Stainless steel, a corrosion-resistant alloy with a minimum of 10.5% chromium content, finds its way into various industries due to its excellent properties. Within the vast family of stainless steels, grades 308 and 309 are two commonly used alloys, each with its own unique characteristics and applications. In this article, we delve into the differences between Stainless Steel 309 vs 308, exploring their composition, properties, and usage scenarios in detail.

Stainless Steel 309 vs 308 – What’s the Difference?

Stainless Steel 309 vs 308 – 1. Composition

The fundamental difference between Stainless Steel 308 and 309 lies in their chemical composition. Stainless Steel 308 is an austenitic stainless steel, primarily designed for welding operations on similar stainless steels, such as type 304. Its composition typically includes chromium, nickel, and manganese, with the nickel content being higher than in grade 309. This composition ensures good corrosion resistance and weldability.

On the other hand, Stainless Steel 309 is a chromium-nickel stainless steel with a higher chromium and nickel content than grade 308. This composition provides excellent oxidation resistance and high-temperature corrosion resistance. It is specifically designed for welding applications where the base metal has a high carbon content or is subject to service temperatures above those normally encountered with grade 308.

Stainless Steel 309 vs 308 – 2. Properties

The compositional differences between these two grades lead to distinct physical and mechanical properties. Stainless Steel 308 offers good ductility and toughness, making it suitable for welding applications that require a high degree of formability. Its corrosion resistance is comparable to that of grade 304 stainless steel, ensuring long-term durability in various environments.

Stainless Steel 309, on the other hand, exhibits superior oxidation resistance and can withstand higher temperatures than grade 308. It is often used in welding applications where the welded joint must perform under severe conditions, such as high-temperature environments or corrosive media. Additionally, the higher chromium content in grade 309 enhances its resistance to scaling and oxidation, making it a preferred choice for high-temperature applications.

Stainless Steel 309 vs 308 – 3. Applications

The distinct properties of Stainless Steel 308 and 309 dictate their specific applications. Grade 308 is commonly used for welding type 304 stainless steel, as it provides a similar corrosion resistance profile and ensures a strong, durable weld. It is often employed in the food processing, chemical processing, and medical equipment manufacturing industries, where corrosion resistance is a critical factor.

Stainless Steel 309, on the other hand, finds its application in welding carbon steel or low-alloy steel to stainless steel, especially when the welded joint will be exposed to high temperatures or corrosive environments. It is also used in the petrochemical, power generation, and heat treatment industries, where materials must withstand extreme thermal and chemical conditions.

Stainless Steel 309 vs 308 – 4. Weldability

Both grades offer good weldability, but their welding characteristics differ slightly. Stainless Steel 308, due to its higher nickel content, exhibits excellent weldability and is less prone to cracking during welding. It is often used as a filler metal for welding type 304 stainless steel.

Stainless Steel 309, while also weldable, may require special welding techniques and procedures to avoid hot cracking and ensure a sound weld. The higher chromium content in grade 309 can increase the risk of hot cracking, necessitating the use of low-hydrogen welding processes and proper preheat and post-weld heat treatment.

Stainless Steel 309 vs 308 – 4. Cost

In terms of cost, Stainless Steel 308 is generally more economical than grade 309. This is primarily due to the difference in raw material costs and the relative ease of welding grade 308. However, the choice between these two grades should not be solely based on cost but should also consider the specific requirements of the application, such as corrosion resistance, high-temperature performance, and welding conditions.

Conclusion

In summary, Stainless Steel 308 and 309, while sharing similarities as stainless steel alloys, have distinct differences in composition, properties, and applications. Grade 308 is suitable for welding type 304 stainless steel and offers good corrosion resistance and weldability. Grade 309, on the other hand, is designed for welding carbon steel or low-alloy steel to stainless steel and exhibits superior oxidation resistance and high-temperature performance.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between Stainless Steel 309 vs 308. If you are looking for Stainless Steel 309 & 308 supplier and manufacturer online now, we would advise you to visit Sino Stainless Steel.

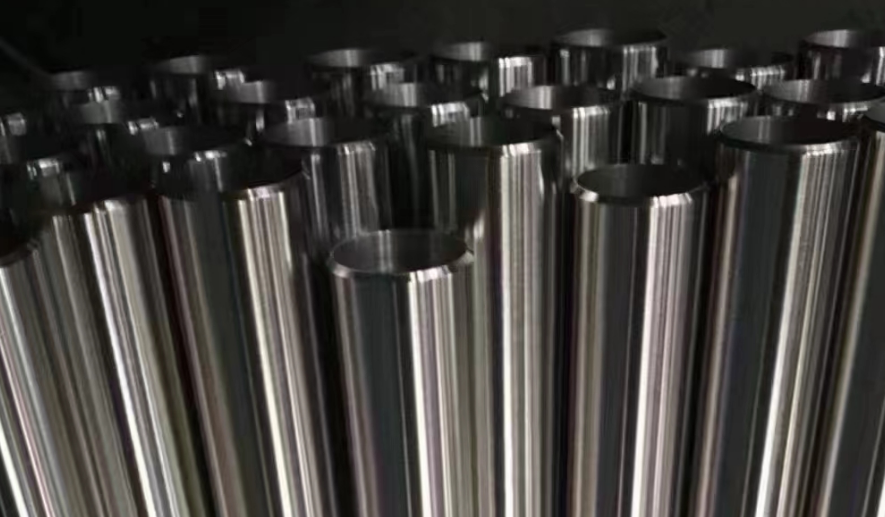

As a leading supplier of stainless steel products from Shanghai China, Sino Stainless Steel offers customers high-quality stainless steel decorative sheets, stainless steel tubes, stainless steel pipes, stainless steel strips, stainless steel coils, stainless steel plates, and stainless steel bars at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

Dive Into Anything

How long is the PCT really?

The Primary Caregiver Treatment (PCT) is a term that can be used in various contexts, often related to health, wellness,

or mental health care. Its duration can vary significantly depending on the specific application and the individual needs of the patient or client.

For instance, in some cases, PCT may involve several weeks or months of

structured programming designed to address particular challenges or conditions.

If we are referring to a treatment plan within a medical or therapeutic context, the length of the PCT can range from a few days

to several years, depending on the condition being addressed.

For example, in cases of addiction recovery or

chronic disease management, PCT may involve ongoing support and therapy sessions spread over an extended period.

It’s also important to consider that the success of a PCT often depends on consistent participation and adherence to the prescribed program.

Therefore, while the duration can vary, it’s crucial for individuals to work closely with their healthcare providers

to create a personalized plan that meets their specific needs and goals.

Top Posts

1. “Understanding PCT: A Comprehensive Guide”

This article provides an in-depth look at what PCT entails,

its various forms, and how it can be tailored to individual circumstances.

It’s a must-read for anyone looking to gain a deeper understanding of

PCT and its applications.

2. “PCT Duration: What You Need to Know”

Explore the factors that influence the length of a Primary

Caregiver Treatment program in this informative piece.

It offers practical advice for patients and caregivers alike.

3. “Case Studies: Successful PCT Outcomes”

Featuring real-life examples of individuals who have benefited from PCT, this article highlights the transformative impact of effective treatment programs.

It’s a powerful reminder of the importance of

accessing quality care.

Here is my web blog :: does jujimufu use steroids

I do consider all the ideas you’ve introduced in your post.

They are very convincing and can definitely work. Still, the posts are very brief for starters.

May just you please extend them a bit from next time? Thanks for the post.

Does your site have a contact page? I’m having a tough time locating it but, I’d like to

shoot you an e-mail. I’ve got some creative ideas for your blog you might

be interested in hearing. Either way, great website and I look forward to

seeing it develop over time.

70918248

References:

amphetaminen Wirkung auf Testosterone