Stainless steel, a corrosion-resistant alloy of iron with a minimum of 10.5% chromium, has been a cornerstone of the metallurgical industry for decades. Its unique properties, including high strength, ductility, and excellent corrosion resistance, have made it indispensable in various industries, ranging from construction to medical equipment. However, the manufacturing process of stainless steel has undergone significant transformations over the years, evolving from traditional methods to cutting-edge technological advancements. So, in this article, let’s delve into the innovations in stainless steel manufacturing: from tradition to technology.

Innovations in Stainless Steel Manufacturing: From Tradition to Technology

In the early days of stainless steel production, the manufacturing process was relatively primitive and labor-intensive. The alloys were produced in small batches, often through manual operations that lacked precision and efficiency. Quality control was also a challenge, as the lack of advanced analytical tools made it difficult to ensure consistent alloy composition and mechanical properties.

Over time, significant advancements were made in the field of stainless steel manufacturing. One of the most notable innovations was the introduction of continuous casting techniques. This technology revolutionized the production process by allowing for the continuous flow of molten steel into molds, resulting in longer, more uniform ingots. This not only increased production efficiency but also improved the quality of the final product by reducing defects and enhancing mechanical properties.

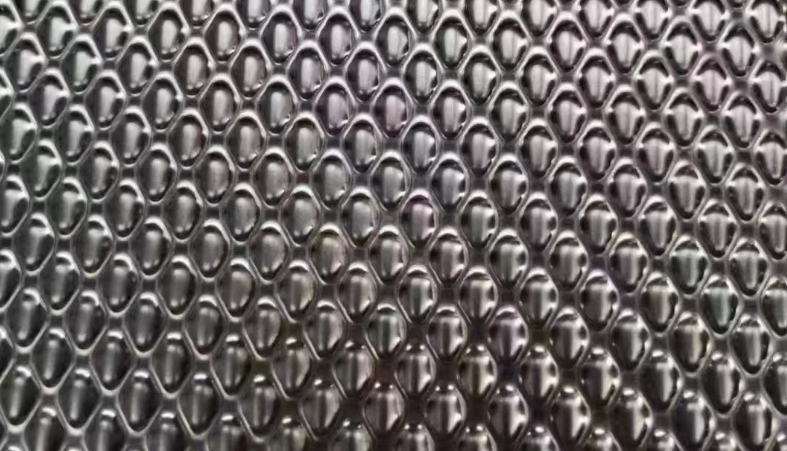

Another significant milestone was the development of advanced rolling and forging techniques. These methods allowed for the precise shaping of stainless steel into various forms, such as sheets, plates, bars, and tubes. The introduction of automated rolling mills and precision forging presses further enhanced the accuracy and repeatability of the process, leading to improved product quality and reduced waste.

The advent of modern metallurgical science also played a crucial role in the evolution of stainless steel manufacturing. With the development of new alloys and improved heat treatment techniques, it became possible to fine-tune the mechanical and corrosion resistance properties of stainless steel to meet specific application requirements. This led to the emergence of a wide range of stainless steel grades, each optimized for different uses.

Moreover, the integration of advanced technology into the manufacturing process has been a key driver of innovation. The use of robotics and automation has significantly increased production efficiency, reduced labor costs, and improved product consistency. Advanced analytical techniques, such as spectrometry and microscopy, have enabled manufacturers to closely monitor alloy composition and microstructure, ensuring that the final product meets strict quality standards.

Furthermore, the environmental impact of stainless steel manufacturing has also been addressed through innovative technologies. The development of energy-efficient production processes and the recycling of scrap steel have helped to reduce the carbon footprint of stainless steel manufacturing. This not only benefits the environment but also contributes to sustainable development and cost reduction for manufacturers.

Conclusion

In conclusion, the manufacturing of stainless steel has evolved from traditional, labor-intensive methods to highly automated and technologically advanced processes. This transformation has been driven by advancements in metallurgical science, automation, and analytical techniques. As a result, stainless steel manufacturers are now able to produce higher-quality products with greater efficiency and sustainability. Looking ahead, continued innovations in stainless steel manufacturing will likely focus on further improving production efficiency, enhancing product performance, and reducing environmental impact.

Thank you for reading our article and we hope it can help you to have a better understanding of the innovations in stainless steel manufacturing. If you are looking for stainless steel product suppliers online now, we would advise you to visit Sino Stainless Steel.

As a leading supplier of stainless steel products from Shanghai China, Sino Stainless Steel offers customers stainless steel sheets, stainless steel tubes, stainless steel pipes, stainless steel strips, stainless steel coils, stainless steel plates, and stainless steel bars at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com