Both 2205 and 2507 stainless steels are excellent representatives of duplex stainless steels, and each has significant advantages in strength, corrosion resistance, and processing performance. However, despite their strong performance, there are still some important differences between the two types of stainless steel. Duplex 2507 vs 2205 – what’s the difference? This article will explore in detail the differences between 2205 and 2507 stainless steels, in order to help you better understand the properties of these two materials and make more informed choices in practical applications.

Duplex 2507 vs 2205 – What’s the Difference?

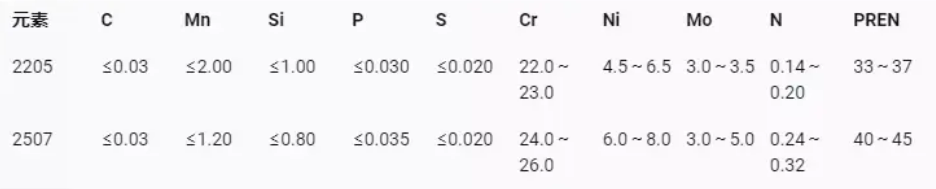

Duplex 2507 vs 2205 – 1. Composition:

Both 2205 and 2507 are duplex stainless steels, which means their metallographic structures consist of two phases: ferrite and austenite, and they have high strength, toughness, and corrosion resistance. Their main differences lie in their chemical compositions and corrosion resistance. The chromium, molybdenum, and nitrogen contents of 2507 duplex stainless steel are higher than those of 2205 duplex stainless steel, so it has stronger resistance to chloride pitting, crevice corrosion, stress corrosion cracking, and general corrosion. The following table compares the chemical compositions and PREN values (pitting resistance equivalent number) of 2205 and 2507 duplex stainless steels.

Duplex 2507 vs 2205 – 2. Application:

As can be seen from the table, the PREN value of 2507 duplex stainless steel is about 10 percentage points higher than that of 2205 duplex stainless steel, indicating that it has stronger resistance to pitting corrosion. The application fields of 2205 and 2507 duplex stainless steels are also different. 2205 duplex stainless steel is suitable for neutral chloride environments, refining industry, petrochemical and chemical industry, chemical industry transportation pipeline, oil and gas industry, pulp and paper industry, fertilizer industry, urea industry, phosphate fertilizer industry, etc.

2507 duplex stainless steel is suitable for more demanding environments, such as seawater environments, energy and environmental protection industries, light industry and food industries, equipment for the food and pharmaceutical industries, high-strength structural components, submarine pipelines, flue gas desulfurization, osmotic desalination and desalination equipment, sulfuric acid plants, etc.

Duplex 2507 vs 2205 – 2. Processing Performance:

The processing performance of 2205 and 2507 duplex stainless steels mainly depends on their microstructure, mechanical properties, and heat resistance. In general, both 2205 and 2507 duplex stainless steels have good hot forming, cold forming, cutting, and welding performance, but there are also some considerations.

Both 2205 and 2507 duplex stainless steels should be processed in the temperature range of 1750°F to 2250°F for hot forming to maintain the stability and uniformity of the duplex structure. If the temperature is too high or too low, it may lead to excessive ferrite or austenite phases, affecting toughness and corrosion resistance. After hot forming, it should be immediately subjected to solution annealing at a minimum temperature of 1900°F and water quenching to restore phase equilibrium, toughness, and corrosion resistance.

Both 2205 and 2507 duplex stainless steels can be cut and cold-formed. Due to their high strength and hardness, they require greater forming forces and smaller springback. After cold forming, if there is a risk of residual stress or intermetallic phase precipitation, solution annealing and water quenching should also be performed.

In terms of cutting, both 2205 and 2507 duplex stainless steels can be cut using carbide, ceramic, or coated tools. Due to their high strength and hardness, they require lower cutting speeds, larger feed rates, and smaller cutting depths. During cutting, attention should be paid to lubrication and cooling to avoid overheating or binding.

In terms of welding, both 2205 and 2507 duplex stainless steels can be welded using GTAW (TIG), GMAW (MIG), SMAW (“stick” electrode), SAW, FCW, or PAW welding methods. During welding, care should be taken to control the welding parameters to avoid overheating or overcooling, and maintain good weld composition and structure. After welding, solid solution annealing and water quenching should be performed to restore phase equilibrium, toughness, and corrosion resistance.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between duplex 2507 vs 2205. If you want to find more information about 2205 and 2507 duplex stainless steels, we’d advise you to visit Sino Stainless Steel.

As a leading supplier of stainless steel products across the world, Sino Stainless Steel provides customers with high-quality stainless steel pipes, stainless steel strips, stainless steel coils, stainless steel plates, stainless steel sheets, stainless steel bars, and stainless steel tubes at an extremely competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com