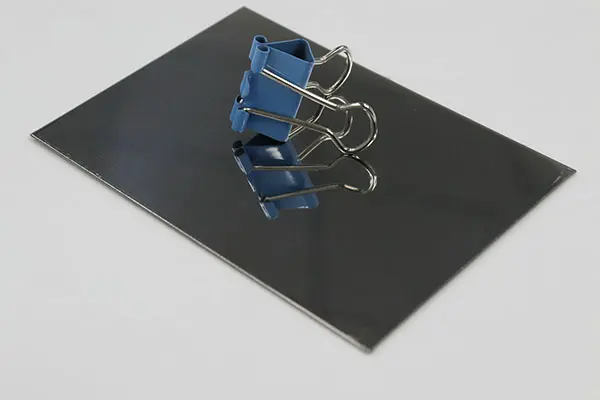

304DQ DDQ Cold Rolled Stainless Steel Coil

Sino-Stainless-Steel offers premium 304DQ (Deep Drawing Quality) and 304DDQ (Deep Drawing and Deep Bending Quality) cold rolled stainless steel coils, designed for advanced forming applications. These coils feature superior surface finishes, including BA, 2B, and No.4, ensuring exceptional formability and corrosion resistance.

Description of 304 DQ DDQ Cold Rolled Stainless Steel Coil, 304 DQ DDQ CRC

- Thickness: 0.2mm – 8.0mm

- Width: 600mm – 2000mm, the narrowed products pls check in strip products

- Max Coil Weight: 25MT

- Coil ID: 508mm,610mm

- Finish: 2B,2D

- Other Names of 304 DQ DDQ: SUS304DQ SUS304DDQ S30408DQ 06Cr19Ni10DQ 0Cr18Ni9DQ S30400DQ

- 304DQ DDQ Chemical Components : C: ≤0.08, Si: ≤0.75 Mn :≤2.0 ,Cr :18.0~20.0 ,Ni :8.0~10.5, S :≤0.03 ,P :≤0.045 N≤0.1

- 304DQ DDQ mechanical properties :

- Tensile strength : > 515 Mpa

- Yield Strength : >205 Mpa

- Elongation (%): > 53%

- Hardness: < HRB92

304 DQ/DDQ Grade Comparison Across Standards

| Country/Region | Standard | Grade for 304 DQ | Grade for 304 DDQ |

|---|---|---|---|

| China | GB/T 3280 | 06Cr19Ni10 (DQ) | 06Cr19Ni10 (DDQ) |

| USA | ASTM A240 | 304 (DQ) | 304 (DDQ) |

| Europe | EN 10088-2 | X5CrNi18-10 (DQ) | X5CrNi18-10 (DDQ) |

| Japan | JIS G4305 | SUS304 (DQ) | SUS304 (DDQ) |

| India | IS 6911 | 304 (DQ) | 304 (DDQ) |

Mechanical Property of 304 DQ/DDQ

| Property | 304 DQ | 304 DDQ |

|---|---|---|

| Tensile Strength (MPa) | 515 – 740 | 485 – 700 |

| Yield Strength (MPa) | 205 – 260 | 170 – 245 |

| Elongation (%) | 40 – 60 | 50 – 70 |

| Hardness (HRB) | ≤ 90 | ≤ 85 |

Differences Between 304DQ and 304DDQ Stainless Steel

304DQ (Deep Drawing Quality) and 304DDQ (Deep Drawing and Deep Bending Quality) are specialized variants of the 304 stainless steel grade, optimized for forming processes. While they share the same basic chemical composition, the two grades differ primarily in their mechanical properties, microstructure, and intended applications. Below are the key distinctions:

1. Mechanical Properties

- 304DQ:

- Higher yield strength and tensile strength.

- Moderate elongation (typically 40-60%).

- Slightly harder, with a maximum hardness around HRB 90.

- Suitable for deep drawing, but limited in extreme forming or deep bending applications.

- 304DDQ:

- Lower yield and tensile strength for improved formability.

- Higher elongation (50-70%), allowing it to withstand severe deformation.

- Softer material, with a maximum hardness around HRB 85.

- Designed specifically for extreme deep drawing and deep bending processes.

2. Surface Finish

Both grades are typically supplied with smooth finishes such as 2B, BA, or specialized polished surfaces, but the finishes in 304DDQ are often optimized further for critical forming applications to reduce friction and enhance deformability.

3. Microstructure

- 304DQ: Maintains a balanced austenitic microstructure optimized for standard deep-drawing operations.

- 304DDQ: Features a more finely tuned austenitic microstructure with lower strain-hardening tendencies, reducing the likelihood of cracking or wrinkling during extreme forming.

4. Applications

304DQ:

- Commonly used for moderate forming operations, such as manufacturing kitchen sinks, food containers, and automotive parts.

- Suitable for applications requiring good drawability but without excessive deformation.

304DDQ:

- Specifically designed for applications involving extreme forming or deep bending, such as cookware (pots and pans), automotive fuel tanks, and other components requiring high deformation tolerance.

- Preferred for products with intricate shapes or significant depth.

5. Cost Implications

304DDQ typically incurs slightly higher production costs than 304DQ due to the additional processing steps and stricter control over material properties to enhance formability.

Summary

- 304DQ: Ideal for standard deep drawing applications where moderate deformation is required.

- 304DDQ: Tailored for extreme forming and bending operations, offering superior elongation and reduced hardness.

By understanding these differences, manufacturers can select the appropriate grade to optimize performance and cost-efficiency in their production processes.

Differences in the Applications of 304 DQ DDQ Materials and General Materials:

304DQ DDQ material is mainly used for these higher processing ratio of the product, of course, the processing ratio of more than 2.0 products generally have to undergo a few passes to complete the stretch. If the raw material extension is not reachable, the product can easily produce cracks and pull-throughs when processing deep-drawing products, affecting the qualification rate of finished products, and of course increasing the cost of the manufacturers.

General materials: Mainly used for materials other than DDQ applications. This material is characterized by relatively low elongation (≧45%), relatively high hardness (≦180HB), and internal grain size grade of 8.0~9.0. Compared with DDQ material, its deep drawing performance is relatively poor. It is mainly used for products that can be obtained without stretching, like spoons, spoons, forks, electrical appliances, and steel pipes for a type of tableware. However, it has an advantage over DDQ materials in that BQ properties are relatively good, mainly due to its slightly higher hardness.

As a leading supplier of stainless steel products across the world, Sino Stainless Steel provides customers with high-quality 304 DQ DDQ Cold Rolled Stainless Steel Coils and other stainless steel products such as Hot-rolled Stainless Coils, Polished Stainless Steel Coils, Stainless Steel Wires, and Precision Stainless Steel Sheets at a very competitive price. at a very competitive price.

Coiled Steel Tubing

Stainless Steel Coil Wire

Stainless Steel Cold Rolled Coils

Stainless Steel Condenser Coil

Stainless Steel Sheet Coil

Stainless Steel Strip Coil

Steel Pipe Coil

304DQ DDQ Cold Rolled Stainless Steel Coil Supplier

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com