Stainless steel, a material renowned for its corrosion resistance and durability, finds applications across a range of industries, from medicine and food processing to architecture and automobile manufacturing. Its unique properties, such as high tensile strength, excellent thermal conductivity, and low coefficient of thermal expansion, make it an ideal material for a variety of uses. In this article, we will explore stainless steel properties, its grades, and its applications in detail.

Stainless Steel Properties, Grades and Applications:

Grade: 301

301 Stainless Steel Properties: Compared with 304 steel, it has lower Cr and Ni content, and its tensile strength and hardness increase during cold working. It is non-magnetic, but magnetic after cold working.

Applications: used in trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, screens, and other applications.

Grade: 301L

301L stainless steel properties: Based on 301 steel, it reduces C content to improve the resistance of the weld seam to intergranular corrosion; it adds N element to compensate for the strength loss caused by the reduction of C content, ensuring the strength of the steel.

Applications: used as frame and external decorative materials for railway vehicles.

Grade: 303

303 stainless steel properties: It adds S to the composition of 304, which has good cutting performance but poorer corrosion resistance than 304.

Applications: It is suitable for occasions that require easy cutting and high surface finish, especially suitable for automatic lathes. It can be processed into bolts and nuts, etc.

Grade: 303Cu

303Cu stainless steel properties: It adds Cu to the basis of 303, which has better cutting and forming properties than 303.

Applications: The same as 303. It is suitable for occasions that require cutting and surface finish for automatic lathes.

Grade: 304

304 stainless steel properties: The most common steel grade in stainless steel. It has good corrosion resistance, heat resistance, low-temperature strength, and mechanical properties. It has good hot workability, such as stamping and bending, without heat treatment hardening phenomenon (non-magnetic, using temperature -196℃~800℃).

Applications: It is widely used in many fields, such as household goods, automotive parts, medical equipment, construction materials, chemicals, food industry, agriculture, ship parts, etc.

Grade: 304L

304L stainless steel properties: As a low-C 304 steel, its corrosion resistance is similar to that of 304 steel under normal conditions. However, after welding or stress relief, it has excellent resistance to intergranular corrosion. It also maintains good corrosion resistance without heat treatment, and the using temperature is -196℃~800℃.

Applications: It is used in chemical, coal, oil industry equipment, construction materials, heat-resistant parts, and parts that are not easy to heat treat due to the need for high resistance to intergranular corrosion.

Grade: 304Cu

304Cu stainless steel properties: It adds Cu to the basis of 304, which improves antibacterial properties and formability, and is beneficial for environments that require hygiene and deep processing products.

Applications: Thermos bottles, kitchen sinks, pots, pans, lunch boxes, door handles, textile processing machines.

Grade: 304H

304H stainless steel properties: It increases the carbon content based on 304 steel, which improves the strength during cold rolling processing.

Applications: It is mostly used for wire materials and fishing hooks.

Grade: 304N

304N stainless steel properties: It adds N to the basis of 304, which improves the strength of the steel.

Applications: It is suitable for occasions that require high cold-forming performance, such as pump shafts and ship shafts.

Grade: 316

316 stainless steel properties: It adds Mo to the composition of 304, which has excellent corrosion resistance, corrosion resistance to atmospheric conditions, and high temperature strength. It can be used in severe conditions with excellent processing hardenability (non-magnetic).

Applications: Equipment used in sea water, chemicals, dyes, paper making, grass acid, fertilizers and other production equipment; photography, food industry, coastal facilities, ropes, CD rods, bolts, nuts and other applications.

Grade: 316L

316L stainless steel properties: As a low-C version of 316 steel, it has the same characteristics as 316 steel in addition to excellent resistance to intergranular corrosion.

Applications: Products that require special resistance to intergranular corrosion in the applications of 316 steel.

Grade: 321

321 Stainless Steel Properties: It adds Ti to 304 steel to prevent intergranular corrosion and is suitable for use at temperatures ranging from 430℃ to 900℃.

Applications: Aircraft, exhaust pipes, boiler drums.

Grade: 309S

309S stainless steel properties: It has good high-temperature oxidation resistance and high-temperature durability. The heat resistance temperature can reach 900℃. Under no-load conditions, the maximum heat resistance temperature can reach 1000℃.

Applications: Heat treatment furnaces, heating furnaces, power plant boiler heat exchangers, flue gas exhaust systems and other high-temperature environmental equipment.

Grade: 310S

310S stainless steel properties: It has good high-temperature oxidation resistance and high-temperature durability. The heat resistance temperature can reach 1000℃. Under no-load conditions, the maximum heat resistance temperature can reach 1100℃.

Applications: Heat treatment furnaces, heating furnaces, power plant boiler heat exchangers, flue gas exhaust systems and other high-temperature environmental equipment.

Grade: 410

410 stainless steel properties: A representative steel of martensite structure. Although it has high strength, it is not suitable for harsh corrosion environments. It has good processing properties, hardens after heat treatment, and is magnetic.

Applications: Blades, mechanical components, oil refining equipment, bolts, nuts and other applications.

Grade: 416

416 stainless steel properties: It increases the S content on the basis of 410 to enhance cutting performance. It can be strengthened by heat treatment. The strength and cutting machinability of 416 are better than those of 304 and 316, and its coefficient of friction is small, but its corrosion resistance is not as good as that of 304 and 316.

Applications: It is widely used in CNC automatic lathes for the production of electromagnetic valves, micro-motors, and electrical components.

Grade: 420

420 stainless steel properties: A high-carbon version of 410. It has good hardness after quenching, corrosion resistance, and magnetic properties.

Applications: Blades, pipe tips, valves, ruler, cutlery (scissors, knives).

Grade: 431

431 stainless steel properties: This is a kind of steel with good strength and toughness among martensitic stainless steels. It has good corrosion resistance to oxidizing acids, most organic acids, and aqueous solutions of organic salts.

Applications: Aircraft parts, bolts, wiper arm bearings, springs, bearings and other applications.

Grade: 440A, 440B, 440C

Properties: High chromium content and good toughness. It can be heat-treated to achieve high hardness.

Applications: Knives, bearings and other applications.

Grade: 430

430 stainless steel properties: As a representative steel of ferrite, it has low thermal expansion rate, good formability, and good oxidation resistance.

Applications: Heat-resistant appliances, burners, household appliances, tableware, kitchen sinks, etc.

Grade: 430F

430F stainless steel properties: It increases the S content on the basis of 430 to improve the cutting performance.

Applications: Heat-resistant appliances, burners, household appliances, tableware, kitchen sinks, etc.

Grade: 630 (17-4PH)

Properties: It is an improved type of 431. It is a precipitation-hardening type. The hardness can be easily adjusted through heat treatment. The cold working hardening is obvious.

Applications: Gears, shafts, valves, etc.

Grade: 631 (17-7PH)

Properties: It is an improved type of 301. It is a semi-austenitic precipitation-hardening type. The forming processing at room temperature is good.

Applications: Aircraft structural materials or precision mechanical springs, etc.

Grade: 2205

Properties: It is a duplex stainless steel that combines the advantages of ferrite and austenite. It has high strength and toughness. The stress corrosion resistance and pitting resistance are higher than that of 316L.

Applications: Oil and gas, petrochemicals, fertilizers, bridges, buildings, and chemical tankers, etc.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of stainless steel properties, grades and applications. If you want to find more information about stainless steel, we’d advise you to visit Sino Stainless Steel for more information.

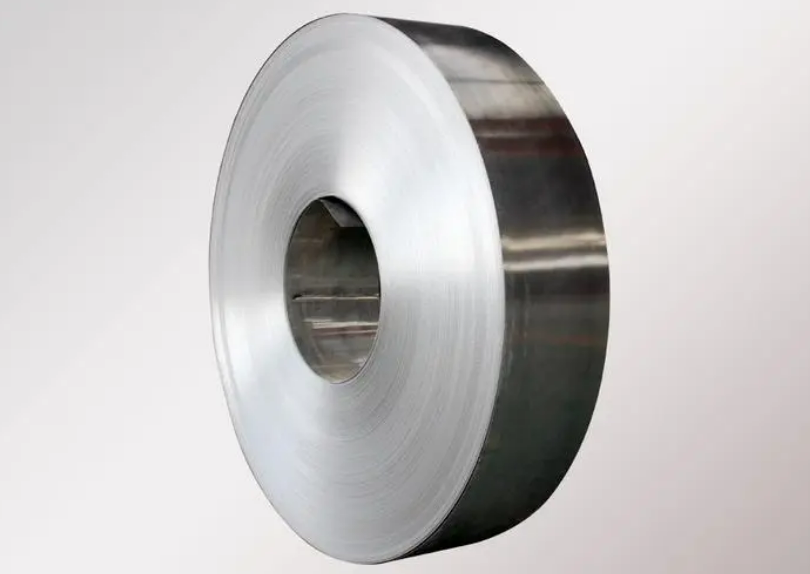

As a leading supplier of stainless steel products, Sino Stainless Steel provides customers with high-quality stainless steel products such as polished stainless steel plates, etched stainless steel sheets, stainless steel bars, stainless steel coils, and stainless steel tubes at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

Do a traditional pushup however increase one knee toward the elbow of the same aspect as you rise (like Spiderman climbing a wall).

Do normal a standard pushup along with your arms

just a few inches other than each other beneath your chest.

Regulate the peak of the handles to target totally different areas of your chest.

By doing this, you’ll guarantee your muscle tissue are

overloaded every session, and thus they may proceed adapting (getting strong and bigger).

In terms of load, you want to select a weight stack that challenges you in these rep ranges.

Essentially, you have to be selecting a weight that brings you to failure

(or close to failure) in the rep vary you’re working.

A study by Paoli et al. (2011) means that cable exercises can effectively target the

chest and improve muscle symmetry. Adjust the cables to different heights

to emphasize numerous portions of the chest. Push-ups are a basic bodyweight exercise that could be modified to

swimsuit any health stage.

Your upper physique’s “pushing” muscles are your chest muscular tissues,

AKA pectorals or pecs, together with the deltoid

and triceps. If you’re looking for straightforward cable machine

chest workouts to add to your routine, cable crossover are a fantastic staple exercise to get

you began. It helps to develop and outline

the decrease and the Inner pectoral muscles.

Whereas all the aforementioned cable chest workout routines are effective, we now have chosen the 15 finest workout routines

so that you can do. Altogether, you can target your chest in so many various ways to ensure every muscle fiber

of your pec major (upper, decrease, middle, inner) is activated

adequately.

This push-up variation helps you construct power and focus on one facet of your chest at a time.

This makes your chest muscle tissue work harder, particularly within the inner a half

of your chest. Many of these workout routines, corresponding to push-ups, diamond pushups, and a few types of

chest flyes may be done at house with minimal gear like free weights.

For extra advanced choices like the smith machine or using a weighted vest, you would possibly favor a health club setting.

The barbell shut grip Larsen press includes holding

the bar with your arms positioned closer together than a regular bench press.

Lie on a flat bench and maintain the bar above your chest together

with your arms fully prolonged. Improved power within the inner chest

also supports higher performance in compound exercises similar to push-ups and bench

presses, which depend on a strong muscular basis from each part of the chest.

Incorporating longer TUT into your chest

workouts entails executing both the concentric (muscle-shortening)

and eccentric (muscle-lengthening) phases deliberately and slowly.

This deliberate tempo increases the period your muscle fibers are exposed to

tension, which is a important factor for muscle hypertrophy.

First and foremost, a neutral grip reduces the pressure on your

shoulder joints. By aligning your wrists and elbows in a more pure and anatomically sound manner,

it minimizes the danger of overextension or awkward angles

that may lead to shoulder discomfort or harm over time.

This ergonomic positioning allows for smoother and safer motion, especially

throughout heavy lifting, the place proper form is crucial

to prevent damage. The means the muscle is linked to the rib cage makes it robust to focus on the internal chest particularly, but some exercises hit the whole chest

while focusing on the center pectoral. The cable supplies fixed resistance, helps develop

central chest muscular tissues, and supplies much-needed stress on the middle pecs.

The close grip bench press is another foundational motion that does work to the inner chest, as well as the triceps.

This is an effective place to start out should you struggle with

different workout routines, or only have a barbell. Something else you’ll discover whereas experimenting with

the place of your pectoralis major is that they’re not engaged in every single

‘movement your arm makes. That’s as a result of your pecs are answerable for

three main movements of your humerus. All of those muscle fibers

stretch throughout your chest and inserts themselves

into the higher joint of your humerus. It’s a part of the complicated jungle of

tendons and muscle tissue that make up your shoulder joints.

There’s simply plenty of pure muscle involved in transferring

your upper arm around.

It originates out of your high 2–4 ribs and inserts

on the coracoid process in your scapula. Its primary functions are

to protract your scapula and rotate your scapula forward.

In phrases of chest hypertrophy and energy coaching, the pectoralis minor

is often negligible, and also often skilled by related exercises as your

pectoralis main anyway. From chest muscle anatomy

and development, to the time-tested workouts that lifters, bodybuilders, and athletes have deployed for many years in pursuit of higher chest measurement and energy.

This particular muscle area is labored finest with a combination of incline or

low-angle movements, with shoulder adduction across the midline of the

chest. Use the tips, exercises, and workouts on this

article to add measurement, definition, and power to your inner chest.

To build the inside chest along the complete size of the muscle,

you’ll have to hit it from completely different angles to coincide with the

alignment of the muscle fibers. Use the professional

ideas for the exercises above, in addition to the coaching

ideas beneath as part of your general inner chest exercise.

To focus even further on a selected section of the pecs,

the incline press works the higher or clavicular portion of the muscle.

Secondly, the inner portion of the pectoralis major actually lights up when the arm crosses the middle of the torso.

Whereas it’s a good chest train, it’s equally pretty a lot

as good on your lats and abs. That said, this exercise is often carried out on chest days (or if you do push-pull superset workouts),

because it does a fantastic job of activating the higher chest.

With the incline bench cable fly, you will be emphasizing your upper chest.

Your front delts will naturally have extra activation than the

flat bench as a end result of shoulder flexion. The cable decline press can be carried

out standing/kneeling by simply setting the handles at the top (or close to the top) of the towers and then urgent down and

inward at an angle. OR, you’ll find a way to set up a

bench in a decline position to imitate that of a decline dumbbell

or barbell press. With the bench, you’ll be able to

actually hone in on your pec major, and extra particularly, the

decrease head, as decline presses do.

Making An Attempt to maximally contract the inner

chest with out first warming up the muscle tissue and shoulder

joint is a recipe for muscle strains. This exercise can be

accomplished with dumbbells, with both choices being nice for

building the power to contract the inner chest collectively.

The bench press is still the king of adding those initial

pounds of mass to your chest for you to then develop further.

Such techniques can be found within the inner chest exercises provided

under. An inner chest exercise needs to focus more on bringing

the upper limb as near (or across) the midline as attainable.

The single-arm chest fly is likely certainly one of

the greatest workouts in the house to get a loopy tension on the inner portion of your chest.

Here’re the 9 greatest internal chest exercises you want to perform to get a gorgeous chest.

Nevertheless, there’re some internal chest particular workouts

you can perform to place extra pressure to the center of your chest where your pecs connect

to the sternum. If you’ve shoulder joint points, it’s important to

consult a healthcare skilled or an authorized coach

to determine which exercises are protected for you.

In some circumstances, modifying exercises or using machines may be recommended to scale back

strain on the shoulders.

Analysis reveals that performing an incline cable fly with a 30 and

45 degree bench angle is one of the best for the upper chest.

Vary the position of the bench to hit completely different angles of the higher

chest. Lat pulldowns are an excellent place to begin if you want to add a

simple but effective cable machine exercise to your workout routine.

Research indicates that the bench press produces higher muscle activation within the chest

compared to many different urgent workouts (Schoenfeld et al., 2015).

This, in turn, will make your whole body stronger, permitting you to go heavier throughout other lifts.

If you’ve ever sat down on the pec deck, then you realize the fundamental movements required to

drag this exercise off. The extensive grip bench press is a variation of the standard bench press train that includes gripping the barbell wider than shoulder-width aside.

This exercise primarily targets the middle and outer chest muscular tissues, in addition to

the triceps and shoulders. The flat bench dumbbell press is a well-liked train for growing chest power and measurement.

The muscle’s medial head has a major function, although all

three heads come into play when the burden is heavy and the velocity of motion increases.

The two movements are remarkably related, however dumbbells require higher

coordination, as a outcome of each side is working independently.

This finally offers a barely greater vary of

motion and for some bodybuilders with shoulder problems, present less stress.

The bench press is a good chest exercise, and when you improve the

weight you presumably can raise on this exercise, your

chest will develop. In this section, we’ll check out 4 of one of the

best chest exercises, that complement one another

in terms of what muscle fibers they target.

Frequent faults in the flat bench press include flaring your elbows out too far, which may put pressure in your shoulders, and allowing your back to

spherical or carry off the bench. These faults can increase your risk

of damage and reduce the effectiveness of the train. Just 20–30° incline is

sufficient to goal the upper chest muscle fibers good,

whereas still getting extra training for your middle muscle

fibers. The bench press is at the identical time elegantly easy and ruthlessly

efficient for rising your chest measurement and strength.

Load up the bar, press it for reps, and repeat often –

every time trying to add somewhat little bit of weight to the bar, or another rep to

your set. Well, that is a tiny muscle, situated beneath your pectoralis major.

Keeping your arms barely wider than shoulder width is ideal for overall chest growth.

It is all the time best to begin with fewer reps and units after

which steadily increase as your energy improves. The dumbbell fly takes

benefit of arm rotation to essentially target all

areas of the pecs, however most importantly, the internal

chest. During the squeeze press, the dumbbells are always involved with each other,

and you’re actively squeezing them inward (against each other) as exhausting as possible.

Coaching the whole chest muscular tissues provides you a balanced

and proportionate chest. Whereas you might suppose that to construct chest muscle definition you want heavy

weight, you’ll be pretty surprised what you’ll find a way to accomplish with resistance

bands.

This type of push-up would be the crown-work of the push-up routine you’ve perfected thus far.

Decrease your self to do a regular push-up and

then explosively clap up, touching both knees with both hands while

you’re up within the air. The purpose is to target each side of your chest equally and enhance coordination. This routine is appropriate

for all fitness levels as you will see in the video above,

there might be a “Beginner’s version” demonstration in the backside lefthand nook of the video.

Due To This Fact, everybody can take part, have some fun, and

make long-lasting real results. Push the handles again out to complete the motion,

ensuring managed and deliberate motions throughout.

The innermost part of the pec muscle tissue –

where the muscle fibers be part of to the breastbone – appears to

be missing in measurement and definition irrespective of how robust

you grow or how a lot you pump your pecs. It doesn’t seem like an orthodox

chest train, but I can promise you that it works very nicely and

may be an effective ending chest workout choice. So, on this article,

I’m going to give you the nine finest inside chest exercises that you want to perform with muscle mid connection to construct up a defined and fuller inside

chest line. Stand within the heart, hold a handle in each

hand, and step ahead barely.3. Maintain a neutral grip as you convey your arms together in a hugging motion.4.

Squeeze your internal chest at the end of the motion,

then return to the beginning position.

Isolation exercises are workout routines that target a single muscle group, whereas compound workouts work a quantity of muscle teams.

Isolation workouts are used to handle a muscle imbalance or

focus on particular muscle groups that are uncared for in compound movements.

The bench press is, undoubtedly, probably the greatest exercises for constructing mass, particularly in the chest, however

chest isolation workouts help sculpt and define the pecs.

In this article, we’ll teach you concerning the anatomy

of the muscle tissue and all of the best isolation chest workouts to help get your pecs outlined.

It’s an effective bodyweight train for building energy and muscle definition in the inside pecs.

To understand the inner chest muscle group, it’s essential to know the anatomy of the chest

muscles and acknowledge its advantages. When training the

inside chest, various factors come into play, corresponding to discovering your line of pull and specializing in mind-muscle connection to achieve effective outcomes.

For 2-3 weeks, couple up a big muscle group (legs, back, chest) with a smaller muscle group (shoulders,

arms, abs) or a push and a pull. Particularly when accomplished

with dumbbells, this exercise works the inside

chest via its fullest range of motion, which is a vital factor

of muscle progress.

After we run through all the cable presses, we are going to get into the flys and pullovers.

Remember to give consideration to high quality over amount; carry out each

rep with excellent type, and don’t be afraid to problem yourself (or to

honor your limits). Now that you realize all the best push-ups for a stronger chest, it’s time to pick which ones will work finest for you.

This blog publish will focus on the 11 greatest push-ups for a

stronger chest.

The Lower Chest fibers originate from the

bottom of the sternum and travel diagonally down towards the middle

of the chest. The Mid Chest fibers that come off

the sternum are oriented in a horizontal direction nearly straight across

the chest. Stretching and warming up earlier than any workout is a should to avoid harm

and get probably the most from your exercise.

Our Pre-Workout Gel boasts 221mg of caffeine, proven to

increase endurance efficiency, that could be consumed straight from the sachet — it’s the last word comfort.

To spherical off our formula, we have included a blend of extracts together with green tea, black pepper, cayenne powder, bladderwrack, and Siberian ginseng.

With each tablet containing 200mg of high-quality caffeine, it is best

to take half an hour to an hour earlier than train so you can push to your peak.

Super-convenient, merely go away a pot in your automotive so

you could get the increase you want by the time you attain the

health club. To see the most effective results from your coaching, pre-workout

diet should be a high priority. Our staff have labored onerous to provide you a spread of unique blends and formulas

to make sure that you’re greatest prepped, each session. Named after a shotgun, designed to appear to be a shotgun shell,

and a few would say as effective as a shotgun in a

zombie film.

XWERKS is a US complement model featured by top publications for his or her innovative products.

Xwerks ignite appears to be every little thing you’d want in an efficient pre-workout complement.

It supposedly works by inhibiting substances that contribute to age-related cognitive

decline and rising production of acetylcholine –

an essential brain chemical. Let’s take a glance at what pre-workouts we’d suggest in this case plus we’ve included a buying guide

and plenty of different helpful info for beginners.

That being mentioned, most pre-workouts will try to hit five vital factors; good pumps, elevated energy, improved endurance, enhanced energy, and improved focus.

For $1.00 per serving, you’re getting 180 mg of caffeine for vitality,

three,000 mg of pure L-citrulline for pumps, 1,250 mg of betaine anhydrous for

power, and 1,600 mg of beta alanine for endurance.

Citrulline Malate is an amino acid that helps to extend nitric oxide levels within the body.

This can lead to higher blood circulate, increased oxygen delivery to the muscular tissues, and a greater muscle pump during exercises.

A pre-workout supplement is a product designed to be consumed before a exercise to enhance efficiency.

If you’re looking for a ready-to-drink pre-workout that’s easy to search out, C4

Vitality is the one you’re most probably to search out in a retailer near you.

Jacked Gorilla was based in 2013, and started publishing bodybuilding supplement evaluations, and well-known workout routines.

It wasn’t acquired by Rich Gorilla Restricted until 2019, and since then each our range

of content material and our viewers have grown considerably.

If you’re not used to consuming caffeine, then at all times begin with a smaller amount

than what’s really helpful.

You can also notice that a fasted run feels great, but a strength training session can use slightly pre-workout meals.

Pay attention to how your body feels during a fasted workout and

tweak your consuming habits accordingly. On the contrary, exercising on an empty abdomen may leave you feeling fatigued,

which could hinder your exercise efficiency.

Pre-workout dietary supplements sometimes contain a blend of ingredients similar to caffeine for

alertness, amino acids for muscle help, and nitric oxide boosters to enhance

blood move. While pre-workouts may help some athletes

push by way of a troublesome exercise, they don’t directly

construct muscle—that comes from consistent coaching and proper vitamin. “Pre-workout dietary supplements may be efficient depending upon the components, dose and timing,” explains Marie

Spano, a sports efficiency nutritionist who works with skilled athletes in Atlanta.

Sturdy pre-workouts present a major quantity of caffeine and other

stimulants to jolt your senses and sharpen your focus, making certain you’re able to go from the

time you enter the fitness center. With the addition of such compounds as citrulline malate and beta-alanine,

additionally they help elevated power, power, and endurance whereas dialing in laser-like focus, to not mention epic

muscle pumps. It has energy ingredients like caffeine and L-theanine which might be scientifically proven to assist improve brain perform.

They also embody different benefits that can enhance

your exercises like potential weight loss, enhance exercise intensity, and assist wholesome muscle

tissue.

Particular Person pre-workout complement tolerance varies,

and a few users can be particularly delicate to the results of particular substances.

An overly potent pre-workout could cause unpleasant unwanted aspect effects like jitters, restlessness, nervousness, a sooner heartbeat, gastrointestinal problems, and even sleep disruptions.

Long-term well being effects may also end result from excessive use or intake of high-stimulant pre-workout dietary supplements.

Third-party testing ought to be taken under consideration when buying pre-workout dietary supplements

to make sure the product’s security, quality, and effectiveness.

Third-party testing includes impartial labs or organizations that analyze dietary supplements to verify their components, efficiency, and common adherence to

legal necessities.

By focusing on the right receptors, you will be dialed in and ready to tackle any workout that comes your means.

This may even add to your motivation to actually enhance

strength training and muscle progress. We’ve put collectively a listing of the Finest Pre-Workouts

For Men of 2024 so you can begin to see those desired gains to muscle

progress, vitality, and boost your power training.

With ingredients like caffeine and beta-alanine, it supports enhanced energy levels and muscle endurance, making it best

for athletes and health enthusiasts. Pre JYM Plus accommodates

creatine monohydrate, beta-alanine, caffeine, nitrates, betaine, citrulline

malate, BCAAs, caffeine, and nootropics to boost energy, endurance,

pumps, energy, and mental focus. This superior pre-workout formula delivers science-backed doses for optimum performance and results.

If you’re on the lookout for an extra enhance in your mental and bodily efficiency,

pre-workouts are a wonderful complement to make use of.

The completely different ingredient formulations can provide

several advantages, including elevated energy,

energy, muscle pumps, and cognitive function.

It’s essential that good pre-workout supplements are clear about components, and you’re able to hint the advantages of each element.

The formulation doesn’t depend on mega doses of sugar and caffeine that can go away you feeling jittery and anxious.

Somewhat, it uses research-backed pure components

like Setria Efficiency blend (Glutathione +

L-Citrulline), Pink Beetroot Powder and their famous Nutrigenesis nutritional vitamins and minerals.

Moreover, it presents the patented mix, NooLVL –

a non-stimulant ingredient that reinforces cognitive performance.

This is amongst the higher testing organizations available, which is a huge plus in our

books. This article presents a subjective perspective on the

subject, crafted by writers who focus on medical writing.

It could explore private experiences with sickness or

medical situations, evaluate products, discuss dietary issues, or provide

other health-related insights.

By selecting this product, you possibly can trust that you just’re providing

your physique with an efficient, high-quality blend that supports your coaching goals.

And smart caffeine — a combo of caffeine anhydrous (150mg) and L-Theanine (200mg).

We all know the boost that caffeine can provide, serving to us to really

feel stronger, more aware, more focused and fewer tired.

Every scoop of Skratch Labs Hydration Combine delivers 20 grams

of quick-absorbing carbs from cane sugar and dextrose, plus 380 milligrams of sodium and other key electrolytes like potassium, magnesium,

and calcium. This electrolyte enhance replaces what you lose through sweat, preserving you hydrated and energized.

Besides easing into it, make certain to drink adequate water throughout your exercise to stay

hydrated. Pre-workouts that taste the best are Gorilla Mode, Clear Labs, 4 Gauge, and NITROSURGE.

By taking a post-workout protein, you could speed up the restoration process as nicely.

This ensures you won’t suffer from any side effects, such as jitteriness and sleeplessness at evening.

Classic Blast is designed for sustained power with

out the frequent post-workout crash. It’s much less appropriate for these needing excessive focus ranges from stronger dosages of focus-enhancing components.

Fantasy Journey is strong in caffeine content material,

ideal for endurance and reaching high-energy exercises.

However, it lacks stability in focus enhancement due to the absence of L-theanine.

The model is also known for other supplements like intra and publish exercise drinks.

Its balanced mix of L-Citrulline, creatine, and caffeine successfully enhances muscle endurance and strength, without the distracting tingling from beta-alanine.

It is possible to search out a fantastic product with out totally breaking

the financial institution. Earlier Than shopping for your pre-workout complement, men should think

about a number of components to seek out one of the best supplement potential.

Except you’ve been taking pre-workout for several years I suggest you keep way from this one.

The formulation has gone a couple of iterations over the years, with the

newest (v3) being released in 2023. This one goes again to the original feel of Flame, giving hours of feel-good power and buzz.

However don’t fear, Crack OG retains all of

the original Crack’s finest options.

When just beginning out, it’s finest to go with pre-workouts that aren’t excessive in caffeine but

quite, contain sufficient to provide you a noticeable enhance in performance.

Pre-workouts are one of the most commonly used and popular performance-aiding dietary supplements.

They serve a special objective and there are research that have proven the effectiveness of these

multi-ingredient products. Creatine is simply a kind of elements that

work and it had higher if it’s nonetheless extremely beneficial after thousands

of studies have proven its efficacy. An amino acid found in red meats and some seafoods, it’s also naturally produced in small quantities by the body.

There are caffeine-containing pre-workouts after which there are non-caffeine/stim variations.

While you don’t need caffeine to expertise useful effects from these ergogenic aids, stimulants are

a kind of drug that may stimulate the nervous system.

Some of the most common artificial sweeteners included in pre-workout supplements are sucralose, aspartame, and saccharine.There is a few debate on whether or not stevia

is a pure or synthetic sweetener. The next FAQ details the nuance of stevia’s

standing as a pure sweetener. Altius is a clinically-dosed, “No BS” pre

exercise without any artificial sweeteners or unnecessary filler ingredients.

We’ve painstakingly reviewed dozens of pre-workouts to identify the cream of the crop with no artificial sweeteners.

Sucralose, aspartame, and saccharine are nowhere to be found in these pre workouts.

If the original does not suit your style, you probably can explore fun choices

like Frozen Bombsicle, Fruit Punch or Rainbow Blast — making it enjoyable to stick to your routine.

A cup of black coffee (with or without sugar) before your exercise is a nice way to up your energy ranges.

Some folks really feel fantastic, however others might expertise jitters or stomach

discomfort. It made a giant impression on our

testers, who stated it delivered a surge of power earlier than their periods and helped with

post-workout DOMS. It also scored prime factors for its mixability and texture, which made

it fast and simple to gulp down.

The physique can use BCAAs for energy synthesis when glycogen levels are depleted.

By together with BCAAs in a pre-workout complement, it makes positive that these amino acids are always ready to be used as fuel, possibly

stopping fatigue and enhancing endurance. It has been proposed that Alpha-GPC helps the body launch progress hormone (GH).

Progress hormone stimulates the breakdwon of fat for

use as gas, thus sparing muscle protein.

Next, it contains 2.5g of Beta-Alanine, an amino

acid that may assist delay muscle fatigue, permitting

you to coach harder and longer. It also options 1g of Glycerol Monostearate, which aids in hydration and endurance, and 1g of Arginine

AKG, a precursor to nitric oxide, further boosting blood move and

muscle pumps. The complement contains 7g of Citrulline Malate, a compound recognized to enhance nitric oxide production, bettering blood move and oxygen delivery to your muscle tissue during workouts.

Take a serving 30 minutes earlier than exertion for clear, environment friendly power to energy you thru your exercise.

Additionally observe, this oil can stack really successfully with different pre workouts you might be

taking.

For this reason, we’ve positioned the best stim-free pre-workouts that

work by way of other potent compounds that

don’t mess together with your nervous system.

Another ingredient in L-norvaline might extend the blood

flow-enhancing effects of citrulline, so this formulation has

lots going for it, particularly for slicing. They’re presently available in three scrumptious flavors (strawberry, apple and white grape), or in a handy trial kit containing all

three, to help you choose a favorite.

Presently, no analysis exists in CKD that elucidates the signaling networks

inhibiting NF-κB stimulating NRF2. Nonetheless, it is posited

that this impact is mediated by way of the controlling of

the enzymes MAFbx (atrogin-1) and MuRF1 inside the ubiquitin-proteasome system.

These methods are activated in reaction to oxidative stress and inflammation,

thereby enhancing the functioning of mitochondria [182,183,184].

Consequently, addressing the NRF2 axis with strategically formulated nutraceuticals may characterize

a viable treatment technique. Numerous investigations have sought to

elucidate the mechanisms of NRF2 stimulation by nutritional substances and to confirm their protecting results in skeletal muscle [185].

In a previous research, inhibition of MSTN by antibody found no change in fat mass in an animal

mannequin [37].

The assays had been run in duplicate and the absorbances of the requirements, samples, and controls have been decided at an optical

density of 450 nanometers with a Wallac Victor[2]

1420 Multilabel counter by PerkinElmer (Boston, MA).

Concentrations of active testosterone, free testosterone, and cortisol

were expressed relative to adjustments in blood serum content material.

Intra-assay coefficients of variation were 5.3% and 6.8%, 7.5% and 5.4%, and

a couple of.4% and 5.0%, respectively, for active testosterone (control I and II), free

testosterone (control I and II), and cortisol (control I and II).

Inter-assay coefficients of variation had been four.8% and four.9%, 0.22%

and 1.28%, and 12.0% and 6.1%, respectively, for energetic testosterone

(control I and II), free testosterone (control I and

II), and cortisol (control I and II). The supplements had been prepared in capsule kind

and packaged in generic bottles for double blind administration by MuscleTech Research

& Growth, Inc., (Mississauga, ON). Supplementation compliance was monitored by

analysis assistants by having the topics return empty bottles of the supplement at the end of 4 and

eight weeks of supplementation. Following the DEXA, topics donated approximately 20 ml of fasting blood from the antecubital vein in the arm

through venipuncture using commonplace and sterile procedures.

Satisfactory progress, and restore of skeletal muscle dependent

on the sort of cells. SCs are a subpopulation of skeletal muscle

progenitors and are positioned beneath the basal lamina of myocytes.

In healthy circumstances, these cells stay inactive until

encountering an activating stimulus similar to harm or train which finally ends up in the initiation of the cell cycle and differentiation to myoblasts, selling the regeneration or development

of myocytes [93]. It has been demonstrated that individuals with CKD possess a smaller amount

of SCs in their skeletal muscle and the remaining SCs

have irregular perform, reducing the regenerative capability of their skeletal muscle [94].

All of these mentioned alterations contribute to the process

of muscle wasting in CKD sufferers.

Researchers reported ~96 mg of epicatechin within the chocolate, but the actual stereoisomer was not reported (+ or –).

Different researchers discovered no benefit to ingesting flavanol-containing (specific flavanols not

reported) cocoa beverages on indices of muscle damage after downhill running (19).

Despite promising evidence in rodent fashions, the

paucity of proof involving (–)-epicatechin supplementation in humans subjects

in combination with exercise coaching is inadequate for interpretation as to if

and the way flavanols modulate train adaptations.

Because of the aforementioned observations with (–)-epicatechin supplementation, it has been advised that

it might be helpful as a method to increase exercise

variations (13). Fifteen days of (–)-epicatechin supplementation alone resulted in increased exercise

performance, reduced muscle fatigue, elevated muscle capillarity and increased mitochondrial biogenesis in mice (14).

In mice selectively bred for low working capacity, 30 days of (–)-epicatechin supplementation successfully

elevated skeletal muscle capillarity and mitochondrial biogenesis (15).

In one other study, (–)-epicatechin supplementation in mice, along with treadmill train over the course of 8 weeks, elevated angiogenesis and mitochondrial biogenesis (16).

This evaluation will concentrate on the impact of myostatin and its inhibition on muscle mass/function, adipose tissue and bone

density/geometry in humans. Although present knowledge

are sparse, myostatin inhibition leads to elevated lean mass and 1 study found

a decrease in fat mass and increase in bone formation. In addition,

myostatin levels are increased in sarcopenia, cachexia and bed rest whereas they are increased after resistance training,

suggesting physiological regulatory of myostatin. Increased myostatin levels have also been present in obesity and ranges lower after weight reduction from caloric restriction. Information on the connection of myostatin with bone is basically based

mostly on animal information where elevated myostatin levels result in decreased BMD and

myostatin inhibition improved BMD. In summary, myostatin appears to be a key factor in the built-in physiology of muscle,

fats, and bone.

To that effect, glucose is first metabolised to pyruvate via glycolysis and might subsequently enter the mitochondria for additional metabolism

inside the TCA cycle. The important upregulation of MAPLC3B (a key gene in cell autophagy) noticed within the present study further

support this notion. Apparently, UA can activate AMPK [38], a

common regulator of both autophagy and GLUT4 expression [39, 40], which can present the mechanism by which UA

exerts its twin effects on glucose uptake and mitochondrial function.

MSTN negatively impacts bone formation by inhibiting osteogenic differentiation of

mesenchymal stem cells and osteoblasts [146, 147].

It additionally suppresses chondrogenesis,

delaying the transition from cartilage to bone throughout

fracture healing, thereby affecting callus formation and bone regeneration [148].

MSTN is proven to be a constructive regulator of osteoclast differentiation, which is answerable for the resorption of aged bone and performs

a task in bone degradation in arthritis and osteoporosis

[149].

Blood sampling is a relatively quick procedure and fewer invasive compared to muscle

biopsies that were obtained also at these two extra

time points. The CSA of vastus lateralis measured by B-module ultrasonography was

validated as an appropriate different to MRI, which is considered the gold standard for measuring muscle dimension,

for measuring changes in muscle size in response to disuse atrophy [23].

Using this technique, with a 18L5 probe (BK Medical North America, Peabody, MA, USA), we measured the CSA of vastus lateralis of the leg randomly assigned for immobilization at days 1, 14,

28, and 42. The process concerned members laying supine for greater than 10 min to normalize fluid shifts in the

physique, and we marked the location for imaging,

50% of the gap between the top of the patellar bone and the greater trochanter of the femur, identified by palpation. Afterward, a

straight line was drawn alongside the longitudinal of the vastus lateralis, and the pictures had been taken at 2 cm increments alongside

the line leading to ~7–9 pictures.

If you don’t need to go the peptide and complement route, you have to use

pure dietary interventions and lifestyle modifications to scale back myostatin expression. Keep In Mind, dietary supplements

alone won’t do the trick—physical exercise and smart dietary selections are simply as essential.

This article hopefully will emphasise that bodybuilding is

a journey with yourself. I wish to see a study carried out on a bunch of hardgainers lifting weights thrice a week and

Flex Wheeler just LOOKING at dumbbells 3 times every week.

In regard to his genetics for constructing muscle, Flex Wheeler is simply a phenomenon.

Resistance training and regular moderate-intensity aerobic

exercise are confirmed effective pure methods for potentially reducing

myostatin ranges and supporting muscle development. While some drugs and dietary supplements declare to

have an effect on myostatin levels, their precise influence alone on muscle growth ought to

be considered with a healthy dose of skepticism.

If you are dedicated to constructing lean muscle mass, you may know it takes a lot effort—hours at the fitness center and

a protein-rich diet are usually the recipe. However

for individuals who have already dialed in their workout

routines and vitamin and are looking for an extra edge, understanding how myostatin inhibitors work would possibly help you reach the subsequent step in achieving those health objectives.

Epi 2.0 by Vital Alchemy provides a centered strategy to enhancing muscle progress by inhibiting myostatin, facilitating improved muscle

measurement and power. Quercetin is a flavonoid that acts as a strong antioxidant and also has potential myostatin inhibiting properties.

It helps endurance and efficiency by improving blood move

and reducing irritation.

This evaluate details the mechanisms behind myostatin’s perform and the assorted inhibitors which

have been tested preclinically and clinically. It additionally examines

the challenges encountered in scientific translation, including

points with drug specificity, differences in serum myostatin concentrations between animal fashions and people, and the

need of neural input for functional improvements. Additionally, we discover promising avenues of analysis beyond muscle dystrophies, significantly within the remedy of metabolic syndromes and orthopedic disorders.

Insights from these alternative applications suggest that

myostatin inhibition could hold the potential for addressing a broader vary of pathologies,

offering new directions for therapeutic improvement. In summary, blocking myostatin signaling

utilizing an anti-myostatin-specific peptibody only partially mitigated muscle atrophy and useful

strength following 14 days of hindlimb suspension of male mice.

Further direct comparisons between spaceflight and

hindlimb suspension will be required to completely assess the utility of the suspension mannequin to address spaceflight

musculoskeletal issues. Results from this examine also suggest that there could be therapeutic potential

for myostatin inhibition in disuse muscle wasting and perhaps even in astronauts assigned to long-duration house missions.

Genetic Enhancements Epicatechin is among the strongest Epicatechin dietary supplements on the market.

With 500mg of Epicatechin per serving, it’s one of the most

potent Epicatechin supplements in the marketplace. For greatest

results, the brand recommends taking 1 serving (1 capsule) twice day by day and biking the complement for a period of eight weeks, followed

by a 4-week break before repeating. You can tip the scales in your favour by consuming

nicely, training effectively and sleeping so much. You can even do it

– at least within the brief time period – by tricking your

physique with steroids and performance enhancers.

Follistatin, in extra, raises the risk of a quantity of malignancies, together with cutaneous, esophageal, abdomen, and prostate cancer.

Nonetheless, high levels of Follistatin have been found to have

a preventive impact towards breast most cancers, while further examine is

needed.It is essential to know that, like different anabolic steroids, YK11 can cause varied opposed effects starting from minor to

extreme. Elevated hair progress, pimples, changes in libido,

sleeplessness, nervousness, irritability, nausea, and complications are all frequent unwanted effects.

Excessive blood pressure, liver injury, renal injury, and heart harm are all attainable opposed results.Given the hazards, it’s suggested

that only these with previous experience with anabolic steroid use think about utilising YK11.

Those considering YK11 supplements must be aware

of the hazards and proceed with caution.

For astronauts on board the Worldwide House Station (ISS), even high-volume resistance train doesn’t totally prevent muscle atrophy and weakness2,

4 and might turn into infeasible if astronaut health had been compromised.

Pharmaceutical therapies that promote or protect muscle mass and strength,

alone or together with train or dietary interventions,

are essential to hold up astronaut health throughout long-duration spaceflight missions.

An improved understanding of mechanisms that underlie spaceflight-induced

muscle loss is thus needed. Fortetropin (Canine Muscle Formulation; Myos, Cedar

Knolls, New Jersey, USA), a nonthermal-pasteurized, freeze-dried,

fertilized egg yolk product, was proven to have an abundance of proangiogenic and host-defense proteins compared

to unfertilized egg yolk (10). Fortetropin is believed to promote muscle growth through the reduction of serum myostatin via an undefined mechanism, yet the measured effect on serum myostatin levels has various

in research (11,12). Nevertheless, a study in older women and men demonstrated

no change in serum myostatin over 21 d of Fortetropin administration, regardless

of demonstrating an 18% improve within the fractional synthetic fee of muscle protein compared to a placebo (13).

There are a selection of open supply and licensed digital screening software/tools

available, and each has its personal constraints that should be overcome to prevent the manufacturing of erroneous

conclusions or artifacts (Gimeno et al., 2019). For VS, licensed software program corresponding to

Molecular Operating Setting (MOE) (Vilar et al., 2008), and the GLIDE module in Schrodinger (Bhachoo and Beuming, 2017) as

properly as open access tools similar to Autodock Vina (Trott and

Olson, 2010), are generally used. Uralensis is native to Asia and is used

as a medicinal herb, sweetener, and in conventional Chinese

medication (Ji et al., 2016). In addition, liquiritigenin, tetrahydroxymethoxychalcone, and

licochalcone B isolated from the EtOAc fraction of G. Uralensis

enhanced myoblast proliferation and differentiation, and

liquiritigenin enhanced muscle regeneration in injured muscles (Lee et al., 2021b).

Uralensis-derived compounds have therapeutic potential for the administration of

muscle-related disorders.

Certainly, the main focus of most scientific studies thus far

has been on diseases corresponding to Duchenne muscular dystrophy

(DMD), sporadic inclusion body myositis (sIBM), and limb-girdle muscular dystrophy (LGMD).

Muscular dystrophies are genetic disorders characterised by

muscle weak spot and degeneration resulting from mutations

in particular genes. Other situations characterised by muscular losing, corresponding to sarcopenia and cancer cachexia, are additionally anticipated to benefit from enhancements

in muscular function. Preclinical studies conducted in MSTN-null mdx mice, a model of DMD and Becker muscular dystrophy (BMD) that includes a premature cease codon within the gene for dystrophin, have

demonstrated elevated muscle size and power [40]. Furthermore, a three-month remedy routine

with anti-MSTN antibodies in mdx mice resulted in enhancements in physique weight, muscle mass,

muscle dimension, and absolute muscle energy,

accompanied by a big discount in muscle degeneration [41].

Given the consistent success in ameliorating muscle losing diseases in animal models,

varied inhibitors have been developed for scientific evaluation (Table 1).

Phytoestrogens like genistein and daidzein (found in soybeans) can modulate inflammation and oxidative stress.

In quick, every day low doses of catechins (such as epicatechins) stimulate the pituitary gland to

produce hormones LH and GnRH. These hormones are

needed indicators that will push the Leydig cells to produce more testosterone.

Although follistatin 344 appears to work naturally, it

can nonetheless be a uncertain compound as a outcome of it’s a

banned substance and since not many individuals have used it.

GHRP 6 works by binding to development hormone

secretagogue receptors (GHSr) located in numerous body parts.

The use, distribution or replica in other forums is

permitted, provided the unique author(s) and the

copyright owner(s) are credited and that the unique publication in this journal is cited, in accordance with

accepted tutorial apply. No use, distribution or reproduction is permitted which doesn’t comply with these terms.

Get unique well being suggestions, early entry

to new merchandise, and particular discounts—straight to your inbox.

Dietary Supplements like epicatechin and quercetin may complement your efforts but are not miraculous solutions.

No single technique, together with drugs, can be thought of one of the best ways to inhibit myostatin universally.

The Place distinct regional differences of fiber type occurred, the counts

have been weighted to the relative area of measurement.

An essential round-up of science information, opinion and analysis, delivered

to your inbox every weekday. This article is based on scientific evidence, written together with specialists and reality checked by our medical staff.

EP1LOGUE is our favourite for people who wish to acquire

weight or construct muscle using epicatechin, due to

it’s very excessive potency (600mg per serving)

along with different helpful components for this function. EP1C Unleashed accommodates top quality epicatechin,

backed by lab analysis from a third party tester.

This pure epicatechin extract is at 90% focus, derived from pure sources similar to green tea catechin.

In this examine, day by day consumption of drinks containing non-alkalized cocoa mixture reduced the intake

of food.

Myokines are known to be concerned in MSC activation and regulate their

main features, for example, they augment proliferation and differentiation charges (Mandai et al., 2017).

Intracellular aggregation of methylglyoxal, a precursor of advanced

glycation end-products (AGEs), and subsequent glycation of biomolecules impaired ECM transforming, and curcumin and

gingerol have been reported to scale back the impression of AGE on myoblasts (Baig et al.,

2017). Moreover, enhanced AGE manufacturing and consequent RAGE (AGE receptor)-AGE interplay hinders the muscle improvement

program. We additionally discovered by in silico evaluation that the MSTN-ACVRIIB interaction is lowered by curcumin or gingerol.

Protein-ligand (curcumin/gingerol and MSTN) and protein-protein interactions (MSTN

and ACVRIIB) studies had been carried out to discover the impact of curcumin and gingerol within the myogenesis processes.

However, the free vitality of MSTN to ACVRIIB binding fell to

−46.fifty five and −47.26, correspondingly, for MSTN-curcumin and

MSTN-gingerol complexes, displaying that curcumin and gingerol intrude with MSTN-ACVRIIB interaction (Baig

et al., 2017). Different TGF-β superfamily members, along with MSTN,

are documented to be effective negative muscle regulators, notably

“activin A” being the second adverse muscle regulator.

The indications being targeted include various muscular ailments and issues, such as Spinal Muscular Atrophy, Muscular Dystrophy, Muscular Atrophy, and Neuromuscular Illnesses.

The most rapidly progressing drug types are monoclonal antibodies and fusion proteins, indicating intense competitors in the field.

The development of medicine under the goal myostatin is spread across multiple international

locations, with the Usa leading in phrases of the variety of drugs

in several phases of growth. Overall, the lengthy run development of target myostatin shows promise in addressing

unmet medical needs within the field of muscular

illnesses and issues. The mechanism of motion of MSTN

is predicated on its interplay with different proteins in the pathway leading to the

transformation of latent MSTN to its mature type and further activation of

the Smad pathway, which leads to the inhibition of myogenesis.

Research have proven PPIs are key mediators of assorted signaling and

regulatory networks (Villoutreix et al., 2008).

This quantity will vary depending on training degree and particular person top,

however for the typical male, an excellent

intermediate weight is round 366 lbs. If you’re a newbie, you’ll doubtless honest lower within the

200lb range. Though it’s essential to keep in mind that putting on heavy weights, especially when beginning out with deficit deadlifts, can result in accidents.

So, take heed to your body and when you notice strange pains then cease and check out a decrease weight till you can deficit deadlift successfully

with out hurting yourself. Sometimes starting out with 10-25% much less weight than you’d during

a traditional deadlift rep is a good rule of thumb to comply with.

A straight bar-pathand the proper pulling mechanics are the instant remedy for this,but it

takes some apply with these stances. In other words,

we’re doing the snatch-grip deadlift to get stronger,to not apply a snatch.

We ought to observe the novice development, deadlifting

every day. After that probably some sort of heavy-light-medium

variation. Or, in case you have entry to your youth, whole milk, and XY chromosomes, the Texas Method.

If you’ve moved past weekly progressions, then you’ve probably been uncovered to

the rack pull, possibly paused deadlifts, and when you have

offended your coach, haltings. At some level in your intermediate to advanced programming it would behoove you to introduce different

deadlift variations.

Dumbbell deadlifts are carried out utilizing a pair of dumbbells angled towards your side.

If you try to place them directly in front of your legs it goes

to be troublesome to get into the proper position. From right here you seize the dumbbells with a hip hinge after which bend at the knees until you are comfortably grasping each

and preserving your spine neutral. This is often a troublesome motion for

those with hamstring mobility points as well as

those with weak hamstrings, glutes and upper again. Nonetheless, it might be

a great train to help improve these areas as properly and is a well-liked accessory train. There are tons of different train variations on the market being touted as a fix to this weak point or one of the best train to enhance

such and such. Right Here is a simple guide to help you understand tips on how to do a few of these extra important variations, why you would perform

them and when they’re greatest to incorporate in your training.

Mobility varies across totally different deadlift styles

and those with extra mobility restrictions will really feel like sure deadlifts are harder than others.

Hamstring and hip mobility are two common limitations and which one you battle with will determine which deadlifts you favor.

While the deadlift is always some model of a hip hinge, not all deadlifts have the very same range of motion. A managed descent (1-2 second

decreasing phase) should work properly for almost all

lifters.

One cause for this is prolonged sitting, which puts your

glutes in a relaxed, stretched place and retains them there for many hours.

Your lats are liable for pulling the load off the ground while preserving

your shoulders safe. They’re also crucial for sustaining a impartial spine and maintaining your again from rounding.

Deficit Deadlift is a complicated version of the deadlift,

and should you plan to degree up, it can be a valuable addition to your workouts!

This kind of Deadlift is effective for these who have hit a

plateau with their Deadlift. It is an effective software for bettering the primary pull and overall

mechanics of the exercise.

I don’t use them all the time, however they are within the toolbox when wanted.

The deficit doesn’t automatically mean you’ll get an additional

advantage. For constructing strength, it’s all about optimizing technique for drive

production. The glutes and hamstrings must work additional

time to get the lunging leg back to the field.

On the opposite hand, when you resolve to focus extra on growing strength, then the standard deadlift will

allow you to carry extra for improved strength features.

This leads to much less knee bend and hip flexion which helps to put more emphasis

on your glutes and hamstrings making it probably the greatest deadlifts

for glute growth.

You also can do larger reps (15+) with a lighter weight for muscular endurance.

Do 3 to four sets of 1 to 5 repetitions, with heavy hundreds (80 % or extra of your one-rep max), resting as needed between sets.

Frequently work up in weight until you attain the very best weight you can safely

move for three to five reps. If you presumably can raise the

burden, especially with a deadlift, you must

have the power to decrease it again to the ground with a reasonable amount

of management. First, utilizing the eccentric portion of the movement (lowering the

weight back to the ground) is a great way to increase muscle activation, energy, and hypertrophy.

This train also helps you stand taller and extra stable at the start.

Bad type is simpler to identify when lifting from a

higher platform. This better form helps together with your common deadlift, making your posture and raise extra efficient.

Like Shred JYM, it has thermogenic components like caffeine, L-carnitine, and capsimax to assault your weight.

However it additionally has added nopal and minerals for better urge for

food control and stronger immunity. She was on a strict food plan and fats loss program to manage her diabetes better, and there appeared to be optimistic outcomes on how

well it worked to burn some extra vitality.

Please not that the portions given are for the serving dimension. Course are

to take two servings a day so you truly eat double the quantity given on the label every day.

The most basic of testosterone boosters, Zinc, Magnesium, Vitamin D3 and D-Aspartic Acid (DAA) are all missing.

As An Alternative of getting 2 grams from your PRE and another 2 grams out of your POST,

you’ll now get all of it proper right here. This is

smart, as a result of there are not any additional benefits to unlock by splitting your dose in half,

all that issues is that you simply get your full dose per day.

The directions on the label say to mix one scoop

of Pre JYM with 14 oz of water about minutes prior to your workout.

Nevertheless there is slight problem with this

comparison, Pre-JYM has a 30 serving possibility and Nutrabio does not(to my information, I seemed on multiple sites).

With the 30 serving consideration in place, Pre-JYM is going to price you 1.63$ a serving which seems to be a major difference in value.

Per 20 servings, you spend about 7.40$ less for Pre-JYM(per 30 servings, 11.10$).

They discover it a good value for cash, they usually report

improved energy and endurance throughout workouts. The “boost” offered by stimulant-based pre-workouts

could be exhilarating, powering you through probably the most

grueling sessions. However like another ingredient,

caffeine is dose-specific.

So I suppose the decision goes to be primarily based on the L-Theanine.

Now L-Theanine is a hugely helpful ingredient and I applaud

it is use in Pre V5. Unfortunately, usually it needs to be in a 2-1 ratio with Caffeine to have the synergistic effect.

Still it does present benefit so I am going to offer this to Pre V5.

A subreddit designed for dialogue of supplements

and nutraceuticals; for well being, efficiency, or any intended (or not intended) objective.

These are things such as complications or heart palpitations during your exercise and vitality crashes afterwards.

This is lots of supplement to devour earlier than you workout, actually it’s 80 calories per serving which

is high for a pre-workout. Once absorbed the Citrulline is then converted into L-Arginine by

your kidneys. L-Arginine is an efficient vasodilator which works by selling nitric oxide, one thing which improves overall blood move.

It may assist with nutrient absorption however

you won’t cause any actual benefit to your muscle pumps.

Additionally, it is created with bodybuilders and performance athletes in thoughts, which can explain the higher doses of

its elements in comparability with Shred JYM. Yet, our exams point

out that it still works properly with energetic people who want to

lose excess fats and achieve visibly toned muscles simultaneously.

The dynamic pair of TeaCrine and Dynamine is in there as well at

100mg and 25mg, respectively, then finally, the same amount of caffeine as the unique at an inexpensive 300mg.

Next I need to just evaluate Agmatine Sulfate(1g) and Arginine Sicilicate(750mg).

I can discover zero evidence(Examine says there is

“[a] lack of human evidence for it is results”) for Agmatine as a pump agent or

something associated to exercise. Arginine does have some effects on the body(and usually is seen as additive with Citrulline although less is absorbed) but generally the dose required is 3-6

Grams.

70918248

70918248

70918248

70918248

70918248

Your HGH dosage will mostly rely upon whether you would possibly be

using steroids with it and what targets you have. Males will want to take up to 8IU day

by day to see maximum muscle growth with HGH when utilizing it with steroids.

This requires utilizing HGH for several months to maximize its

full potential. Water retention and swelling are unwanted side effects many anabolic steroid

users might be acquainted with. The wrists and ankles are mostly affected by water retention, resulting in a noticeable swelling of those areas,

which might hamper your motion.

Anavar, also recognized as Oxandrolone, has a

half-life of 8-12 hours when taken orally. This signifies that

it takes 8-12 hours for half of the dosage to be eliminated from the physique.

Explore when to take Anavar for peak results—morning, pre-workout, or evening, with dosage and cycle info.

Take three tablets in the morning and 3 tablets in the afternoon or night.

Do not exceed really helpful dosage as Anavar® is a potent anabolic agent.

It is necessary to notice that these unwanted effects are usually dose-dependent and

might differ from individual to individual. Cycle DurationThe duration of an Anavar cycle is often between 6 to eight weeks.

This timeframe permits for important advantages whereas minimizing the potential strain on the physique.

It is essential to notice that longer cycles might increase the risk of side effects and suppress natural hormone manufacturing.

Get the very best high quality Anavar for sale, trusted by athletes and bodybuilders.

Only tablets are available for purchase, they usually have to be swallowed complete.

Nonetheless, most women are prone to discover that Anavar is the

one that gives them the most effective balance of

minimal side effects and distinctive results. Depending on your goals, you might add another compound to increase the cycle for a

quantity of weeks after stopping Anavar.

In one other post in these Anavar series, I actually have already mentioned the importance of selecting the right

dose. Extreme adverse effects are common from this stack, with levels

of cholesterol doubtlessly rising to excessive ranges.

However, Winstrol will trigger elevated LDL cholesterol levels (7), increases in blood strain, whereas straining the liver and shutting down testosterone.

Developed in the Sixties and FDA-approved,

Anavar is an anabolic steroid used for selling muscle development, bone development,

and weight gain. When energy ranges are low, the immune system is less in a position to battle off an infection and disease.

Therefore, sustaining high power levels is essential for optimal well being and performance in sports,

fitness, and bodybuilding. Anavar works by growing the production of

proteins within the physique, which leads to increased muscle mass.

Alcohol should be prevented when utilizing oral anabolic steroids,

as we’ve found it to exacerbate liver values. We generally observe this kind of slicing stack when bodybuilders are preparing for a contest, making

an attempt to reduce physique fats and protect muscle tissue.

This is amongst the least-serious potential Anavar side effects, however

still one value noting. Anavar could be safe when used under a doctor’s supervision for medical purposes.

Any misuse can result in serious unwanted aspect effects, although, so comply with the

prescribed dosage fastidiously. Anavar also

can affect temper in women, leading to increased aggression, irritability, or anxiety.

Then consider the slicing stack in case you are trying

to mix Anvarol with different comparable nice chopping supplements.

In addition, Anavar also can improve blood stress and levels of cholesterol, each of that are threat components for coronary heart illness.

As a outcome, people who take Anavar may be at an increased risk of developing

heart disease.

Anavar and Winstrol possess many similarities, with

both lowering fats mass and water retention while growing lean muscle mass.

Anavar, or oxandrolone, is considered one of the most commonly used anabolic

steroids, with each men and women cycling it. Some bodybuilders utilize Anavar all yr spherical, just like testosterone replacement

therapy (TRT). Nevertheless, this is not beneficial due to extreme hepatic and renal toxicity.

Whereas Anavar offers numerous advantages for health enthusiasts,

it’s crucial to pay attention to potential

unwanted aspect effects and take essential precautions to make sure a protected and effective cycle.

Oxandrolone is known for its relatively

gentle nature, however some people should still experience

unwanted side effects. These can embrace pimples, oily skin, modifications in libido, and potential liver toxicity.

The cysts can grow and accumulate within the liver, changing normal hepatocytes that may lead to liver failure and dysfunction.

Withdrawal of the medicine can halt cyst development and cyst regression. Anavar usage has been shown to scale back intercourse hormone binding globulin (SHBG).

Discount in SHBG reduction will increase the amount of free testosterone (active)

within the physique.

Anti-aging is one other area where HGH can have some highly effective advantages, and it is likely one of the reasons many people will select to use

HGH regardless of whether they’re bodybuilders or athletes or not.

Anavar is considered safer than Dianabol because of its milder nature and lower

threat of severe side effects. And if you’re in search of alternatives to Anavar with TRT – that

is authorized and safer – pure steroids are choices I might really

beat my chest and recommend to you. Different folks feel that pure steroids are a

better various as a end result of they are not as prone

to cause side effects.

Testosteronology is more particular than Endocrinology, which offers with all hormones in women and men.

And it is completely different from Urology, a surgical specialty that does not focus on the common medical features of how androgens effect men. Anavar does spike dihydrotestosterone (DHT) ranges which may contribute to zits and hair loss.

The cause why pimples can happen on Anavar is as a end result of DHT triggers the androgenic receptors in your skin leading

to increased sebum manufacturing and body hair whereas suppressing hair

growth on your head. ALL anabolic steroids will shut down testosterone levels to totally different

extents. How a lot you’ll be shut you down will differ, depending on which steroid you take.

One of the the reason why Anavar’s so in style is as a

end result of its unwanted aspect effects are very gentle,

in comparison with other anabolic steroids.

By stimulating the synthesis of creatine phosphate

in muscle cells, it can enhance muscular endurance and explosiveness.

This makes it notably useful for athletes taking part in sports that require velocity, agility, and energy,

corresponding to sprinting, weightlifting, or

martial arts. Moreover, Anavar is thought for

its capability to facilitate fat loss. It promotes a extra efficient metabolism and encourages the utilization of saved body fats

as an energy supply. This can help people obtain a leaner and extra outlined look, particularly during chopping phases when decreasing body fats is a major objective.

When it involves utilization, Anavar is often included into

steroid cycles for varied purposes.

Anavar is metabolized primarily by the kidneys and to

a lesser extent by the liver. Oxandrolone is the one oral steroid

that is not primarily metabolized by the liver.

This is most probably why it has diminished hepatotoxicity relative to other oral steroids.

Nevertheless, possessing or utilizing Oxandrolone without a prescription for non-medical causes,

corresponding to bodybuilding or athletic efficiency enhancement, is considered illegal.

Penalties for illegal possession or distribution can vary

relying on the quantity and the precise circumstances, ranging from fines to potential imprisonment.

Daniel Louwrens is a well-rounded fitness skilled with over 10 years of experience in bodybuilding

and fitness.

When running Anavar the pumps may be intense as the blood circulate will increase to

the muscle tissue. It is important to keep extra hydrated and