activation. –

Prioritize rows over vertical pulling to target the muscle tissue in your

again more successfully. With the one arm variation, you can obtain a larger vary of motion and

isolate particular muscle groups for optimal ends in your

again workout routine. To further enhance your back workout routine,

incorporating the barbell bent over row can considerably contribute to growing a sturdy and well-defined back.

To carry out the Kettlebell Two Arm Row, hold a kettlebell in each hand with an overhand grip.

In this review, We’ll break down what Athletic Greens AG1

can do for you, serving to you decide if it’s the best choice.

Firms like AMRA sell bovine (cow) colostrum as a powder complement

in travel stick or jar choices. AMRA sells 30-single-serving stick packs for $39.ninety nine unflavored and $49.99 flavored, whereas the bulk jar model

is for $109.ninety nine for roughly a four-month supply.

Athletic Greens may also be useful for athletes

and health lovers who need to gas their our bodies with important vitamins to support performance and

recovery. The product is designed to offer a comprehensive blend of nutritional

vitamins, minerals, and other nutrients that can assist assist power

ranges, immune function, and total well being and wellness.

Athletic Greens is a superfood powder that beats out practically every considered

one of its opponents with an excellent formula and extremely potent components.

The benefits of supplementing with greens powders are

endless in case you are taking the best one. Take a have

a look at this comprehensive Athletic Greens evaluation to see how we decided this nutritional complement to

be one of many top three greatest superfood drinks in the

marketplace. Basically, the extra health benefits you’re

after, then the more components you wish to get in.

Many of the same compounds are found within the AG 1 Superfood Complicated.

The Superfood Advanced (7.388 grams) includes Wheat

Grass, Spirulina, Alfalfa, Chlorella, Grape Seed, Green Tea

Leaf, Apple powder, and extra. Both corporations use natural elements extensively of their formulas.

Green Vibrance states “certified organic” on a quantity of components; nevertheless, we didn’t discover the USDA Certified Natural seal on the package

or within the company’s marketing supplies. Both merchandise are non-GMO, gluten, soy, and dairy-free, as

nicely as vegan-friendly.

In short Athletic Greens is good, however it’s not one of the best greens powder.

Greens powder products such as Athletic Greens AG1 are a well-liked

supplement made well-known by social media influencers for

his or her capacity to be an “all in one” resolution to wellness.

Coming in at $100 for a month’s provide, AG1

could look like a convenient, albeit costly, various for offering a concentrated source of nutrients.

This one-and-done greens powder has an ingredient record that

contains more than 75 nutritional vitamins and minerals, as nicely as a handful of high quality whole meals and adaptogens.

However general, Athletic Greens incorporates loads of well-researched elements,

most of that are dosed at efficient levels. Without correct

digestion, you not solely get annoying signs, but you’re additionally more likely to have a suboptimal nutrient intake.

This could result in other advantages, similar to enhanced immunity and

improved mind operate. A lot of the ingredients in Athletic Greens are natural, but some aren’t categorized as organic.

We simply don’t know but if all of these components work properly collectively or if

any counteract each other. Moreover, AG1 claims to use ingredients that work synergistically, enhancing

each other’s benefits. This is certainly the case with their two probiotic strains which have

proven to work harmoniously. They are committed to sourcing only

components with the best bioavailability.

You could possibly inform just by looking at the ingredients label, but this a

half of our Flora vs Athletic Greens evaluation is right here to make issues extra clear.

Unlike Flora, Athletics Greens isn’t natural however

it does comprise 3x the elements and 6x the amount of veggies and fruits.

In addition, AG1 is vegan, whereas Flora is vegetarian only (due to probiotic sources), and generally, it’s just

obtained a whole lot extra in its formula. Mix this formulation into water, juice, or smoothies for a simple method

to stay on track along with your vitamin needs. I know, the name Athletic Greens makes it sound like it’s just

for active people. And despite the fact that it’s used heavily throughout the athletic group (it’s NSF certified safe for

sports), it’s for anyone who desires a handy, daily product to help

enhance their well being.

And even if you don’t get severely sick, just having low-level sickness

or feeling unwell too typically can restrict your overall life satisfaction, energy, and

productiveness. But even in developed areas, folks can have micronutrient inadequacies,

mainly by consuming an energy-rich, low-nutrient food plan (and that is extra common than you might think).

Regardless, each ingredient goes through strict testing for

high quality and security, you may be assured that Athletic Greens has a high-quality formulation.

You can buy a single or double subscription to Athletic Greens, which suggests

that you could get either 30 or 60 servings of Athletic

Greens delivered monthly, respectively. The Athletic Greens

drink is advertised to be a handy choice for busy people on the

go and for anybody needing to get more nutrition into their

food plan.

And with major advantages such as improved digestion, power levels

and immune system make it well well price the cash.

The benefits of AG1 began to reveal themselves inside only

a few days, with enhancements to digestion and energy ranges.

Amongst the fruits and vegetables, dark leafy greens, cruciferous vegetables,

citrus, and dark-colored berries appear to have essentially the most benefits for well being promotion and disease prevention.

Supplementation doesn’t provide any advantages when you already get adequate

calcium within the food regimen, corresponding to from dairy merchandise, canned fish with bones,

and leafy greens. Nevertheless, most individuals don’t need extra vitamin B6

in their food plan to adequate consumption of animal foods

and fortified products, corresponding to cereal. And you might wrestle with bloating, indigestion, nausea, diarrhea,

or different signs. While there are numerous options to

Athletic Greens, none of them evaluate in phrases

of high quality and worth for worth.

Discover our skilled comparison of two of the preferred greens complement manufacturers in the marketplace and

find out why we choose Stay it Up Tremendous Greens for dietary energy.

Both Rheal and Athletic Greens provide one-time purchases so you

can strive the merchandise. However, if you would like

to make green superfood powers a habit, in addition they have subscriptions which work out cheaper.

Athletic Greens has so many different micro-nutrients that it’s hard to make a case for

Rheal in relation to making a nutritional comparison. It is nevertheless

worth stating that Rheal has a wide range of

different merchandise that do differ in nutritional worth.

Green Vibrance has a sturdy probiotic mix with twelve strains delivering 25 billion CFUs;

nevertheless, it’s nonetheless not a sufficient dose to

replace a true probiotic product. The Eleuthero found in Green Vibrance’s

Adaptogen blend is similar compound as in AG 1 within the Herbs and Antioxidants.

The Skeletal Support (228 mg) blend in Green Vibrance features Calcium as its essential compound in roughly double

the dose found in AG 1. The Antioxidant Blend (1.580 grams) options Acerola, Goji Berry, Turmeric, Ginko Biloba, Grape Seed,

and Green Tea. This mix aligns extra closely with the AG 1 Antioxidant Mix;

nonetheless, the businesses classify elements similar to Green Tea differently.

Many of these compounds are anti-inflammatory as well as

antioxidant. The Cereal Grasses (3.675 grams), Barley, Oat, and Wheat Grass

are licensed natural.

Calcium supports regular digestive enzyme perform, while biotin maintains regular mucous membranes, such because the intestine lining.

Meals supplements aren’t an various selection to a balanced and various

food plan and a healthy way of life. Please inform and consult your physician before consuming this product.

Not appropriate for children and adolescents beneath 18 years, pregnant or

breastfeeding women.

As highlighted in a narrative review revealed in Vitamins,

nutritional vitamins and minerals are important for the optimal mobile features.

Deficiencies may lead to psychological and physical fatigue as they

play a important function in the neuronal perform and energy metabolism.

Detailed product data, including benefits, elements, and usage, helps in guiding

potential customers toward making informed choices. Partaking

content, corresponding to testimonials and case studies,

provides credibility. Athletic Greens can also be full of components

that will support immune operate, alleviate inflammation, and forestall the overproduction of

inflammatory cytokines. For instance, this blend incorporates a bacteria referred to as Lactobacillus

acidophilus – UALa-01. Research show that certain strains of

this bacteria help enhance immune response and stop infection.

The complement contains components that foster beneficial gut micro organism progress,

aiding digestion and nutrient absorption. A

wholesome gut microbiome is essential for general health, as it influences digestion,

immune function, and even mental well-being. By

promoting a balanced intestine, AG1 helps reduce bloating

and supports better nutrient absorption, improving digestive consolation and efficiency.

Athletic Greens, founded by Chris Ashenden in 2010, is a health and wellness company

devoted to creating complete dietary dietary supplements.

The brand emphasises high-quality components, rigorous high quality management, and scientific research in their product growth.

Athletic Greens or AG1 has a distinct taste that comes

across as earthy and semi-sweet, with out utilizing sweeteners.

This unique style makes it stand out from other green powders available on the market.

Whereas some customers find it pleasant, others discover

it tough to eat with water because of its style and texture (Forbes Health).

Mixing it with a smoothie or juice may be a more palatable possibility for people who aren’t followers of the taste.

Please note that this isn’t an exhaustive record of vitamins in Athletic Greens,

and it’s important to evaluation the complete dietary profile

before figuring out if the product is appropriate on your

needs. Usually, green powders have different components

crushed into powder. You’re getting more bang for

your buck, contemplating you’re paying for lower than a cup of latte at your favorite espresso

store.

You’ll get 30 energy, three grams of fiber, and a pair of grams

of protein from every scoop, along with a spread of vitamins and

minerals. Organifi is an natural green juice powder that may help decrease stress

levels and increase full-body wellness. It may be blended into water or

added to your smoothie for an extra kick. It’s USDA-Certified

natural, so you might have that extra peace of thoughts figuring

out that what you’re ingesting meets such excessive standards.

On the powdered greens listing of health benefits, probiotics are also very popular.

Additionally, sure vitamins in Athletic Greens, such as calcium and magnesium, could affect the absorption or effectiveness of certain antibiotics or thyroid

medicines. Everyone is attempting to juice their fruits and

veggies now in order to make certain they’re getting 100 percent of the benefits.

Many customers report elevated vitality and a constructive influence on their general well-being.

Nevertheless, some customers have highlighted the excessive worth,

occasional digestive discomfort, and gritty texture.

It’s necessary to notice that AG1 just isn’t beneficial for youngsters, pregnant or breastfeeding ladies.

Mineral deficiencies also can impair physical performance, so those who wouldn’t have an sufficient

diet can benefit from the mineral content of Athletic Greens.

The compensation we receive from advertisers doesn’t influence the recommendations or recommendation our editorial group provides

in our articles or in any other case impression any of

the editorial content on Forbes Well Being. We obsess over product compliance, which is why our product is

made based on the very best manufacturing standards in TGA registered amenities.

Or if stress management was a main goal, it’d be important to search for a complement with adaptogenic herbs.

It’s not as highly-dosed as AG1, and it also doesn’t embrace practically as many nutritional vitamins or minerals.

And it’s additionally one of many lower-priced superfood formulation on the market

at $49.95 for 30 servings. But that’s the best price you’ll pay as you can save cash with both their bulk options or

subscription choice (which is beneath forty bucks per container).

If you’re considering AG1, proceed reading this Athletic Greens evaluation. With that mentioned, we really do NOT consider Athletic

Greens is well worth the worth. Here’s why…Athletic Greens prices

the very same amount as our prime ranked superfood powder, Whole Living Drink Greens.

Nonetheless, the precise fact is that sometimes I

am very busy, working, training or just running round dwelling

life, and at times I in all probability don’t eat enough of the best things on the proper

instances. Fortunately, our Athletic Greens evaluation reveals that the corporate

has really carried out its homework before making this product.

Athletic Greens tastes in a unique way to totally different customers, and it might be

an acquired taste for some. The powder is

flavored with vanilla, pineapple, carrot, cherry, broccoli, and papaya.

If you’re within the US, you want to get your Athletic Greens package deal

between 3-5 enterprise days at most with standard precedence transport.

Stay it Up Super Greens costs just $39.ninety nine ($1.33 per serving) with a month-to-month subscription. While several ingredients in AG1 seem to be dosed properly, corresponding to

vitamins, minerals, and probiotics, others will not be as efficient.

For example, with seventy five elements packed into just one tablespoon, there may not be enough room for a good

amount of each superfood. AG1 does not use synthetic

sweeteners or added sugar, which is nice information from my perspective.

As An Alternative, this greens powder includes the pure non-caloric sweetener stevia leaf powder.

The taste was surprisingly pleasant, making it easy

to combine with water alone. Another draw back is the price—it’s undeniably a premium product, which could possibly be a stretch for these

on a tighter budget. Its earthy, barely grassy style was manageable

in a smoothie however not perfect when blended with just

water.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.com/en/register?ref=JHQQKNKN

By combining distinctive innovation, product development capabilities

and an extensive world distribution community, GNC manages a best-in-class product portfolio.

one hundred twenty micrograms of vitamin K per day

to support blood clotting and bone health. Good sources of vitamin K embrace leafy greens,

liver, and fermented foods. 15 milligrams of vitamin E per day to assist antioxidant protection and pores and skin well being.

Good sources of vitamin E include nuts, seeds, vegetable oils, and

leafy greens. 90 milligrams of vitamin C per day to assist immune operate,

wound therapeutic, and antioxidant protection. Good sources of vitamin C embrace citrus fruits, strawberries, broccoli, and bell peppers.

It plays a crucial function in energy production, significantly throughout high-intensity, short-duration workout

routines like weightlifting and sprinting. While some research on dietary supplements is sparse at greatest, the data on creatine is robust.

Outcomes persistently present that taking 3 to 5 grams

a day (even upwards of 10 grams) is safe and efficient. People who

take the popular sports activities complement creatine and

carry weights don’t construct muscle any faster than those

that do resistance training without the supplement, new research reveals.

More ATP means extra reps, heavier lifts, and greater

gains—if you’re constant along with your coaching. Think of it

like giving your muscles a limiteless all-access cross to fuel

up once they want it most. No, creatine supplementation does not affect testosterone ranges within the physique.

According to Dr. Jampolis, this brand of creatine is also used by the

U.S. It’s caused by water retention within the muscles

and sometimes subsides after the loading phase or as soon as your physique adjusts to regular creatine

use.

Its micronized nature, purity, confirmed advantages, and flexibility are

its major advantages. While it might require a loading section and will lead to water retention in some instances, these elements

are sometimes outweighed by the positive influence on muscle power and power.

Muscletech Platinum 100% Creatine Powder provides a pure dose of creatine monohydrate shown in research to increase

muscle strength, power, and lean muscle growth. Backed by science, it delivers three grams of pharma-grade creatine

per serving for eighty three servings.

It mixes easily, is actually tasteless, and would

not have any of that gritty texture creatine powders

can generally have. A substance normally found in muscle

cells, creatine helps your muscular tissues produce explosive

vitality during exercise, similar to HIIT or weightlifting.

For years, athletes and sports activities folks have taken creatine to realize an edge on their efficiency — to achieve power, measurement and muscle and improve exercise capacity.

Creatine supplementation can lead to 2-4lbs of weight acquire in every week – your muscle tissue

retain water so as to heighten protein synthesis (the constructing of muscles).

This, nonetheless, is nothing to fret about, especially for everyday athletes.

While creatine doesn’t immediately set off weight reduction, its impression on exercise efficiency not directly contributes to shedding

unwanted kilos. Enhanced exercise performance results in elevated calorie expenditure and improved

fats loss during exercise. It Is about tapping into the advantages that creatine supplementation provides,

no matter gender, and embracing its potential to elevate your fitness expertise.

Folks can review the product they intend to make use of with Informed Choice,

NSF International, or Shopper Lab. Folks should look for merchandise that meet good manufacturing practice (CGMP) rules.

This ensures that the product is protected and has

the components and energy it claims to have. The firm states that an individual can take this creatine supplement 30 to 90 minutes before

or after exercise. Though ‘new and improved’ versions of creatine pop up all the

time, none have consistently confirmed themselves to be any better than regular creatine

monohydrate. In other words, should you wanted to, say, look

hulked for a high school pool party in a week, the loading part could be a good

suggestion. But if you’re a dad who is just on the lookout for

a little help schlepping around the kid, there’s no actual

have to creatine load.

Individuals who don’t wish to or can not take creatine dietary supplements can consume red meat and seafood to extend

their bodies’ creatine ranges naturally. Bare claims this product accommodates the very best grade creatine monohydrate complement obtainable available

on the market. The body more simply absorbs micronized substances,

which could make it simpler. Usually, the case for taking creatine during a exercise is built on ATP (adenosine triphosphate) an natural chemical

that contributes to mobile power and muscle contractions.

Steadily increase the weight lifted over time to problem your muscular tissues

and stimulate development continually. This could be achieved by including more weight to the barbell, performing extra repetitions, or decreasing relaxation intervals between sets.

To maximize your grip power from deadlifting,

practice holding the barbell, dumbbells, or kettlebells for longer intervals

at the top of each rep, Johnston suggests. For instance, instead of flowing by

way of the rep and lowering the weights as soon as you stand upright,

maintain for a count of two to three breaths before transferring on. It’s essential to note that powerlifting opponents ought to often perform a traditional or

sumo deadlift as a outcome of these are the only two variations allowed.

Nonetheless, variations can help improve weaknesses in specific

elements of the raise when wanted . Since it’s a compound motion, lifting capacity

is much higher than isolation workouts.

Their compound nature permits for heavy hundreds to be used, resulting in larger improvements in energy compared to isolation exercises.

Deadlifts effectively result in broader muscle progress and energy across the physique.

So, let’s pull back the curtain and study the

science that makes deadlifts such a important part

in muscle building and improvement. Steven is a licensed personal trainer and fitness enthusiast

primarily based in La.

There’s this persistent fable that deadlifts are just for competitive lifters

or bodybuilders, however I think that’s misguided.

Whether Or Not you’re a runner, a cyclist, or someone just stepping into health, the benefits

are vast. Improved posture, enhanced power for every day

tasks, and better athletic performance are all achievable,

they usually go far beyond just wanting good in the fitness

center. The Romanian deadlift is another glorious variation, targeting the hamstrings extra intensely.

By maintaining your knees straighter, you obtain a deeper stretch in your hamstrings, which is essential for

hypertrophy in this space. The trap bar deadlift can also be a good choice, as the hexagonal

bar design permits for a extra balanced load distribution.

Seek the advice of your physician for questions you may have regarding your health or a medical condition. If you might be having a

medical emergency, call your physician or 911 immediately.

The Peloton Guide also can help you improve your kind because you see your self on the screen next to the trainer, permitting

you to right your kind during a workout. Here’s what you need to know to

verify you’re getting the most out of each deadlift you complete—and staying

protected within the process.

Posterior-chain workouts such because the squat, deadlift, and good

mornings, are considered compound movements. Compound actions, contain a number of

different muscular tissues teams that are activated on the similar time,

which may build and enhance functional power, mobility, and defend your physique from injury.

The posterior chain also includes strengthening of secondary muscular tissues enhancing mobility, posture, and adaptability.

This variation of the stiff leg deadlift targets the

hamstrings, glutes, and lower back muscles.

It is a unilateral exercise that requires balance and

stability to perform appropriately. To do this train, stand on one foot together with your reverse knee barely bent.

Maintaining your core tight and chest up, hinge at the hips whereas reaching for the bottom with each arms till you’re feeling a stretch in your

hamstring.

In addition to that, you could use a barbell, some

dumbbells, or perhaps a kettlebell. The deadlift also works the shoulder muscles,

together with the medial deltoid and the trapezius.

The shoulder blade and scapula specifically

play a major role when deadlifting heavy weight. A lot of instances you’ll

hear to squeeze your shoulder blades together or roll your shoulders again. For power improvement, purpose for 3-5 units of 5-8 reps.

For hypertrophy (muscle growth), goal for 3-4 sets of 8-12 reps.

Whereas it’s possible to do both deadlifts in the

same workout, it’s greatest to prioritize one or the other.

In the standard deadlift, the initial level change to grasp

the bar comes by way of a mixture of hinging on the

hips and bending your knees. In a normal deadlift, your torso angle

at the beginning of the pull shall be roughly 30–45 degrees above horizontal.

Good for newbies looking to ease into deadlifting, these with lower back issues, or

anyone looking for a balanced raise that’s easier on the

joints.

If you solely have a barbell, standard or sumo deadlifts

are the way to go. For these with access to a trap bar, it can be a flexible alternative for decreasing strain while sustaining

energy features. In this guide, we’ll cover what the deadlift is, the advantages, the main types of deadlifts

(conventional, sumo, and lure bar), and how to perform every

one safely and successfully. If you could have entry to weights and a barbell

at home, you can carry out deadlifts in your individual space.

Deadlifts offer versatility, and there are numerous variations that cater to completely different health ranges, targets, and preferences.

By setting an instance as a strong, empowered woman in the world of health, you encourage future generations of women to interrupt free from limitations and embrace their strengths.

A strong core not solely aids in maintaining an upright stance but

also supports the backbone throughout everyday actions.

The energy gained from deadlifting translates into real-life purposes, corresponding

to lifting groceries, moving furniture, or carrying kids.

70918248

70918248

70918248

70918248

70918248

Nevertheless, clenbuterol is extra highly effective by method of pure weight loss, due to its robust thermogenic

effects. This turns into significantly easier when you have a quicker metabolism and burn extra energy each day (which clenbuterol causes to happen).

If you eat in a calorie deficit, do cardio and taken clen – expect some rapid weight reduction. I say ‘compounds’ because winstrol is a steroid

however clenbuterol technically isn’t. Nevertheless it is often used

alongside different fat burning steroids which is why it typically is wrongly listed

as a chopping steroid. Wegovy copies the action of a

natural hormone in the physique known as glucagon-like peptide-1 (GLP-1), which helps regulate blood

sugar ranges, slows digestion, and reduces urge for food.

Anvarol uses PeakATP®, a patented form of ATP that helps improve vascular health and muscle excitability,

making your heavy lifts and harder coaching bouts that instead more efficient.

It is classified as a managed substance in lots of international locations, together with the Usa.

There are additionally some psychological effects to keep in mind,

so referred to as ‘roid-rage’.

Psychologically, Anavar abuse can result in aggressive habits, mood swings, and increased anxiety.

You may also end up experiencing intense cravings, especially

during withdrawal intervals. These cravings could make

you’re feeling restless or irritable, serving as a transparent sign of potential dependency.

Anavar can even interfere with laboratory tests, probably resulting in false outcomes.

All The Time inform healthcare suppliers about your

Anavar use before present process any testing.

This selective motion is a key factor in its profile, enabling customers to achieve specific health targets with lowered

unwanted effects.

Anavar’s ability to increase energy is

especially due to it being exogenous testosterone.

Nevertheless, we discover it also has a dramatic impact

on adenosine triphosphate manufacturing and creatine content inside the muscle cell.

Higher ranges of ATP are beneficial for individuals wanting enhanced power when bulking.

Primobolan will lower endogenous testosterone levels notably,

but we now have discovered it to be the least

suppressive anabolic steroid. Primobolan just isn’t overly androgenic, so fats loss is not going to be dramatic.

Thus, Primobolan is extra generally utilized to modestly accelerate fat-burning while trying to preserve muscle and energy

on lower calories.

Additionally, Anavar might help you protect your muscle tissue when you’re dieting or coaching hard.

Anavar, a gentle but effective anabolic steroid, is

extensively employed in the fitness and bodybuilding industry to improve physique and

efficiency. Its outcomes, however, can vary significantly based

on the duration of usage, dosage, and the user’s traits, like gender.

In the desk below, we examine individuals’ progress from

2 to 8 weeks of Anavar utilization, highlighting the distinctive transformations observable in each female and male customers.

Reviewing a sequence of earlier than and after photos for females reflects an equally spectacular transformation.

Winstrol is not appropriate for newbies because of the

severity of unwanted effects which may be usually experienced.

Winstrol dosages for men are usually 50 mg per day however can go as high as double that.

This creates an much more enhanced look, with increased muscle tone

and definition. Oil-based Winstrol is stronger than the

water-based or oral type of the drug. However, this isn’t to say it is only used by ladies, with

several male powerlifters and bodybuilders also using Anavar

to good effect.

We have discovered this to be essentially the most efficacious oral cycle for

getting ripped. Proviron will enhance Winstrol’s anabolic results whereas growing androgenicity additional, aiding fat loss.

Some novices may make the most of an Anavar-only cycle, with it posing much less toxicity than different anabolic steroids.

Nevertheless, Anavar still causes probably troublesome unwanted effects (which are detailed in the unwanted

facet effects section below). A PCT is not wanted when taking authorized steroids

or steroid alternatives, as they gained’t shut down women’s natural

testosterone manufacturing. You can also stack all three of these collectively for max fat

loss and muscle positive aspects.

It is necessary to notice that Anavar should not be used for longer than 8 weeks at a time,

as extended use can lead to liver damage. Anavar,

also known as Oxandrolone, is a synthetic anabolic steroid

that’s commonly used for fats loss in each women and

men. Some widespread unwanted effects embrace water retention, gynecomastia (enlargement of the breast tissue), acne, hair

loss, and masculinization (changes in intercourse characteristics).

You ought to at all times converse with your doctor

before beginning any sort of TRT therapy to keep away from any potential unwanted effects.

No matter what your fats loss targets are, there’s

a standard dosage of Anavar so that you just can take.

Anavar is an oral steroid that helps with weight loss and muscle gains.

Anavar’s chemical name is Oxandrolone, which suggests it doesn’t aromatize into estrogen-like different steroids do.

This is a reasonably latest concept that as Anavar doesn’t

considerably inhibit the pure testosterone system, it could be used effectively during

post-cycle remedy (PCT). It’s not a brand new thought; the rationale comes from

Dianabol getting used at a small AM dose of 10mg every day during PCT.

This theory may maintain some water as a outcome of Anavar

not being over-ally suppressive to pure testosterone production. We cannot say how much Anavar can suppress the

body’s personal testosterone because of genetic predisposition, so it can prove troublesome.

This attribute ends in hard, dense muscles, not just inflated mass.

Thus, the gains from this drug are typically extra sustainable, even after discontinuing its use.

Anavar, also called Oxandrolone, is a synthetic anabolic steroid introduced into

the market in 1964 by the pharmaceutical company G.D.

The main goal behind this drug’s growth was to offer a less poisonous and safer various to different anabolic steroids.

As A Outcome Of of its effectiveness impacts in comparison to different up to date anabolic steroids, its

recognition elevated over time. Since it’s an oral steroid, there might be increased threat of liver injury if used in excessive dosages.

Anavar additionally causes giant decreases in HDL accompanied with massive increases in LDL.

This kind of look isn’t everyone’s aim, so it comes right down to your aesthetic preferences.

Though Anadrol causes fluid retention, this stack is superb

as a pre-competition combination as a result of results might be full,

dry, and ripped with mass added. The key to reducing Anadrol’s fluid retention so you’ll find a way to

still obtain a dry look on this stack is to maintain your

sodium consumption very low through the cycle.

Nonetheless, I’ve come throughout many ladies excited

about using Winstrol as a substitute or working a Winny cycle and comparing it to previous

experiences with Anavar. Winny is there that can help you shed water weight, get those veins popping, harden the muscles, and supply most muscle definition in time for a contest (or your next seaside vacation).

50mg is a regular Winstrol dose that many males won’t see the need ever to exceed.

At this degree, Winstrol’s main effects of dryness, muscle hardness, and

vascularity will become outstanding, but side effects should remain manageable

for most customers.

Female athletes and bodybuilders discover it to be effective in rising lean muscle

mass without the risk of opposed unwanted effects such as virilization – the event

of male bodily traits in girls. It is important to notice

that using applicable dosages and carefully monitoring

the usage can mitigate these dangers. Anavar is known for its capability to advertise muscle development and improvement

of lean muscle mass. It works by increasing protein synthesis

and nitrogen retention, that are important for muscle development.

While it’s straightforward to search out via this

technique, keep in thoughts that importing or transport Winstrol into the US

can also be unlawful, and penalties will apply if you’re unlucky enough to get caught.

You should not have any downside finding Winstrol on the market anyplace

on the earth. Each oral and injectable types are extensively out there; however, oral is

typically extra well-liked. The identical brand of Anazol

additionally is out there in oral form in 2mg tablets, which may be interesting if you’re taking decrease doses of Stanozolol.

DHEA (dehydroepiandrosterone) is a medicine we commonly prescribe to ladies suffering from hypoandrogenism (low testosterone).

Winstrol dosages above 5 mg are prone to trigger

complications for women looking to keep away from masculine

characteristics. Anadrol is probably certainly one of the most hepatotoxic steroids in our testing, causing notable rises in ALT and AST

enzymes (markers of liver stress). This extra fluid will increase blood viscosity, resulting in the

heart having to pump more durable, causing an increase in blood pressure and restricted blood circulate.

That’s why, from Anavar / Check cycle, there are low chances that your liver would suffer an excessive quantity of, and all of the liver enzymes increase would happen from Oxandrolone.

Injectable testosterone has been found to extend the liver enzymes

but has such a small influence in your liver,

that’s not liver poisonous at all.

By doing so, you will reduce the danger of side effects and maximize your outcomes.

If you are trying to get essentially the most out of your Anavar and testosterone cycle, make sure to observe these pointers.

Lastly, when using Anavar and testosterone together, it may be very

important keep your doses in examine.

As A End Result Of Anavar is a c-17 alpha-alkylated steroid, alanine aminotransferase

(ALT) and aspartate aminotransferase (AST) ranges could be expected to rise.

In distinction, customers ought to prioritize reducing the

danger of cardiotoxicity by participating in common cardiovascular exercise and consuming a food plan rich in unsaturated fat, low in saturated

fat, and low in salt. In individuals with normal blood

lipids, the usage of Anavar isn’t expected to result in cardiac antagonistic effects.

Anavar is very in style among bodybuilders since it’s considered as a reasonably innocuous substance.

Although there are a variety of side effects, the vast

majority of them can typically be avoided because

the chemical is neither robust nor dangerous.

Our mission is to supply reliable, evidence-based information on Types and

Profiles of dietary supplements, effective Cycles and Dosages,

and insights into Health and Muscle Building.

Thus, the risk-reward ratio on Anavar is positive for the majority of

our sufferers. Outcomes could differ, but generally, customers begin noticing refined enhancements inside the first couple of

weeks. As the cycle progresses, these enhancements turn into extra pronounced,

leading to seen modifications in muscle definition, energy,

and fats loss by the end. Following an eight-week cycle of Oxandrolone,

vital outcomes can sometimes be seen. This interval marks

the conclusion of a standard cycle for male customers and closes in on the

final section for female users.

Winstrol and all other anabolic steroids are listed as Schedule

III managed substances within the Usa. The US has a

few of the strictest laws round AAS in the world, where it’s not legal to possess Winstrol

even for private use. Winstrol is certainly one of the most popular steroids on Earth, so almost all suppliers will always have it in stock.

It’s considered a comparatively low-cost anabolic steroid and is undoubtedly more reasonably priced than Anavar (to which it’s often compared).

In these circumstances, when you’re already very lean,

you don’t have plenty of fat to lose apart from some stubborn areas.

Winstrol outcomes will start coming on fast due to its fast-acting nature,

and without any estrogenic side effects, you won’t be worried about bloating ruining your physique.

Most girls won’t select Deca-Durabolin as the primary steroid

to use for lean gains, cutting, or performance because there are better choices like Anavar that come with fewer unwanted effects.

An superior stage of supplement experimentation often leads users in course of

the Primobolan Anavar cycle. Incorporating Anavar,

one other anabolic steroid, in tandem with Primo

can present a doubtlessly potent combination, significantly for knowledgeable customers

aiming to optimize muscle definition and loss of fat.

This cycle can offer the benefits of two highly effective efficiency enhancers,

strategically mixed for maximal benefits.

600mg weekly of Tren and 100mg weekly of Testosterone Enanthate to assist testosterone operate offers a robust cycle for

either bulking, lean mass, or slicing. IGF-1 is of course increased each time you

train without the use of steroids, however Deca supercharges

this course of past what the body is capable of alone.

IGF-1 is a progress hormone, so it is responsible for the muscle’s progress at its most basic.

It’s a significant hormone for rising lean mass, enhancing protein synthesis, burning fat,

and repairing and recovering muscle tissue.

By maintaining a positive nitrogen balance, it creates an optimal surroundings for protein synthesis and prevents muscle breakdown (catabolism).

Elevated purple blood cell rely improves oxygen transportation to the muscle tissue, enhancing

endurance and delaying fatigue throughout bodily exertion. This attribute can be

notably helpful for athletes engaged in activities requiring extended stamina and

efficiency. In addition to its anabolic results, Anavar has a modest impact

on metabolic activity. It can improve basal metabolic price (BMR), which refers to

the variety of energy burned at relaxation.

Bodybuilders commonly buy testing kits, enabling them to determine if

their Anavar product is authentic. A frequent rip-off we’ve been made aware of is sellers labeling merchandise

as Anavar, however the raw ingredient being Dianabol. Dianabol is a very inexpensive

oral to supply; thus, by deceiving individuals in this way, dealers can dramatically increase their revenue margin.

Anavar produces nice outcomes, particularly when it comes to strength and pumps.

Take 3+ grams of fish oil and do your cardio, and cholesterol

shouldn’t be a difficulty, even when you’re sensitive

to your lipids. Anavar is superior, yet costly, since

you need to take a lot for results.

I focus on creating personalized workout plans and providing diet advice to assist my clients reach their health goals.

Some of the larger mg tabs such as the 50 mg tabs are actually a ache within the ass to me,

because I need to cut them up. I’ve tried “pulse cycling” before (only operating orals on coaching days

in larger amounts), taking 1 giant dose an hour before I prepare, and I never get as sturdy doing it that means.

I’ve always found any oral to work higher in smaller dosages all through the day somewhat than simply 1 large

dosage once per day. Anavar promotes muscle development and with

good self-discipline and legit Anavar, one can do an terrible lot of changing in a pair short

months.

Expect an increase in power and endurance, however the unwanted

aspect effects of Clen can hurt your exercise ability (lowering

the dose is right if you’re delicate to stimulants).

Anavar will present the capability to build muscle and preserve strength

whereas weight-reduction plan. At its most elementary, Anavar is nearly always stacked

with Testosterone for hormone substitute functions.

This shall be at a low dose, the place the testosterone won’t contribute much to your performance.

However to take it a step additional, elevating your Testosterone dose can bring about powerful anabolic results with muscle and

power positive aspects. Nonetheless, more advanced customers will go additional than this, using one or

more different compounds at performance-enhancing doses alongside Anavar.

However, testosterone and Deca Durabolin, both

have much less damaging results on ldl cholesterol in our LPTs (lipid profile tests) and no effect on the liver.

Testosterone and Dianabol are both estrogenic and moist compounds; thus,

gynecomastia should be categorised as high-risk.

To forestall this, an efficient SERM could be taken (Nolvadex) throughout

the complete cycle. Testosterone propionate is another fast-acting

ester, albeit slower than suspension. Some bodybuilders view propionate

as cost-effective as a outcome of its worth is lower; nonetheless, propionate is dosed at a hundred mg/mL instead of 250 mg/mL (the usual testosterone dosage).

Ladies who are snug with greater doses of Anavar and who

don’t suffer virilization results can consider adding one other 5-10mg to the Anavar dose suggestion above.

Masteron is thought to be a greater temper enhancer than Anavar,

but this effect can be very individual-dependent.

Most Masteron customers will also see a higher increase to the libido than is usually experienced with Anavar.

On the draw back for Masteron, it dries out the joints and can cause joint pain, whereas Anavar can be joint supportive

to a level.

By following a structured cycle, users goal to maximise the

advantages of Anavar while minimizing potential dangers and unwanted effects.

Understanding the important thing components

and considerations of an Anavar cycle is essential

for attaining desired outcomes and sustaining total health and well-being.

In this section, we are going to provide a comprehensive overview of an Anavar example cycle, which serves as

a roadmap for individuals contemplating the use of this in style anabolic steroid.

Testosterone levels will turn out to be extra suppressed, and cholesterol levels and blood pressure will spike, in addition to

liver values, when running this intermediate cycle.

We discover these to be the main side effects users need to manage when biking Winstrol.

We have seen users acquire notable amounts of lean muscle (up to 10 lbs) from this cycle while reducing their body fat share considerably.

During the preliminary section of incorporating Oxandrolone into their

routine, most customers experience noticeable adjustments of their energy and

endurance levels.

At a dose of 80mg, daily for the primary 5-6 weeks of the steroidal cycle is common or used throughout the cycle (if 6-8 weeks) when chopping.

You can even improve the dose of Anavar extra time to compensate for the tolerance

the body will begin to build if need be. Anavar is

well generally known as the one anabolic steroid girls can use with little

to no danger of unwanted side effects – as lengthy as doses don’t exceed 20mg per

day.

Despite the above protocol being effective, DHEA is the official medical therapy prescribed to

ladies for low androgen ranges. Anavar’s half-life can improve

past this vary, relying on the age of the user.

For instance, its half-life could be as high as thirteen.three hours in the elderly (23).

Thus, if we state the half-life as 10.4 hours, a post-cycle therapy protocol ought to begin 57 hours after the ultimate dose.

People that buy underground lab Anavar via the black market

might declare doses of 15–25 mg per day are modest. This

is due to copious scams where the label states forty mg of Anavar, however actually, it is only 20 mg.

One Other purpose this has been such a successful

drug is that it has been proven to be less toxic

for the liver [3]. However, most studies have looked at short-term use, and people have assumed that

much less toxic means that it will not result in liver failure in any respect.

Different medicine might work together with oxandrolone, including prescription and over-the-counter medicines, vitamins, and natural merchandise.

Inform each of your health care providers about all medicines you utilize now and any drugs you begin or stop using.

Oxandrolone won’t improve athletic performance and

should not be used for that function. Do not take this medicine in bigger

or smaller amounts or for longer than beneficial.

By following these important steps, you’ll have the ability to optimize your results and decrease potential risks.

Anavar Dosage GuidelinesTo maximize the advantages

and decrease potential dangers, it’s essential to stick to appropriate dosage guidelines when using Anavar.

The optimal dosage of Oxandrolone varies depending on an individual’s experience, goals, and tolerance level.

For these unaware, every week we have a specific steroid

or PED up for dialogue. The aim of those threads

is to generate dialogue concerning the posted compound and get all

kinds of person experiences and suggestions about it.

These threads are extraordinarily helpful as an archive

for brand spanking new users, and for skilled customers researching a

new compound. This is all anecdotal, of course,

and you should take these evaluations with a grain of salt.

This is a pleasant contest prep stack fitted to hardcore customers and

competitors. One Other Anavar stack for males is a pure slicing cycle and consists of another cutting-specialist steroid in Winstrol.

Winstrol is probably certainly one of the best cutting compounds obtainable,

and when combined with Anavar, it proves to be a potent duo for ultimate shredding.

All of those stacks will require a post-cycle remedy

protocol afterward.

By making knowledgeable selections, in search of guidance, and

following best practices, you’ll find a way to optimize your Anavar expertise

and work in the direction of achieving your desired fitness and efficiency targets.

In this section, we will provide a complete overview

of an Anavar instance cycle, which serves as a roadmap

for people contemplating the use of this well-liked

anabolic steroid. Anavar cycles are rigorously planned intervals of time throughout which the

steroid is taken, with particular dosages and durations in thoughts.

While there’s a lack of scientific research on the topic,

anecdotal research performed by bodybuilders reveals that

oxandrolone can certainly be a muscle-building drug.

Anavar or Oxandrolone is specifically a dihydrotestosterone (DHT) hormone that has been structurally altered.

It is DHT with an added oxygen atom changing the carbon-2 within the A-ring.

This alteration tremendously will increase the hormone’s anabolic exercise,

in addition to prevents it from being metabolically broken down. However,

should you do know about the risks to your health

and legally and you need to purchase oxandrolone, all you have

to do is make pals in a hardcore bodybuilding fitness center.

This leads to a extra aesthetically pleasing physique, which is very wanted in competitive

bodybuilding and fitness circles. The high quality of muscle gained

with Anavar is often described as hard and vascular, contributing to a extra chiseled look.

Anavar for ladies is a popular anabolic steroid that gives significant benefits, corresponding to increased muscle

mass, improved muscle definition, and effective fat loss. However, it is important for feminine customers to observe the really helpful

dosage and keep Anavar cycles quick to minimize the chance of

any adverse results. It helps promote lean muscle growth, improve energy, and

improve endurance. Female users could experience improved muscle definition and a toned physique, making it a beautiful possibility for these centered on aesthetics.

Additionally, Anavar can aid in fats loss

by increasing metabolic rate and supporting the preservation of lean muscle mass during slicing phases.

It is necessary to notice that longer cycles may increase the danger of side effects and suppress

pure hormone manufacturing. Testosterone replacement remedy does not require users to

implement cycles. However, bodybuilders utilizing supraphysiological doses of testosterone or different anabolic steroids

aren’t advised to take them repeatedly as a result of extended toxicity.

Anadrol is an oral steroid, which makes it advantageous for people who wish to circumvent injections.

Anecdotally, we’ve observed that first-time Anadrol cycles can produce over 30 kilos in weight.

Primobolan helped these sufferers shift from a cachectic state into an anabolic one.

It additionally eliminated water retention as a result of

Primobolan not aromatizing into estrogen (being a dihydrotestosterone-based steroid).

Anavar dramatically increases protein synthesis, nitrogen retention, and IGF-1 (insulin-like development factor) levels, causing important improvements in muscle hypertrophy (size) and energy.

Primobolan can add as a lot as 10 kilos of muscle whereas inducing

subcutaneous fats loss. Comparable to Anavar, Primobolan is more

widespread among women, with fewer incidents of virilization in our

experience. We find that endogenous testosterone ranges usually normalize several weeks following cycle cessation.

It’s when a steroid person is going to use one thing other

than the “kick-starting” steroid of their cycle as the main steroid or the spine of it.

If you’re in search of a secure and legal different to Anavar,

then we recommend trying out CrazyBulk’s Slicing Stack.

We believe that the human body is capable of wonderful things

with out the utilization of medication. If you’re a professional bodybuilder or

athlete competing in a examined federation, then Anavar may be a

essential evil. If you have any history of coronary heart disease in your family, or in case you

have excessive cholesterol, you must discuss to your physician earlier than taking Anavar.

If you expertise any changes in your pores and skin colour

while taking Anavar, you want to report them to

your physician. In most cases, the discoloration will resolve

on its own when you stop taking the medication.

Trenbolone and Anavar could be stacked together during bulking or chopping

cycles, resulting in appreciable fat loss and super features in muscle mass.

Nonetheless, because of the presence of trenbolone, we consider this to be a harsh cycle and never appropriate

for novices. Anavar’s capability to extend power is mainly as

a result of it being exogenous testosterone.

70918248

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Saque Rápido e Seguro: Como Retirar Seus Fundos do [bingo](https://bingo-br.com) Sem Complicações!