The question ” Can you weld stainless steel to mild steel?” is often raised in the metalworking industry, as it concerns the feasibility and the potential challenges involved in this process. The answer to this question is not straightforward, as it depends on several factors, including the specific types of stainless steel and mild steel involved, the welding techniques and materials used, and the requirements of the end application.

Can You Weld Stainless Steel to Mild Steel?

Properties of Stainless Steel and Mild Steel:

Before delving into the welding process, it is crucial to understand the fundamental properties of stainless steel and mild steel.

Stainless steel, as the name suggests, is known for its corrosion resistance, which is mainly attributed to its high chromium content. It is typically used in applications where durability and resistance to rust and staining are essential.

On the other hand, mild steel, also known as low-carbon steel, is the most common type of steel used in industry due to its good weldability, formability, and relatively low cost. It is less resistant to corrosion than stainless steel but is suitable for a wide range of structural applications.

Welding Considerations:

When considering welding stainless steel to mild steel, several factors need to be taken into account:

- Compatibility of Materials: Stainless steel and mild steel have different chemical compositions and mechanical properties. This can lead to compatibility issues during the welding process, such as the formation of brittle intermetallic compounds or differences in thermal expansion coefficients that can cause stress and distortion.

- Welding Techniques: The welding technique chosen can significantly affect the quality of the weld joint. Common welding methods include manual metal arc welding (MMA), tungsten inert gas welding (TIG), and metal inert gas welding (MIG). Each technique has its own advantages and disadvantages when used to weld stainless steel to mild steel.

- Welding Materials: The selection of welding wire and filler metal is crucial. The choice should be made based on the specific types of stainless steel and mild steel being welded, as well as the desired mechanical properties and corrosion resistance of the weld joint.

- Post-Weld Treatment: After welding, it may be necessary to perform post-weld treatment such as heat treatment or pickling to remove any residual stress or scale formation. This is particularly important when welding stainless steel, as it can be sensitive to heat treatment.

Feasibility of Welding Stainless Steel to Mild Steel:

From a technical standpoint, it is possible to weld stainless steel to mild steel. However, it is not always recommended due to the potential compatibility issues mentioned earlier. If the weld joint is exposed to corrosive environments, the stainless steel may become susceptible to corrosion at the weld interface due to the formation of galvanic cells. Additionally, the difference in thermal expansion coefficients can lead to stress and distortion, which can affect the structural integrity of the weld joint.

To mitigate these issues, several approaches can be taken:

- Using a Compatible Welding Wire: Choosing a welding wire that is compatible with both stainless steel and mild steel can help ensure a strong and corrosion-resistant weld joint.

- Using a Transition Metal: Inserting a transition metal between the stainless steel and mild steel can help improve compatibility and prevent the formation of brittle intermetallic compounds.

- Careful Preparation and Execution: Ensuring clean and properly prepared surfaces, using the correct welding parameters, and exercising careful technique during the welding process can help produce a higher-quality weld joint.

Conclusion

In summary, while it is technically possible to weld stainless steel to mild steel, it is not always advisable due to the potential compatibility issues and the resulting corrosion and structural concerns. If such a weld is necessary, it is crucial to take into account the specific materials involved, the welding techniques and materials to be used, and the requirements of the end application. Following best practices and using compatible materials can help ensure a strong and durable weld joint that meets the necessary performance criteria.

Thank you for reading our article and we hope it can help you to find the answer to the question – Can you weld stainless steel to mild steel? If you are looking for stainless steel suppliers online now, we would advise you to contact Sino Stainless Steel.

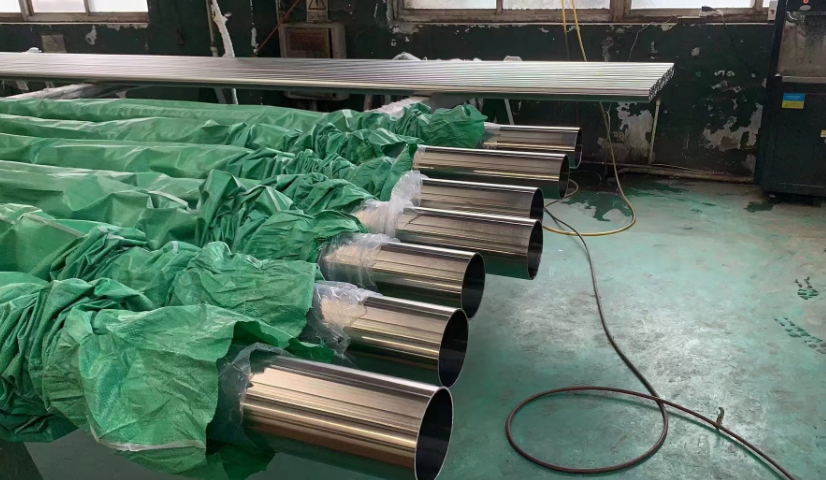

As a leading supplier of stainless steel products from Shanghai, China, Sino Stainless Steel provides customers with high-quality stainless steel pipes, stainless steel strips, stainless steel coils, stainless steel plates, stainless steel sheets, stainless steel bars, and stainless steel tubes at an extremely competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

(–)-Epicatechin has been shown, by a number of studies, to increase capillary

and mitochondrial density, decrease myostatin expression and improve follistatin expression in people

(12, 24). The results of this research revealed an inhibitory

effect of (–)-epicatechin supplementation on improvement of peak relative aerobic

power and mitochondrial density as determined by skeletal muscle SDH

protein content material in response to cycle coaching.

These observations were observed despite equal will increase

in peak power obtained through the peak oxygen consumption take a look at.

The PLA group elevated relative peak VO2 by a median of 7.four ± 5.7 ml/kg/min whereas the EPI group only elevated by an average of 2.0 ± four.4 ml/kg/min.

While myostatin inhibitors like peptides and SARMs are gaining reputation, you can also

decrease your myostatin ranges naturally by way of meals and supplements.

And whereas the proof is both anecdotal or comes from animal fashions, these pure options are nonetheless an excellent place to start.

Myostatin, also referred to as development differentiation factor 8 (GDF-8), is a

member of the TGF-beta superfamily. While that feels like the other

of what you’re in search of in your health

story, myostatin really performs an important role in sustaining muscle

homeostasis and preventing uncontrolled development.

As discussed above, in the course of the activations of various

signaling processes, and thus, the activations of atrophic genes,

MSTN interacts with a massive number of completely different proteins, which supplies clues

for the design of peptide inhibitors of MSTN. MSCs divide symmetrically to increase their quantity, or asymmetrically to

supply cohorts of dedicated satellite cells and consequently progenitors after they

have been activated. Myogenic progenitors multiply and ultimately differentiate by

fusing with different myogenic progenitors or injured fibers to have the ability to restore

fiber integrity and performance (Dumont et al., 2015; Dueweke et al., 2017).

SM consists of muscle fiber with a unique construction, which

primarily consists of actin and myosin filaments that

permit muscle tissue to contract and loosen up.

Each muscle fiber represents a muscle cell, which

has a elementary cellular unit often identified as the sarcomere.

Fascicules are formed by bundles of myofibers, and muscle tissue

is fashioned by bundles of fascicles, with every layer being

contained by the ECM and maintained by cytoskeletal networks (Lieber and Friden, 2000).

It’s not well elucidated in the research I’ve discovered but there might be probably a feedback loop that

prevents too much myostatin inhibition to occur, whether its by way of receptor saturation or some

rate-limiting step in the reaction chain that we’re not absolutely aware of yet.

Age-related muscle loss, aka Sarcopenia, might also be attributed to myostatin exercise.

Myostatin obviously has a essential operate with

respect to muscle growth and regulation thereof. Most bio-chemical processes within the body have countering processes which form cycles to ensure there

aren’t any runaway reactions. One method people think they’ll inhibit myostatin is thru “gene doping,” the place human DNA is immediately altered to develop muscle extra simply.

This is usually done in secret as a result of its worldwide ban, since “gene doping” may have severe well being

consequences we all know nothing about [40].

Designing peptide inhibitors concentrating on PPIs is challenging as a outcome of large sizes of PPIs.

Nonetheless, substantial progress has been reported within the subject of PPI inhibitor design during the previous couple of years

(Jones and Thornton, 1996; Lu et al., 2020; Valtonen et al., 2020).

The use of self-derived peptide inhibitors has been one of the most profitable PPI inhibitor design strategies.

This strategy involves deriving inhibitory peptides from PPIs that

act by inhibiting their cognate interactions. The use of self-inhibitory peptides has attracted a lot interest as a means

of inhibiting PPIs that are thought-about important therapeutic targets (Vlieghe

et al., 2010). MSTN activity can additionally be inhibited by

disrupting the interaction between MSTN and its receptor.

Unlike steroids, the advantages of epicatechin on muscle

growth are far more refined and work with the

body’s natural systems that support blood flow and pure muscle building.

FMOD suppresses muscle growing older by negatively regulating the MSTN gene or lowering the motion of MSTN protein, while MSTN promotes muscle getting older by

positively regulating the expressions of the Atrogin1, CD36, and PPAR genes in muscle tissues (Lee et al., 2021a).

In vivo research have reported that the overexpression of

this glycoprotein has hypertrophic results on mouse muscular

tissues much like these noticed in MSTN null mice (Winbanks et al., 2012).

Moreover, a homozygous mutation in the FST gene reduces muscle mass, which suggests

it performs an necessary role in the regulation of myogenesis (Lee et al., 2010; Liu et al.,

2021).

Ever since its discovery, intensive analysis has been carried out to suppress the exercise of MSTN using soluble activin sort IIB (sACVRIIB) receptors, peptides or propeptides, small molecules, neutralizing antibodies, or MIPs

(Table 1). Primarily Based in Canada, Katrina is an experienced content material author and

editor specializing in well being and wellness. With a journalistic approach,

she’s crafted over 900,000 words on supplements, striving to debunk myths and foster a holistic approach to healthi…

Though epicatechin and quercetin are thought-about

safe supplements, don’t go all in with out doing your personal research.

If you’re on medications or have a well being situation, this implies talking together with your healthcare professional to make sure it is acceptable for your

fitness aims. By doing this, you also can make more informed decisions, maximizing your efforts whereas safeguarding your

well being.

Curcumin significantly hinders proteolytic routes, including the

calcium-dependent calpain, and cathepsin L path, suggesting that curcumin may impede a number of

proteolytic processes by way of its quick impact on muscle catabolism

[207]. The sophisticated situation of the sufferers

assessed in the subsequent trial appears to be a confounding

variable, attributed to insufficient bioavailability and quick metabolism [202].

It is essential to note that extrapolating the correct curcumin dosage for people

from mouse analysis has proven difficult.

SRK-015, lately designed by Scholar Rock for the therapy

of SMA, is a monoclonal antibody that inhibits the activation of myostatin.

In vivo, SRK-015 analogs effectively improved muscle mass

and performance in mouse models of SMA [69] and prevented muscle atrophy induced

by dexamethasone therapy [68]. SRK-015 is presently being investigated in a section 2 medical trial in patients with SMA.

Theoretically, decrease myostatin levels will permit muscle cells to distinguish and proliferate at a larger price.

Research has certainly discovered an inverse correlation between circulating myostatin ranges and

lean muscle mass [16]; in different words,

people with decrease myostatin levels tend to have more muscle mass and vice versa.

Apparently, myostatin expression will increase rapidly after skeletal

muscle disuse (e.g. being on bed rest for several consecutive days) [17].

Focusing On this method could operate as an area for developing medicine in cachexia remedy and

antagonism of melanocortin receptors can present a therapeutic strategy for

inflammation-mediated cachexia in CKD. It has been reported that central blockade of MC4-R may reduce uremic

cachexia in experimental animals [11, 21]. The administration of agouti-related peptide (AgRP)- an MC4-R antagonist- in mice with CKD, led to the augmentation of meals intake, regulation of basal metabolic price, as properly as the enhancement of total body weight and

lean physique mass. Therefore, AgRP administration improves uremic cachexia with out dietary effects

by involving muscle mass modulation through myostatin and IGF-I balance [9].

Muscle mass increases by IGF-I whereas myostatin inhibits muscle mass growth [146].

Cheung and coworkers assessed the protecting effect of pegylated leptin receptor antagonist (PLA)

in cachectic mice with CKD. Their results

indicated that PLA treatment (7 mg/kg per day) might

improve urge for food, weight achieve, lean mass as nicely as muscle operate,

along with lowering power expenditure, and recovering hepatic levels of TNF-α and IL-6 mRNA.

Epicatechin has quite a few advantages for the physique, and it’s understandable

that you’d want some of these, however you can’t simply binge on chocolate everyday hoping that

you’re getting enough of the compound. That’s why we

did the leg give you the outcomes you want and reviewed a few of the

greatest dietary supplements containing it. Bodybuilders aiming to develop big muscles can supplement their

high-intensity workouts and diet with follistatin 344 to hurry up the process.

The samples had been then centrifuged at 3000 rpm for 10 min at 4 °C to gather the

supernatant. The ranges of the neurotransmitters acetylcholine (ACh), glutamate (Glu), gamma-aminobutyric acid (GABA), and serotonin (5-HT), which are related to fatigue,

had been measured utilizing ELISA following the manufacturer’s directions.

The absorbance at 550 nm and 340 nm was measured using a spectrophotometer or microplate reader.

The kits used on this examine were evaluated for consistency of efficiency throughout completely different batches of kits by recovery checks with recoveries starting from 90%-110% and calibrated by standards.

The equipment used had a measurement accuracy

of zero.01% and was calibrated before each experiment. Ltd.

(Wuhan, China), and cultured in DMEM supplemented with 10% FBS and 1% penicillin/streptomycin (Cell-specific

DMEM; Procell, Wuhan, China) in an incubator at

37 °C with 5% CO2.

The key characteristic of cachexia is a weight lack

of more than 5% in the previous 12 months or a BMI (body mass index) of lower than twenty kg/m2.

However, within the case of CKD, as a result of an inclination for elevated physique weight in affected sufferers,

detecting low BMI wouldn’t be a great choice resulting in a late analysis, despite the actual fact that it is a valid and

delicate method to regulate cachexia [13, 17]. In protein–protein docking, the energy of interaction between two proteins

is measured by means of world power with a excessive

(negative) world power worth thought of because the interplay

efficiency of a protein with its receptor [18,30]. In this study, MSTN interacted with ACVRIIB with a worldwide power of −61.sixty three, whereas MSTN–MIF1 and MSTN–MIF2 interacted with world energies of −59.69 and −53.91, respectively.

These variations between global energies indicate that MIF1 and MIF2 weakened MSTN–ACVRIIB binding.

This flavonoid is synthesized within the human guts after consumption of meals rich in ellagitannins (like

pomegranate, Punica Granatum) and is a powerful anabolic

that stimulates muscle progress whereas concurrently stopping muscle breakdown. Though no

human trials have confirmed these outcomes, animal-based studies counsel that

follistatin can cut back the life and progress of most cancers cells and decrease the probabilities of metastasis (4).

However, in males, greater ranges of follicle-stimulating hormone (FSH) restrict

muscle development and trigger abnormal testicle functioning.

Unbound Epicatechin is called a muscle amplifying agent as a

end result of this complement will assist enhance your overall muscle development.

The serum from the remaining separation tube was separated, labeled,

and stored in micro centrifuge tubes at -80°C for later evaluation. Following completion of the study,

samples were analyzed for energetic testosterone, free testosterone, and cortisol with an enzyme immunoassay (EIA) assays using Goat-Anti-rabbit IgG (GARG) coated microplates.

Assays had been performed using a Jitterbug microplate shaker (Boekel Scientific-Philadelphia, PA) and a Tricontinent Multiwash Benefit microplate washer

(Grass Valley, CA).

Upon reaching 80% confluence, the cells have been switched

to DMEM containing 2% horse serum to provoke differentiation for 4 days, with the medium being refreshed

every different day. After finishing rigorous exercise,

we measured LG levels within the liver and MG ranges within the gastrocnemius muscle.

Additionally, we measured the LA, CK, LDH, BUN, SOD, and MDA levels in the

serum utilizing the specified kits, following the manufacturer’s instructions.

Hippocampal tissue homogenates were rapidly prepared

in an ice tub and centrifuged at 12,000 rpm for 10 min at four °C to gather the supernatant.

Literature on human studies utilizing high-flavanol cocoa indicate that Epi-rich preparations

could be administered safely over extended

intervals [15]. Moreover, medical research utilizing pure Epi

(oral doses of 1-2 mg/kg) have not reported opposed results

[16]. Huttermann et al additionally just lately reported that after the withdrawal of Epi (1 mg/Kg BID) animals retain the stimulatory effect on exercise

capability 14 days after remedy whereas exercise conditioned animals failed to take action [18].

In this study, we utilized classical forced treadmill training to create a mouse model of train fatigue, which concerned 6 days

of compelled excessive exercise.

EAA elevated muscle high quality (e.g., grip energy and

maximal carrying load) without corresponding changes in markers of

mitochondrial biogenesis and neuromuscular junction stability.

In conclusion, RT amplifies muscle mass and power through modifications in muscle protein turnover

at the facet of adjustments in implicated signaling,

whereas EAAs enhance muscle quality by way of unknown mechanisms.

Beige and brown adipocytes exist in WAT, contributing to the entire body’s vitality

expenditure. Totally Different stimuli (i.e. advanced hormonal interplay and quite a few environmental factors) lead to WAT browning.

Vitamin D can be stored in adipose tissue; thus its insufficiency might contribute to

aberrant adipogenesis.

Preliminary results from a research only out there in abstract type [18] evaluated the results

of 5-methyl-7-methoxyisoflavone supplementation (800

mg/day for 8-weeks) on coaching diversifications in 14 resistance-trained men. Inclendon et al[18] reported 5-methyl-7-methoxyisoflavone supplementation didn’t significantly affect modifications in body weight, body mass index, bone mineral content

material, or isokinetic peak force between teams. Nevertheless, DEXA decided FFM elevated by 1.three

kg within the methoxyisoflavone group while being unchanged (0.1 kg) in the placebo group leading to a major discount in physique fats

p.c. Results of the current research do not assist the purported ergogenic worth of 5-methyl-7-methoxyisoflavone supplementation in resistance-trained males.

Though MSTN isn’t highly expressed in adipose tissue, it

performs a significant function in mediating adipose tissue

perform. Metabolically, MSTN-null mice present increased energy expenditure and leptin sensitivity [137].

Inhibition of MSTN upregulates enzymes concerned in lipolysis and mitochondrial fatty acid oxidation, growing fat breakdown in peripheral tissues, and lowering lipid accumulation [138].

In vitro studies have proven that like FST, FLRG binds to activin and BMPs to inhibit

their biological actions (Tsuchida et al., 2001). Furthermore, endogenous latent MSTN advanced largely circulates in association with propeptide and FLRG, which both act independently as unfavorable regulators

of MSTN, most likely by stopping MSTN binding

to its receptor (Thies et al., 2001). Reviews suggest that

FLRG potently inhibits MSTN activity in a concentration-dependent manner (Hill et al., 2002).

In healthy older males, decrease serum MSTN ranges have been linked to lower SM mass, but not

in ladies (Peng et al., 2018). It can additionally be evident that serum MSTN does not differ in younger

and sarcopenic aged males (Ratkevicius et al., 2011).

Topics had been requested to maintain their regular diet all through the research and were not allowed to ingest any dietary complement that contained probably ergogenic vitamins.

Nonetheless, topics have been permitted to ingest energy-based sports activities drinks,

power bars, and protein powders provided that

they did not comprise any ergogenic nutrients.

The cause for this was that many resistance-trained athletes ingest these

energy-based supplements as a method to maintain their recommended dietary intake

of energy.

As a personal coach and writer, Terry loves changing lives via teaching and the written word.

In Kinesiology and is an ACSM Certified Private Coach and ISSA Certified Strength and Conditioning Specialist.

He enjoys enjoying music, reading, and watching films when he’s not writing or training.

Here’s a complete guide on the means to carry out the scapular wall slide.

Extra persistent cases could require corticosteroid injections, shoulder manipulation, or surgical procedure.

If conservative measures are ineffective, you may want surgical procedure to drain or take away the affected bursa.

In these cases, there’s no underlying situation or ache that’s related to your shoulder cracking.

You would possibly hear a grinding or popping sound if you attempt to use your shoulder for any cause.

Find out what happens during surgery and all concerning the rehab and restoration process within the subacromial decompression section.

The cable shrug is a variation of the shoulder shrug and one of

many finest higher trap cable workouts to build the higher back’s

trapezius muscle. It is sensible for developing unilateral upper-body power and enhancing your balance and the power and stability

of your core. You can do that exercise using one

arm at a time, allowing you to change the vary of movement by adjusting the start

or end position.

Over time, the repetitive pressure in your shoulder joints, tendons, and muscular tissues can result in inflammation and ache.

This is very common whenever you push your self to lift heavy weights without allowing your physique adequate time to recuperate.

When it comes to constructing impressive upper physique power

and aesthetics, few muscle groups make as much of an influence as the shoulders.

Strong, well-developed shoulders not solely create the coveted “V-taper” look but also support functional actions in sports,

lifting, and day by day actions. The shoulders are complex, consisting of three primary heads—anterior (front),

medial (side), and posterior (rear) deltoids—each requiring targeted exercises

for balanced improvement.

Also, keep in thoughts that you hit your anterior and posterior deltoids together with

your again and chest, so it’s essential to emphasize lateral

delt workout routines in your coaching. Clients have completely different experiences with the

cargo straps’ lift capability. Some find them easy to use and efficient for lifting heavy objects

with legs instead of arms. Nonetheless, others report issues the place the straps do not lock correctly, requiring the use of forearms to carry heavy furnishings or fridges.

Focus on performing the increase in a clean, managed movement, bracing your core to prevent any momentum

from serving to to ‘swing’ the weight up. Focus on main together with your

elbow and bringing your arms parallel together with your

shoulders. With many shoulder accidents referring to the rotator

cuff, it is essential to incorporate shoulder workout routines that focus on these smaller muscles to reduce back the danger of damage.

Furthermore, it could possibly also result in injuries within the pectoralis major tendon. The most common way people experience damage is in the course of the contraction portion of the movement.

To give your deltoids extra definition, purpose for a

moderate load rep range for at least half of your sets per week.

The remaining half must be divided between mild and heavy weights.

For your entrance and rear delts, purpose for between 4 and 12 units per week.

The T-bar row primarily targets the muscular tissues

of the upper again, together with the latissimus dorsi, rhomboids,

and traps.

If the bursa becomes inflamed, you might really feel

a painful stabbing or heat. You might also hear a “pop”

when you try to transfer your arms in any direction. You can find out more

concerning the causes, symptoms, diagnosis and treatment

options in the Brachial Neuritis part. You can find out more about the causes, symptoms,

analysis and remedy options in the Arm Nerve Ache part.

Nerves carry indicators to and from the brain/spinal cord to muscular

tissues regarding motion and sensation. Any

irritation to a nerve, similar to pinching or inflammation can have an result on the signal transmission or over sensitize

the nerve.

The leaning position maximizes the isolation of the shoulders all through the movement.

They are appropriate for both newbies and execs as a result of they are often performed with varied weights.

It can additionally be popular amongst athletes and

power trainers for its capability to develop explosive power, coordination, and

power. The Barbell Z Press is a challenging and effective shoulder exercise that strongman Zydrunas Savickas popularized, hence the name “Z Press. In different words, this variation requires less effort to stabilize body place in the course of the row because the chest is supported on the bench.

The shoulder and arm exercise is intended for intermediate to superior lifters. They find them sturdy and well-made, appropriate for shifting heavy objects like entrance load washers. The straps are thick and simple to make use of, with strong stitching that should last a long time. They work well for shifting dressers and smaller objects, with shoulder harnesses.

Bent over flyes are good for dumbbell shoulder exercises focusing on the rhomboid muscular tissues in your higher again and shoulder region. Upright rows are a great barbell shoulder exercise for focusing on the shoulders and higher back, primarily the traps and the deltoids. Research has proven that the staple transfer of old-school muscle-building applications just like the Blueprint to Mass hits both the entrance and medial delts more than different dumbbell press variations.

Neer’s impingement sign is elicited when the affected person’s rotator cuff tendons are pinched underneath the coracoacromial arch. The test4 is performed by inserting the arm in compelled flexion with the arm absolutely pronated (Figure 5). The scapula ought to be stabilized through the maneuver to forestall scapulothoracic movement.

Orthopedic surgeons typically discourage lifting over 25 kilos post-surgery to stop problems. Adhering to guidance from skilled shoulder surgeons and bodily therapists is key to a secure recovery. Consulting experienced shoulder surgeons and bodily therapists ensures tailored recommendation and helps forestall potential issues.

Shrugs construct your trapezius, a large muscle that runs from the bottom of your neck, throughout your shoulders, and right down to the center of your back. Well-developed traps enhance the look of your back and your delts, making the shrug a vital exercise for StrengthLog’s again and shoulder exercise. It’s the best exercise to target your traps directly, and you can perform it using either a barbell or a pair of dumbbells. Second, hold your movement to make your shoulder muscle tissue robust and secure. Postural exercises sometimes require you to carry your movements which can assist cut back shoulder ache. Furthermore, postural exercises contain strengthening the higher back muscles and stretching chest muscle tissue, which will enhance posture, so it won’t hurt as a lot in your shoulders. The shoulder workouts you are capable of do with no gear primarily encompass body-weight workout routines.

One of the biggest issues individuals have with overhead work for each pressing and pulling is a scarcity of shoulder stability. Our trade likes to pressure feed mobility fixes for stability issues, however the one place that gets athletes and lifters is chronically injured. Inherently, this recruits the forearms muscle tissue and the little shoulder stabilizer muscular tissues to turn on and fire as nicely.

Since most upper-body actions contain your shoulders in some way or another, you only need to do one unique shoulders exercise per week. Instead, you would incorporate some shoulder exercises (like those under, which are perfect for fitness center or at-home shoulder workouts) into your total-body exercises. If you want to build a bigger and stronger rear delt, you should add bent-over lateral raises to your shoulder workout routine.

Under are five alternative shoulder workouts to body weight workouts you could carry out with health club equipment. The following ten body weight workouts target and engage your shoulder muscle tissue, serving to you construct energy and improve overall shoulder perform. The anterior deltoid head sits on the front of your shoulder joint and inserts onto the clavicle.

Unfortunately, while jacked shoulders are a objective for many, plenty of lifters wrestle to truly construct fully developed delts. The barbell lying triceps extension stands out as an incredibly efficient train for creating super triceps. It presents the advantage of permitting you to handle heavy weights while positioning your upper arms in a fashion that optimally activates all three heads of the triceps. It’s an effective way to kick off your triceps session in this shoulder and arm workout. One of the best remedies for shoulder pain is relaxation, which supplies the shoulder time to heal and prevents re-injury.

Usually, we recommend doing a number of good workout routines per muscle group. But within the case of the shoulder muscle tissue, we’re basically looking at three completely different muscular tissues in one. With the front and side delts taken care of, it’s time to turn our consideration to the rear delts. Moving back to a compound train, the behind-the-neck press is a variation of the usual overhead press. The push press is a variation of the overhead press, where you utilize your legs to assist push the bar up. However it’s also just as essential to attempt to elicit a training impact; treating people like delicate flowers always hardly ever works. Particularly in relation to overhead motion, it’s all I can do to keep my corneas from leaping out my eye sockets.

Patients who have undergone minimally invasive surgery sometimes undergo a physical therapy program of 12 weeks. After this, they’re usually able to doing upper-body exercises like push-ups, shoulder flies and presses utilizing gentle weights. In the case the place a affected person underwent revision surgery, the recovery timeline could differ. It is essential to note that some patients underwent revision surgical procedure, which could additionally affect their recovery course of. Consistency in performing rehabilitative exercises is essential to prevent stiffness and manage pain successfully. By following a structured physical remedy program, patients can obtain useful enchancment and put together their shoulders for extra demanding weightlifting actions. Workout Routines similar to scapula retraction and elbow vary of motion are useful for strengthening surrounding muscular tissues and improving restoration.

Rear deltoid workout routines are key to any shoulder workout routine because they aim the muscular tissues behind the shoulder. The rear delts allow shoulder extension and horizontal abduction, making them liable for pulling movements and retraction of the shoulder blades in each train and every day life. Rear deltoid exercises consist of motions that specifically target these muscle tissue, together with however not restricted to reverse flyes, face pulls, and rear deltoid raises. Cable shoulder workouts are a class of resistance training exercises that use cable machines to coach the shoulder muscle tissue. Cable workout routines generally allow for a larger vary of movement than conventional free weights. The workout is consequently useful for building strength and dimension within the shoulder muscles, such because the deltoid, rotator cuff, trapezius, and rhomboids. Cable shoulder workouts involve a wide range of movements to focus on the muscle tissue of the shoulder.

It is recommended to consult together with your orthopedic surgeon and bodily therapist to establish a secure weight limit and restoration plan. Correct kind, utilizing lighter weights, and relaxation intervals between sets are important to forestall re-injury during weightlifting. Following advice from shoulder surgeons and bodily therapists ensures that the recovery process stays on observe and optimal outcomes are achieved. Monitoring progress after shoulder substitute includes patient-specific timelines and adjustable rehabilitation plans.

If we can find a method to do upright rows in a method that feels good, that space should develop extra strong. The overhead press is the big compound carry that’s dedicated to bulking up the fronts and sides of our shoulders, together with our higher chests, upper traps, and serratus anterior muscles. The good news about lateral raises is that they’re straightforward to arrange, straightforward to do, straightforward on our shoulder joints, and straightforward to recover from. This makes them a fantastic raise for newbies and a great raise for folks with cranky shoulders. A higher approach is to easily just make sure you can even really feel your aspect delts working.

There are several variations of each raise, and every has some nuance to it. Moreover, the shoulders are a difficult joint, and never everybody will have the power to perform all three actions with out aggravating their shoulders (i.e. shoulder impingement). Right Here are some simple shoulder workouts that you are capable of do to strengthen your shoulder muscles and forestall accidents. The heavier the weights, the extra secure your shoulders need to be — so give them some further attention. Sure, scapular wall slides help posture by strengthening the back and shoulders, targeting the traps and rhomboids.

The conventional deadlift is usually seen because the extra intuitive alternative

for novices. The sumo deadlift can be a great possibility for people who wish

to minimize decrease again involvement. This variation locations a powerful emphasis on hinging at the hips, which engages the entire bottom

of your body. This form starts with a big hip hinge, which

locations lots of rigidity on the hamstrings. On the opposite hand,

the traditional deadlift requires greater hamstring flexibility.

In this setup, the shorter torso allows

for a pure ahead lean without excessive pressure, while the longer arms

assist keep a good leverage, lowering the gap the bar has to

travel.

Although the Squat is undoubtedly the king of lifts

for building the lower-body energy needed to excel

on the football field, the Deadlift is another integral

piece of the strength and conditioning puzzle. Typical Deadlifts, where the toes are shoulder-width aside and the hands are

positioned exterior the legs, are inclined to rule the weight room.

There is nothing inherently incorrect with this kind of exercise, however the Sumo

Deadlift is a safer and better approach to construct the

muscle tissue wanted for football.

Fully extend your knees to reset the stress to your hips,

and then push your knees out exhausting as you drive your hips forward into the

bar. This movement should flex your entire decrease physique out

of your glutes down through your whole legs in order that every little thing is tight, and nothing is unfastened or relaxed.

Find the most effective place for you, and when you have

hip mobility problems you must attempt to enhance them before each coaching session. Any pulling

movement involves the biceps and forearms

plus you naturally start to improve your grip power by pulling heavyweight.

The athlete will assume a position over the med ball, hinge on the waist,

forcefully raise the ball, drive the hips, and lifting with the arms,

throw the med ball as high into the air as potential.

Some lifters may change which grips they mix (right-supinated, left pronated

and vice versa) but this might be exhausting to trace after lots of of reps

and sets over the course of a lifter’s career.

Choosing the best variation is determined by your particular person wants, targets, and physical limitations.

By understanding the nuances of each train and exploring different variations, you can find the perfect deadlift

for your health journey. I wouldn’t advocate squatting in deadlift

slippers if you have poor ankle mobility, as they have very flat,

thin rubber soles that gained’t help your ankles or improve your squat depth.

Nonetheless, when you have an excellent ankle range

of movement, you could possibly wear deadlift slippers with a rubber backside for grip for typical squats while sustaining good kind.

Bear In Mind to keep up control throughout the whole movement and avoid any jerky or fast motions.

Focus on partaking the focused muscle teams to maximize

the effectiveness of the sumo squat. It’s important to hold up a impartial spine all through the movement and avoid rounding your again. Utilizing the right approach ensures

that you just have interaction the best muscular tissues and keep away

from pointless strain in your joints.

Usually, we suggest exploring what failure seems like, but because any

deadlift variation will be heavy and involve your backbone, it’s not the best thought for beginners to do that.

Err on the aspect of lifting too mild, and if it’s too light, count it as a warm-up.

Maintain working up, and you’ll know when the burden is

right for your goal reps. In the sumo deadlift, the feet are positioned wider aside, and the arms grip

the bar contained in the knees. This stance reduces the

ROM and shifts the emphasis towards the quadriceps and glutes.

The torso stays extra upright, decreasing the pressure on the decrease again and

making it a more quad-dominant movement.

According to Cholewicki et al. (1991), the standard deadlift results in greater spinal

extension torque, growing the workload on the lower back.

By strengthening the glutes, you can improve your power in the final phase of

the lift. Make positive you are spacing out heavy deadlift

sessions with at least seventy two hours of recovery time, notably if

you’re alternating between variations throughout the identical week.

A widespread mistake is allowing the knees to collapse inward

during the carry, which not solely reduces the effectivity of the lift

however also can put a big pressure on the knee joints, increasing the likelihood of damage.

You might want to take time to experiment/play around with each of those changes and any kind of combination of them to find a

way to discover what works/feels finest for you. Pain that is perceived as aching or

tender, especially over areas that have more muscle tissue are typically

the end result of unhealthy tendons or overly tight

muscular tissues. This locations about 10% less pressure on the lower again because of a more upright

torso position. There are three crucial classes you need

to target with the Sumo Deadlift. That’s just an average, however it can help you choose the right weight.

Additionally, thoracic mobility workout routines like cat-cow stretches might help maintain your upper spine cell, which is vital for

achieving proper positioning in both variations. In contrast,

the conventional deadlift aligns nicely with back coaching,

given its emphasis on the spinal erectors, traps,

and total posterior chain. The human body is highly adaptive; when you carry out the identical workout routines repeatedly,

your muscular tissues may turn into accustomed to the motion, which can lead to stagnation.

For the sumo deadlift, sustaining proper knee alignment is essential,

yet typically ignored. Beginners have a tendency to grasp the mechanics of the standard deadlift more rapidly, as it requires fewer changes by method of foot

positioning and is much less depending on hip flexibility.

The sumo deadlift is popular among many powerlifters because of its mechanical benefit.

70918248