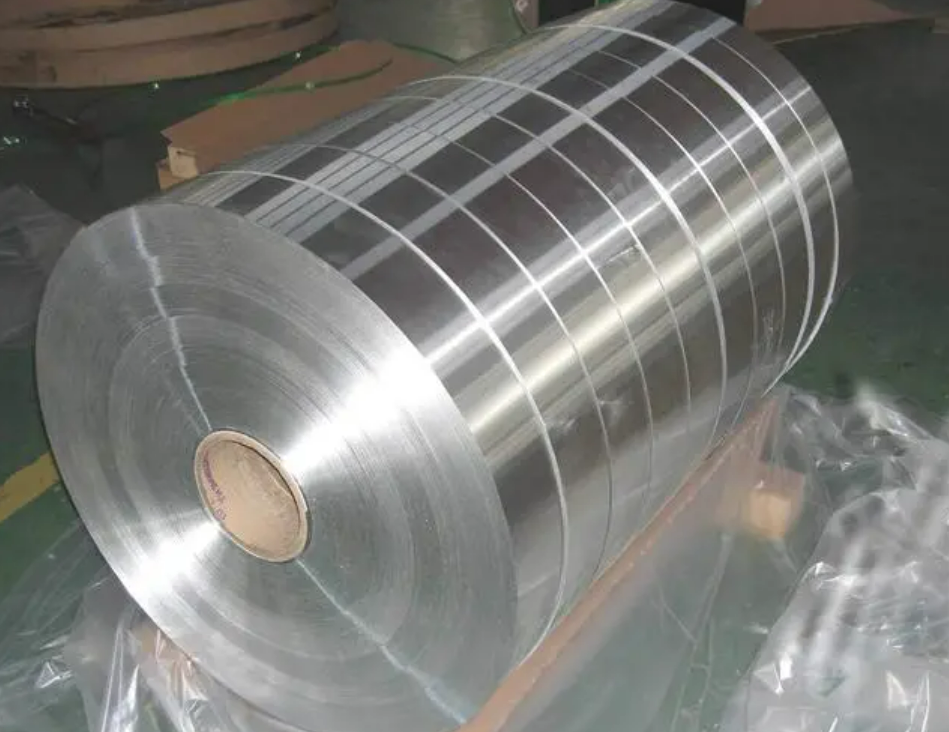

With the rapid development and transformation of communication, electronic, and office automation equipment, user requirements for stainless steel strips are becoming increasingly stringent. Unlike conventional stainless steel sheets, precision stainless steel strips typically refer to strips with a thickness of less than 0.3mm. As a high-end product in the field of stainless steel strips, precision stainless steel strips have excellent strength, precision, surface roughness, and other properties, and are widely used in electronic stamping parts, optical cables, diamond blades, light-blocking materials, and the like. In this post, we’ll take a close look at the manufacturing process and features of the cold-rolled precision stainless steel strip.

Currently, the main production processes for precision stainless steel strips include cold rolling, bright annealing, and finishing.

Precision Stainless Steel Strip Rolling Process

The performance requirements of precision stainless steel strips for extreme thinness, high strength, and high precision place high demands on the rolling process. Conventional rolling processes cannot meet the production of precision stainless steel strips.

Currently, the 20-roll rolling machine is mainly used to produce precision stainless steel strips, and its complete production process includes cold rolling, annealing, and finishing. In the rolling process, attention should be paid to selecting an appropriate reduction system, tension system, speed system, and roll shape. To improve the production capacity of the rolling mill, while fully utilizing the main drive power of the rolling mill and the front and rear coilers, it is necessary to maximize the reduction rate in each pass to reduce the number of rolling passes.

Tension can reduce rolling pressure, improve plate shape, and stabilize the rolling process. The rolling process of a 20-high mill generally uses high tension and should be adjusted according to the plate shape at any time. When there are waves in the middle of the material, the tension should be reduced to prevent pulling the edge or breaking the strip. When the strip produces side waves, the tension can be appropriately increased.

Within the speed range allowed by the mill, the highest possible rolling speed should be adopted to improve the production capacity of the mill. At the same time, when the rolling speed increases, the rolling pressure decreases accordingly. During the first pass of rolling, a lower rolling speed is generally used.

Cold Rolling Equipment

Based on the rolling principle, the maximum pressure condition should use the work rolls with the smallest possible diameter, and to achieve this goal, multi-roll rolling mills such as 6-roll, 12-roll, and 20-roll rolling mills have been developed. Among them, the 20-roll rolling mill is the preferred equipment for producing precision stainless steel strips due to its high rigidity and small elastic flexural deformation of the work rolls.

Thickness and Shape Control

To maintain good consistency in the thickness of the rolled strip and eliminate the influence of the incoming material thickness, the most reliable method is to add feedforward control to the traditional control mode. Based on the measured change in strip thickness, the delay controller adjusts the roll gap to ensure that the final rolled strip thickness remains constant.

In the AGC control system of traditional roller mills, product thickness accuracy is achieved by repeated calculations by the feedback system. In modern AGC control systems, based on trigonometric principles and automatic roller management systems, geometric calculations of the roller system are solved, as well as position setting.

In modern roller mills, AGC control calculates the set position of the support roller eccentric wheel based on the actual size of the working roller to keep the working roller at zero position. This method avoids accidents caused by reverse adjustment during manual adjustment.

In terms of shape control, a series of advanced shape-control technologies have been developed internationally in the past 20 years. By using certain roll profiles with bending, shifting, and other technologies, the increasingly stringent requirements of users for shape quality accuracy have been met. Two shape measurement rolls are installed at the inlet and outlet of the rolling mill, and numerous pressure sensors are installed along the axial direction of the shape measurement rolls.

The strip is pressed on the shape measurement rolls during the rolling process, so the output signal of the pressure sensors in the shape measurement rolls changes with the strip shape. These signals are comprehensively processed by the shape control system and then act on the hydraulic valve, and the movement of the hydraulic valve adjusts the support roller eccentric slightly. At the same time, these signals also control the transverse movement of the first intermediate roll, so that the strip shape is effectively controlled.

Tension Control

The tension control system of the 20-roll rolling mill adopts a mixed control method of indirect tension and direct tension. When the steel strip is engaged by the coiler tongs and enters the coiler, the indirect tension control is carried out by the speed control system, which is a three-loop speed/current/voltage control system.

As the low-speed creeping speed of the coiler is generally 5%-10% higher than the creeping speed of the main rolling mill, the steel strip is quickly tensioned. When the tension value reaches 70%-80% of the set value, the system automatically switches to direct tension control, and the tension regulator is put into operation to achieve three-loop control of tension, current, and voltage.

Roll Shape Adjustment Mechanism

The roll shape adjustment mechanism of the 20-roll rolling mill includes AS-U convexity adjustment for the support roll, a movable intermediate roll with a conical end. The AS-U convexity adjustment passes through two intermediate rolls, and the first intermediate roll is transmitted to the working roll. Therefore, this adjustment method has a small influence on the roll shape of the working roll, and can only make a small adjustment to the roll gap, increasing convexity and causing the central part of the strip to extend more, and reducing convexity and causing the edge part of the strip to extend more.

However, for more complex shape defects such as quarter-scale camber, the AS-U convexity adjustment effect is small. The first intermediate roll has a conical end and can be moved axially, effectively eliminating the influence of the working roll end deflection on the strip edge wave. Axial movement of the first intermediate roll not only has a large effect on the edge part of the strip deformation but also has some effect on the central part of the strip extension.

Heat Treatment and Finishing Process

The heat treatment process of precision stainless steel strips is the same as the heat treatment process of ordinary stainless steel plates. The typical heat treatment process for 300 series austenitic stainless steel is solution treatment. In the heating process, the carbides dissolve into the austenite, heated to 1050-1150°C, properly held at a short time, so that the carbides are completely dissolved in the austenite, and then quickly cooled to below 350°C, resulting in a supersaturated solid solution, i.e. uniform one-way austenitic structure. The key to this heat treatment process is rapid cooling, requiring cooling rates of up to 55°C/s, quickly passing through the temperature range of post-solidification of carbides (550-850°C).

The holding time should be as short as possible, otherwise, the grains will become coarse and affect the surface finish. 400 series ferritic stainless steel has a lower heating temperature (around 900°C) and is often slow-cooled to obtain an annealed softened structure. Martensitic stainless steel can also be treated by segmented quenching and tempering.

Another key issue in the heat treatment of cold-rolled stainless steel strips is the requirement for uniform microstructure in both the width and length of the entire strip. The Muffle-type bright annealing furnace uses large-size muffle tubes, and the heating air flows uniformly in a spiral manner from the outside of the muffle tube, ensuring uniform heating of the strip.

To ensure uniform microstructure along the length of the strip, it is necessary to maintain a constant linear velocity of the strip in the heating furnace. Therefore, modern vertical bright heat treatment furnaces are equipped with precision adjustable roller tension adjusting devices at both the inlet and outlet. These devices not only meet the heat treatment speed requirements by adjusting the strip speed at the inlet and outlet, regardless of whether the looping quantity is empty or full but also establish and precisely adjust the small tension of the strip according to its shape condition to meet the requirements for shape control.

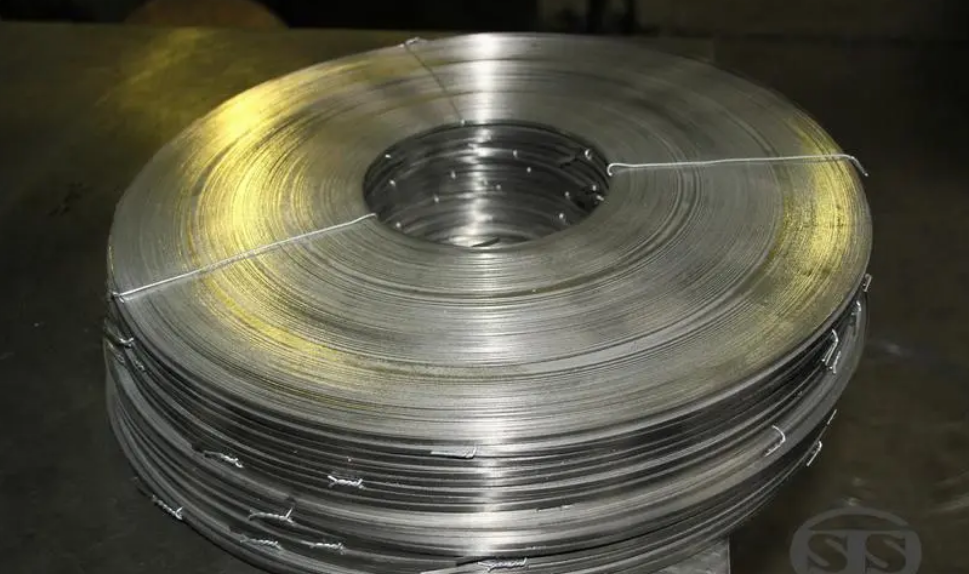

The finishing of precision stainless steel strips mainly includes tension leveling and longitudinal cutting. After annealing, to obtain good shape, machining performance, and deep drawing performance, the strip usually undergoes a stretching and leveling unit, which operates by combining stretching and continuous alternating bending to produce plastic elongation and correction of the strip.

The strip can eliminate defects such as center wave, quarter wave, edge wave, longitudinal bending, and transverse bending through the stretching and leveling process, but the brightness is reduced by 1%. The flatness accuracy of the finished strip after stretching and leveling can reach 1% of the incoming flatness. To trim and slit wide strips into finished narrow strips, longitudinal cutting machines are commonly used.

Nowadays, many new technologies have been developed for longitudinal cutting machines, such as automatic adjustment of the cutting tool insertion and axial clamping, quick change systems for scissors that reduce changeover time by 50% compared to conventional methods, and vacuum technology for safe transportation, automatic cutting of strips, and prevention of any damage to the strip surface.

Cold-rolled Precision Stainless Steel Strip Supplier

Thank you for reading our article and we hope it can help you to have a better understanding of the cold-rolled precision stainless steel strip. If you want to find more information about cold-rolled precision stainless steel strips, we advise you to visit Sino Stainless Steel for more information. As a leading supplier of precision stainless steel strips across the world, Sino Stainless Steel offers high-quality cold-rolled precision stainless steel strips, stainless steel wire, sheets, and embossed stainless steel plates at an extremely competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

deep web links darkmarkets deep web drug url

darknet seiten darknet seiten dark web drug marketplace

darknet market darknet markets 2024 dark web search engines

how to get on dark web tor darknet dark markets

tor dark web dark web search engines deep web links

dark web links drug markets onion deep web markets

tor markets 2024 darkmarket darknet market lists

darkmarkets tor market url dark web sites

dark web markets darknet market bitcoin dark web

dark markets 2024 darkmarkets dark web site

darkmarket tor dark web tor markets links

the dark internet tor darknet deep web drug links

dark market 2024 darknet links tor marketplace

deep web drug links darkmarkets darknet websites

dark web market list darknet drug links dark market onion

tor markets links dark web link deep dark web

dark markets 2024 darknet markets 2024 darkmarkets

dark web search engines dark web access dark web drug marketplace

dark net darknet market lists bitcoin dark web

tor market url dark markets best darknet markets

dark web market tor markets 2024 dark market

dark web market links darkmarket url darkmarket list

tor marketplace dark web access tor markets 2024

dark web market links dark web search engines darkmarket 2024

onion market darknet markets 2024 darknet markets

darknet drug market dark market darknet site

dark web websites dark web markets tor darknet

darknet site bitcoin dark web deep web sites

dark web websites darknet site deep dark web

dark web drug marketplace deep web markets tor markets links

darknet markets dark market darknet drugs

onion market deep web sites dark web market

dark web sites darknet market dark internet

darkmarket link dark web search engines darknet links

tor market links dark market link dark web link

deep web search dark market 2024 dark web drug marketplace

bitcoin dark web dark web markets darknet market links

darkmarket link dark web search engines dark web search engines

dark web sites links dark web market list darknet market list

dark website onion market darknet drugs

dark website dark web sites darknet drug market

dark web links dark web websites dark web drug marketplace

tor market links deep web markets deep web drug url

darkmarket list deep web search dark net

deep web links dark websites deep web search

darknet drug market deep web markets dark market list

free dark web dark web sites dark web market list

free dark web dark net dark web sites

dark net darknet seiten dark web market list

darknet websites blackweb official website tor markets links

tor markets 2024 deep web sites dark market url

dark websites deep web sites dark web market

blackweb official website darknet market lists dark markets 2024

deep web search darkmarkets dark markets 2024

tor markets 2024 tor darknet darknet market list

deep web drug url dark web websites deep web drug url

black internet bitcoin dark web dark web market list

darknet links darknet markets dark web site

onion market dark web sites links deep web drug url

darknet market list tor markets 2024 darknet search engine

the dark internet darknet markets 2024 darknet market list

blackweb official website dark web sites links deep web drug url

dark web search engines deep web drug markets dark market list

blackweb official website bitcoin dark web dark market onion

dark web sites links dark web site dark internet

blackweb official website dark market link how to get on dark web

tor market links drug markets onion darkmarket

deep web drug url tor market links darknet drugs

tor markets 2024 darkmarket url dark internet

darkweb marketplace deep web drug url darkmarket url

darknet markets dark web sites darknet market lists

dark markets 2024 black internet darknet search engine

drug markets dark web dark web market list darknet market lists

darknet drugs tor market url dark web sites links

darknet websites dark web search engine deep web search

dark web site tor darknet dark web access

the dark internet darknet sites deep web sites

tor market links how to access dark web darknet drugs

best darknet markets darknet market links dark web search engines

deep web links tor markets tor market links

dark markets 2024 free dark web drug markets onion

darkmarket 2024 dark websites darkweb marketplace

dark web site dark web search engine darknet marketplace

dark web site darknet market list dark websites

free dark web darknet markets 2024 how to access dark web

dark web site dark web search engines darkmarket url

deep web drug links darknet seiten dark web site

dark web markets darkmarkets drug markets onion

dark market 2024 darkmarket list black internet

how to access dark web darkmarket deep dark web

deep dark web blackweb free dark web

darkmarket 2024 dark market onion dark web drug marketplace

black internet darknet markets dark market 2024

darknet links darknet market list dark web link

darknet market list the dark internet tor market

drug markets onion tor marketplace deep dark web

darkmarket onion market darknet marketplace

darknet drug links darkmarkets darknet market list

how to get on dark web dark websites darkmarkets

darknet market list best darknet markets darknet marketplace

dark web markets darknet search engine dark market link

dark web drug marketplace tor markets links dark web markets

dark web sites links dark web site dark markets 2024

dark web market links dark web access darkmarket 2024

how to access dark web darknet markets 2024 darknet sites

darknet site dark internet dark market 2024

dark market url dark market link dark websites

darknet markets tor marketplace tor market url

dark web search engine dark websites darkmarket list

darknet websites deep web drug url tor marketplace

deep web drug url drug markets onion dark web market links

the dark internet free dark web darknet drugs

deep web drug links deep web markets deep web links

tor market url dark websites deep web drug markets

how to access dark web darknet market list darknet market

dark web market links dark internet darkmarket url

tor markets tor darknet tor marketplace

darkmarket dark markets darknet market links

dark web sites links tor dark web dark internet

darknet sites deep web search dark markets 2024

deep web drug markets darknet drugs dark web site

dark web sites dark web access blackweb

dark web market links darknet drug market dark internet

dark market list how to get on dark web darknet markets

darknet site darknet market list darknet markets

dark web access dark web drug marketplace dark web links

tor market darknet site dark market 2024

dark internet drug markets onion darkmarket link

darkmarket link tor markets drug markets onion

deep web drug links dark web links dark market link

dark web search engine darkmarket tor marketplace

darknet websites dark market link darknet market

tor market url tor markets dark website

darknet search engine darknet websites best darknet markets

darkmarket link tor market links darknet drug links

dark web sites dark market url darknet search engine

dark market link deep dark web tor marketplace

darkmarket blackweb official website tor market links

deep web markets dark web market links darknet markets 2024

how to access dark web deep web markets darknet drug market

bitcoin dark web blackweb official website dark markets

darknet site deep web markets dark web link

tor markets 2024 dark web markets tor markets links

dark market onion tor market links dark web sites

darknet market lists dark market url dark market url

dark web access dark market list dark market list

darknet websites dark web search engine tor markets

dark web market list darknet sites how to access dark web

darknet markets darknet search engine drug markets dark web

darknet links dark net onion market

deep web drug markets dark websites darkweb marketplace

dark web search engine dark markets 2024 tor market

deep web drug markets dark web link darknet websites

dark web drug marketplace deep web markets darknet market lists

dark market bitcoin dark web tor darknet

deep web markets dark net dark market link

dark web search engines dark market 2024 darknet markets

tor market links dark websites darkmarket url

tor dark web darknet drug links tor dark web

tor markets the dark internet darknet market lists

tor dark web darknet sites drug markets dark web

darknet market lists deep web drug links dark web search engine

darknet drug links tor darknet deep web links

dark web market dark market 2024 dark web market links

darknet seiten bitcoin dark web dark web search engines

darknet drugs drug markets onion deep web drug store

darknet market dark web market list blackweb

darkmarkets dark web websites darknet market list

deep web search dark web market list how to get on dark web

darknet markets 2024 deep web markets darknet search engine

dark web site deep dark web dark website

tor darknet dark market 2024 dark web search engine

darknet marketplace dark websites darknet drug links

darkmarket list darkmarkets tor market links

darknet links dark net deep dark web

darkweb marketplace darknet markets how to access dark web

dark web market list darkmarket darkmarket 2025

dark web markets darknet market list blackweb

dark market 2025 darknet drug market tor markets 2025

dark web market tor market url how to get on dark web

how to access dark web blackweb dark web site

tor markets 2025 darknet market lists https://github.com/darknetmarkets24/darknet-markets – darknet site

dark market 2025 tor marketplace https://github.com/darknetmarkets24/darknet-markets – dark web websites

darknet drug links darkmarket link https://github.com/darknetmarkets24/darknet-markets – tor darknet

deep web drug store deep dark web https://github.com/darknetmarkets24/darknet-markets – dark web search engines

darknet seiten darknet marketplace https://github.com/darknetmarkets24/darknet-markets – darknet websites

dark web links drug markets dark web https://github.com/darknetmarkets24/darknet-markets – drug markets dark web

dark web sites links dark web market list https://github.com/darknetmarkets24/darknet-markets – darkmarket link

darkmarket list bitcoin dark web https://github.com/darknetmarkets24/darknet-markets – darknet drugs

dark web site darknet markets 2025 darknet websites

darknet drug store dark web websites deep web markets

how to get on dark web deep web markets deep web markets

drug markets onion darknet market list darkmarket 2025

deep dark web darknet marketplace darkweb marketplace

tor market tor markets 2025 deep web sites

deep web sites dark web link blackweb

darknet marketplace darkmarket list deep web drug markets

dark market onion deep web sites deep web drug store

dark websites darknet market tor market

darknet links dark web site darknet search engine

darkmarket url tor marketplace deep web drug markets

darknet drug market darkmarket dark markets 2025

dark web market dark websites

dark web market links https://github.com/darknetmarkets24/darknet-markets – tor markets 2022

dark market list darknet sites

deep web drug store https://github.com/darknetmarkets24/darknet-markets deep web markets

blackweb official website darknet search engine deep web drug links

tor marketplace dark web link

dark websites dark web sites links

tor market url how to get on dark web darknet market links

dark markets https://github.com/darknetmarkets24/darknet-markets – darknet market links

dark internet how to get on dark web darknet links

darknet market list dark market link

tor market https://github.com/darknetmarkets24/darknet-markets darknet marketplace

dark web market darkmarket list

deep web drug url dark market deep web drug url

deep dark web https://github.com/darknetmarkets24/darknet-markets – tor market links

darknet site dark websites

tor darknet https://github.com/darknetmarkets24/darknet-markets dark market url

tor markets 2022 tor markets 2022

darkmarket url dark web market links onion market

darkmarket dark market link

dark market url dark web drug marketplace

darkweb marketplace tor marketplace

best darknet markets darknet drug links darkmarket 2025

darknet market tor darknet

dark market https://github.com/darknetmarkets24/darknet-markets – dark market onion

darkmarkets dark web link

darknet drug market best darknet markets

darknet websites deep web sites tor markets 2025

darknet market tor markets links

dark market list darknet market links dark web search engines

blackweb dark web market list deep web drug links

darknet sites tor markets darknet websites

deep web drug url darknet drug market

deep web drug links https://github.com/darknetmarkets24/darknet-markets – dark market list

darknet market lists darkmarket the dark internet

tor marketplace https://github.com/darknetmarkets24/darknet-markets dark web market list

dark markets darknet market tor darknet

dark market onion tor market url

bitcoin dark web https://github.com/darknetmarkets24/darknet-markets – dark market link

dark markets 2025 darknet marketplace dark web sites

drug markets dark web https://github.com/darknetmarkets24/darknet-markets deep web drug links

tor darknet dark markets

darknet markets the dark internet deep web drug url

darkmarket url deep web drug url

darkmarket list https://github.com/darknetmarkets24/darknet-markets – darkmarket list

best darknet markets darkmarkets dark web access

darkmarket 2022 https://github.com/darknetmarkets24/darknet-markets tor marketplace

tor market url dark market url

dark websites dark web websites darknet drug market

best darknet markets tor markets 2022

darknet drug store https://github.com/darknetmarkets24/darknet-markets – dark markets 2022

tor darknet deep web drug store tor dark web

drug markets onion best darknet markets

deep web drug links tor darknet

dark markets 2022 dark markets 2022

darknet markets https://github.com/darknetmarkets24/darknet-markets – darkmarket url

darknet market dark web market links

tor darknet https://github.com/darknetmarkets24/darknet-markets darknet marketplace

tor markets links tor market url

darknet sites blackweb official website tor dark web

dark websites drug markets onion

deep web drug markets https://github.com/darknetmarkets24/darknet-markets – darkmarket list

darknet market links tor darknet

tor market url drug markets dark web tor darknet

darkmarket tor dark web

darknet market list dark market link

dark market link dark markets

deep dark web https://github.com/darknetmarkets24/darknet-markets dark market onion

darknet sites dark market onion

dark web links https://github.com/darknetmarkets24/darknet-markets – dark web drug marketplace

darkmarkets dark market url

dark web markets darknet marketplace

dark web links dark web markets

darkmarket list https://github.com/darknetmarkets24/darknet-markets – darkmarkets

dark websites https://github.com/darknetmarkets24/darknet-markets dark web market list

dark web sites tor markets 2022

darkmarket list https://github.com/darknetmarkets24/darknet-markets – darknet marketplace

darknet market darknet websites

darkweb marketplace https://github.com/darknetmarkets24/darknet-markets – darknet markets

dark web markets dark web sites

dark market onion https://github.com/darknetmarkets24/darknet-markets deep web drug store

darknet market dark web market list

dark web sites tor marketplace

darkmarket 2022 https://github.com/darknetmarkets24/darknet-markets – dark markets 2022

dark websites drug markets dark web

tor markets links dark market 2022

tor market https://github.com/darknetmarkets24/darknet-markets tor markets 2022

dark web sites links darknet marketplace

dark markets 2022 darknet websites

dark market link https://github.com/darknetmarkets24/darknet-markets – tor markets

dark markets 2025 darkmarket darknet markets 2025

darknet market list darknet drugs tor dark web

dark web market list dark web market list

dark web sites https://github.com/darknetmarkets24/darknet-markets – dark web markets

darkmarket link drug markets dark web

onion market dark market

deep web links darkmarket list dark websites

deep web markets https://github.com/darknetmarkets24/darknet-markets – dark market onion

dark market https://github.com/darknetmarkets24/darknet-markets darknet marketplace

tor dark web dark market url

tor darknet darknet websites

bitcoin dark web dark market dark websites

darknet market deep web drug markets darkmarket url

dark web link https://github.com/darknetmarkets24/darknet-markets – dark web drug marketplace

darknet markets darkmarket url

darknet markets https://github.com/darknetmarkets24/darknet-markets darkweb marketplace

darkmarket link deep web drug url

dark market url deep web drug url

dark market url https://github.com/darknetmarkets24/darknet-markets – darkweb marketplace

darknet drug market darknet market list

deep web drug markets https://github.com/darknetmarkets24/darknet-markets tor market url

dark web market list darkmarket 2022

dark market dark market

onion market https://github.com/darknetmarkets24/darknet-markets – tor markets links

tor market tor markets

dark market 2022 dark market onion

darknet marketplace best darknet markets

darkmarkets https://github.com/darknetmarkets24/darknet-markets – darknet markets

drug markets dark web dark web sites

dark market onion darkmarket

darknet drug market https://github.com/darknetmarkets24/darknet-markets darknet market

tor dark web dark market onion

blackweb https://github.com/darknetmarkets24/darknet-markets dark market url

dark web markets darknet websites darknet drugs

deep web drug links https://github.com/darknetmarkets24/darknet-markets – darkweb marketplace

tor market links darknet market list

darkmarket url darkweb marketplace

dark market link tor market url

darkmarket url https://github.com/darknetmarkets24/darknet-markets dark websites

deep web search https://github.com/darknetmarkets24/darknet-markets dark market onion

dark markets https://github.com/darknetmarkets24/darknet-markets – darknet marketplace

dark web market list drug markets onion

dark web market list https://github.com/darknetmarkets24/darknet-markets – dark market

dark web drug marketplace https://github.com/darknetmarkets24/darknet-markets dark market 2022

dark web search engines https://github.com/darknetmarketslinks/darknetmarketlinks – the dark internet darknet drug links

darknet site darkweb marketplace

tor market links https://github.com/darknetmarkets24/darknet-markets – darknet markets

deep dark web https://github.com/darknetmarkets24/darknet-markets dark market url

tor market url https://github.com/darknetmarketslinks/darknetmarketlinks – dark web market links dark market

deep dark web darknet drug links

darknet markets dark web market

darkweb marketplace https://github.com/darknetmarkets24/darknet-markets – darkmarket link

darkmarket https://github.com/darknetmarkets24/darknet-markets tor market

tor markets darkweb marketplace

dark web links deep dark web

darknet markets dark market list

darknet drug store https://github.com/darknetmarkets24/darknet-markets – darkmarket list

deep web search https://github.com/darknetmarketslinks/darknetmarketlinks – darknet markets darknet drug links

darknet market links https://github.com/darknetmarkets24/darknet-markets deep web drug url

tor darknet deep dark web

deep web drug links darknet sites

tor darknet https://github.com/darknetmarketslinks/darknetmarketlinks – drug markets dark web tor darknet

dark web links darkmarket link

dark web market links https://github.com/darknetmarkets24/darknet-markets – deep web drug store

tor market links tor markets links

tor dark web https://github.com/darknetmarkets24/darknet-markets darknet websites

dark web sites links https://github.com/darknetmarketslinks/darknetmarketlinks – darknet market darkmarket url

darknet marketplace dark market link

darkmarket link https://github.com/darknetmarkets24/darknet-markets – darkmarket list

darknet market list darkmarket list

dark market link https://github.com/darknetmarkets24/darknet-markets deep web drug links

darknet sites dark markets 2022

dark website https://github.com/darknetmarketslinks/darknetmarketlinks – darkweb marketplace dark web links

darkmarket link darknet marketplace

darknet drug store https://github.com/darknetmarkets24/darknet-markets dark markets

dark markets 2022 best darknet markets

drug markets onion dark web market list

onion market https://github.com/darknetmarkets24/darknet-markets deep dark web

tor markets links dark market url

dark web link https://github.com/darknetmarkets24/darknet-markets drug markets dark web

dark market https://github.com/darknetmarketslinks/darknetmarketlinks – deep web drug url deep web drug url

dark market list drug markets onion

darkmarkets https://github.com/darknetmarkets24/darknet-markets dark web market list

dark market 2022 deep web drug markets

darknet websites https://github.com/darknetmarketslinks/darknetmarketlinks – deep web drug store darkmarket

deep web drug url https://github.com/darknetmarkets24/darknet-markets darknet market lists

drug markets dark web dark markets 2022

onion market https://github.com/darknetmarkets24/darknet-markets – tor markets 2022

tor market links tor darknet

dark web markets https://github.com/darknetmarketslinks/darknetmarketlinks – darknet market list how to get on dark web

dark web market https://github.com/darknetmarkets24/darknet-markets darknet markets

darknet site dark websites

darkmarket url https://github.com/darknetmarketslinks/darknetmarketlinks – drug markets onion darknet market lists

tor marketplace https://github.com/darknetmarkets24/darknet-markets dark web links

deep dark web dark websites

tor darknet dark web sites

bitcoin dark web https://github.com/darknetmarketslinks/darknetmarketlinks – dark web drug marketplace darknet markets

dark web sites links https://github.com/darknetmarkets24/darknet-markets darknet market

tor market url https://github.com/darknetmarkets24/darknet-markets – deep web drug markets

dark web sites tor markets links

tor darknet https://github.com/darknetmarketslinks/darknetmarketlinks – darknet market links best darknet markets

deep web markets https://github.com/darknetmarkets24/darknet-markets darknet drug links

deep web drug url dark market onion

deep web drug markets deep web drug url

dark web links https://github.com/darknetmarketslinks/darknetmarketlinks – darknet market links darknet search engine

darkmarket 2022 https://github.com/darknetmarkets24/darknet-markets – deep web markets

dark web drug marketplace https://github.com/darknetmarkets24/darknet-markets darkmarket list

darkmarket deep web drug links

dark web sites links dark market 2022

deep dark web https://github.com/darknetmarketslinks/darknetmarketlinks – best darknet markets tor market

tor markets links https://github.com/darknetmarkets24/darknet-markets darknet market list

deep web markets https://github.com/darknetmarkets24/darknet-markets – darknet marketplace

dark market darknet sites

best darknet markets darknet markets

deep dark web https://github.com/darknetmarketslinks/darknetmarketlinks – dark website dark net

tor marketplace https://github.com/darknetmarkets24/darknet-markets tor market url

dark web links https://github.com/darknetmarkets24/darknet-markets – tor dark web

dark markets dark markets 2022

darknet drug market deep web drug store

tor market links https://github.com/darknetmarketslinks/darknetmarketlinks – deep web links dark web market list

dark market link https://github.com/darknetmarkets24/darknet-markets dark websites

darknet drug store https://github.com/darknetmarkets24/darknet-markets – tor darknet

dark markets 2022 darknet drug store

darknet market links https://github.com/darknetmarkets24/darknet-markets deep web drug links

darknet drug links https://github.com/darknetmarkets24/darknet-markets – darknet site

dark web sites tor dark web

dark market url tor markets

best darknet markets https://github.com/darknetmarketslinks/darknetmarketlinks – deep web sites tor marketplace

dark market onion https://github.com/darknetmarkets24/darknet-markets darknet market links

tor marketplace https://github.com/darknetmarkets24/darknet-markets – darkmarket

best darknet markets darkmarket url

deep web markets darknet drug market

deep web sites https://github.com/darknetmarketslinks/darknetmarketlinks – dark web search engines free dark web

dark web links https://github.com/darknetmarkets24/darknet-markets tor markets 2022

dark web market https://github.com/darknetmarkets24/darknet-markets – dark web sites links

darkmarket https://github.com/darknetmarketslinks/darknetmarketlinks – dark website darknet market

darknet markets 2025 https://github.com/darknetmarkets2025/darknetmarketlinks – darknet seiten dark web drug marketplace

dark web link onion market

drug markets dark web https://github.com/darknetmarketslinks/darknetmarketlinks – tor markets dark web market list

darkweb marketplace https://github.com/darknetmarkets24/darknet-markets darknet drug links

deep web drug store https://github.com/darknetmarkets24/darknet-markets – dark web drug marketplace

darknet market list darkmarket 2022

dark market link darknet sites

dark web markets https://github.com/darknetmarketslinks/darknetmarketlinks – darknet drugs deep web drug markets

dark market onion https://github.com/darknetmarkets24/darknet-markets – dark web markets

darknet websites deep web markets

blackweb https://github.com/darknetmarketslinks/darknetmarketlinks – drug markets onion darknet drug store

dark websites dark websites

dark market onion https://github.com/darknetmarkets2025/darknetmarketlinks – the dark internet dark market list

tor markets links https://github.com/darknetmarkets24/darknet-markets tor market

tor markets https://github.com/darknetmarkets24/darknet-markets – darknet drug store

black internet https://github.com/darknetmarketslinks/darknetmarketlinks – darknet websites tor market

dark web market tor markets

darknet markets https://github.com/darknetmarketslinks/darknetmarketlinks – darknet seiten bitcoin dark web

darknet drug store tor dark web

dark market https://github.com/darknetmarkets2025/darknetmarketlinks – darknet search engine dark websites

darknet drugs https://github.com/darknetmarketslinks/darknetmarketlinks – darknet drug market deep web markets

darkmarket list https://github.com/darknetmarketslinks/darknetmarketlinks – dark web drug marketplace drug markets onion

deep web drug url https://github.com/darknetmarkets2025/darknetmarketlinks – deep web drug store onion market

darknet drug store https://github.com/darkwebmarketslinks/darkwebmarkets – deep web markets tor dark web

dark market link https://github.com/darknetmarketslinks/darknetmarketlinks – dark web drug marketplace dark market link

darkmarket url https://github.com/darknetmarkets2025/darknetmarketlinks – darknet drug links deep web sites

dark web drug marketplace https://github.com/darkwebmarketslinks/darkwebmarkets – darknet markets darkmarkets

darknet links https://github.com/darknetmarketslinks/darknetmarketlinks – darknet drug links bitcoin dark web

deep web search https://github.com/darknetmarketslinks/darknetmarketlinks – darknet markets 2025 darknet market

free dark web https://github.com/darkwebwebsites/darkwebwebsites – onion market darknet websites

tor marketplace https://github.com/darkwebmarketslinks/darkwebmarkets – dark web market list darknet sites

tor marketplace https://github.com/darknetmarketslinks/darknetmarketlinks – darkmarket darknet markets 2025

dark web access https://github.com/darknetmarketslinks/darknetmarketlinks – dark market 2025 darknet market list

darkmarket 2025 https://github.com/darkwebwebsites/darkwebwebsites – dark website darknet websites

deep web drug links https://github.com/darkwebmarketslinks/darkwebmarkets – dark internet dark net

how to get on dark web https://github.com/darknetmarketslinks/darknetmarketlinks – free dark web onion market

darknet links https://github.com/darknetmarkets2025/darknetmarketlinks – dark web markets tor markets

tor markets https://github.com/darknetmarketslinks/darknetmarketlinks – deep web search darkmarket

deep dark web https://github.com/darknetmarketslinks/darknetmarketlinks – dark web market links dark net

darknet market links https://github.com/darknetmarkets2025/darknetmarketlinks – deep web drug markets dark internet

darkmarket list https://github.com/darknetmarketslinks/darknetmarketlinks – dark market url dark web drug marketplace

onion market https://github.com/darkwebmarketslinks/darkwebmarkets – black internet darknet search engine

darknet market links https://github.com/darknetmarketslinks/darknetmarketlinks – free dark web dark market 2025

darkmarket url https://github.com/darknetmarkets2025/darknetmarketlinks – black internet darkmarket link

deep dark web https://github.com/darkwebmarketslinks/darkwebmarkets – darknet websites darknet market list

dark market list https://github.com/darknetmarketslinks/darknetmarketlinks – darknet seiten darknet drug store

dark market list https://github.com/darknetmarketslinks/darknetmarketlinks – drug markets onion dark web search engine

tor markets 2025 https://github.com/darknetmarkets2025/darknetmarketlinks – dark web access deep dark web

deep dark web https://github.com/darknetmarketslinks/darknetmarketlinks – deep web markets darknet drugs

darknet market list https://github.com/darkwebmarketslinks/darkwebmarkets – deep web markets dark internet

dark market 2022 https://github.com/darkmarketlinkp22jr/darkmarketlink – tor darknet

dark web sites links https://github.com/darknetwebsitesgflpx/darknetwebsites – darknet market

deep web drug url https://github.com/darknetdruglinksvojns/darknetdruglinks – deep web drug markets

dark internet https://github.com/darknetmarketslinks/darknetmarketlinks – darknet market darknet drug links

dark markets 2022 https://github.com/darknetmarketlinks2025/darknetmarkets – darknet market

black internet https://github.com/darkwebwebsites/darkwebwebsites – dark website dark web markets

dark websites https://github.com/tormarkets2025ukaz1/tormarkets2025 – darkmarket url

deep web links https://github.com/darknetmarkets2025/darknetmarketlinks – dark market url dark web links

darknet sites https://github.com/darknetmarketslinks/darknetmarketlinks – deep web search dark web markets

darknet market list https://github.com/darkwebmarketslinks/darkwebmarkets – dark web link dark market onion

drug markets dark web https://github.com/darknetwebsitesgflpx/darknetwebsites – dark web link

bitcoin dark web https://github.com/darknetdruglinksvojns/darknetdruglinks – dark web market list

dark web websites https://github.com/darknetmarketslinks/darknetmarketlinks – dark web link tor marketplace

dark market url https://github.com/darknetmarketlinks2025/darknetmarkets – darknet marketplace

dark market list https://github.com/tormarkets2025ukaz1/tormarkets2025 – dark websites

dark web sites https://github.com/darkwebwebsites/darkwebwebsites – deep web markets how to access dark web

how to get on dark web https://github.com/darknetmarkets2025/darknetmarketlinks – darknet drugs drug markets dark web

deep web drug store https://github.com/darknetmarketslinks/darknetmarketlinks – deep web drug markets dark web websites

dark market https://github.com/darkmarketlinkp22jr/darkmarketlink – tor market url

bitcoin dark web https://github.com/darknetwebsitesgflpx/darknetwebsites – tor market links

darknet market lists https://github.com/darkwebmarketslinks/darkwebmarkets – darknet drug links dark web search engine

dark market link https://github.com/darknetdruglinksvojns/darknetdruglinks – tor markets 2022

dark web websites https://github.com/darknetmarketslinks/darknetmarketlinks – dark net dark market 2025

drug markets onion https://github.com/tormarkets2025ukaz1/tormarkets2025 – tor markets 2022

deep web drug links https://github.com/darkwebwebsites/darkwebwebsites – deep web drug links deep web drug store

darknet market list https://github.com/darknetmarkets2025/darknetmarketlinks – how to access dark web dark web market links

darkmarket list https://github.com/darknetmarketslinks/darknetmarketlinks – deep web drug links deep web search

dark markets 2022 https://github.com/darkmarketlinkp22jr/darkmarketlink – deep web markets

darkmarket 2022 https://github.com/darknetwebsitesgflpx/darknetwebsites – deep web drug markets

darknet marketplace https://github.com/darkwebmarketslinks/darkwebmarkets – dark web sites tor market url

tor market https://github.com/darknetdruglinksvojns/darknetdruglinks – deep dark web

dark market list https://github.com/darknetmarketslinks/darknetmarketlinks – tor dark web blackweb

dark markets https://github.com/tormarkets2025ukaz1/tormarkets2025 – darknet markets

tor markets 2022 https://github.com/darkmarketlinkp22jr/darkmarketlink – dark web sites

darkmarkets https://github.com/darknetwebsitesgflpx/darknetwebsites – drug markets dark web

tor darknet https://github.com/darkwebwebsites/darkwebwebsites – dark internet dark web market links

how to get on dark web https://github.com/darknetmarkets2025/darknetmarketlinks – darknet market list darkmarket list

darkmarket url https://github.com/darknetdruglinksvojns/darknetdruglinks – dark markets 2022

bitcoin dark web https://github.com/darknetmarketslinks/darknetmarketlinks – deep web drug store darknet drug store

darkmarket 2025 https://github.com/darkwebmarketslinks/darkwebmarkets – dark markets darknet drug store

darkmarket 2022 https://github.com/tormarkets2025ukaz1/tormarkets2025 – best darknet markets

darknet market https://github.com/darkmarketlinkp22jr/darkmarketlink – dark websites

drug markets onion https://github.com/darknetwebsitesgflpx/darknetwebsites – dark markets

bitcoin dark web https://github.com/darkwebwebsites/darkwebwebsites – best darknet markets tor marketplace

dark web sites links https://github.com/darknetmarkets2025/darknetmarketlinks – dark market how to get on dark web

onion market https://github.com/darknetdruglinksvojns/darknetdruglinks – tor marketplace

tor market https://github.com/darknetmarketlinks2025/darknetmarkets – dark market list

tor markets links https://github.com/darkwebmarketslinks/darkwebmarkets – darkmarkets dark market url

darkweb marketplace https://github.com/darkmarketlinkp22jr/darkmarketlink – tor markets links

dark market link https://github.com/darknetwebsitesgflpx/darknetwebsites – tor markets

darknet sites https://github.com/darknetdruglinksvojns/darknetdruglinks – deep web drug url

tor markets https://github.com/darkwebwebsites/darkwebwebsites – dark web websites tor darknet

free dark web https://github.com/darknetmarkets2025/darknetmarketlinks – deep web links darknet drug links

dark markets 2022 https://github.com/darknetmarketlinks2025/darknetmarkets – tor market

darkmarket link https://github.com/darknetmarketslinks/darknetmarketlinks – dark market 2025 darknet links

deep dark web https://github.com/darkwebmarketslinks/darkwebmarkets – tor marketplace tor market

drug markets onion https://github.com/darkmarketlinkp22jr/darkmarketlink – deep web markets

dark web access https://github.com/darknetmarketslinks/darknetmarketlinks – drug markets onion dark web markets

dark web market list https://github.com/darknetdruglinksvojns/darknetdruglinks – dark web drug marketplace

dark web links https://github.com/tormarkets2025ukaz1/tormarkets2025 – tor darknet

dark market https://github.com/darknetmarketslinks/darknetmarketlinks – darknet sites darknet seiten

darknet markets https://github.com/darknetmarkets2025/darknetmarketlinks – darknet links dark markets 2025

darknet market lists https://github.com/darkmarketlinkp22jr/darkmarketlink – dark market 2022

the dark internet https://github.com/darkwebmarketslinks/darkwebmarkets – tor markets darknet websites

tor markets https://github.com/darknetwebsitesgflpx/darknetwebsites – darkmarkets

darknet marketplace https://github.com/darknetmarketslinks/darknetmarketlinks – darkmarkets dark market url

darknet markets https://github.com/darknetdruglinksvojns/darknetdruglinks – darknet markets

tor darknet https://github.com/tormarkets2025ukaz1/tormarkets2025 – dark web sites

the dark internet https://github.com/darknetmarketslinks/darknetmarketlinks – onion market dark markets

tor markets links https://github.com/darkwebwebsites/darkwebwebsites – darkmarket url best darknet markets

darkweb marketplace https://github.com/darknetmarkets2025/darknetmarketlinks – deep web links best darknet markets

drug markets dark web https://github.com/darkmarketlinkp22jr/darkmarketlink – darknet market links

dark market 2022 https://github.com/darknetwebsitesgflpx/darknetwebsites – darknet marketplace

dark market 2025 https://github.com/darknetmarketslinks/darknetmarketlinks – darkmarket 2025 darknet market links

dark web link https://github.com/darknetdruglinksvojns/darknetdruglinks – darkmarket link

tor market url https://github.com/darknetmarketlinks2025/darknetmarkets – onion market

dark web search engines https://github.com/darknetmarketslinks/darknetmarketlinks – deep web drug store deep web sites

dark web market list https://github.com/darkmarketlinkp22jr/darkmarketlink – dark web link

tor markets https://github.com/darkwebwebsites/darkwebwebsites – dark web links darknet market list

bitcoin dark web https://github.com/darknetmarkets2025/darknetmarketlinks – best darknet markets dark web websites

darkweb marketplace https://github.com/darknetwebsitesgflpx/darknetwebsites – deep dark web

free dark web https://github.com/darknetmarketslinks/darknetmarketlinks – dark web access how to access dark web

darknet drugs https://github.com/darkwebmarketslinks/darkwebmarkets – the dark internet darknet market list

dark web sites https://github.com/darknetdruglinksvojns/darknetdruglinks – deep dark web

darknet search engine https://github.com/darknetmarketslinks/darknetmarketlinks – dark market url darknet markets

dark market onion https://github.com/darkmarketlinkp22jr/darkmarketlink – dark web market links

darkmarket https://github.com/darknetwebsitesgflpx/darknetwebsites – dark market url

tor darknet https://github.com/darkwebwebsites/darkwebwebsites – darkmarket list darknet sites

dark web market list https://github.com/darknetmarkets2025/darknetmarketlinks – darknet market lists dark web site

dark web search engine https://github.com/darknetmarketslinks/darknetmarketlinks – darknet market lists dark web websites

tor marketplace https://github.com/darkwebmarketslinks/darkwebmarkets – dark web market links darknet websites

darkmarket https://github.com/darknetmarketslinks/darknetmarketlinks – dark market link dark web market links

dark website https://github.com/darknetmarketslinks/darknetmarketlinks – dark market url deep dark web

dark markets https://github.com/darknetmarkets2025/darknetmarketlinks – dark web sites links dark web site

dark web market list https://github.com/darknetmarketslinks/darknetmarketlinks – dark web links darknet markets 2025

best darknet markets https://github.com/darkwebmarketslinks/darkwebmarkets – darkmarkets deep dark web

blackweb https://github.com/darknetmarketslinks/darknetmarketlinks – darkmarket drug markets dark web

tor market url https://github.com/darkwebwebsites/darkwebwebsites – dark websites dark market url

how to get on dark web https://github.com/darknetmarkets2025/darknetmarketlinks – darknet drug market dark markets 2025

darkmarkets https://github.com/darknetmarketslinks/darknetmarketlinks – tor market url tor markets

dark net https://github.com/darkwebmarketslinks/darkwebmarkets – dark markets 2025 darkweb marketplace

deep web search https://github.com/darknetmarketslinks/darknetmarketlinks – deep web markets dark web sites links

tor marketplace https://github.com/darkwebwebsites/darkwebwebsites – dark web links deep web drug url

darknet sites https://github.com/darknetmarkets2025/darknetmarketlinks – dark website the dark internet

dark web market links https://github.com/darknetmarketslinks/darknetmarketlinks – dark web links blackweb official website

dark web sites https://github.com/darkwebmarketslinks/darkwebmarkets – dark market onion dark web access

deep web markets https://github.com/tormarkets2025ukaz1/tormarkets2025 – tor markets links

darkmarket https://github.com/darkwebwebsites/darkwebwebsites – dark web site how to access dark web

dark markets 2025 https://github.com/darknetmarketslinks/darknetmarketlinks – tor darknet darknet search engine

tor marketplace https://github.com/darknetmarkets2025/darknetmarketlinks – darkmarket link darknet search engine

darkmarkets https://github.com/tormarkets2025ukaz1/tormarkets2025 – dark markets

darknet drug store https://github.com/darkwebmarketslinks/darkwebmarkets – deep web markets dark market 2025

deep web drug url https://github.com/darknetdruglinksvojns/darknetdruglinks – dark web market links

darknet markets https://github.com/darknetmarketslinks/darknetmarketlinks – dark web drug marketplace dark market

dark net https://github.com/darknetmarkets2025/darknetmarketlinks – dark market darknet websites

dark markets https://github.com/darknetmarketlinks2025/darknetmarkets – darkweb marketplace

dark market url https://github.com/darkmarketlinkp22jr/darkmarketlink – darknet drug store

deep web sites https://github.com/darkwebmarketslinks/darkwebmarkets – darkmarket dark web site

darkweb marketplace https://github.com/darknetmarketslinks/darknetmarketlinks – darknet market darknet links

darknet seiten https://github.com/darkwebwebsites/darkwebwebsites – dark web search engine dark markets 2025

darknet websites https://github.com/darknetmarkets2025/darknetmarketlinks – tor marketplace dark websites

best darknet markets https://github.com/darknetmarketlinks2025/darknetmarkets – dark market

dark market list https://github.com/darknetwebsitesgflpx/darknetwebsites – darknet drug market

deep web drug url https://github.com/darkmarketlinkp22jr/darkmarketlink – dark web link

drug markets dark web https://github.com/darkwebmarketslinks/darkwebmarkets – deep web drug markets bitcoin dark web

darkmarket 2025 https://github.com/darknetmarketslinks/darknetmarketlinks – the dark internet dark web link

darknet site https://github.com/darkwebwebsites/darkwebwebsites – darknet seiten free dark web

tor market url https://github.com/darknetmarkets2025/darknetmarketlinks – free dark web dark market url

tor market https://github.com/darkwebmarketslinks/darkwebmarkets – tor markets 2025 dark market onion

darknet market lists deep web sites how to get on dark web

drug markets onion darknet markets dark market onion

darkmarket 2025 dark web sites links darkmarket 2025

dark markets 2025 deep web drug url how to get on dark web

dark web search engines darkmarket darknet marketplace

bitcoin dark web dark web market darknet sites

deep web drug store deep web search dark websites

dark web websites dark market link tor markets

deep web markets darknet links tor darknet

dark market dark web websites dark net

deep web drug store https://github.com/darknetwebsitesgflpx/darknetwebsites – darknet websites

tor market url https://github.com/darknetmarketlinks2025/darknetmarkets – dark market 2022

dark web market https://github.com/darknetdruglinksvojns/darknetdruglinks – deep web drug store

dark web links dark web link darknet marketplace

how to access dark web darknet markets black internet

darknet site https://github.com/darknetwebsitesgflpx/darknetwebsites – dark market 2022

tor markets 2025 how to get on dark web bitcoin dark web

tor dark web https://github.com/darkmarketlinkp22jr/darkmarketlink – drug markets dark web

tor market links dark market onion blackweb official website

tor market dark web access how to get on dark web

darknet site https://github.com/darknetwebsitesgflpx/darknetwebsites – dark markets

dark market 2025 dark websites darkmarket url

tor market darknet market lists dark web search engines

deep web drug url darknet market links darknet market list

tor markets https://github.com/darknetwebsitesgflpx/darknetwebsites – dark web market list

dark web market list deep web drug links darknet seiten

dark web market links https://github.com/darknetmarketlinks2025/darknetmarkets – tor markets links

tor darknet https://github.com/darknetdruglinksvojns/darknetdruglinks – tor market url

blackweb official website darkmarket link dark market link

darknet drug store drug markets dark web darknet marketplace

tor market url https://github.com/darknetwebsitesgflpx/darknetwebsites – darkmarket list

dark market link darkmarket tor darknet

dark web drug marketplace https://github.com/tormarkets2025ukaz1/tormarkets2025 – deep web drug url

darknet links darknet drugs how to access dark web

darkmarket https://github.com/darknetwebsitesgflpx/darknetwebsites – dark web link

darkmarket 2025 darkmarket list darknet sites

dark web search engine dark web market links dark market

drug markets onion https://github.com/tormarkets2025ukaz1/tormarkets2025 – deep dark web

dark websites https://github.com/darknetdruglinksvojns/darknetdruglinks – deep dark web

darkmarket https://github.com/darknetwebsitesgflpx/darknetwebsites – deep web markets

dark markets 2025 dark web access darknet market list

best darknet markets dark web site dark market url

dark markets https://github.com/tormarkets2025ukaz1/tormarkets2025 – tor dark web

tor markets https://github.com/darknetdruglinksvojns/darknetdruglinks – deep web markets

tor market url dark markets 2025 darkweb marketplace

darkmarket https://github.com/darknetwebsitesgflpx/darknetwebsites – darkmarket 2022

dark web link deep dark web dark web link

dark web markets free dark web black internet

tor market url https://github.com/tormarkets2025ukaz1/tormarkets2025 – darkmarket

dark web market https://github.com/darknetmarketlinks2025/darknetmarkets – dark web sites links

tor darknet https://github.com/darknetdruglinksvojns/darknetdruglinks – darknet market

darknet marketplace dark market list tor markets 2025

darkmarkets https://github.com/darknetwebsitesgflpx/darknetwebsites – darknet market

dark web sites dark web search engines dark markets

darkmarkets https://github.com/darkmarketlinkp22jr/darkmarketlink – tor dark web

darknet site tor markets 2025 dark web market

darknet market list https://github.com/darknetmarketlinks2025/darknetmarkets – dark market

dark web link https://github.com/darknetdruglinksvojns/darknetdruglinks – dark markets

dark markets 2025 deep dark web darknet links

deep web drug store https://github.com/darknetwebsitesgflpx/darknetwebsites – tor dark web

dark market dark web sites darkmarket

dark markets 2022 https://github.com/darkmarketlinkp22jr/darkmarketlink – deep dark web

dark web drug marketplace https://github.com/darknetmarketlinks2025/darknetmarkets – darknet site

dark market list https://github.com/darknetdruglinksvojns/darknetdruglinks – dark markets 2022

dark web link darkmarket dark internet

deep web drug markets https://github.com/darknetwebsitesgflpx/darknetwebsites – best darknet markets

deep web links best darknet markets darknet drug links

dark net tor markets 2025 darknet market links

tor market https://github.com/darkmarketlinkp22jr/darkmarketlink – dark market list

darknet market https://github.com/tormarkets2025ukaz1/tormarkets2025 – dark web drug marketplace

dark market https://github.com/darknetmarketlinks2025/darknetmarkets – darkmarket link

dark market https://github.com/darknetdruglinksvojns/darknetdruglinks – darkmarket link

darknet search engine tor markets links onion market

dark web websites dark web websites deep web search

deep web sites deep dark web darknet drug market

darknet market lists https://github.com/darknetmarketlinks2025/darknetmarkets – darkmarkets

darkweb marketplace dark market 2025 darknet sites

tor marketplace https://github.com/darknetwebsitesgflpx/darknetwebsites – darknet websites

dark web search engine darknet site drug markets onion

dark websites https://github.com/darkmarketlinkp22jr/darkmarketlink – darknet market

dark markets 2022 https://github.com/darknetdruglinksvojns/darknetdruglinks – deep web drug store

darknet market lists https://github.com/darknetwebsitesgflpx/darknetwebsites – drug markets onion

darkmarket url dark web search engines tor market

bitcoin dark web deep web drug markets dark web access

deep web drug store dark web search engines darknet market links

drug markets onion https://github.com/tormarkets2025ukaz1/tormarkets2025 – dark web market list

dark market https://github.com/darknetdruglinksvojns/darknetdruglinks – tor darknet

dark markets 2022 https://github.com/darknetwebsitesgflpx/darknetwebsites – dark markets

dark web search engines darknet market links tor market

tor marketplace dark market url dark web link

darknet market links dark web market dark web websites

tor marketplace https://github.com/tormarkets2025ukaz1/tormarkets2025 – tor market url

dark markets https://github.com/darknetdruglinksvojns/darknetdruglinks – dark web link

darknet site how to get on dark web dark web market list

tor market url https://github.com/darknetwebsitesgflpx/darknetwebsites – dark market list

darknet drugs dark market url deep web markets

dark market link how to access dark web drug markets dark web

dark market https://github.com/tormarkets2025ukaz1/tormarkets2025 – darknet drug market

darknet marketplace https://github.com/darkmarketlinkp22jr/darkmarketlink – dark websites

tor markets links https://github.com/darknetdruglinksvojns/darknetdruglinks – darknet markets

deep web drug markets darknet links darknet sites

dark web market blackweb official website dark web sites links

dark internet deep web markets deep web drug store

darknet market links darknet links dark web link

tor dark web dark net dark web websites

tor markets drug markets onion dark market url

tor markets links dark web search engine dark web link

darknet sites darknet links deep dark web

dark net dark web drug marketplace dark internet

darkmarket deep web markets dark web access

tor dark web dark market deep web drug store

tor market links darkmarket list darknet markets 2025

darknet drug store https://github.com/darkmarketlinkp22jr/darkmarketlink – deep web drug links

dark web access dark web websites darknet sites

dark market darkmarket list tor market links

darknet sites https://github.com/tormarkets2025ukaz1/tormarkets2025 – dark market

darknet market list dark market darknet market list

darknet drug links https://github.com/darknetdruglinksvojns/darknetdruglinks – darknet sites

darkweb marketplace https://github.com/darkmarketlinkp22jr/darkmarketlink – darkmarket

darknet market list tor darknet deep web search

deep web drug markets darknet search engine dark market 2025

bitcoin dark web dark market url dark web market links

darkweb marketplace https://github.com/darknetwebsitesgflpx/darknetwebsites – darkmarkets

darknet drug links https://github.com/darknetdruglinksvojns/darknetdruglinks – darkmarket url

tor market links https://github.com/darkmarketlinkp22jr/darkmarketlink – darkmarket link

dark market dark net dark web sites links

darkmarket link darknet market lists tor market

darkmarket 2025 tor darknet dark markets

darkmarkets https://github.com/tormarkets2025ukaz1/tormarkets2025 – tor darknet

dark web sites links dark internet darkmarkets

darknet market list https://github.com/darknetmarketlinks2025/darknetmarkets – darkmarket url

darknet websites https://github.com/darknetdruglinksvojns/darknetdruglinks – darknet markets

darknet sites https://github.com/darkmarketlinkp22jr/darkmarketlink – dark web market links

tor dark web deep dark web darkmarket link

darkmarket list deep web drug url deep web drug markets

dark web search engine best darknet markets dark markets

deep web markets https://github.com/darknetwebsitesgflpx/darknetwebsites – dark market list

deep web markets https://github.com/darknetmarketlinks2025/darknetmarkets – dark web sites links

tor market https://github.com/darknetdruglinksvojns/darknetdruglinks – dark market url

drug markets onion https://github.com/darkmarketlinkp22jr/darkmarketlink – darknet market lists

dark web market list darknet drug store best darknet markets

dark web search engine dark web market links tor market links

how to access dark web dark web drug marketplace drug markets dark web

black internet dark web access black internet

tor market https://github.com/tormarkets2025ukaz1/tormarkets2025 – dark web drug marketplace

deep dark web https://github.com/darknetmarketlinks2025/darknetmarkets – darknet sites

darknet market list https://github.com/darknetdruglinksvojns/darknetdruglinks – dark web market list

darknet market https://github.com/darkmarketlinkp22jr/darkmarketlink – dark market onion

dark markets 2025 blackweb official website dark website

blackweb official website darknet market list darknet drug links

dark markets 2022 https://github.com/tormarkets2025ukaz1/tormarkets2025 – drug markets onion

drug markets onion https://github.com/darknetmarketlinks2025/darknetmarkets – dark market onion

dark market https://github.com/darknetdruglinksvojns/darknetdruglinks – tor market url

darkmarket list https://github.com/darkmarketlinkp22jr/darkmarketlink – tor dark web

dark market link darknet market links darknet websites

dark web sites darknet seiten dark internet

deep web drug links dark market list dark web search engines

darknet markets https://github.com/tormarkets2025ukaz1/tormarkets2025 – tor darknet

tor markets https://github.com/darknetmarketlinks2025/darknetmarkets – drug markets onion

darkweb marketplace https://github.com/darknetdruglinksvojns/darknetdruglinks – darkmarket 2022

deep web drug store https://github.com/darkmarketlinkp22jr/darkmarketlink – dark websites

tor market url darknet seiten darknet drugs

deep web sites drug markets onion deep web markets

tor market darknet market lists deep web drug links

deep web drug store https://github.com/darknetwebsitesgflpx/darknetwebsites – tor market url

darknet markets https://github.com/darknetmarketlinks2025/darknetmarkets – darknet marketplace

dark market onion https://github.com/darknetdruglinksvojns/darknetdruglinks – tor markets links

darknet markets https://github.com/darkmarketlinkp22jr/darkmarketlink – dark market list

dark web drug marketplace best darknet markets darknet drug market

dark websites tor darknet darkmarket 2025

tor markets darknet drug links darkmarket link

best darknet markets https://github.com/darknetwebsitesgflpx/darknetwebsites – darkmarket 2022

darknet market links https://github.com/darknetmarketlinks2025/darknetmarkets – tor market

tor markets 2022 https://github.com/darknetdruglinksvojns/darknetdruglinks – dark web markets

dark web markets https://github.com/darkmarketlinkp22jr/darkmarketlink – dark market 2022

tor markets 2025 darkmarket url tor markets links

darknet market dark web search engine dark market link

deep web search drug markets onion dark web websites

darknet site dark web drug marketplace dark web markets

dark websites darknet market list darkweb marketplace

dark web links https://github.com/darknetwebsitesgflpx/darknetwebsites – dark web markets

how to access dark web deep web drug links deep web drug links

darkweb marketplace https://github.com/darknetdruglinksvojns/darknetdruglinks – dark web market

darkweb marketplace darknet market lists dark web links

darknet market links dark web link blackweb

bitcoin dark web darknet market lists darkmarket link

darknet websites https://github.com/darknetmarketlinks2025/darknetmarkets – dark websites

darknet site onion market darknet market lists

deep web drug url dark website darkmarket list

dark web market https://github.com/darknetwebsitesgflpx/darknetwebsites – darkmarket list

bitcoin dark web dark market deep web drug url

darknet sites https://github.com/darkmarketlinkp22jr/darkmarketlink – onion market

tor darknet bitcoin dark web how to get on dark web

darkmarkets https://github.com/darknetdruglinksvojns/darknetdruglinks – drug markets onion

darknet market tor market url dark web market list

dark web sites links tor markets 2025 darkmarket url

darknet market lists tor market darkmarkets

darknet markets 2025 deep web drug store dark markets

dark web sites links deep web drug url tor market links

deep web links deep dark web darknet drug store

best darknet markets dark web market links darkmarket 2025

darknet drug market dark web search engines darknet site

darknet market list darkmarket url deep web sites

dark web market list darknet market list darknet site

free dark web the dark internet dark web markets

tor markets links darkmarket link dark web link

dark markets 2025 darknet drugs free dark web

darknet markets deep web drug markets dark web search engines

tor darknet dark market onion darknet markets

darkweb marketplace https://github.com/tormarkets2025ukaz1/tormarkets2025 – dark web markets

dark market 2022 https://github.com/darknetmarketlinks2025/darknetmarkets – darknet drug links

deep web drug markets deep dark web deep web search

dark markets 2025 dark markets 2025 blackweb official website

dark web market list the dark internet dark web market list

dark web market urls dark websites dark websites

darknet site dark market 2025

darknet drug store darknet sites

dark web market links darkmarket url

darkmarket 2025 darknet market

dark market 2025 dark web market list dark web drug marketplace

darknet market list darknet sites dark websites

dark market url darknet drug market darknet drug store

dark websites dark market onion

tor drug market darknet markets url darkmarkets

dark market url dark web market links

onion dark website dark web marketplaces

darknet links dark web market list darknet market list

darknet markets onion darkmarket list dark market 2025

darkmarket link dark market 2025

darknet marketplace darkmarket 2025

dark web drug marketplace best darknet markets darkmarket link

dark web link darknet links

darknet markets 2025 darknet drugs darknet markets onion

dark market list darkmarket url darkmarket list

darknet site dark web link darknet links

dark web link darknet sites

dark market 2025 dark market 2025 darknet drug market

dark market list dark web market links

darknet markets dark markets darknet markets url

darknet site dark web market list

dark web link darkmarket list bitcoin dark web

darknet drug store darknet markets onion

darknet drug links darknet markets url

darknet market lists dark market list dark market 2025

dark market 2025 darknet drug store

onion dark website darknet markets darknet drug links

darknet drug links dark web market list

darknet marketplace darknet sites dark web market

darknet drug store darknet site

darknet drug store darknet markets links

dark web sites darknet market darknet markets

dark web marketplaces best darknet markets

dark web market list darknet drug links

dark market link dark web market links darknet markets url

darknet market list darknet market links darknet drug market

darknet markets onion darknet drug market dark market

dark market url dark web market urls dark websites

darknet drug links dark web market urls darknet market list

darknet markets darknet markets onion darkmarket

darknet drug links bitcoin dark web darknet websites

darknet drugs dark web market list darknet sites

darknet market lists dark market 2025

dark market url darknet markets 2025 darknet market list

darknet markets links dark web sites

onion dark website darkmarket url

darknet market lists dark market onion dark web market urls

dark market onion dark web drug marketplace

dark market list darknet market links

darknet markets tor drug market

dark web market list darknet markets url darkmarkets

darknet market list dark web sites

dark web market links darknet drug market darkmarket 2025

darknet markets links bitcoin dark web

darknet drugs darknet market lists

darknet drug store darknet websites

dark markets dark market list darkmarket 2025

darkmarket link dark web market list

bitcoin dark web dark market

darknet links dark web markets

darknet market links darknet site dark web market

darkmarket list dark web market

darknet markets url darknet market lists

darknet markets dark web drug marketplace darknet drugs

best darknet markets darkmarket 2025

darknet websites darknet sites

dark market 2025 darkmarket dark market link

darknet markets 2025 darknet markets 2025

darkmarket url best darknet markets

dark market link darknet market lists darkmarkets

dark web market links darkmarket url

dark market link dark web markets

darknet markets 2025 dark web market list

darkmarket 2025 darknet markets url darknet links

darkmarket list darknet markets links darkmarkets

onion dark website darkmarket

dark market link tor drug market

darkmarkets dark market list

darknet drug market dark market link darknet drugs

dark web drug marketplace darkmarket link

darknet market lists dark market onion darkmarket link

darknet market list darknet site

dark web marketplaces dark markets 2025

darkmarket link dark market link darknet site

darknet marketplace darknet sites

darknet websites dark web sites

dark market url darkmarket url

darknet markets links darknet markets 2025 dark web market links

dark web marketplaces darknet markets 2025

tor drug market darknet market links

dark websites onion dark website darkmarket link

darkmarket list dark markets 2025

darkmarket link dark market link

dark web market urls darknet market list

dark web link dark market list

darknet markets 2025 dark web market list

dark web markets darknet markets onion address

darkmarket dark web drug marketplace

dark market bitcoin dark web

dark markets dark market onion

darknet markets 2025 darknet markets onion address

dark market list dark web markets

dark websites darknet markets url

onion dark website dark web sites

darknet markets onion address onion dark website

best darknet markets darkmarket 2025

dark web market list darknet markets links

darknet markets onion address darkmarkets

darknet markets onion dark market

darknet drugs dark web market urls

darknet sites dark market onion

darknet drugs dark web link

darknet site bitcoin dark web

darknet markets 2025 dark markets 2025

darknet markets links darkmarket

bitcoin dark web darknet market links

darknet markets darknet site

darkmarket link dark market 2025

dark market 2025 dark market

darknet sites best darknet markets

darkmarket dark market link

dark market url dark market 2025

darkmarket onion dark website

darknet links dark market onion

darknet websites darknet marketplace

darkmarket 2025 dark market url

darknet websites dark market url

darkmarket url darknet markets links

darknet markets darkmarket url

bitcoin dark web darknet markets 2025

dark web link darkmarket 2025

dark web link darknet sites

dark web markets dark web market

darknet drug links tor drug market

dark web markets darknet market lists

darknet marketplace darknet markets links

dark market 2025 darkmarket link

dark markets 2025 darknet marketplace

dark markets 2025 darknet markets onion

dark markets bitcoin dark web

darknet drug store darkmarkets

dark markets 2025 darknet markets onion

dark market url darknet links

darkmarket 2025 darkmarket link

darkmarket 2025 darknet markets onion

bitcoin dark web darknet drugs

dark market darknet drug market

darknet sites darknet markets 2025

dark web link darknet market lists