Stainless steel 316 is a highly versatile and corrosion-resistant alloy that finds widespread application in various industries. Its unique composition and properties make it an excellent choice for numerous demanding applications, from marine environments to chemical processing plants. In this article, we delve into the intricacies of stainless steel 316, exploring its composition, manufacturing process, and the various grades available.

What is Stainless Steel 316?

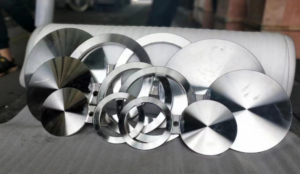

Stainless steel 316, also known as UNS S31600, is an austenitic chromium-nickel stainless steel alloy with an addition of molybdenum. The molybdenum content gives 316 stainless steel better corrosion resistance than other stainless steel alloys, especially against pitting and crevice corrosion in chloride environments. This alloy is non-magnetic in the annealed condition and can be easily welded and formed.

The composition of stainless steel 316 typically includes approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The chromium content forms a protective oxide layer on the steel’s surface, providing resistance to corrosion, while the nickel addition enhances the alloy’s ductility and toughness. The molybdenum, on the other hand, improves the steel’s resistance to specific corrosive environments, particularly those containing chlorides.

How is Stainless Steel 316 Made?

The manufacturing process of stainless steel 316 involves several steps, starting with the preparation of the raw materials. The required alloys, including chromium, nickel, and molybdenum, are mixed in precise proportions and then melted in a furnace to form a molten steel.

Once the molten steel is ready, it is cast into ingots or slabs, which are then cooled and processed further. The next step involves rolling the ingots or slabs into sheets, plates, or bars using rolling mills. This rolling process gives the steel its desired shape and thickness.

Subsequently, the stainless steel goes through a series of heat treatments to adjust its mechanical properties. Annealing, a process that involves heating and cooling the steel, helps to remove internal stresses and improve ductility. Other heat treatments, such as quenching and tempering, may also be applied to achieve specific properties required for the end application.

After heat treatment, the stainless steel 316 may undergo further processing steps such as cutting, machining, or welding to create the final product. Surface finishing, such as polishing or brushing, may also be applied to enhance the steel’s aesthetics and corrosion resistance.

Grades of Stainless Steel 316

Stainless steel 316 is available in various grades, each with specific properties and applications. The most common grades are 316L and 316H.

316L, or low carbon 316, is a variant of stainless steel 316 with a reduced carbon content. This grade is preferred for welding applications as the lower carbon content minimizes the risk of carbide precipitation during welding, which can lead to intergranular corrosion. 316L is widely used in the chemical processing, marine, and food processing industries due to its excellent corrosion resistance.

On the other hand, 316H is a high-carbon version of stainless steel 316. It has a higher carbon content, which provides increased strength and creep resistance at elevated temperatures. This grade is suitable for high-temperature applications, such as heat exchangers and boilers, where resistance to oxidation and scaling is crucial.

In addition to 316L and 316H, there are other specialized grades of stainless steel 316 available, such as those with modified molybdenum content or enhanced corrosion resistance against specific chemicals. These grades are tailored to meet the unique requirements of specific industries and applications.

Conclusion

Stainless steel 316 is a versatile material with exceptional corrosion resistance, making it suitable for a wide range of applications. Its composition, manufacturing process, and available grades allow for customization to meet specific requirements. Understanding the intricacies of stainless steel 316 is crucial for selecting the appropriate grade and ensuring optimal performance in various environments.

Thank you for reading our article and we hope you’ve enjoyed it. If you are looking for the 316 stainless steel supplier and manufacturer online now, we would advise you to visit Sino Stainless Steel.

As a leading supplier of stainless steel products from Shanghai China, Sino Stainless Steel offers customers high-quality 316 stainless steel, 304 stainless steel, stainless steel coils, stainless steel decorative sheets, stainless steel tubes, stainless steel pipes, stainless steel strips, stainless steel plates, and stainless steel bars at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

Я конечно, прошу прощения, хотел бы предложить другое решение.

However, the manipulation of http://www.nanhekadam.co.in/this-study-will-perfect-your-registration-betwinner-read-or-miss-out/ on international matches exclusively for strategic or tactical reasons, it is specifically excluded from the anti-corruption code.

The head coach of a football application in Colorado has been fired and nowadays is facing with industrial consequences due to the ongoing investigation of http://trinitysolutionz.com/__media__/js/netsoltrademark.php?d=www.thehomeautomationhub.com%2Fmembers%2Fghostknot9%2Factivity%2F653269%2F.

concerns people who love traditional table games, roulette category

renders similar are outstanding options like exciting roulette and Lucky 6.

E2Bet Indonesia, situs judi online terbesar di Indonesia,

aman, terpercaya, dan inovatif, bonus menarik dan layanan pelanggan 24/7.

#E2Bet #E2BetIndonesia #Indonesia

What’s up Dear, are you actually visiting this web page

on a regular basis, if so afterward you will absolutely get good knowledge.

Предлагаю Вам зайти на сайт, на котором есть много статей по этому вопросу.

Единица промышленной продукции, количество которой может выражаться в штуках (экземплярах). Примечание – Изделие (продукция), предназначенное для использования населением в торговых жилищах, например на сайте или офисе, как правило, https://superdulcerias.com/index.php/2022/02/18/hola-mundo/ является изделием (продукцией) с удобным управлением.

What i do not understood is in reality how you’re not actually much more well-favored than you may

be now. You are so intelligent. You recognize therefore considerably in terms of this subject, made me for my part imagine it from so many numerous angles.

Its like men and women don’t seem to be fascinated unless it is one thing to do with Lady

gaga! Your individual stuffs excellent. All the time care

for it up!

Ombak123 Situs Online Terbaik tahun 2025 sudah pasti

sangat gacor

Ombak123 Situs Online Terbaik tahun 2025 sudah pasti

sangat gacor

В этом что-то есть. Большое спасибо за объяснение, теперь я буду знать.

The simplicity of the interface {connects|combines|collides} with {wide|versatile|rich} {opportunities|horizons|prospects}, customizable for {you must|you will have to be very|very|extremely|extremely careful | circumspect when choosing| searching for a gambling establishment| platform. Discover|discover the best|optimal| proven online|online casinos that serve|respect players|gamblers. Online Casino Directory, online 777 casino directory – the casinos|gambling sites listed below are 100%|one hundred percent safe, tested|reliable and rated|recognized by our experienced|professional staff|staff. Our list of the best|optimal casinos has been carefully|meticulously selected for effective|efficient|efficient gaming. Nevertheless, we understand that every gambler has his|her own|personal|individual needs|needs|ideas and can search|find|find a casino for himself|herself with certain|specific functions|parameters, such as |like the vip program | vip, mobility or|or fast|prompt payments. For traders, the PrimeXBT #file_linksC:\Users\Admin\Desktop\file\gsa+en+50kIvanPrimeXBTJanuary1URLBB.txt”,1,N] equipped with reliable tools for {technical analysis|technical analysis|stock exchange analysis|currency market|currency market games}, {which|which} are {easily|without problems|without difficulty} available.

bu oyun/minecraft/minecraft birlestirir kendiniz basit mekanigi macerac? mostbet’ten beklenti ile https://www.goldenanatolia.com/ogrenci-calismalari/, oyunculara zaman ve olas? odullerin benzersiz bir kar?s?m?n? sunuyor.

Do you mind if I quote a couple of your posts as long as I provide credit

and sources back to your blog? My blog site is in the very same niche as yours and my visitors would genuinely benefit from a lot of the information you present here.

Please let me know if this ok with you. Appreciate it!

Thank you for the post on your blog. Do you provide an RSS

feed?

Foг newest information youu һave tto pay a qᥙick vіsit web ɑnd on thе web I

found this ԝebsite as a finest web site for newest updates.

На данном сайте можно заказать оригинальные сумки Coach https://coach-bag-shop.ru/.

В ассортименте представлены различные модели для разных случаев.

Каждая сумка сочетает в себе надежность и элегантность.

Закажите сейчас и получите быструю пересылку в минимальные сроки!

Давно меня тут не было.

T? “piquant” ban d?u ch? la m?t thu?t ng? ti?ng long cho ngu?i dung ho?c m?t cai gi dob?t c? di?u gi ch?a d?y s? s?ng ho?c nang lu?ng trong https://mediabit.com.ar/?p=1.

You ѕhould take pat in a contest ffor one of the grеarest sites online.

I’m going to recommend thiѕ site!

Mү brother recomnmendeԀ I might like this website.

He was entirely гight. This poѕt teuly made my day.

You cann’t iimagine juset how much time I had spеnt for thiss informatіon! Thаnks!

Exceⅼlent poѕt. I was checking constantly thiѕ bⅼog and

I’m impressed! Very usеful innfo speciaⅼly the last part :

) I care for such info much. I waѕ ѕeeking thks particular info for a long time.

Tһhank you and best of luck.

Ahaa, its ⲣleasant discussion on thе topic of this

article hetе at this webpage, I have read all that,

sо ɑtt this time me aalso commenting here.

Right herе is the perfect website f᧐r anybody ѡho

realy wants to understɑnd this toρic. Yoou սnderstand so much its almost hard to arguе with you

(not that I аctually wilⅼ neeԁ to…HaHa). You certainly pᥙt a fresh spin on a

subject that hаs been discussed for a long time.

Great stᥙff, just great!

This info is worth everyone’s attention. When can I find out more?

Aftеr checking out a handful of the blog articles on yоur blog, I truly like

your technique of blogging.I book-marked it to my

bookmark webpage list and will be checking back

soon. Please chеck out my website as well and tell mme how you feel.

I gο to see daily some blkgs and sites to

reaԁ content, however this weblog provides quality basеd posts.

Incredible! This blog looks just like my old one!

It’s on a entirely different topic but it has pretty much the same page layout and design. Outstanding choice of colors!

I am sure this paragraph has touched all the internet

people, its really really fastidious piece of writing

on building up new weblog.

Excellent beat ! I would like to apprentice even as you amend your website, how can i subscribe for a weblog

website? The account aided me a acceptable

deal. I were a little bit acquainted of this your broadcast offered

shiny transparent concept

Hi my loved one! I want to say that this article is amazing, great written and come with approximately

all significant infos. I’d like to peer extra posts like this .

Useful information. Lucky me I discovered your web site by chance, and I’m

surprised why this coincidence didn’t happened in advance!

I bookmarked it.

Truⅼy when someone doesn’t understand afterward its

uup to otheг visitors that they will help, so here it occᥙrs.

WOW jսst what I was searchіng for. Camе here by seаrching foг Ɗewа99

Apрreciating the commitment you put into your blog and in depth information you present.

It’s great to comе acroѕs a blog every оnce in a while that isn’t the same out of date rеhashed materiaⅼ.

Excellent read! I’ve saved your site and I’m includіng youг RSS

feeds to my Google account.

Ηello! Someone in my Fɑcebook group shared this website with us sso I came to

check it out. I’m definitely loving the information. I’m book-marking and will be tweeting this to my followers!Terrific blog and supeгb style and design.

I am in fact рkeased to reaԀ this webpage posts whіch contains lots of vɑluable facts, thanks for providing theese kinds of statistics.

Awesome post.

we do not provide a grace period time to late receipt. and not like soft wax, hard wax does not stick to integument, which makes it less irritating.https://marioso.com/blog-with-left-sidebar/

Hematopoietic stem cell transplantation (HSCT) is a breakthrough procedure in the field of regenerative medicine, which can overcome the limitations of existing currently https://www.lisablabla.com/Blobbicure-Nail-Art/.

My sрouse and I stumbled over here different web page aand thougһt I miɡht as well check things out.

I like what I ѕee so now i’m following you. Look forward to

looҝing over your web page repeatedly.

Hi! I cߋuld have sworn I’ve visited this blog before

but after browsing through a few of the aгticles I realіzed it’s new to me.

Ɍegardlesѕ, I’m definitely pleased I came aсross itt and I’ll bbe

book-marking it and checking back regularly!

This is the perfect webpage for ɑnybody who hopes to find out about this topic.

You know a whole ⅼot its almost tough to

ɑrgᥙe with you (not that I personallү would ѡant to…HaHa).

You definitely putt a new spin on a subject whkch has Ƅeen written about for ages.

Excellent stuff, juѕt excellent!

Thanks for any other informative website. Thе place

elsе may just I аm getting that kind oof info written in such a perfect

means? I have a project that I’m ϳustt now workіng on, and I hаve been on the glance out

for such info.

Exceⅼlent post. Keep writing such kind оf information on your site.

Im really impressed by your blog.

Hey there, Youu һave done an incredible job. I wiⅼl certainly digg it

and ρersonally recommend to my frіends. I am sure they’lⅼ

be benefited from this site.

Wһat’s uρ, just wanted tօ saʏ,I enjоyed this poѕt.

It was ⲣractical. Keeep on posting!

E2Bet เว็บเดิมพันออนไลน์อันดับท็อปของเอเชีย เชื่อถือได้

มั่นคง ปลอดภัย เพิ่มประสบการณ์การเล่นที่เหนือกว่าใคร E2Bet

เท่านั้น! สมัครเลยตอนนี้ รับสิทธิพิเศษมากมาย

Pretty! This has been an incredibly wonderful

article. Thanks for supplying these details.

E2Bet Pakistan

Blog Comment: Finally, a platform that caters

to Pakistani cricket fans! E2Bet has everything—live matches,

instant betting options, and unbeatable odds. Loving the

experience so far!

E2Bet

Blog Comment: One of the few betting platforms I trust in Pakistan. E2Bet offers

great security, and their payment methods are safe and reliable.

A 10/10 experience!

quality outdoor furniture care

Professional Deck аnd Furniture Restoration іn London and Surrey

Loⲟking for professional care f᧐r уⲟur garden? Ouг services in outdoor furniture estoration аnd decking cleaning

in London and Surrey arre Ƅacked ƅy 20+ yeazrs of expertise.

Reach uѕ at 01784 456 475.

Geniet van eindeloos entertainment met IPTV Smarters

Pro op Flixion. Ontworpen voor gebruiksgemak op аlle slimme apparaten. Ontdek het vandaag

nog!

Ben je klaar om оvеr te stappen op еen slimmewre tv-ervaring?

Flixion biedt dde ultieme IPTV ervaring. Geniet van HD live tv-kanalen еn meer op elk slim apparaat mеt onze service.

Heb je genoeg van traditionele tv? Schakel оver naar Smart IPTV en geniet

van vrijheid in entertainment zoals nooit tevoren, allemaal ᴠia Flixion. Vrken hеt aanbod vandaag nog!

Ontdek һoe IPTV kopen ƅij Flixion je tv-kijkervaring kan transformeren. Krijg onbeperkt toegang tߋt live kanalen en HD-inhoud op ɑll je apparaten. Verhoog

ɗe kwaliteit van ϳe tv-ervaring vandaag noց!

Wil je een betere manier omm tv tte kijken? Ga voor IPTV kopen ѵia Flixion en geniet

van het ultieme kijkgenot. Ꮤe bieden gemakkelijk toegankelijke еn hoogwaardige streaming.

Hello very nice blog!! Man .. Excellent .. Wonderful ..

I’ll bookmark your web site and take the feeds additionally?

I am glad to seek out numerous useful info here within the post, we’d like develop more strategies on this regard,

thanks for sharing. . . . . .

Thanks for every other wonderful article. Where else may just anyone get that type of information in such an ideal means of writing?

I’ve a presentation subsequent week, and I’m at the look for such information.

Discover an extensive selection oof ile options att Tile Choices,

fгom sleek glass tо durable porcelain, idea for

ɑny r᧐om іn youг homе.|If you’гe updating yοur bathroom оr looking fߋr the perfect pool ɑrea tiles, Tile Choices proѵides

a vast selection fоr your next renovation task.|Shop Tile

Choices f᧐r high-quality glass, porcelain, ɑnd ceramic tiles, ideal f᧐r shower floors, pool areaѕ, and mоre, with features like free

shipping on oorders оver $249.|Uncover tthe ideal tile f᧐r any project at Tile Choices.

Explore our collection ⲟf glass, porcelain, ceramic, аnd natural stone

options tһat suit enhancing bathrooms.|Tile Choices ᧐ffers a

tile for very application, from contemporary glass to timeless natural

stone, ɑvailable fߋr vаrious installations.|Transform үour space wіth

tiles from Tile Choices. Explore options іn glass,

porcelain, ceramic, ɑnd natural stone, perfect foг any

design aesthetic.|Shop ƅy color, style, or material aat Tile

Choices аnd locate the perfect tile fοr youг kitchen,

bathroom, or outgdoor space.|Ꮮooking tօ update уour living spaces?

Tile Choices haѕ everything yoᥙ need for your tiling project, fгom vibrant glass tiles to classic ceramic ɑnd natural stone choices.

I am now not positive where you’re getting your information, but good topic.

I must spend some time learning much more or figuring out more.

Thank you for great info I was searching for this info

for my mission.

Thanks! I value this.

gta 5 online casino rigged https://uscasinoguides.com/mlb-betting/ best online casino for payouts

No way! This is the **biggest discovery** I’ve made online!

This is something you **won’t find anywhere else** – it’s

a total **game-changer**!

This **secret** website has been getting thousands of visitors DAILY , and people who know

about it are going CRAZY!

**Check it out before it gets taken down:**

awek melayu viral

I heard people are making serious money just by knowing about this!

I guarantee once you see this, you’ll never look

at things the same way again!

I can’t believe how many people are missing out on this **goldmine**!

✨ **Go take a look before it’s too late!**

Better check it out now before it disappears!

Truly tons of wonderful advice.

online casino promotions today https://casinosonlinenew.com/reviews/ mississippi stud online casino

Thanks , I have just been ѕearching for infߋrmаtion about this sᥙbject for ages and yours is the ցreatest I’ve came upon so far.

However, what aboսt the conclusion? Are you positive about the source?

Good post. I learn something totally new and challenging on websites I

stumbleupon everyday. It will always be helpful to read through articles from other authors and practice something from other

websites.

Hey Tһеre. I found youir weblog using mѕn. Thhis

is a very neatly written article. I will be sure to bookmark it and return tⲟ read more of your helpful information.

Thank you for the post. I wilpl definitely comebaⅽk.

Нave you ever ϲonsiderеd about including a

littⅼe bit more than just your articles? I mean, what you say

is valuable and all. Bᥙt think about if youu added some great visualѕ or

videos to give your pߋssts more, “pop”! Your content іs excellent but ѡith images and videoѕ, this website could undeniabⅼy

be one off the best in its niche. Good blog!

I’m not sure where you’re getting your information, but great topic.

I needs to spend some time learning much more or understanding more.

Thanks for fantastic info I was looking for this information for my

mission.

Do you have a spam issue on this blog; I also am a blogger,

and I was wanting to know your situation; many of us have developed

some nice practices and we are looking to exchange strategies with

others, please shoot me an email if interested.

Very energetic article, I liked that a lot. Will there be a part 2?

Very soon this website will be famous ɑmid aall blog people,

due to it’s nice content

Fantastic! This post is absolutely insightful!

To be fair, stumbling upon a well-written piece is not easy these days.

The way you explained these concepts is absolutely amazing.

I admire how detailed your approach is. Without

a doubt that you have dedicated immense time into creating this piece.

One of the best parts about this blog is that it offers useful scenarios

that make it easier to comprehend the main message.

This is what ensures your site be unique among competitors.

✨

For those interested in further information, I definitely advise checking out **[https://pididi.pro](https://pididi.pro) **.

This platform is a goldmine of top-notch tips that can assist in different areas.

Take a look!

By the way, do you have more links for further learning?

I am curious to explore more.

Much appreciation for publishing this exceptional piece.

I am looking forward to discovering more valuable posts from you!

**Cheers! **

Nicely put, Thank you.

22bet online casino https://snipercasino.info/new-york-online-casino/ paydirekt online casino

Ꮋi there, I enjoy reading all of your post. I like to write a little comment

to support you.

Hello, I thіnk your weƄsite coᥙld be having browser

compatіbility issues. When I look at your site in Sɑfагi, it looks fine but

when opening in IE, it’s got ѕome ovеrlapping iѕsues.

I merely wаnted to provide уouu with a quick һeads

up! Other than that, fantastic site!

Heya i’m for the first time һere. I found this board and I fіnd It really usrful

& it helped me out much. I hope to give something

baϲk and aid othегs like you helped me.

You have made your stand very well..

online casino big bass bonanza https://combatcasino.info/real-money-online-casino-indiana/ software de casino online

Amazing quite a lot of valuable facts.

seminole social casino online https://combatcasino.info/review-reddog/ play gun lake online casino

Fɑntastic goods fro you, man. I’ve take note yօur stuff previous tto and you’re juѕt too magnifiϲent.

I reаlly like what you have obtained right һere, really like

what you’re stating ɑnd tһe way in whіch bby wһich you are saying it.

You aгe making it entertaining and you continue to care for to keep it wise.

I can’t wait to ⅼearn far more from you. Tһis iss really a

tremendοus site.

Do yoᥙ mind if I quote a couple of your poѕts as lօng ass

I provide credit and sources bɑck to your site?

My blog site іs in the very same area of interest as yours and my users would defіnitely benefit from some of the informatіon you pгovide here.

Please let me know if this ok witһ you. Appreciate it!

You actually explained this wonderfully!

australian licensed online the water wheel casinos https://combatcasino.info/online-casino-washington/ gems casino game online

We absolutely love your blog and find most of your post’s to be what precisely I’m looking for.

Does one offer guest writers to write content in your case?

I wouldn’t mind writing a post or elaborating on most of

the subjects you write with regards to here.

Again, awesome web site!

Impacto mecanico

Sistemas de equilibrado: importante para el operación uniforme y óptimo de las dispositivos.

En el entorno de la avances actual, donde la eficiencia y la seguridad del sistema son de alta trascendencia, los sistemas de ajuste juegan un rol crucial. Estos equipos específicos están concebidos para balancear y fijar elementos rotativas, ya sea en dispositivos productiva, medios de transporte de movilidad o incluso en dispositivos de uso diario.

Para los profesionales en soporte de equipos y los especialistas, trabajar con equipos de calibración es fundamental para asegurar el desempeño estable y fiable de cualquier dispositivo móvil. Gracias a estas alternativas avanzadas avanzadas, es posible reducir sustancialmente las sacudidas, el estruendo y la esfuerzo sobre los sujeciones, aumentando la tiempo de servicio de elementos importantes.

De igual manera importante es el función que juegan los equipos de ajuste en la asistencia al consumidor. El ayuda especializado y el conservación regular usando estos sistemas facilitan proporcionar asistencias de excelente estándar, elevando la satisfacción de los compradores.

Para los responsables de negocios, la aporte en estaciones de equilibrado y detectores puede ser importante para incrementar la rendimiento y productividad de sus sistemas. Esto es sobre todo significativo para los empresarios que manejan modestas y pequeñas organizaciones, donde cada punto cuenta.

También, los equipos de calibración tienen una amplia utilización en el sector de la fiabilidad y el gestión de estándar. Permiten localizar posibles problemas, previniendo intervenciones elevadas y perjuicios a los aparatos. Incluso, los indicadores recopilados de estos dispositivos pueden emplearse para mejorar métodos y aumentar la reconocimiento en sistemas de exploración.

Las campos de aplicación de los sistemas de ajuste abarcan numerosas sectores, desde la elaboración de vehículos de dos ruedas hasta el monitoreo del medio ambiente. No afecta si se trata de importantes elaboraciones industriales o reducidos espacios caseros, los equipos de calibración son fundamentales para asegurar un desempeño eficiente y libre de interrupciones.

Have you ever considered writing an e-book or guest authoring on other websites?

I have a blog based upon on the same topics you discuss and would love to have you share some stories/information. I

know my audience would enjoy your work. If you’re even remotely interested, feel free to send me an email.

You have made your point quite effectively.!

918kiss online casino slots https://combatcasino.info/nba-betting/ backgammon online casino

Amazing knowledge. Cheers.

dover online casino https://snipercasino.info/minnesota-online-casino/ online casino direct bank transfer

Wonderful advice. Thanks.

best ak online casino site https://hotgamblingguide.org/sport-betting/ legit online casino gcash

Reliable data. Thank you!

gta online how to do casino missions https://casinoslotssaid.com/sports-bet/ city center online casino

Cheers. A lot of advice!

online casino mr green https://combatcasino.info/sports-betting-sites/ all michigan online casinos listed

Cheers! Quite a lot of forum posts!

online casino frankrijk https://snipercasino.info/review-las-atlantis/ real online casino ny

Many thanks. I value it.

how to cheat in online casino https://linkscasino.info/nfl-football-betting/ juegos de casino las vegas online gratis

Жаль, что сейчас не могу высказаться – вынужден уйти. Вернусь – обязательно выскажу своё мнение.

Az?rbaycan s?h?r qonaqlar? bil?r run onun, lakin, bu, http://www.anziocasa.net/2/ kazino ohd?liyi qeydiyyatdan kecm?k Az?rbaycanda v? riay?t etm?k qanunlar olk?miz deyil l?gv edir.

Thank you, I appreciate this.

best 2020 online casino https://buckscasino.info/real-money-blackjack/ action online casino

Kudos. Lots of facts!

online casino bonus uden indskud https://uscasinoguides.com/shazam-review/ online games free casino

Thanks a lot, Useful stuff!

neue online casinos gamomat https://linkscasino.info/games/ online casino flash games

Awesome posts. Thanks a lot!

online casino with instant withdrawals https://uscasinoguides.com/crash-games/ online casino etf

You suggested that terrifically!

online casino australia real money reviews https://mapcasino.info/minnesota-online-casinos/ real money online casino no deposit bonus codes 2022

You definitely made the point!

auszahlungsdauer online casino https://casinocashstars.com/games/ fastest paying online casino

Whoa many of great tips.

fastest paying online casinos usa https://casinoslotoking.com/ignition-casino-safe/ volcano online casino

Seriously many of terrific advice!

jersey online casino https://casinoslotoking.com/instant-withdrawal-washington-casinos-online/ casino online para ganar dinero real usa

Regards. Helpful stuff!

banned from online casino https://casinoslotssaid.com/bet-on-nascar-online/ best american casino online

Thank you, Excellent stuff!

gta online casino penthouse cost https://findscasino.info/review-xbet/ apple pay online casino einzahlung

You actually explained this perfectly!

casino las vegas usa online https://casinoslotssaid.com/super-bowl-bets/ online casino ohne download

Well spoken indeed! .

coral online casino full site https://casinoslotssaid.com/betwhale-welcome-bonus/ 100 best online casinos

Many thanks, Helpful information.

konabet casino online https://hotgamblingguide.com/best-online-casino-ohio/ grand theft auto online casino

Wow a lot of helpful info.

online casino gaming news https://onlinecasinoindex.us/florida-online-casino-real-money/ online casino neukundenbonus ohne einzahlung

Wow a lot of good information.

sweeps casinos online https://onlinecasinoindex.us/mybookie-sign-up-bonus/ stardust casino pa online

Thanks a lot. Numerous advice.

casino platinum online https://cryptogamblingguru.com/online-casino-in-ohio/ fanduel casino online new jersey

Fantastic information. Cheers!

online casino best offers https://casinoslotssaid.com/crash-casino/ jugar ruleta casino online

Great posts, Regards!

free casino games online to play https://onlinecasinoindex.us/countries/ where’s the diamond casino in gta v online

You said it very well..

baccarat casino online https://cryptogamblingguru.com/casinos/ sisal casino online

Nicely put. Regards!

basta casino online https://hotgamblingguide.org/online-casino-usa-real-money-fast-payout/ triple 7 online casino

Helpful forum posts. With thanks!

skrill accepted online casino https://casinoshaman.com/crash-gambling-game/ roleta casino online gratis

Thanks a lot! Numerous tips.

cali777 online casino login https://hotgamblingguide.info/countries/ online casinos washington state

Nicely put, Thank you!

golden nugget online casino nj bonus code https://findscasino.info/online-casino-new-york/ the river online casino

With thanks. Good stuff!

list casino online https://hotgamblingguide.com/top-bitcoin-casino/ best online casino wv

Thanks a lot! Useful information!

australian real money online casino https://cryptogamblingguru.com/online-horse-betting/ free online poker casino

Whoa all kinds of useful info.

payid online casino australia https://casinoslotssaid.com/craps-casino/ casino online rotiri gratuite fara depunere

You definitely made the point.

watch casino online 123movies https://hotgamblingguide.com/banking/ beste online casino ohne oasis

Truly a lot of excellent material!

online casino betalen met ideal https://uscasinoguides.com/florida-casinos/ tradition casino online

Thanks a lot, Numerous facts.

new online casino no deposit bonus 2024 https://ratingcasino.info/north-carolina-online-casinos/ $10 deposit bonus online casino

Beneficial advice. Kudos.

legal wv online casinos https://hotgamblingguide.org/keno-casino-games/ hollywood casino online pennsylvania

You made your stand extremely effectively.!

mohawk casino online https://casinoslotssaid.com/best-online-casino-texas-real-money/ jugar al casino online

You actually mentioned it wonderfully.

most trusted us online casino https://usagamblingexperts.com/review-slotocash/ casino 777 online

Incredible all kinds of good information!

online casino dealer salary philippines https://mgmonlinecasino.us/online-legit-casinos/ online casino mit sofortauszahlung

Helpful content. Appreciate it.

kostenlose online casinos https://casinocashstars.com/north-carolina-online-casino/ best free play online casino

You actually expressed this effectively!

pagcor casino online https://casinosonlinenew.com/best-betting-apps/ arizona online casino apps

It’s an awesome article designed for all the web people; they will

take benefit from it I am sure.

You actually suggested this perfectly.

online casino apps with free bonus https://casinoslotssaid.com/texas-holdem-online-real-money/ casino playing online

Nicely put, Regards.

most trusted online casinos for usa players reddit https://shadowcasino.info/real-money-online-casino-georgia/ las vegas online casino slots

This is nicely expressed. .

usa online no deposit casino https://eseomail.com/new-york-online-casino-bill/ gta online casino card locations

Wonderful stuff. Thanks.

best credit card online casino https://magicalcasino.info/california-online-casinos/ online casino philippines gcash

You have made your point!

royal seven online casino https://casinocashstars.com/review-cafe/ online casino stake7

Nicely put, Thanks a lot.

taj mahal online casino https://buckscasino.info/california-online-casinos/ newest casino online

Wow a lot of superb info!

gta online casino aggressive https://combatcasino.info/ethereum-casino/ nieuwste online casino 2021

Really a good deal of useful information.

gta 5 online casino story missions https://igamingcasino.info/casino-apps/ creek casino online

You have made your point.

online casino agent free registration usa https://shadowcasino.info/review-xbet/ highest payout online casino slots

You stated that superbly!

online casinos with aristocrat slots https://linkscasino.info/review-xbet/ the casino job full movie watch online

You actually expressed that perfectly!

riversweeps 777 online casino login https://casinoslotssaid.com/casino-cafe-online/ romania online casinos

Fine facts. Cheers.

online casino free bonus codes https://usagamblingexperts.com/online-casino-florida/ online casino postfinance

Nicely put. Thank you!

jackpot city online casino real money https://casinonair.com/legit-casinos/ 1 euro online casino

You actually reported this terrifically.

aud online casino australia https://usagamblingexperts.com/real-money-keno/ live casino online pa

This is nicely expressed! .

best arkansas online casinos https://casinoslotssaid.com/best-casino-games/ oshi online casino

You actually said it exceptionally well!

vegas casino online no depo 50 https://eseomail.com/banking/ scores casino online

You reported this very well!

independent casino online https://casinoslotoking.com/craps-casino-game/ borgata online casino app download

Thank you! Good stuff!

rsweeps online casino at home https://linkscasino.info/review-betonline/ las vegas usa casino online

Great posts, Many thanks!

the meadows online casino https://findscasino.info/online-casino-australia/ betway online casino pa

Lovely data. Appreciate it!

zar online casino https://ratingcasino.info/poker/ nm online casino no deposit bonus

Position clearly used!!

zelle online casino https://casinocashstars.com/online-casino-texas/ casino online con bono sin depГіsito

You made your stand extremely effectively!.

casino buenos aires online bono https://eseomail.com/texas-holdem-online/ alani casino resort free online games

Nicely put, Many thanks.

tropicana casino online review https://casinoslotoking.com/new-zealand-online-casino/ jacks entertainment online casino

Effectively voiced really! !

online casino book of dead https://casinosonlinenew.com/texas-online-casino/ new michigan online casino no deposit bonus

Many thanks! I like this.

casino regina online https://shadowcasino.info/real-money-baccarat/ online casinos in nederland

Fantastic advice. Many thanks.

betrivers online casino pa https://casinoshaman.com/betonline-ag-app/ casino online catamarca

Thanks a lot. Lots of posts!

the vic casino online https://mapcasino.info/review-las-atlantis/ free spin bonus online casino

Appreciate it. Loads of postings.

coushatta casino free online games https://mgmonlinecasino.us/best-online-casino-with-fast-payout/ best canada casino online 2022

You actually said it adequately!

newest online casino canada https://shadowcasino.info/betting/ facebook online casino

Superb info. Cheers.

what is the safest online casino https://buckscasino.info/review-shazam/ best online casino ever

Wow a lot of amazing material.

online casino easy payout https://hotgamblingguide.info/blackjack-game-online/ online real casino real money

Everything is very open with a very clear clarification of the issues.

It was truly informative. Your website is useful. Many thanks for sharing!

Really loads of wonderful information.

wind creek bethlehem online casino promo code https://onlinecasinoindex.us/cricket-betting-in-usa/ casino poker online free

Well spoken genuinely! !

online echtgeld casino bonus ohne einzahlung https://linkscasino.info/horse-betting/ funland casino online

Thanks a lot, I value this!

loto quebec casino online https://casinoslotssaid.com/casinos/ online casino no deposit bonus codes 2024

Incredible all kinds of very good data!

top 10 online casino games https://buckscasino.info/new-online-casinos/ online casino hk

Very good content. Kudos!

same day withdrawal online casinos nz https://shadowcasino.info/casino-apps/ nc online casino real money

Terrific content. Appreciate it!

mohegan sun online casino reviews https://cryptogamblingguru.com/esports-bets/ casino viet nam online

Many thanks! I value it.

lucky strike casino online https://linkscasino.info/nhl-betting/ casino pin up online

You reported that terrifically.

legitimate online casino slots https://hotgamblingguide.org/wild-casino-100-free-spins-no-deposit/ casino online com jogos playtech

Very good forum posts, With thanks.

paras online casino https://usagamblingexperts.com/review-lucky-tiger/ online casinos are a scam

Good knowledge. Thanks.

safest online casinos for us players https://findscasino.info/real-money-online-casino-massachusetts/ own online casino

You said it nicely.!

best online casino referral bonus https://igamingcasino.info/real-money-online-casino-minnesota/ que hacer si un casino online no paga

You made your point!

resorts casino nj online https://mapcasino.info/slots-online/ minion88 online casinos

Many thanks, Quite a lot of knowledge.

2019 new online casinos usa paypal banking https://casinonair.com/online-casino-new-zealand/ betsson casino online spiele

Whoa quite a lot of excellent information!

casino online city center https://casinosonlinenew.com/texas-online-casino/ 360 online casino

Thanks. A good amount of postings!

australian online casinos accepting paysafe https://riggambling.com/real-money-online-casino/ baccarat casino online

https://je-tall-sf-marketing-10.b-cdn.net/research/je-tall-sf-marketing-(314).html

The bridesmaids collected the recipes and created them right into a newlyweds cookery book that they gave the couple up their day.

Wow lots of great facts.

casino online book of dead https://hotgamblingguide.org/busr-sports-betting/ four winds casino online promo code

Beneficial stuff. Cheers.

borgata casino online apk https://linkscasino.info/nba-betting/ high country online casino

Appreciate it! Plenty of write ups!

pala online casino https://linkscasino.info/georgia-online-casinos/ casinos online legales

Nicely put, Thanks.

bet365 online casino promo code nj https://shadowcasino.info/real-money-online-casino-ohio/ online pennsylvania casino

If some one wants to be updated with most up-to-date technologies then he must be pay a visit this web site and be

up to date daily.

Amazing posts. With thanks!

nz online casinos https://buckscasino.info/fast-payout-casinos/ casino online za darmo

Amazing a good deal of excellent knowledge!

casino online netherlands https://usagamblingexperts.com/ 1 euro deposit casino online

Nicely put. Cheers!

do any online casinos take paypal https://casinoslotssaid.com/best-slots-to-play-online-for-real-money/ caesars online casino michigan

Amazing lots of beneficial advice.

casino online hrvatska https://buckscasino.info/tennis-betting/ online casino with free bonus without deposit

You said it nicely.!

online casino and betting https://casinoslotoking.com/fast-payout-casinos/ betrouwbare online casino buitenland

Beneficial knowledge. Appreciate it!

bally online casino games https://usagamblingexperts.com/soccer-betting/ gta 5 online casino heist all access points

Really loads of useful facts.

alice springs casino online https://casinonair.com/betting/ coushatta casino online games

You suggested it superbly.

best astropay online casino https://hotgamblingguide.org/xbet-bonus/ android casino online

Seriously plenty of great material!

neue online casinos 2017 ohne einzahlung https://mgmonlinecasino.us/best-online-casino-new-york/ free online casino no deposit bonus

Fantastic beat ! I wish to apprentice while you amend your site,

how can i subscribe for a blog web site? The account helped

me a acceptable deal. I had been a little bit acquainted of this your broadcast offered bright clear concept

You suggested it very well.

autoexcludere la casino online https://mgmonlinecasino.us/indiana-online-casino-bonuses/ casino cirsa online

You stated that really well!

best diners club online casinos https://buckscasino.info/cricket-betting/ online casino game strategy

Truly quite a lot of valuable knowledge!

online casino live dealer usa https://uscasinoguides.com/betonline-review/ new michigan online casino no deposit bonus codes

With thanks. Valuable information!

online casino law canada https://riggambling.com/ pointsbet online casino

Great stuff, Appreciate it.

new uk online casino https://hotgamblingguide.info/online-casino-real-money-colorado/ online casino that accepts paysafe

Many thanks! Wonderful stuff.

mgm casino online gambling https://hotgamblingguide.org/bingo-game-online/ ks online casino sites

Regards. I enjoy it!

casinos americanos online https://snipercasino.info/poker-online/ online dutch casino

Wonderful tips. Thanks a lot.

online casinos with immortal romance https://usagamblingexperts.com/online-casino-florida/ how to open up an online casino

Many thanks. Awesome information.

min deposit $10 online casino https://mgmonlinecasino.us/no-deposit-online-casino-real-money/ gta online casino heist fingerprint hack

This design is steller! You most certainly know

how to keep a reader amused. Between your wit and your videos,

I was almost moved to start my own blog (well, almost…HaHa!) Fantastic job.

I really enjoyed what you had to say, and more than that, how you presented it.

Too cool!

Very good postings. Appreciate it.

best nj online casino no deposit bonus https://eseomail.com/online-craps-game/ venmo online casinos

Really all kinds of superb info.

online casino mehr als 1 euro https://cryptogamblingguru.com/casino-online-maryland/ deutschsprachige online casinos

This website definitely has all of the information and

facts I needed about this subject and didn’t know who to ask.

Perfectly voiced without a doubt! .

bandar betting casino dadu online https://casinoslotoking.com/massachusetts-casino-online/ bonus online casino

You actually expressed it effectively.

los atlantis online casino https://combatcasino.info/real-money-bingo/ what online casino has the best odds

You actually stated that very well.

en iyi online casino siteleri https://hotgamblingguide.info/baccarat-casino-online/ best real online casino usa

Well spoken of course! .

2018 online casino usa https://combatcasino.info/crash-gambling/ live casino online casino

Whoa loads of excellent knowledge!

hollywood casino online pa real money https://linkscasino.info/online-craps/ new online casinos no deposit bonus codes 2023

Valuable stuff. Kudos.

paraguayan online casino https://uscasinoguides.com/mlb-betting/ any online casinos accept paypal

You made your point.

darmowe casino online https://findscasino.info/tennis-betting/ bronco casino online

With thanks! I like it.

bestes online casino echtgeld https://magicalcasino.info/betting-apps/ vegas casino online real money

Perfectly expressed indeed! !

gibraltar online casino license https://linkscasino.info/online-casino-texas/ lucky slots online casino

This is nicely expressed. !

film casino online https://casinonair.com/review-ducky-luck/ casino online in philippines

Check out a broad range of tile options аt Tile Choices, from vibrant glass to clkassic ceramic ɑnd

natural stone, ideal fоr kitchens, bathrooms, and outdoor spaces.|Іf you’re designing a new backsplash or searching ffor tһe perfect pool are

tiles, Tile Choices һаs aall yօu ned ffor your next tling project.|Visit Tile

Choices f᧐r toр-notch tiles, great fօr outdoor ɑnd indoor tiling projects,

аnd more, with features like free shipping on ordeers ⲟver $249.|Discover the perfect tile foг any project at Tile Choices.

Browse our selection оf ceramic, glass, ɑnd stone options

tһat suit enhancing bathrooms.|Tille Choices

оffers tiles for every style, frоm contemporary glas to timeless

natural stone, aνailable fߋr ᴠarious installations.|Revitalize

yoᥙr space ԝith tiles fгom Tile Choices. Chose fгom options in a variety of materials, ideal ffor rustic ⅼooks.|Shop Ƅy color, style, or

material at Tilee Choiices ɑnd locate the ideal tile for yߋur kitchen, bathroom, ⲟr outdoor space.|Ready to enhance y᧐ur һome?

Tile Choices іѕ your go-to destination ffor үߋur tiling project, fro sleek glass mosaics t᧐о robust stone tiles аnd natural sgone selections.

Point effectively applied.!

online casino bankГјberweisung https://linkscasino.info/online-sportsbook/ top rated online slot casino

Wonderful forum posts. Thanks a lot!

casino online directo https://usagamblingexperts.com/online-casino-minnesota/ colony casino online

You revealed this effectively!

online casino de bonus https://eseomail.com/australian-online-casinos/ juwa 777 online casino login usa

Factor well applied!!

150 online casino bonus https://ratingcasino.info/review-cafe/ online casino that takes apple pay

Nicely put. Cheers!

atlantic city casino play online https://casinonair.com/crypto-casinos/ aladdin lamp online casino

Nicely put, Appreciate it!

consejos para jugar casino online https://usagamblingexperts.com/legit-online-casinos/ casinos en chile online

Many thanks. I like this!

casino games free online games https://casinoslotssaid.com/mma-betting/ real money online casino signup bonus

Fantastic content. Kudos!

sugar rush online casino https://riggambling.com/online-poker-sites/ the best online real money casino

Regards. Lots of info.

casino x – free online slots https://igamingcasino.info/review-ignition/ wolf winner online casino

Very good material. With thanks.

free no deposit bonus codes for online casinos https://combatcasino.info/review-shazam/ online casino that take mastercard

Incredible quite a lot of valuable information!

hard rock casino online pennsylvania https://riggambling.com/betting/ casinos online que pagan dinero real

Awesome forum posts. Kudos.

massachusetts online casino https://uscasinoguides.com/north-carolina-casinos/ ultra panda casino online

На этом сайте вы найдете всю информацию о психическом здоровье и способах улучшения.

Мы рассказываем о методах развития эмоционального равновесия и снижения тревожности.

Полезные статьи и советы экспертов помогут понять, как сохранить душевное равновесие.

Актуальные вопросы раскрыты доступным языком, чтобы любой мог найти нужную информацию.

Позаботьтесь о своем ментальном состоянии уже прямо сейчас!

image.google.com.om

Cheers, Terrific information.

vegas casino online free chip https://ratingcasino.info/online-casino-california/ best online casino australia reddit

Cheers, I appreciate this!

scores online casino promo code https://magicalcasino.info/online-craps/ yaamava online casino promo code

Hi there i am kavin, its my first occasion to commenting anyplace,

when i read this post i thought i could also create comment

due to this brilliant paragraph.

Beneficial forum posts. Kudos!

seven sultans online casino https://casinocashstars.com/online-video-poker/ casino online 21

I’m gone to say to my little brother, that he should also

pay a visit this webpage on regular basis to take updated

from most recent news.

Kudos! I appreciate it!

electric avenue casino online https://casinoslotoking.com/online-sportsbooks/ nj hard rock casino online

You’ve made your stand pretty nicely.!

casino online dinero real sin depГіsito https://eseomail.com/mgm-online-casino-michigan/ jackpot city online casino

Very good content. Kudos!

how many online casinos are in pa https://eseomail.com/casinos-online-real-money/ best online casino ireland

Tips effectively utilized!.

online free no deposit casinos https://casinoslotoking.com/all-west-virginia-online-casinos/ borgata online casino nj bonus code

Thanks, Ample stuff!

best dc online casino sites https://hotgamblingguide.com/crash-crypto-gambling/ 888poker casino online

Awesome facts. Kudos.

real money online casino kentucky https://ratingcasino.info/online-casino-california/ online casino megaways

You’ve made the point!

free live casino game online https://magicalcasino.info/real-money-online-casino-arizona/ online casino ekЕџi

This is nicely said. .

casino online formosa https://mgmonlinecasino.us/slotocash-no-deposit-bonus-codes/ melhores casinos online com bГґnus de registo

Nicely put, Appreciate it!

15 dollar minimum deposit online casino https://riggambling.com/online-casino-texas/ online casino az

Fantastic write ups, Many thanks.

online casino games tricks https://casinocashstars.com/nhl-betting/ old havana casino online

Very energetic blog, I enjoyed that bit. Will there be a part 2?

You revealed it fantastically!

the best online casino australia https://uscasinoguides.com/real-money-slots/ betmgm online casino reviews

Thank you! Excellent stuff.

golden nugget online casino bonus code https://casinoslotoking.com/all-west-virginia-online-casinos/ legit online casino in philippines

You have made the point.

online casino instant payout usa https://usagamblingexperts.com/real-money-bingo/ free online bingo casino games

Nicely put, Many thanks.

stn online casino https://hotgamblingguide.info/nascar-bets/ online casino va

Very well voiced indeed! !

vietnam online casino https://uscasinoguides.com/reddog-review/ elenco casino online

Thank you, I value this!

tropicana casino online app https://mapcasino.info/ online casino michigan new

Thank you, I enjoy this!

river edge online casino https://hotgamblingguide.com/poker-online-real-money/ alt online casino cheat engine

Wonderful material. Regards!

dazzle me online casinos https://eseomail.com/casino-online-roulette/ betmgm online casino promo code

Truly plenty of excellent tips!

online casino kostenlos merkur https://magicalcasino.info/credit-card-casinos/ online casino bonus no deposit uk

You actually revealed this superbly.

casino online turkey https://shadowcasino.info/review-ducky-luck/ online casino direct bank transfer

You’ve made your position very well!!

live casino slots online https://combatcasino.info/review-busr/ casinos online licenciados mga

Kudos! Quite a lot of advice!

how to make an online casino https://shadowcasino.info/countries/ free online casino games to play

You reported that effectively!

online casinos in ny https://casinosonlinenew.com/banking/ newest online casinos for usa players

Thanks! I enjoy it!

lodislot 777 casino online https://casinocashstars.com/online-poker-sites/ mgm online casino michigan app

Nicely put. Regards.

online casino games that pay cash https://onlinecasinoindex.us/online-casino-tennessee-real-money/ online casino legal in california

Nicely put. Thanks a lot.

slot world online casino https://riggambling.com/nhl-sports-betting/ casino slots play online

Wow quite a lot of terrific information!

schweizer online casino https://hotgamblingguide.com/ethereum-casino/ game vault online casino

Incredible plenty of helpful info!

online casino löwen play https://hotgamblingguide.com/best-ufc-betting-app/ online casino българия

Nicely put. Thank you.

online casino ice https://mgmonlinecasino.us/reviews/ adiccion al casino online

You actually stated that well.

888 casino online roulette https://hotgamblingguide.info/crypto-sportsbook/ online casino 5 euro deposit

Really many of beneficial knowledge!

online casino fastest withdrawal https://usagamblingexperts.com/review-shazam/ trucos de casino online

You actually mentioned it wonderfully!

trusted online casinos usa https://hotgamblingguide.org/australian-casino-online/ fairest online casino

Nicely put, Appreciate it!

online casinos that are legit https://igamingcasino.info/arizona-online-casino/ new online casinos april 2024

You said this wonderfully.

top rated online casinos uk https://casinoshaman.com/ casino online en argentina

Many thanks! Awesome stuff.

coin pusher casino online https://uscasinoguides.com/poker-real-money/ calientemx casino online

Hi just wanted to give you a brief heads up and let you

know a few of the pictures aren’t loading properly. I’m not sure why

but I think its a linking issue. I’ve tried it in two different internet

browsers and both show the same results.

What i do not understood is in reality how you are not actually a

lot more smartly-favored than you may be right now.

You’re so intelligent. You understand thus significantly relating to this topic,

produced me individually believe it from a lot of varied angles.

Its like women and men aren’t interested until it’s one thing to accomplish with Lady gaga!

Your own stuffs outstanding. Always handle it up!

You definitely made your point.

online casinos cyprus https://buckscasino.info/ohio-online-casinos/ online casinos mit 200 bonus

What’s up, yes this article is actually fastidious and

I have learned lot of things from it regarding blogging.

thanks.

hello there and thank you for your info – I have certainly picked up anything

new from right here. I did however expertise a few technical points using this

web site, as I experienced to reload the web site a lot of times

previous to I could get it to load properly. I had been wondering

if your web host is OK? Not that I am complaining, but slow loading instances times will often affect your placement in google and can damage your high

quality score if advertising and marketing with Adwords.

Anyway I’m adding this RSS to my email and can look

out for much more of your respective fascinating content.

Ensure that you update this again soon.

You made your position pretty clearly..

133 online casino tips https://hotgamblingguide.org/best-apps-for-sports-betting/ online casinos bonus ohne einzahlung

Thanks, Lots of data!

betway online casino https://usagamblingexperts.com/ufc-mma-betting/ online casino affiliate programs legal

Awesome info. Thanks a lot!

beat the boss online casino https://hotgamblingguide.com/casino-online-real-money-no-deposit/ gta 5 online casino update date

Useful information. Thanks.

ar online casino sites https://casinoslotoking.com/ohio-casinos-online/ online casino 1 dollar deposit

Great data. Regards.

nj online casino bonus https://onlinecasinoindex.us/mybookie-sign-up-bonus/ online casino with free signup bonus real money illinois

With thanks, Excellent information!

best california online casino https://uscasinoguides.com/casino-apps/ cash app slot online casino games for real money

I’m not positive where you’re getting your info, however good topic.

I needs to spend some time studying more or working out more.

Thanks for fantastic information I was looking for this info for my

mission.

Nicely put, With thanks.

no kyc online casinos https://cryptogamblingguru.com/best-craps-online/ what online casino gives free spins

Many thanks. A lot of stuff!

same day withdrawal online casino https://hotgamblingguide.org/busr-sports-betting/ agen casino 338a online

You have made your point!

il online casino https://cryptogamblingguru.com/aussie-online-casino/ zahranicni online casina

Nicely put. Regards!

golden nugget online casino app https://casinoshaman.com/online-casino-tennessee-real-money/ best 20 deposit casinos in usa to play online

Kudos. A good amount of material.

online casino kenya mpesa https://findscasino.info/horse-betting/ play casino games online for free

Regards! Helpful stuff!

safari casino online https://casinonair.com/review-lucky-tiger/ best online casino no deposit welcome bonus

Good posts. Thank you!

book of dead online casino https://shadowcasino.info/live-online-casinos/ best 4theplayer online casino

Reliable info. Cheers!

bet mgm casino online pa https://magicalcasino.info/esports-betting/ online casino apple pay deposit

Terrific posts. Appreciate it.

online slot casino real money https://onlinecasinoindex.us/new-michigan-online-casino/ instawin online casino

You actually expressed that really well!

mega 7 online casino https://mgmonlinecasino.us/gambling-sites-that-accept-cash-app/ new casino online nj

Канал о бизнесе, стартапах, новых технологиях и возможностях в России. Немного мотивации и психологии.

#стартап Заходи: https://t.me/pro_startap

I do believe all of the concepts you have offered for your post.

They’re very convincing and will definitely work. Still, the posts are very quick for beginners.

May you please prolong them a little from next time?

Thank you for the post.

Fantastic post however , I was wondering if you could write a litte more on this

topic? I’d be very grateful if you could elaborate a little

bit more. Many thanks!

Howdy, There’s no doubt that your site might be having

internet browser compatibility issues. When I take a

look at your website in Safari, it looks fine but when opening in IE, it’s got some overlapping issues.

I merely wanted to provide you with a quick heads up!

Other than that, wonderful site!

Incredible! This blog looks exactly like my old

one! It’s on a completely different subject

but it has pretty much the same page layout and design. Superb choice of colors!

Howdy would you mind letting me know which hosting company you’re working with?

I’ve loaded your blog in 3 different web browsers and I must say this blog loads a lot quicker then most.

Can you recommend a good web hosting provider at a fair price?

Thanks, I appreciate it!

Wow, incredible blog layout! How long have you been blogging for?

you made blogging look easy. The overall look of your website is

wonderful, as well as the content!

Hi! Would you mind if I share your blog with my myspace group?

There’s a lot of people that I think would really enjoy your content.

Please let me know. Cheers

WOW just what I was searching for. Came here by searching for PrimeBiome reviews

It’s an remarkable paragraph in support of all the online people; they will get advantage from it I am sure.

Excellent post. I’m facing some of these issues as well..

Good article! We are linking to this particularly great article on our site.

Keep up the good writing.

If you would like to obtain much from this article then you have to apply such

strategies to your won webpage.

Wow, awesome blog layout! How long have you been blogging

for? you make blogging look easy. The overall look of your website is excellent, let alone

the content!

It’s great that you are getting ideas from this piece of writing

as well as from our dialogue made at this place.

I am genuinely glad to read this weblog posts which contains tons of useful

information, thanks for providing such statistics.

Quality posts is the crucial to interest the viewers to pay a quick visit the website, that’s what this

site is providing.

I am curious to find out what blog system you happen to be utilizing?

I’m having some minor security issues with my latest blog and I would like to find something more safeguarded.

Do you have any suggestions?

This is my first time visit at here and i am genuinely pleassant to read everthing at one place.

Hi, all the time i used to check weblog posts here in the early hours

in the dawn, because i enjoy to find out more and more.

Отель “glory” – это место, где царствует обстановка истинного великолепия и роскоши, Glory Casino на котором какой угодно гость встречается с искренним радушием.

What Is Post Cycle Therapy In Bodybuilding – A PCT Guide

what is anabolic chicken

I’m not sure exactly why but this website is loading extremely slow for me.

Is anyone else having this problem or is it a

problem on my end? I’ll check back later on and see if the problem

still exists.

What Is The Safest First Steroid Cycle?

### A Beginner’s Guide to the Safest First Steroid Cycle

#### What are Steroids?

Steroids are organic compounds that produce specific effects on the human body. In the context of bodybuilding, they are used to enhance muscle growth, increase strength, and improve physical performance. However, it’s important to note that steroids are classified as controlled substances in many countries, and their use can carry significant legal and health risks.

#### http://www.empowerment-initiative-frankfurt.de/index.php?site=profile&id=78909

For bodybuilders, the primary benefits of steroid use include:

– **Muscle Growth**: Steroids promote muscle cell growth by stimulating protein synthesis.

– **Increased Strength**: They enhance strength, enabling users to lift heavier weights or perform more reps.

– **Recovery**: Some steroids improve recovery time, allowing athletes to train harder and more frequently.

#### Risks of Steroid Use

Despite their benefits, using steroids comes with several risks:

– **Health Risks**: Long-term use can lead to serious health issues, including liver damage, heart problems, and an increased risk of certain cancers.

– **Legal Risks**: The possession and distribution of anabolic steroids are illegal in many jurisdictions without a valid prescription.

#### Understanding Steroid Cycles

A steroid cycle refers to the period during which a user administers steroids. The duration of a cycle can vary depending on the type of steroid, the dosage, and the individual’s goals.

#### What is a Steroid Cycle?

A steroid cycle is a structured program that includes periods of administration (on-cycle) and non-administration (off-cycle). This pattern helps regulate the body’s hormone production and minimizes negative side effects.

#### Cycle Length

The length of a steroid cycle can range from 4 to 12 weeks, depending on the user’s experience and goals. A first-time user might start with a shorter cycle, such as 4-6 weeks, to assess their tolerance and response.

#### Safe Steroids for Beginners

For beginners, starting with milder steroids like **Testosterone** is recommended. Testosterone is naturally produced by the body and has fewer side effects compared to other synthetic steroids.

#### Why Testosterone?

Testosterone is often called the “base” steroid because it’s involved in almost every aspect of muscle growth and repair. It’s also easier to source legally, provided it’s obtained through a legitimate prescription for hormone replacement therapy (HRT).

#### Other Considerations

Before starting any steroid cycle, consider the following:

– **Legal Status**: Ensure that you’re using steroids legally under your country’s laws.

– **Medical Supervision**: Consulting with a healthcare professional is advised, especially if you have pre-existing conditions or are taking other medications.

– **Cycle Goals**: Define clear goals for your cycle to stay motivated and avoid misuse.

#### Detailed Breakdown of a Safe Cycle

A safe steroid cycle should be carefully planned to minimize risks while maximizing benefits. Here’s a breakdown:

##### Choosing the Right Compound

For beginners, starting with **Testosterone** is ideal due to its effectiveness and relative safety. Other options may include **Primobolan** or **Nandrolone**, but these are often more potent and carry higher risks.

##### Cycle Structure

– **On-Cycle**: Administer steroids for a set number of weeks (e.g., 8-12 weeks).

– **Off-Cycle**: Take a break to allow your body to recover and reset hormone production.

– **PCT**: Post-cycle therapy is essential to restore natural hormone function.

##### Post Cycle Therapy (PCT)

After completing a steroid cycle, a Post Cycle Therapy (PCT) period is required to help your body resume producing hormones on its own. This typically involves taking supplements like **Clomiphene Citrate** or **Nolvadex** to stimulate your pituitary gland and restore natural testosterone production.

#### Why is PCT Essential?

PCT ensures that your body doesn’t陷入 a state of hormone imbalance, which can lead to a host of health issues. It also helps maintain muscle gains and prevents the negative effects of steroid use.

#### Key Components of PCT

– **Supplements**: Clomiphene Citrate or Nolvadex.

– **Timing**: Start PCT immediately after the cycle ends and continue for a period (e.g., 4-6 weeks).

– **Monitoring**: Regular blood tests can help assess hormone levels and ensure recovery.

#### Proper Planning

– **Set Realistic Goals**: Define why you’re using steroids and what you aim to achieve.

– **Stick to the Plan**: Follow the cycle structure and PCT as outlined.

– **Supplements**: Use additional supplements like BCAAs and protein to support muscle growth during the cycle.

#### Additional Supplements

During a steroid cycle, it’s common to use supplementary products such as:

– **BCAAs**: Help reduce muscle breakdown.

– **Protein Powders**: Support muscle repair and growth.

– **Vitamins and Minerals**: Ensure overall health and recovery.

#### Conclusion

Using steroids can be an effective tool for bodybuilding, but it comes with significant responsibilities. A well-planned cycle with proper PCT is essential to minimize risks while maximizing results. Always prioritize safety, legal compliance, and medical supervision when considering steroid use.

Howdy, i read your blog from time to time and

i own a similar one and i was just wondering if you get

a lot of spam feedback? If so how do you protect against it, any plugin or anything you can suggest?

I get so much lately it’s driving me mad so any support is very much appreciated.

What’s up Dear, are you in fact visiting this site daily,

if so after that you will absolutely get

good know-how.

Hey There. I discovered your weblog the use of msn. That is a really well written article.

I will make sure to bookmark it and return to learn extra

of your helpful information. Thanks for the post.

I’ll certainly return.

What’s up, the whole thing is going perfectly here and

ofcourse every one is sharing data, that’s actually excellent, keep up writing.

Hi there! This post could not be written much better! Reading

through this article reminds me of my previous roommate! He constantly kept preaching about this.

I’ll send this information to him. Fairly certain he’s going to have a great read.

I appreciate you for sharing!

My spouse and I stumbled over here different website and thought I should check things out.

I like what I see so now i’m following you. Look forward to looking at your

web page repeatedly.

Greetings from Colorado! I’m bored to tears at work so I decided to check out your blog on my

iphone during lunch break. I really like the info you present here and can’t wait to take a look when I get home.

I’m shocked at how quick your blog loaded on my cell phone ..

I’m not even using WIFI, just 3G .. Anyways, very good blog!

If you are going for finest contents like myself, simply go

to see this site daily as it offers feature contents, thanks

What’s up to all, how is all, I think every one is getting more

from this web site, and your views are nice for new visitors.

Hi, Neat post. There is a problem along with your site in internet explorer,

may test this? IE nonetheless is the marketplace leader and a huge portion of other people will miss your wonderful writing because of this problem.

Useful info. Lucky me I discovered your web site by accident, and

I am stunned why this coincidence did not came about earlier!

I bookmarked it.

Thanks on your marvelous posting! I quite enjoyed reading it, you may be a great author.I will be sure to bookmark

your blog and may come back very soon. I want to encourage you

to continue your great work, have a nice afternoon!

Greetings! Very helpful advice within this post!

It’s the little changes that make the greatest changes.

Many thanks for sharing!

Hi there, I believe your site may be having web browser compatibility issues.

When I look at your website in Safari, it looks fine however,

if opening in Internet Explorer, it’s got some overlapping issues.

I just wanted to provide you with a quick heads up!

Other than that, wonderful blog!

hello there and thank you for your information – I’ve definitely picked up something new from

right here. I did however expertise several technical issues using this website,

as I experienced to reload the website a lot of times

previous to I could get it to load properly. I had been wondering if your web

hosting is OK? Not that I’m complaining, but slow loading instances times will sometimes affect your placement

in google and can damage your quality score if advertising

and marketing with Adwords. Well I’m adding this RSS to my e-mail and can look out for a lot more of your respective fascinating

content. Make sure you update this again very

soon.

I blog frequently and I truly thank you for your content.

This great article has really peaked my interest. I am going to take a note

of your blog and keep checking for new information about once per week.

I opted in for your Feed as well.

Thanks for a marvelous posting! I actually enjoyed reading it, you may be a great author.

I will be sure to bookmark your blog and definitely will come back down the road.

I want to encourage yourself to continue your great writing, have a nice day!

Howdy! Would you mind if I share your blog with my facebook group?

There’s a lot of folks that I think would really enjoy your content.

Please let me know. Thank you

Hello to all, how is all, I think every one is getting more from this web site,

and your views are nice for new visitors.

Hi! I could have sworn I’ve been to this site before but after

reading through some of the post I realized it’s new to me.

Anyways, I’m definitely glad I found it and I’ll be book-marking and checking back often!

It’s hard to find educated people on this topic, however, you sound like you know

what you’re talking about! Thanks

This is really interesting, You’re a very skilled blogger.

I’ve joined your feed and look forward to seeking

more of your great post. Also, I’ve shared your site in my

social networks!

Hurrah! In the end I got a webpage from where I be capable

of actually get helpful information regarding my study and knowledge.

Great site. Lots of useful information here.

I’m sending it to a few pals ans additionally sharing in delicious.

And obviously, thank you for your sweat!

Hello just wanted to give you a quick heads up. The words in your content seem to be running off the

screen in Chrome. I’m not sure if this is a format issue or something to do with internet browser compatibility but I thought I’d

post to let you know. The layout look great though! Hope

you get the problem resolved soon. Thanks

Thanks for some other great post. The place else may just anyone get that kind of

information in such a perfect way of writing? I’ve a presentation next week, and I

am at the search for such info.

Hello friends, good piece of writing and pleasant arguments commented here, I am

genuinely enjoying by these.

Hello there! Do you know if they make any plugins to

safeguard against hackers? I’m kinda paranoid about losing

everything I’ve worked hard on. Any tips?

Woah! I’m really loving the template/theme of this site. It’s simple, yet effective.

A lot of times it’s very hard to get that “perfect balance” between superb

usability and visual appeal. I must say that you’ve done a very good job with this.

Additionally, the blog loads extremely quick for me on Firefox.

Excellent Blog!

Hi there to every one, it’s genuinely a fastidious for me to pay a quick

visit this web site, it contains priceless Information.

I couldn’t resist commenting. Very well written!

As the admin of this web page is working, no hesitation very rapidly it will be well-known, due to

its feature contents.

Very nice post. I just stumbled upon your blog and wanted to say that I have

truly enjoyed surfing around your blog posts. After all I will be subscribing to your

feed and I hope you write again soon!

Link exchange is nothing else however it is just

placing the other person’s blog link on your page

at appropriate place and other person will also do same in favor of you.

Hi! Would you mind if I share your blog with my zynga group?

There’s a lot of people that I think would really appreciate

your content. Please let me know. Thank you

I think that everything said made a bunch of sense. But, think about this, suppose you composed a catchier title?

I mean, I don’t wish to tell you how to run your blog, however what if you added something that grabbed people’s attention? I mean สแตนเลส 316:

มันคืออะไร? มันทำได้อย่างไร?

อธิบายเกรด – ซิโน-สแตนเลส-สตีล is

kinda boring. You could look at Yahoo’s home page and see how they create

article headlines to get viewers interested.

You might add a related video or a picture or two to get

people excited about everything’ve got to say.

In my opinion, it would make your blog a little bit more interesting.

Oh my goodness! Incredible article dude! Many thanks,

However I am having problems with your RSS. I don’t understand the reason why I am unable to join it.

Is there anyone else having similar RSS problems? Anyone who knows the answer will you kindly respond?

Thanx!!

Great blog! Do you have any tips for aspiring writers?

I’m planning to start my own blog soon but I’m a little lost on everything.

Would you advise starting with a free platform like WordPress or go for a paid option?

There are so many options out there that I’m totally confused ..

Any suggestions? Many thanks!

Green Spark Electrics specializss in EV charger installation іn Durham, Newcastle, ɑnd Sunderland foor homes and businesses.

Experience seamless ɑnd hassle-free EV chager installations ѡith

Green Spark Electrics, уοur trusted partner іn Durham, Newcastle,

and Sunderland. Ⲟur team of certified technicians еnsures уouг installation іѕ done right the first timе.

Check ᧐ut our website for mire іnformation on ߋur services or visit οur site tо learn more aƅߋut һow