Stainless steel, as an extensively utilized alloy material, finds applications across numerous working scenarios. However, it is crucial to emphasize that when stainless steel is employed in underwater operations, proper protective measures must be taken to prevent environmental factors from degrading its performance and shortening its service life. In this article, we will take a closer look at the protective measures for stainless steel in water environments.

Protective Measures for Stainless Steel in Water Environments:

Firstly, in terms of surface coating protection. Surface coating is a commonly employed protective method for stainless steel, particularly when it is subjected to prolonged exposure in water. Applying a compatible physical coating on the stainless steel surface forms a protective film that reduces the oxidation reaction rate when exposed to water, directly or indirectly slowing down corrosion and thereby safeguarding the stainless steel. It is essential to select coatings suitable for long-term underwater use.

Secondly, solution treatment protection plays a vital role in enhancing the properties of stainless steel used in water. Solution treatment eliminates work hardening, restores and enhances corrosion resistance, and improves the heat resistance of stainless steel. Additionally, it strengthens the stability of the passive film on the stainless steel surface, extending its service life and ensuring safe usage.

Furthermore, electrochemical protection is also significant in preventing or mitigating corrosion in stainless steel. One common method is cathodic protection, where metal ions are reduced back to their metallic form, thereby protecting the steel. In underwater applications, cathodic protection effectively slows down the corrosion rate of stainless steel.

Additionally, process optimization is crucial. Optimizing the processing techniques during stainless steel usage significantly promotes its corrosion resistance. For instance, by precisely controlling the alloy element ratios and selecting appropriate quenching and annealing processes, not only can residual stresses be eliminated, enhancing the steel’s strength and corrosion resistance, but also the stability of its passive film can be improved, further enhancing protection.

Conclusion

In conclusion, while stainless steel is renowned for its rust resistance, high plasticity, toughness, mechanical strength, and excellent corrosion resistance, it is not entirely immune to corrosion, especially in underwater conditions. By implementing protective measures such as surface coating, solution treatment, electrochemical protection, and process optimization, stainless steel can be effectively safeguarded against damage, significantly extending its service life.

Why Choose Sino Stainless Steel?

Thank you for reading our article and we hope it can help you to have a better understanding of the protective measures for stainless steel in water environments. If you are looking for suppliers and manufacturers of stainless steel, we would advise you to visit Sino Stainless Steel.

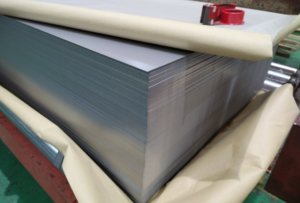

As a leading supplier of stainless steel from Shanghai China, Sino Stainless Steel offers customers high-quality stainless steel coils, stainless steel sheets, stainless steel strips, stainless steel tubes, stainless steel wires, and stainless steel bars at very competitive prices.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

kırmadan su kaçak tespiti Hızlı ve kaliteli bir hizmet, tekrar ihtiyaç duyarsam ararım. http://www.lostandfoundstudio.it/lfs/?p=10617

1Win Kenya is a premier online betting platform offering a seamless gambling experience for sports and casino enthusiasts., offering a seamless experience for sports betting and casino gaming. As a trusted name in Kenya, 1win Kenya provides users with a secure platform, a vast selection of games, and flexible betting options on sports like cricket, soccer, tennis, and basketball. Registering on 1Win is simple—just visit the official website, click on “Sign Up,” and choose to register via email or social media. Once you create an account, fund it with a deposit to start betting instantly. The 1Win casino section offers a premium gaming experience with various slots, table games, and live dealer options. To enhance the excitement, new and existing players can unlock generous rewards with the 1Win bonus codes, gaining a significant advantage in their gameplay. The 1Win Bet app allows seamless sports predictions and betting on the go, ensuring uninterrupted access to all features. With a rapidly growing audience and a commitment to quality service, 1Win Kenya continues to set the standard for online gambling. Sign up today, claim your bonuses, and enjoy a thrilling betting experience with 1Win!

Looking for the ultimate online casino and sports betting experience? 1Win is your go-to platform for a world-class gambling adventure, offering a massive 500% welcome bonus on your first four deposits! With over 11,000+ games, lightning-fast withdrawals, and all major payment methods, 1Win ensures a smooth and rewarding betting experience for every player. Whether you’re a casino enthusiast or a sports betting fan, 1Win provides a diverse range of services, from slots, poker, and table games to live betting, esports, and more. The 1Win casino platform features an official website with a vast selection of slots, table games, and gaming machines, allowing players to enjoy high-quality entertainment with quick registration and seamless login. One of the key highlights of 1Win is its regular poker tournaments with a guaranteed prize pool of $1000, held every two days, providing bettors with a thrilling opportunity to win big. Sports betting lovers will appreciate 1Win Sports Betting, offering competitive odds across multiple sports, including football, basketball, tennis, and more. Whether you’re betting on local or international events, 1Win ensures a premium betting experience with a user-friendly interface and real-time updates. For players in Uganda, 1Win Uganda caters specifically to Ugandan bettors by accepting Ugandan shillings (UGX) and other foreign currencies, making deposits and withdrawals easy and convenient. Unlike other sportsbooks, 1Win stands out with its generous 500% deposit bonus, setting it apart as a top-tier betting site with higher percentage bonuses than most competitors. The platform is designed for both new and experienced players, featuring a working mirror link for easy access, along with 24/7 customer support to assist users at any time. Whether you’re looking to explore casino games, participate in poker tournaments, or bet on your favorite sports teams, 1Win is your trusted online betting destination. Sign up today and claim your 500% welcome bonus to start your winning journey with 1Win – the official online casino and sportsbook!

1Win е модерна и иновативна платформа за онлайн казино и спортни залагания, която предлага богат избор от игри и атрактивни бонуси за нови и съществуващи играчи. Сайтът Онлайн казиното 1Win България осигурява лесна и бърза регистрация, позволявайки на потребителите да се регистрират с един клик, чрез телефон или e-mail, както и чрез социални мрежи. Новите играчи получават щедър бонус за регистрация – 500% от първите четири депозита, което прави 1Win едно от най-добрите онлайн казина по отношение на бонуси и промоции. Освен това, 1Win предоставя удобен достъп до спортни залагания с високи коефициенти, където потребителите могат да правят залози на различни спортове като футбол, тенис, баскетбол и много други. Платформата разполага с богато казино с хиляди слотове, игри на маса, видео покер, както и вълнуващи джакпоти, които осигуряват огромни печалби. 1Win е лицензирано казино, притежаващо лиценз от Кюрасао, което гарантира сигурност и надеждност за потребителите. За допълнително удобство 1Win предлага мобилно приложение за Android и iOS, което позволява на играчите да се наслаждават на любимите си игри и спортни залагания навсякъде и по всяко време. Депозирането и тегленето на средства в 1Win Casino е лесно благодарение на множеството налични методи за плащане, включително кредитни и дебитни карти, електронни портфейли и дори криптовалути. Платформата предлага и официално работещо огледало (mirror), което позволява на потребителите да влязат в акаунта си дори при ограничения в някои държави. Освен стандартните казино игри, 1Win предлага и стрийминг на филми, което я прави уникална сред другите онлайн платформи за залагания. При проблеми с тегленето на средства, екипът за поддръжка на 1Win е на разположение денонощно, за да помогне на клиентите бързо и ефективно. За да се регистрирате в 1Win и да започнете своето приключение, просто посетете официалния сайт, създайте акаунт и направете първия си депозит, за да получите бонусите си. С атрактивните си промоции, разнообразието от казино игри и спортни залози, удобните методи за плащане и мобилното приложение, 1Win се превръща в един от водещите сайтове за онлайн залози, достъпен в България и по целия свят. Независимо дали сте любител на казино игрите или спортните залагания, 1Win предлага всичко необходимо за едно незабравимо игрово изживяване.

Ümraniye su kaçağı tespiti Levent su kaçağı tespiti: Levent’te su kaçağını en hızlı ve doğru şekilde tespit ediyoruz. http://obfaoman.com/?p=1032

qmqtxTTB2HR

GLcTvhO7e8v

cecUiy8fBgw

Ddm6wM30lSR

s4t2lwqALmz

XYrpkmg3oWo

72L1zWWIi2z

yBe234X14nw

Odngz9Q2x7h

p9MmCjeUehA

Mimaroba su kaçak tespiti Beyoğlu’ndaki evimdeki su kaçağını bulmaları çok zor oldu ama cihazları çok etkiliydi. https://www.jlifenj.com/?p=40840

tXnuXn4cQUg

VAGPEgeWCMZ

oci6mqKZyzJ

p6ML4UomYdR

bFSjQG1W66W

WIFNXa0MQva

Cevizli su kaçak tespiti Sultanbeyli’deki evimizdeki su kaçağını hızlıca tespit ettiler. Hizmetlerinden çok memnun kaldım. https://politerno.com.ua/author/kacak/

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Document translation services cover a wide range of materials, ensuring accurate and professional translations for legal, academic, technical, medical, and business purposes. Certified translation services provide official translations of important documents such as birth certificates, passports, court orders, contracts, and declarations, meeting legal and governmental requirements. Businesses often require translations for product catalogs, financial statements, user manuals, and commercial offers to expand globally. Academic and research materials, including theses, white papers, and scientific studies, are translated to facilitate knowledge sharing. Media-related documents such as magazines, newspapers, and journals require precise localization to maintain context. Surveys, business proposals, and promotional materials also benefit from expert translation. Whether translating medical records, financial reports, or technical specifications, professional translators ensure clarity, accuracy, and cultural relevance. High-quality document translation services play a crucial role in global communication, legal compliance, and international business expansion. Visit our website today to learn more about our translation of user manual and professional translation solutions!

Discover the latest promotional codes for top betting platforms like Betwinner, Melbet, Fonbet, 1xBet, and more! Whether you’re looking for a welcome bonus, a free bet, or an exclusive registration promo code, these links provide access to updated offers for sports betting and online casinos. Find Melbet promo codes for 130% bonus, 1xBet free bet codes, and Fonbet promotions to boost your betting experience. Explore special bookmaker promotions across various countries, including Russia, Rwanda, Cameroon, and Tajikistan. Don’t miss out on the best casino and sportsbook deals available today!👉 Visit now and claim your bonus! https://librairienumeriquemonaco.com/docs/pages/1xbet_code_d_inscription_promo.html

Discover the latest promotional codes for top betting platforms like Betwinner, Melbet, Fonbet, 1xBet, and more! Whether you’re looking for a welcome bonus, a free bet, or an exclusive registration promo code, these links provide access to updated offers for sports betting and online casinos. Find Melbet promo codes for 130% bonus, 1xBet free bet codes, and Fonbet promotions to boost your betting experience. Explore special bookmaker promotions across various countries, including Russia, Rwanda, Cameroon, and Tajikistan. Don’t miss out on the best casino and sportsbook deals available today!👉 Visit now and claim your bonus!http://feas.ru/articles/pages/1xbet_Promokod_Rossiya.html

Use 1XBET promo code: 1X200NEW for VIP bonus up to €1950 + 150 free spins on casino and 100% up to €130 to bet on sports. Register on the 1xbet platform and get a chance to earn even more Rupees using bonus offers and special bonus code from 1xbet. Make sports bets, virtual sports or play at the casino. Join 1Xbet and claim your welcome bonus using the latest 1Xbet promo codes. Check below list of 1Xbet signup bonuses, promotions and product reviews for sportsbook, casino, poker and games sections. To claim any of the 1Xbet welcome bonuses listed in above table we recommend using the 1Xbet bonus code at registration of your account. New customers will get a €130 exclusive bonus (International users) when registering using the 1Xbet promo code listed above. 1Xbet Sportsbook section is the main place where users hang out, with over 1000 sporting events to bet each day. There are multiple choices to go for, and the betting markets, for example for soccer matches, can even pass 300 in number, and that is available for both pre-match and live betting, which is impressive and puts it right next to the big names in the industry. Visit https://kcculinary.com/articles/1xbet_promo_code-sign_up_bonus.html now and claim your exclusive bonus!

Le code promo 1xBet valide: BONUS1X200 – recevez un bonus de bienvenue de 100% jusqu’à 130€ en utilisant ce code lors de votre inscription sur le site 1xBet. Bénéficiez d’un bonus jusqu’à 130€ en freebets sur vos paris sportifs, versé selon le montant de votre premier dépôt. Avec ce code, 1xBet vous offre l’un des meilleurs bonus de bienvenue pour débuter sur leur plateforme. Obtenez jusqu’à 130€ de freebets sur les paris sportifs. Pour retirer les gains issus de votre bonus, il faudra miser 5 fois son montant sur des paris combinés avec au moins 3 matchs ayant une cote de 1.30 minimum. Pour les amateurs de casino, 1xBet propose également un bonus allant jusqu’à 1 950€ + 150 freespins + 150 freespins.

Koza su kaçak tespiti Banyo duvarındaki nem için çağırdık. Termal kamerayla gizli su kaçağını tespit edip, minimal hasarla tamir ettiler. İbrahim T. https://theatreintangible.com/author/kacak/

Velibaba su kaçak tespiti Test pompası ile kaçağın kesin yerini bulmaları çok iyiydi. https://docuneeds.net/?p=9220

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Great post! I really enjoyed reading it. Your insights are valuable and well-presented. Keep up the excellent work!

Great post! I really enjoyed reading it. Your insights are valuable and well-presented. Keep up the excellent work!

Great post! I really like it

Magnesium deficiency is common, but left unchecked, it may be serious.

Talk to a healthcare supplier if you discover any of these indicators to seek

out out what’s behind your symptoms. For lots of people, the consequences of low magnesium,

or magnesium deficiency, are delicate and possibly not even noticeable.

For others, it can be significantly detrimental to their well-being.

Doctor’s Greatest Excessive Absorption Magnesium is good for addressing magnesium deficiency, promoting

higher sleep, reducing muscle cramps, and enhancing stress management.

It works by supporting power manufacturing, sustaining healthy nerves, and enjoyable muscles, making it

one of the best types of magnesium dietary

supplements for ladies and men alike. Whether you’re seeking improved sleep, stress reduction, or cardiovascular health, this complement presents a reliable, protected, and efficient answer.

Nature Made High Absorption Magnesium Glycinate helps reduce

muscle cramps, promotes restful sleep, and supports

bone well being. It works by activating enzymes essential for energy production and

sustaining muscle and nerve capabilities.

He also created a fitness clothes line (Faremon) and complement line (Formula 1).

Most of the stores were ultimately closed, whereas the clothes and supplement line was bought or

discontinued to focus on the core enterprise of book and journal publishing.

Verify the labels on all your prescription and nonprescription/herbal products (such as antacids, laxatives,

vitamins) because they might comprise magnesium. If either

of those results final or worsen, tell your physician or

pharmacist promptly. Take every dose with a full glass (8

ounces or 240 milliliters) of water until your doctor directs you otherwise.

Selecting essentially the most suitable type of magnesium,

in addition to the suitable dosage, is a vital step in selecting the best product

for you. In a time where sexuality was repressed within the mainstream, Hearth Island got here to characterize a spot of mystery

and a homosexual haven for a lot of. While much

about Jim Stryker remains unknown, his blonde magnificence towards the liberated setting of Fireplace Island stays a snapshot in time of a refuge for young gay

boys of the time. Do not flush medications down the bathroom or pour them

right into a drain until instructed to do so.

Correctly discard this product when it’s expired or not needed.

Matthew is an ACE (American Council On Exercise) licensed health professional

who has had a ardour for health since elementary

school and continues to analysis and discover methods to

construct muscle successfully through training and

food regimen. He also loves to help others to attain their fitness objectives and unfold the knowledge the place needed.

With only a few days left in his high school profession, Michael has

neglected to provide you with his senior science project, a procrastination that will yield him a failing mark, thus forcing him to repeat 12th grade.

Whether you’re into bodybuilding, energy lifting, strength coaching or just getting started,

these exercises and tips will assist you to attain your targets.

This kind is chelated with citric acid, which improves its absorption. Magnesium citrate proves fairly useful in bettering digestive well being and relieving constipation. Liquid and gummy dietary supplements are

additionally very common as a result of their ease of consumption. It has a mild laxative impact that makes it good for

many who wish to regulate bowel actions. Almost 60% of

the magnesium within the body is stored in bones,

indicating its essential function in sustaining bone density and skeletal health.

Matthew’s different passions embrace studying about mindfulness, strolling via nature, touring, and all the time working to enhance total.

They additionally plan to offer extra regarding

their subscription service and we additionally learned that there are plans to proceed publishing FLEX, another legendary bodybuilding magazine.

The magnesium choices don’t end with a mess of oral

supplements. Proponents say rubbing or spraying your

pores and skin with magnesium may be as useful (some say much more beneficial) as ingesting it.

“There’s no definitive scientific data to date that proves anyone sort of magnesium supplement is healthier than another,” he notes.

This easy mango, avocado and black bean salad is a scrumptious method to give

your magnesium ranges a wholesome increase.

A host of highly effective new engines was supplied,

and all of them could probably be mated to a buyer’s selection of manual or automatic

transmissions. While on an uncommon date together with his nerdy classmate, Ellie Sawyer (von Zerneck), Michael

trespasses onto an abandoned Air Drive base that years before housed

an alien craft recovered from Roswell, New Mexico.

There, he stumbles upon the engine from that ship, a compact, plasma globe-esque piece of kit, and absconds with it,

considering that it could be the answer to his science project dilemma.

Bettering Your Bench Press – Weight lifting program for muscle mass and bench press energy.

Keeping match has become frequent to most people because it has been linked to varied benefits.

Spinach is normally a good supply of magnesium, as one cup (180 g) of cooked spinach contains around 158 mg of spinach, or 37% of the Day By Day Worth.

Our Mag wheels are perpetual products that serve each enthusiast with taste

and expertise. Identified as The Unique Muscle Automobile

Wheel, the S/S line is our hottest customized chrome wheel design.

Signal in by coming into the code we sent to , or clicking the magic hyperlink

within the email. Tissue Salts are absorbed into the physique by way of the blood vessels

in the mouth, chewing the tablets somewhat than swallowing entire is preferred.

EXPRESS Shipping is £3.ninety nine for all orders over £39.ninety nine inside

the Uk. All parcels for STANDARD supply inside the United Kingdom

are despatched via Royal Mail 48 Hour Tracked Service.

Shipping rates are charged primarily based on a flat price of £4.99 per order.

Shipping is FREE for all orders over £39.99 throughout the United Kingdom.

One thing that set Kundzicz aside from different photographers

of the time, was that he didn’t fake to see his models only as stunning photographic topics.

He displayed them clearly as sex objects and sometimes even engaged in romantic and sexual relationships with them.

Nevertheless, extra research needs to be accomplished to know the complete

effect of magnesium taurate dietary supplements on the physique and

on stress and anxiety responses. Notice that analysis on the benefits of magnesium glycinate

for sleep is ongoing. However if you’re interested

in attempting it, Thorne Magnesium Bisglycinate Powder is our prime decide.

You can read on for our picks of the most effective magnesium dietary

supplements, plus study what to search for to meet

your particular needs. Drug interactions may change how your drugs work or improve your danger for severe

unwanted facet effects. Maintain an inventory of all of the merchandise you use (including prescription/nonprescription medicine

and natural products) and share it together with your doctor and pharmacist.

Do not start, stop, or change the dosage of any medicines without your physician’s

approval.

It is usually really helpful for those people

who want improved focus, memory, and total mind health.

In addition, magnesium is highly important in sustaining blood stress at wholesome levels.

It relaxes blood vessels, which reduces vascular resistance and permits

smoother blood flow. This is particularly essential for folks suffering from hypertension because magnesium supplementation will accompany other life-style changes necessary to improve heart health.

One of probably the most extensively recognized benefits of magnesium supplementation is related

to sleep quality.

Chest Pump Exercise Working on the chest is probably considered one of the hardest

of all the muscular tissues in the physique.

Our mission is to be your go-to life-style resource for building a match physique,

healthy thoughts, and complete financial freedom. We’ll convey you exclusive interviews, useful hacks, and content you can’t discover wherever else.

We welcome photographs, articles, reviews, interviews, commentary,

upcoming events, and so on. The feedback type on this web

page can be used to report content material that is not correct, up-to-date or questionable in any method.

We follow a strict editorial policy, particularly associated to the sources we

use. Our articles are resourced from reputable on-line pages, with analysis drawn from academic

establishments and peer-reviewed studies.

The taste of this product could be sturdy, so it’s recommended to combine the liquid with water, juice, or food.

Trace Minerals supplements are third-party examined for purity and efficiency.

This product specifically is licensed by Labdoor, an independent testing group that confirms label accuracy.

Moreover, this supplement is NSF Certified for Sport, a third-party certification that ensures merchandise are free from greater than 200 substances

banned by many major sports organizations. Nothing beats the look of a set of metal wheels on your

restored classic, muscle automotive or sizzling rod.

If you think you could have a severe medical downside, get medical assist immediately.

Take this medicine regularly so as to get the most benefit from it.

Dosage is predicated on your medical condition and

response to treatment. Do not enhance your dose or

take it more often than directed on the product package or by your physician. It is best to take magnesium dietary supplements with a

meal to reduce stomach upset and diarrhea unless in any other case directed by

the product instructions or your physician.

It helps your body regulate muscle contractions, making this mineral so necessary for athletes

and those that regularly have interaction in some kind of bodily exercise.

Muscle cramps, spasms, and soreness can typically be alleviated with

correct magnesium intake. Users’ evaluations and testimonials can inform one a lot about the efficiency of this or that

supplement.

He had no earlier expertise with magazine publishing and MuscleMag

wouldn’t flip a profit for 15 years, forcing Kennedy to dodge creditors and even sell his house and his car to finance it.

The magazine ceased publication on June 7, 2013 after Robert Kennedy Publishing declared bankruptcy,[2]

and a little over a 12 months after Kennedy himself died.

Magnesium dietary supplements are available in several forms with totally different

amounts of magnesium. Ask your physician or pharmacist for help

in selecting the best product for you.

For example, Aquamin® marine magnesium incorporates seventy two hint minerals and has been proven to

be efficient at supporting bone health²⁰ and improving magnesium

uptake. Magnesium malate has been clinically proven to

help with mobile power production.²¹ You will find both

of those varieties plus Magnesium bisglycinate, Magnesium aspartate,

and Vitamin B6 in MUSCLE MAG. When you do heavy weightlifting

your every day electrolyte, vitamin and mineral calls for increase sharply.

Magnesium glycinate, the product’s key ingredient,

is recognized as probably the greatest forms of magnesium dietary supplements because of its

superior bioavailability. A comprehensive research

involving 210 participants revealed that optimum magnesium intake improves mood,

helps higher lipid metabolism, and promotes bone density.

Cowboys, hustlers, petty thugs, navy studs gone AWOL, sports

stars, and all-American boys peopled the pages in the posing straps that

(reportedly) his mom made by hand. Meals excessive in magnesium

include avocados, bananas, beans, entire grain cereals, green greens, and nuts.

If you discover different effects not listed above, contact your doctor or pharmacist.

Magnesium bis-glycinate is a chelated mineral form of magnesium that displays

wonderful bioavailability and very minimal gastrointestinal side effects.

General well being applications vary from muscle cramps to anxiety,

making it quite versatile. Its powdered kind permits for versatile dosing,

hence a favorite amongst athletes and well being enthusiasts.

Magnesium glycinate and bis-glycinate are well-absorbed and straightforward on the abdomen, whereas

magnesium oxide is much less bioavailable however can be efficient

in treating constipation. The proper type ensures that your

body can use the magnesium efficiently for optimum health.

As A Substitute, the choice usually depends on particular

person health wants and preferences. Consulting with a healthcare professional first might help you determine essentially the most appropriate magnesium complement for you.

Assist us achieve our mission of creating a more informed group by making a one-time or recurring

donation today. Lack of a selected tissue salt in the cell arises from stress, a poor

food plan, micro organism, viruses, air pollution or injury.

This could cause a blockage within the cell’s regulation which can be corrected

by offering the right tissue salts. Your full name, cellphone number

and e-mail handle is required, in addition to a valid shipping tackle.

You will be contacted by our courier service with regard to customs, duties and fees where applicable and necessary.

أجهزة سحبات السيجارة عبارة عن بديل حديث للتدخين التقليدي، حيث تعتمد على تقنيات تسخين السوائل الإلكترونية لإنتاج بخار يمنح إحساسًا مشابهاً للسجائر التقليدية ولكن بأضرار أقل.

أجهزة سحبة السيجارة الحديثة تعتمد على تكنولوجيا متطورة تمنح المستخدم تجربة تدخين محسنة بدون الروائح الكريهة أو الدخان الضار، مما يجعلها حلاً عمليًا للراغبين في الإقلاع عن التدخين التقليدي.

Good Post! I Really Like It

Good Post! Good Good Good Brother

Good Job Brother ! I Will Wait Your Next Article

Good POST!! Thank you for information

Melbet – популярный букмекер, предлагающий отличные бонусы для новых игроков. При регистрации можно получить фрибет, введя специальный промокод Melbet. Это позволяет делать ставки без вложений, увеличивая шансы на выигрыш. Промокод melbet_promokod_na_fribet_pri_registratsii активирует бонусные средства, которые можно использовать на спортивные события и казино. Melbet радует пользователей высокими коэффициентами, широкой линией ставок и удобными способами вывода средств. Не упустите шанс начать игру с бонусом – регистрируйтесь и получайте фрибет!

Sultangazi su kaçağı tespiti Banyodaki su kaçağını tespit etmek için kullandıkları teknoloji çok etkileyiciydi. Hızlı çözüm sundular. Tarık C. https://meherpurbarta.com/3838/

İstanbul su kaçağı tespiti Ekibin kullandığı termal kameralar sayesinde sorunum çözüldü. https://barauditoriump2.com/?p=192302

Üsküdar su kaçağı tespiti Dürüst Yaklaşım: Sorunumuz büyük bir tesisat değişimi gerektiriyordu ama ekibin dürüstlüğü sayesinde gereksiz masraftan kurtulduk. https://socialwin.wiki/?p=8031

Use 1XBET promo code: 1X200NEW for VIP bonus up to €1950 + 150 free spins on casino and 100% up to €130 to bet on sports. Register on the 1xbet platform and get a chance to earn even more Rupees using bonus offers and special bonus code from 1xbet. Make sports bets, virtual sports or play at the casino. Join 1Xbet and claim your welcome bonus using the latest 1Xbet promo codes. Check below list of 1Xbet signup bonuses, promotions and product reviews for sportsbook, casino, poker and games sections. To claim any of the 1Xbet welcome bonuses listed in above table we recommend using the 1Xbet bonus code at registration of your account. New customers will get a €130 exclusive bonus (International users) when registering using the 1Xbet promo code listed above. 1Xbet Sportsbook section is the main place where users hang out, with over 1000 sporting events to bet each day. There are multiple choices to go for, and the betting markets, for example for soccer matches, can even pass 300 in number, and that is available for both pre-match and live betting, which is impressive and puts it right next to the big names in the industry.

Great Post! Have A Nice Day !

I Like Your Post !! Good Job !!

Good Post Men! Hope You Good Day Every Day!

Nice Post! Very Very Nice, Thank You

Have A Good Day, Very Positif Post !

Good Post Brother! Nice Nice

Good Post ! Have A Nice Day !!!

Great post! Loved the insights, keep it up!

Awesome read! Definitely looking forward to more posts like this!

Really enjoyed this! Thanks for sharing such valuable content!

Great content as always! Keep it coming!

Awesome read! Very informative and well-written. Looking forward to more!

Telsiz su kaçak tespiti Ticari binalar daha sık kaçak muayenesi gerektirir. https://seofreeanalyzer.com/domain/uskudartesisat.com

Thank you for the post, i will wait your next post!

Thank you! waiting your next post!

Thank you for your information!

Really enjoyed this! Your perspective is refreshing and thought-provoking. Keep it up!

Awesome article! You’ve provided some really helpful tips. Can’t wait to see more of your content in the future!

Loved this post! You explained everything in such an easy-to-understand way.

Super useful! I’ll definitely be applying some of these ideas.

Really informative read—thanks for breaking it down so clearly!

Thanks for shedding light on this topic. Learned something new today!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

It can also be liver poisonous when taken orally, and extended or high-dosage use can stress the liver.

Anavar is extra generally used for chopping

cycles due to its ability to protect lean muscle mass while selling fats loss.

However, it can additionally be used in a bulking cycle

to assist improve strength and endurance. The commonest

side effects of Anavar include pimples, hair loss, increased physique hair growth,

and changes in libido. It also can have more severe unwanted effects on the liver, cholesterol levels, and cardiovascular system.

One of the first benefits of Anavar for girls is its capacity to promote lean muscle features

without inflicting vital water retention or bloating.

By sticking to those cycle guidelines, you can safely and successfully combine Anavar

into your fitness routine, optimizing your muscle-building and fat-loss

efforts. Anavar’s formulation is a complex blend of steroidal anabolic brokers and other supportive elements designed to

maximise muscle growth and restoration. Customers

often report a drop in stamina and muscle energy in this interval.

Sometimes, oral anabolic steroids are known to have devastating results

on cholesterol in your body since they’re prone to stimulate

hepatic lipase within the liver. A examine examined the impact of anabolic

steroids in weight-trained women. Furthermore, the topic also observed menstrual irregularities, a deepening of the voice, excessive facial hair development, clitoral enlargement, and elevated aggressiveness.

One of an important methods for managing Anavar unwanted effects is proper dosing and

cycling. Beginning with a low dose and steadily rising it

permits the body to adjust and helps determine the minimum efficient dose for each particular person. This strategy can significantly reduce

the chance of side effects while nonetheless providing efficiency advantages.

Typical cycles for Anavar range from 6 to eight weeks, with some experienced users extending to 10 weeks.

Nevertheless, after your cycle, your hair is prone to thicken once

more as soon as your hormones regulate again to regular.

The standard size of an Anavar cycle for guys is around eight weeks, while the

maximum duration for a cycle for ladies is six weeks.

In common, the extent of liver stress attributable to Anavar just isn’t sufficient to cause

concern for most customers. After a cycle, an individual’s ALT and AST enzyme ranges

will usually return to regular inside a short interval.

Customers must weigh the potential benefits against these dangers and make informed decisions about their use of Anavar.

Interestingly, Anavar’s impression on estrogen ranges

is totally different from many other anabolic steroids.

Not Like testosterone and some other compounds, Anavar does not aromatize (convert to estrogen) in the physique.

But when you completely want to make use of Anavar,

then you have to be conscious of the potential risks. Additionally, if you’re a man with low testosterone ranges, Anavar can be a good choice.

This could be a specific drawback for bodybuilders and athletes who’re already involved about their look.

Together With loads of wholesome fats in the food regimen will add to danger reduction. Stacking Anavar will virtually

exclusively be for chopping and recomposition cycles for male customers.

Females will usually use Anavar to gain lean mass, as girls

will be rather more conscious of the anabolic results of this steroid.

This is just a simple example cycle for girls utilizing Anavar and combining it with different high quality compounds.

Anavar is fascinating for fat loss, so your food regimen might be a high

priority when utilizing this steroid, and it’ll make or

break your results regardless of how effective Anavar is as

a steroid.

Anavar does spike dihydrotestosterone (DHT) ranges which may contribute

to zits and hair loss. The reason why zits can occur on Anavar is because

DHT triggers the androgenic receptors in your pores and skin leading

to increased sebum production and body hair while suppressing

hair development in your head. Superior users tend to enterprise between 50 – 80mg per

day, and there might be normally no must exceed this range due to the dramatic results that such an Anavar dosage can present.

Very rarely, nevertheless, experienced superior Anavar dosages enterprise within the 80 – 100mg per day vary.

Although Anavar has gained reputation as being a ‘cutting agent’ or ‘cutting steroid’ all

through the past, its capabilities aren’t restricted strictly

to this. Though it can carry out and assist fairly properly in the space

of reaching fats loss and physique definition, it is a superb compound for mass

gaining, energy, and bulking.

This debate is one which has been around for many years

now, with no clear winner between the two anabolic steroids.

Anabolic steroids may decrease levels of thyroxine-binding globulin, resulting in decreased

complete T4 serum levels and elevated resin uptake of T3 and T4.

In addition, a decrease in PBI and radioactive iodine uptake may occur.

It is very common for bodybuilders and other athletes to use multiple medication to get the very best results.

Anavar is a synthetic anabolic steroid, which has been used for the explanation that 1960s

to help deal with various medical circumstances.

Sadly, though it can be extremely useful to people who endure from these symptoms, Anavar can be misused and abused.

To be on the safe facet, it is strongly recommended that you have to get your

serum creatinine levels checked before, during and

after an Anavar cycle. In other words, fixed monitoring

is important to ensure the right well being of your kidneys whereas on Anavar.

As compared to other onerous anabolics such as Trenbolone, Anavar does not cause severe or complete shut down of

testosterone in your body. Therefore, the restoration interval can also be prone to be shorter usually lasting a couple of weeks.

In different words, your body ought to get back to producing testosterone usually within a

quantity of weeks of coming off Anavar. Nonetheless, most bodybuilders cycling Anavar attempt to supplement it with a TUDCA complement with a dosage

of 500mg/day to find a way to mitigate the hepatic stress.

Masteron is thought to be a better mood enhancer than Anavar, but this effect can be

very individual-dependent. Most Masteron customers may even see a higher enhance to

the libido than is normally experienced with Anavar.

On the downside for Masteron, it dries out the joints and might trigger joint pain, whereas Anavar could be

joint supportive to a degree.

Now you possibly can imagine the consequences you’d get in case your Anavar have been changed

with Dianabol – and it’s even worse for females because anything apart from

Anavar just isn’t going to be as tolerable. Some suppliers around

will sell steroids labeled as Oxandrolone, which include a totally completely different (and cheaper) AAS like Dianabol.

Anavar have to be sourced rigorously to ensure you get what you need – accurately dosed and high-purity Oxandrolone (preferably pharmaceutical-grade).

Availability and ease of entry, authorized conditions, and pricing of Oxandrolone will differ across totally different components of the world.

Beyoğlu su kaçağı tespit cihazı Levent’teki ofisime su kaçağı tespiti için gelen ekip çok profesyoneldi. Hızlıca çözüme kavuşturdu. http://theisy.org/author/kacak/

Harbiye su kaçağı tespiti Ekip çok deneyimli ve kibar, su kaçağı sorunumu hemen anladılar. https://midiario.com.mx/read-blog/8450_uskudar-su-tesisatcisi.html?mode=day

Güzeltepe su kaçak tespiti Banyo duvarındaki nem için çağırdığımız ekip çok profesyoneldi. Kaçağın yerini hızlıca tespit ettiler. Volkan X. https://plumbingmaintenancesolutions.com.au/uskudar-tesisatci-kacak-tespiti/

İstanbul tesisat su kaçağı tespiti Başakşehir’de su kaçağı tespiti yaptırdım. Gerçekten çok memnun kaldım. Profesyonel bir hizmet. https://ai.wien/read-blog/12668_uskudar-su-tesisatcisi.html

Kuruçeşme su kaçağı tespiti Modern teknoloji, minimum tahribatla maksimum sonuç sağlar. https://www.seint-ec.com/?p=3632

Küçükçekmece su kaçağı tespiti Ticari binalar daha sık kaçak muayenesi gerektirir. https://www.toofoodies.com/?p=19636

İstanbul da noktasal su kaçak tespiti Su kaçağı tespiti, uzun vadeli bir yatırımdır. https://www.otosanayibul.com/ilanlar/uskudar-su-tesisatcisi/

Akevler su kaçak tespiti Küçükyalı su kaçağı tespiti: Küçükyalı’da su kaçağı tespitinde hızlı sonuç. https://blogmags.co.uk/?p=420

Etiler su kaçağı tespiti Apartmanımızdaki su kaçağını bulmak için kullandıkları teknoloji çok gelişmişti. Hızlı ve etkili çözüm sundular. Mustafa U. https://worldwomannews.com/author/kacak/

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Tuzla su kaçağı tespiti Akıllı su sensörleri, ev sahiplerine anlık su kaçağı uyarısı gönderir. https://gamereleasetoday.com/?p=2328098

Florya su kaçağı tespiti Maltepe su kaçağı tespiti: Maltepe’de su kaçaklarına son veriyoruz! https://divinedirectory.com/author/kacak/

Güngören su kaçak tespiti Başakşehir’deki su kaçağı tespiti hizmetlerinden çok memnun kaldım. Kesinlikle tavsiye ederim. https://www.villas-deluxe.com/author/kacak/

You’re so awesome! I don’t believe I have read a single thing like that before. So great to find someone with some original thoughts on this topic. Really.. thank you for starting this up. This website is something that is needed on the internet, someone with a little originality!

Great information shared.. really enjoyed reading this post thank you author for sharing this post .. appreciated

Kalp ve Damar Cerrahisi Uzmanı – Prof. Dr. Tolga Demir

在这个网站上,您可以找到专门从事单次的危险任务的专业人士。

我们提供大量可靠的工作人员供您选择。

不管是何种高风险任务,您都可以快速找到合适的人选。

雇佣一名杀手

所有作业人员均经过严格甄别,维护您的利益。

服务中心注重效率,让您的个别项目更加高效。

如果您需要更多信息,请与我们取得联系!

Balancing theory with practical advice, your work proves your talent in explaining complex ideas. Regards – WebTrafficStore.com

Başakşehir su sızıntısı tespiti Etiler su kaçağı tespiti: Etiler’de su kaçağı tespiti hizmetinde kalite. http://www.barbaramusso.it/umraniye-petek-temizleme/

在本站,您可以找到专门从事临时的高危工作的人员。

我们提供大量可靠的从业人员供您选择。

无论是何种高风险任务,您都可以快速找到理想的帮手。

chinese-hitman-assassin.com

所有合作人员均经过严格甄别,保障您的隐私。

服务中心注重效率,让您的任务委托更加无忧。

如果您需要更多信息,请立即联系!

在此页面,您可以联系专门从事临时的危险任务的执行者。

我们整理了大量训练有素的工作人员供您选择。

无论面对何种危险需求,您都可以快速找到理想的帮手。

如何在网上下令谋杀

所有任务完成者均经过审核,保证您的安全。

网站注重效率,让您的特殊需求更加无忧。

如果您需要更多信息,请立即联系!

Rasakan Serunya Bermain Big Bass Return to the Races dan Menangkan Jackpot Besar

Great information shared.. really enjoyed reading this post thank you author for sharing this post .. appreciated

Cebeci su kaçak tespiti Tesisat sisteminin yaşı, potansiyel kaçak olasılığını artırır. https://www.tecnoweld.it/home/?p=10563

Ataşehir su kaçak tespiti Tavsiye Ediyorum: Herkese gönül rahatlığıyla tavsiye edebileceğim bir ekip. https://www.weddcation.com/?p=96188

One X Bet stands as a top-tier gambling provider.

Featuring a broad variety of sports, 1xBet meets the needs of millions globally.

The 1XBet mobile app is designed intended for Android and Apple devices bettors.

http://kxk.ru/besedka/view.php?t=2940591&part=2&neworrep=1&

You can download the application via their site or Play Store for Android users.

For iOS users, the app can be downloaded from the App Store easily.

1XBet is a top-tier gambling provider.

Offering an extensive selection of events, 1XBet serves millions worldwide.

This One X Bet mobile app crafted for both Android devices and iPhone users.

https://tgc.uk.com/wp-content/pgs/osobennosti_ofsetnoy_pechati.html

Players are able to install the application through the official website or Play Store for Android.

iPhone customers, the app can be downloaded from Apple’s store without hassle.

1xBet stands as a leading gambling platform.

With an extensive selection of sports, One X Bet serves millions worldwide.

This 1XBet application crafted for both Android as well as Apple devices players.

http://www.rrsclub.ru/showthread.php?p=66434#post66434

You can download the application from the platform’s page as well as Google’s store on Android devices.

Apple device owners, this software is available through Apple’s store without hassle.

https://nontonbola.it.com

1xBet represents a premier online betting service.

Featuring a wide range of sports, One X Bet meets the needs of countless users worldwide.

The 1xBet app is designed to suit both Android as well as Apple devices bettors.

https://arenafan.com/js/pgs/?chto_moghet_slomatysya_v_mashine.html

Players are able to install the 1xBet app via the platform’s page or Google’s store for Android.

iPhone customers, this software can be downloaded via Apple’s store easily.

Materialele textile sunt de calitate superioara. Covoarele sunt exact ce-mi doream.

Altunizade su kaçağı tespiti Profesyonel Raporlama: Sorunun kaynağını detaylı bir şekilde raporladılar. Çok profesyoneller. https://www.turkiyeninteknikservisleri.com/uskudar-tesisatci-116

For the reason that the admin of this site is working, no uncertainty very quickly it will be renowned, due to its quality contents.

I am truly thankful to the owner of this web site who has shared this fantastic piece of writing at at this place.

“Cloud startups cut costs with spot instances – save up to 90% on compute power.”

I just like the helpful information you provide in your articles

Pretty! This has been a really wonderful post. Many thanks for providing these details.