302HQ stainless steel vs 304 are two grades that are often encountered in various industrial and commercial applications. Both alloys offer excellent corrosion resistance, ductility, and weldability, making them popular choices for a wide range of uses. However, there are several key differences between 302HQ and 304 stainless steel that can significantly affect their performance in specific applications.

302HQ Stainless Steel vs 304 – What’s the Difference?

302HQ Stainless Steel vs 304 – 1. Composition

The primary difference between 302HQ and 304 stainless steel lies in their composition. Both alloys are austenitic stainless steels, meaning they have a high chromium and nickel content that gives them their corrosion resistance and ductility. However, 302HQ has a higher carbon content than 304, typically ranging from 0.15% to 0.25% carbon, while 304 has a maximum carbon content of 0.08%.

This higher carbon content in 302HQ stainless steel gives it superior strength and hardness compared to 304. However, it also makes 302HQ more susceptible to corrosion in certain environments, particularly when exposed to chloride-containing solutions.

302HQ Stainless Steel vs 304 – 2. Mechanical Properties

The mechanical properties of 302HQ and 304 stainless steel also differ. 302HQ, with its higher carbon content, offers higher tensile strength and yield strength than 304. This makes 302HQ a better choice for applications that require higher strength and wear resistance, such as springs, fasteners, and cutting tools.

On the other hand, 304 stainless steel has excellent ductility and toughness, making it suitable for applications that require good formability and impact resistance. It is commonly used in fabrications that require bending, welding, and other forming operations.

302HQ Stainless Steel vs 304 – 3. Corrosion Resistance

Both 302HQ and 304 stainless steel exhibit good corrosion resistance, but their resistance profiles differ slightly. 304 stainless steel has become a popular choice for its excellent resistance to corrosion in a wide range of environments, including atmospheric conditions, fresh water, and many chemical media. Its high chromium and nickel content form a protective oxide layer on the surface, known as the passive layer, which resists corrosion.

However, 302HQ’s higher carbon content can affect its corrosion resistance, particularly in chloride-containing environments. Chloride ions can penetrate the passive layer and initiate pitting corrosion, which can lead to localized corrosion and failure. Therefore, 302HQ is not recommended for use in chloride-rich environments such as seawater or saltwater pools.

302HQ Stainless Steel vs 304 – 4. Applications

The unique properties of 302HQ and 304 stainless steel make them suitable for different industrial applications. 302HQ is commonly used in applications that require higher strength and wear resistance, such as springs, fasteners, cutting tools, and bearings. It is also used in some automotive and aerospace components that require high strength and corrosion resistance.

On the other hand, 304 stainless steel is widely used in applications that require good corrosion resistance and ductility, such as kitchenware, food processing equipment, medical devices, and architectural components. Its excellent weldability and formability also make it a popular choice for fabricating complex shapes and structures.

Conclusion

In summary, 302HQ and 304 stainless steel both offer excellent corrosion resistance and ductility, but their differences in composition, mechanical properties, and corrosion resistance make them suitable for different applications. 302HQ is stronger and harder due to its higher carbon content, making it suitable for applications that require high strength and wear resistance.

However, it is less resistant to chloride-induced corrosion than 304. On the other hand, 304 stainless steel offers good strength, ductility, and corrosion resistance, making it a popular choice for a wide range of industrial and commercial applications.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between 302HQ Stainless Steel vs 304. If you are looking for 302HQ Stainless Steel & 304 Stainless Steel suppliers online now, please don’t hesitate to contact Sino Stainless Steel.

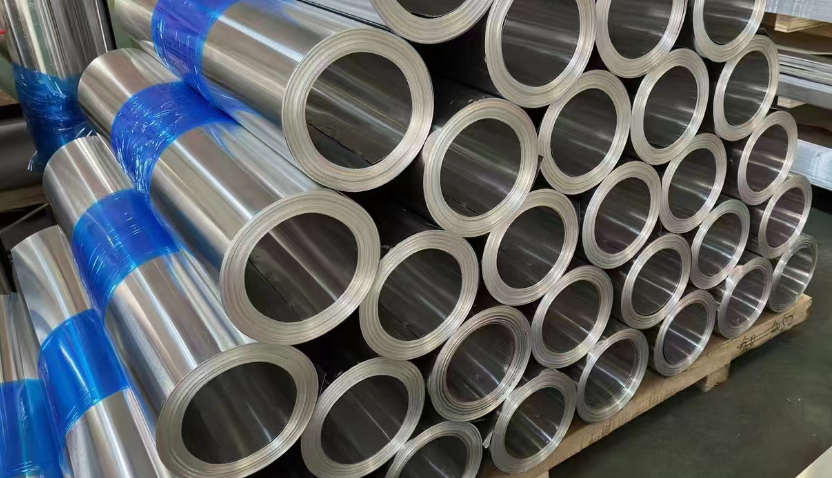

As a leading supplier of stainless steel products from Shanghai China, Sino Stainless Steel offers customers high-quality stainless steel sheets, stainless steel tubes, stainless steel pipes, stainless steel strips, stainless steel coils, stainless steel plates, and stainless steel bars at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

I was suggested this web site by my cousin. I am

not positive whether or not this submit is written through him as

no one else know such distinctive approximately my trouble.

You’re incredible! Thank you!

Thanks designed for sharing such a nice thought, post is

nice, thats why i have read it completely

I’m really enjoying the design and layout of your blog.

It’s a very easy on the eyes which makes it much

more pleasant for me to come here and visit more often. Did

you hire out a designer to create your theme?

Superb work!