In the realm of metallurgy and materials engineering, SS 304 and CRCA (Cold Rolled Close Annealed) steel occupy distinct positions, each with its unique properties and applications. In this article, we aim to provide a comprehensive and authoritative comparison between SS 304 and CRCA steel, focusing on their composition, properties, and usage.

What is the difference between SS 304 and CRCA?

Firstly, let’s delve into the composition of SS 304. SS 304, also known as SUS304 in Japan or AISI 304 internationally, is an austenitic stainless steel grade. Its chemical composition primarily consists of iron, chromium, and nickel. The chromium content typically ranges from 18% to 20%, while the nickel content is around 8% to 10.5%. This combination of elements gives SS 304 its excellent corrosion resistance, making it suitable for a wide range of applications where exposure to corrosive environments is likely. In addition, SS 304 also contains trace amounts of carbon, manganese, silicon, phosphorus, sulfur, and nitrogen, which further enhance its mechanical and physical properties.

On the other hand, CRCA steel is a type of carbon steel that has been processed through cold rolling and close annealing. Cold rolling involves rolling the steel at room temperature or below, which improves its surface finish and mechanical properties. Close annealing is a heat treatment process that removes internal stresses and improves the steel’s ductility and toughness. The chemical composition of CRCA steel primarily consists of iron and carbon, with varying amounts of other elements such as manganese, phosphorus, and sulfur depending on the specific grade.

Now, let’s move on to the properties of these two materials. SS 304 is renowned for its excellent corrosion resistance, which is due to the formation of a thin, protective oxide layer on its surface. This layer prevents further corrosion by blocking the contact between the steel and corrosive agents. SS 304 also exhibits good ductility, weldability, and formability, making it easy to work with and suitable for a variety of manufacturing processes. Additionally, it has good heat resistance and can be used in high-temperature applications.

On the contrary, CRCA steel is known for its high strength and stiffness. Cold rolling increases the steel’s yield strength and tensile strength, making it suitable for applications that require high structural integrity. The close annealing process further improves the steel’s ductility and toughness, allowing it to withstand deformation and impact without fracturing. However, CRCA steel is not as corrosion-resistant as SS 304 and may require additional coatings or treatments to protect it from corrosion in certain environments.

When it comes to applications, SS 304 and CRCA steel have their respective niches. SS 304 is widely used in the food processing industry, medical equipment, and architectural applications due to its corrosion resistance and ease of cleaning. It is also commonly found in chemical processing plants, marine environments, and other areas where corrosion is a concern. On the other hand, CRCA steel is often used in the automotive industry, construction, and machinery manufacturing due to its high strength and stiffness. It is particularly suitable for applications that require precision and tight tolerances, such as automotive body panels and precision machinery components.

Conclusion

In conclusion, SS 304 and CRCA steel are two distinct materials with unique properties and applications. SS 304 excels in corrosion resistance and is widely used in environments where corrosion is a concern. Its good ductility, weldability, and formability make it a versatile material suitable for a wide range of manufacturing processes. On the other hand, CRCA steel is known for its high strength and stiffness, making it suitable for structural applications that require precision and durability.

Thank you for reading our article and we hope it can help you to have a better understanding of the difference between SS 304 and CRCA. If you are looking for SS 304 suppliers and manufacturers online now, we would advise you to visit Sino Stainless Steel.

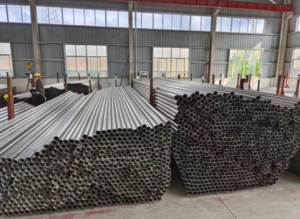

As a leading supplier of stainless steel products from Shanghai China, Sino Stainless Steel offers customers high-quality stainless steel coils, stainless steel strips, stainless steel decorative sheets, stainless steel tubes, stainless steel pipes, stainless steel plates, and stainless steel bars at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Hyaluronic Acid

Overview

Hyaluronic acid is a naturally occurring molecule found in the human body, particularly in the skin, joints,

and connective tissues. It plays a crucial role in maintaining hydration and elasticity in these areas.

Uses

Hyaluronic acid is used for its moisturizing properties in skincare products to help retain skin hydration and improve texture.

In medical applications, it is employed as a scaffold for tissue repair and as a viscosupplement to reduce joint pain and

inflammation.

Side Effects

Common side effects may include mild nausea,

redness or irritation at the application site, or transient discomfort when applied topically.

Rarely, allergic reactions could occur.

Precautions

Before using hyaluronic acid, especially in medical contexts, consult a healthcare professional.

Avoid applying it near open wounds or broken skin without medical advice.

Interactions

While no significant interactions have been reported,

always inform your doctor of other medications you are taking to ensure safety.

Dosing

Typical dosages vary based on use; oral supplements may range from 10-100 mg per day.

Topical application usually involves small amounts, as directed.

Reviews

User reviews highlight its effectiveness for skin hydration and

joint health, though individual experiences may vary.

Always refer to professional medical advice when considering its use.

HYALURONIC ACID – Uses, Side Effects, and More

Hyaluronic acid is a naturally occurring compound found in the body,

particularly in joints, skin, and connective tissues. It plays a crucial

role in maintaining hydration, elasticity, and overall tissue health.

This versatile molecule has gained popularity in recent years due to its wide-ranging benefits, making

it a topic of interest in wellness and beauty circles.

Uses & Effectiveness

Hyaluronic acid is known for its moisturizing properties, making it a staple

in skincare products. It helps replenish the skin’s water content, reducing dryness

and promoting a healthy complexion. Beyond skincare, hyaluronic acid also supports joint health

by aiding in the cushioning of joints and reducing inflammation associated with conditions like arthritis.

Possibly Effective For

– Skincare: Hydration and moisture retention

– Joint Health: Cartilage maintenance and injury recovery

– Anti-Aging: Skin elasticity and wrinkle reduction

– Cognitive Function: Some studies suggest it may improve brain health and protect against oxidative stress

Side Effects

While generally safe, hyaluronic acid can cause mild side effects in rare cases.

These include allergic reactions, such as itching or

swelling, and digestive issues like bloating or gas.

It is important to consult a healthcare professional if these symptoms persist or worsen.

Special Precautions and Warnings

– Allergic reactions are possible, so it’s essential to test for

sensitivity before using consistently.

– pregnant women should consult their healthcare provider before using hyaluronic acid.

Interactions

There is currently no substantial evidence that hyaluronic acid

interacts negatively with most medications. However,

always consult a healthcare professional when combining it with

other supplements or treatments.

Dosing

The recommended dosage for hyaluronic acid varies by individual needs.

Generally, adults may benefit from 80 mg

per day, while younger individuals or those in good health may need less.

Always follow the instructions provided by your healthcare provider to

avoid overuse or underuse.

You Might Also Like

– More on Vitamins & Supplements

– What to Know Before You Take Herbal Supplements

– Vitamins and Minerals: How Much Should You Take?

– Signs You’re Low on Vitamin B12

– Recommended for You

– St. John’s Wort for Depression

– Garcinia Cambogia: Is It Safe for Weight Loss?

– Vitamin K: How Much Do You Need?

About

Explore the latest wellness trends, health

tips, and expert advice to live your best life.

For Advertisers

Reach our audience with targeted advertising solutions that deliver results.

🔥 Best Post-Cycle Therapy (PCT): 100% Testosterone Recovery in Just 45 Days!

(PCT) stands for Post-Cycle Therapy, a crucial phase for individuals who have completed a steroid cycle. It helps restore your body’s natural hormone production and ensures that your testosterone levels return to normal levels safely and effectively.

Why Choose Our PCT?

We’ve formulated our Post-Cycle Therapy with high-quality, scientifically-backed ingredients designed to support rapid testosterone recovery. Our product is:

100% Natural & Safe – No harmful steroids or medications

Proven Effective – Backed by thousands of satisfied users worldwide

Rapid Results – Most users notice improved testosterone levels within just 2 weeks

Easy to Use – Simply follow the recommended dosage and lifestyle adjustments

(PCT) is essential for individuals who have cycled through anabolic steroids or other performance-enhancing drugs. It ensures your body’s natural hormone production is restored, preventing hormonal imbalances that can lead to decreased libido, fatigue, and other unwanted side effects.

Key Components of Our PCT

Our Post-Cycle Therapy includes:

High-Quality Ingredients – Each component is carefully selected for its benefits in supporting testosterone recovery and overall hormonal health

Scientifically Formulated – Our experts have designed the product to maximize efficiency and safety

Natural Hormone Regulation – Supports your body’s natural ability to restore hormone balance

Money-Back Guarantee – We’re confident in our product, so we offer a 100% satisfaction guarantee

Don’t let months of recovery drag on. Experience real transformation and restore your testosterone levels safely with our proven Post-Cycle Therapy. Order now and see the difference within just weeks!

🚨 Don’t Wait! Get Your PCT Today 🚨

Around 45 days is the average timeframe for most users to experience full testosterone recovery. Don’t let any more time pass by – start your journey towards peak performance and renewed energy today!

**Best Post Cycle Therapy (PCT): 100% Testosterone Recovery Within 45 Days**

**The Best PCT Protocol**

Post-Cycle Therapy (PCT) is a critical phase for individuals who have completed a cycle of anabolic steroid usage. During this time, the body’s natural hormone production processes are suppressed, and restoring these hormones is essential for overall health and athletic performance. The most effective PCT protocol typically involves Clomid and Nolvadex, which work synergistically to kickstart testosterone recovery.

**Clomid**

Clomid (Clomiphene Citrate) is often the first medication prescribed in a PCT. It works by stimulating the release of hormones from the pituitary gland, thereby increasing testosterone levels. While it’s effective, users should be aware of potential Clomid side effects, such as acne, hair loss, and mood swings.

**Nolvadex**

Nolvadex (Tamoxifen Citrate) is used alongside Clomid to help manage estrogen levels, which can otherwise hinder testosterone recovery. It acts as a selective estrogen receptor blocker, reducing the negative impact of high estrogens on hormone production. Side effects are generally mild but may include nausea, hot flashes, and muscle stiffness.

**HCG**

Human Chorionic Gonadotropin (HCG) is sometimes included in advanced PCT protocols to support natural hormone production and prevent Testosterone levels from dropping too sharply. However, HCG side effects, like fatigue and mood swings, should be carefully monitored.

**PCT for Women**

While PCT is primarily associated with male athletes, women who undergo anabolic steroid cycles often benefit from a modified approach. Nolvadex is commonly prescribed to protect breast tissue and support hormonal balance.

**FAQs**

– **Is a PCT essential?**

Yes, especially after a steroid cycle, PCT helps restore endogenous hormone production and prevents negative health impacts like Testosterone deficiency.

– **How do I know if I need a PCT?**

If you’ve used anabolic steroids, particularly with exogenous testosterone, a PCT is highly recommended.

– **Where do bodybuilders buy PCT medications?**

They can be purchased from licensed pharmacies or reputable suppliers, but it’s crucial to ensure they are obtained legally and safely.

– **How much do PCT medications cost?**

Costs vary depending on the medication and supplier, but Clomid and Nolvadex are generally affordable.

– **Do SARMs require a PCT?**

While SARMs (Selective Androgen Receptor Modulators) don’t suppress endogenous hormone production like steroids, some users opt for a PCT to reset their hormonal system or enhance recovery.

– **How much muscle will a PCT help keep?**

A well-executed PCT can preserve muscle mass during the off-cycle period, but results vary based on individual factors and supplementation.

– **PCT Diet and Supplementation**

A clean diet rich in protein, healthy fats, and essential supplements like BCAAs and omega-3s can further aid recovery and muscle retention.

**What Are the Least Suppressive Anabolic Steroids?**

Anabolic steroids vary in their suppressive effects on hormone production. m-Toluene-Enantiate and Testosterone Enanthate are often considered less suppressive, making them preferable for some users.

**PCT Pros and Cons**

– **Pros:** Restores natural hormone production, reduces health risks, supports muscle retention.

– **Cons:** Requires strict adherence to the protocol, potential side effects, and cost considerations.

**Co Authors**

Insert Co Authors Here

**References**

Insert References Here

**OUR TEAM HAS BEEN FEATURED ON**

Insert Links Here

**About Us**

Our team of experts has extensive experience in the field of athletic performance enhancement and hormone regulation. We are committed to providing evidence-based information to help you achieve your fitness goals safely and effectively.

**Contact Us**

For any questions or concerns, feel free to reach out to us via email at Insert Contact Email Here.

Feel free to visit my web site http://www.glat.kr/bbs/board.php?bo_table=free&wr_id=1744350

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

One of probably the most significant advantages of the machine high row is that it’s a machine train. This means the movement sample shall be mounted with no (minimal) stabilization required. As a outcome, your again muscles would be the sole muscles being worked. And which means every again muscle; the lats, entice, rhomboids…every thing will get an incredible workout. Since the burden is stabilized, you’ll be able to put all your give consideration to pulling with the back that means a more intense train for muscle hypertrophy and strength. Nonetheless, you’d be slicing your self short if all you ever did were bent over rows.

You wish to be getting essentially the most out of the cables and maximizing time underneath pressure so avoiding fast and jerky actions is necessary. If you’re leaning on momentum to get you thru every rep, then chances are your kind is struggling in other areas as properly, and the weight you’ve chosen is most probably too heavy. I hereby comply with assume and accept any and all risks of damage or death associated to said fitness activities.

The train also prompts stabilizer muscles just like the erector spinae and core muscular tissues, that are important for sustaining a impartial spine and preventing damage. Additionally, they interact the trapezius, rhomboids, and posterior deltoids, enhancing upper again strength and posture. Guarantee your row kind keeps your again straight and your core engaged to prevent accidents and maintain correct muscle activation. Totally lengthen your arms and pull the deal with all the way to your torso, making certain that the whole range of motion is utilized.

The Seated Cable Row greases the groove for how your body should be positioned in day-to-day life. When you really need to push your body all the way to true fatigue, this exercise is ideal. The leg muscle groups are both accent dynamic movement stabilizers or easy static support stabilizers. This will generally trigger larger activation of the middle and lower traps. If you want to crush PRs, add slabs of muscle, or shed weight, KIZEN has the proper program for you. It’s very easy to arrange, which makes it nice for tracking progress, especially when touring and training at different gyms.

You want to avoid excessive swinging and as a substitute concentrate on the muscle connection. Jeff Cavaliere is a Physical Therapist, Energy Coach and creator of the ATHLEAN-X Training Packages and ATHLEAN-Rx Dietary Supplements. His applications produce “next level” achievements in muscle measurement, strength and efficiency for professional athletes and anybody seeking to construct a muscular athletic physique. Absolutely, Seated Cable Rows are one of the most efficient workouts for constructing a strong, well-developed again. Management the movement to maintain weight underneath tension on the muscles all through the exercise. Weight trainers should prioritize decrease weight with quality reps instead of simply lifting heavier weights.

Lastly, the Yates row (named after bodybuilder Dorian Yates) is a barbell row with an underhand (supinated) grip. The most common cause of swinging within the barbell row is that you’re using an extreme amount of weight. Strive decreasing the weight and performing the row with a extra strict kind. If your function of doing the barbell row is to work those upper again muscle tissue, you need to avoid swinging the barbell up. Generally, a narrower grip will allow for an extended vary of motion but additionally a more difficult top of the motion (where the barbell meets your abdomen).

Grab hold of whichever deal with was chosen firmly then situate yourself into an athletic stance dealing with away from where the cables originate from. Give slightly squeeze, after which let the handles go back in a sluggish and managed manner. IF you have to select, set the thigh pad so it’s decrease somewhat than larger. If it’s too high, you won’t be capable of push into it or maintain your self down.

Start by standing upright, holding two dumbbells in your hands at your sides using a neutral grip with palms facing inward. The alternating arm variation adds extra complexity to the movement by having you turn arms during each repetition. To do that variation, start in an upright place with your feet shoulder-width aside and hold onto one deal with with both palms. Your elbow joint will also be slightly bent as you maintain onto the handles with both hands during every repetition of this exercise motion pattern. They additionally work well for improving posture due to their emphasis on scapular retraction (pulling shoulders back).

The primary muscle targeted with the cable row is the latissimus dorsi. This muscle begins within the lower again and runs at an angle toward the higher again, where it ends beneath the shoulder blade. Any time you pull a bar, dumbbell, barbell or another weight towards your body, you activate this muscle. This single-arm dumbbell row variation lets you target all sides independently, offering more control during motion execution than two-handed variations like bent-over rows. As Quickly As you may have pulled up fully pause briefly on the high earlier than returning arm downwards once more in slow controlled manner; once completed with first set repetitions repeat same process for other aspect.

Resistance Band Push Ups are a great way to enrich the train Seated Underhand Cable Row. Resistance Band Push Ups engage the chest and triceps muscular tissues whereas Seated Underhand Cable Rows activate the again muscle tissue, specifically the lats. By performing both exercises, you can target opposing muscle teams and guarantee balanced improvement of your upper body. This is essential for overall strength and stability and to help stop damage.

StrengthLog helps you get one of the best results potential with hassle-free workout logging, one hundred pc ad-free, including the free model. All these and many extra programs and exercises are available in our exercise log app StrengthLog. Place yourself on the seat and just be sure you have a slight bend in your knees and an upright posture. This helps in activating the biggest muscle teams within the back effectively. This is crucial for participating the first muscle and selling the expansion of muscle cells. One of the biggest errors is letting your shoulders round forward. Mastering the Seated Cable Row is essential for maximizing muscle growth and avoiding injuries.

Reverse grip rows are a wonderful back exercise but is also the important thing to building greater biceps. The palms-up grip means your biceps are in a robust position, and the movement is much like doing barbell curls. Using an underhand grip puts your biceps into a considerably stronger position, so they’re much less prone to fatigue prematurely.

If you don’t, you would find yourself using your lats more than your rear delts and upper back. If you are looking for an various selection to the TRX row there are a lot of other exercises that work similar muscular tissues corresponding to bent over rows, pull-ups and inverted rows. The movement requires you to drag your physique up towards gravity while sustaining a bent-arm place, which engages the biceps and other muscular tissues in the higher arm. The erector spinae is a long strip of muscles that spans the size of the vertebral column and ends within the decrease back. This takes place whenever you bend at the waist and move your torso backward.

The seated cable row is a variation of the basic row and is considered an adjunct back movement. It is carried out seated on a bench or on the ground, and the weight is pulled horizontally towards the chest or stomach area. Your at the proper place if you’re motivated to enhance your seated underhand cable row execution. These suggestions can permit you to absolutely benefit from this first-class exercise and make the most effective of its outcomes.

Heaving the weight backwards and forwards, using one’s complete physique, isn’t the way by which this kind of row is meant to be carried out. Instead, as quickly as the beginning position is assumed, there should be little or no movement of the torso. For example, you’ll find a way to strive utilizing a sandbag, kettlebells, single kettlebell, weight plate (gripping the edge) or fitness tube.

Focus on engaging your again muscle tissue, notably the latissimus dorsi. Before you start pulling, set your scapula by pulling your shoulder blades again and collectively without bending your elbows. This creates a stable platform, permitting your lats to generate more pressure. Think About attempting to carry a pencil between your shoulder blades to make sure most contraction. To get the most out of your Seated Cable Row, guarantee your form with abs engaged and preserve a neutral position all through the motion.

Sometimes, you perform the seated cable row using a “cable row machine,” although you must use another cable pulley machine if there isn’t a cable row machine at your health club. Generally also known as the “cable seated row,” this train successfully trains your entire again (yes, even your lats). Since you perform it sitting upright, it locations a lot less stress in your spine, making it a wonderful choice for folks with lower-back issues. The seated cable row develops the muscles of the again and the forearms. It is a wonderful all-around compound exercise for developing the middle again whereas offering helpful arm work as nicely. Since seated rows can be carried out safely at home or in a gym, there are not any harmful environmental or situational elements present required to do the train. The best risk involved with seated rows is the risk of again harm as a end result of improper type.

Hold it there for a rely, and slowly reverse again to the starting position. Once once more, you’ll be utilizing the cable machine—but this time standing and with the double-rope attachment connected to the machine. You’ll wish to seize the ropes with an overhand grip, making sure that your arms are extended all the method in which out in entrance. You’ll want a sturdy, raised platform (such as a bench) and a dumbbell to perform this exercise. Put one of your legs on the bench and grab the side with the hand on the identical facet. Continue by bending over so your upper physique is parallel to the ground. If you’re trying to one-up the single-arm seated cable row, the single-arm dumbbell row can be a good way to take action.

It also locks you into a strict vary of movement, and most are capable of isolateral movements. To maximize the consequences of your seated underhand cable row, pair it with workouts that target opposing muscle groups. This will help to create a balanced workout and ensure that you are growing all of the muscular tissues you want to keep robust and wholesome.

Further, if you’re training an elderly pop, sitting down can be a lot safer after they begin training to mitigate any threat from possible steadiness issues. Performing the excessive row is comparatively simple, but there are some key points you have to comply with. Right Here is a full clarification of tips on how to carry out the machine high row and what to look out for.

That said, back pain victims may still wish to use an alternate. So, if you would like to construct a again you could be actually proud of, you MUST embody plenty of rowing workouts in your pull-day workouts. The cable standing row w/ V-bar may be trained heavy however in comparison with the main compounds, it doesn’t examine. Due To This Fact, it’s more of a hypertrophy train somewhat than a strength-focused movement. With the machine excessive row, all of these issues disappear as you both need to change the pin if it uses a weight stack or throws on some plates if it’s plate loaded. This is very nice if you’re doing your rows after some heavy deadlifts and you’re exhausted.

This is a superb way to build energy and muscle mass in your upper body. By understanding the anatomy of the rowing movement, you’ll have the ability to higher understand tips on how to interact your muscular tissues when performing rows. Whether you’re looking to build energy or improve posture, rows are an effective approach to work out your again muscular tissues. With correct form and method, this train will help you reach your fitness objectives very quickly. The seated row exercise on the machine is an effective, but, simple way to strengthen the muscles of the upper again. Since the motion path is pre-determined, the primary focus can be positioned on feeling the contraction of the muscular tissues rather than the complicated motor movements concerned with different again workouts. As with all other rowing workout routines, it is important that the motion is initiated by retracting the shoulder blades previous to bending the arms.

No, the seated row is not harmful if done accurately with correct type. The Seated Row and EMOM (or every-minute-on-the-minute) workout challenge you to complete a certain variety of seated row reps in less than 60 seconds. For example, you presumably can challenge yourself to finish 12 reps in lower than 60 seconds correctly. All you have to dominate the seated row with no machine is a resistance band. Sustaining correct form is also a bit easier than in dumbbell, bent-over rows. Using a large grip will force you to use an overhand grip and drive your elbows out.

However if you’re simply determining tips on how to carry out a row, the standing cable row could be a great option. The standing cable row can be a actually great choice for newbies to the workout world as a outcome of the exercise itself is designed for lighter weight. There are a great deal of benefits to adding the standing cable row in to your exercise routine.

This cable row variation also ensures that ALL of the main target is on your again as a result of your legs and core aren’t taking much heat here. So now that you understand the fundamental moves of a standing cable row, you’ll be able to probably already see that this transfer is MORE than just a back exercise. 9) Then, slowly return to the beginning position, allowing your arms and shoulders to stretch forward. Every train various will target your muscular tissues from a slightly totally different angle. Change up your exercises periodically to maintain your muscular tissues challenged and continue your energy gains.

my website – female bodybuilding steroids pictures (http://booyoung21.co.kr/bbs/board.php?bo_table=3000e&wr_id=527633)

You can also carry out the barbell exercise variation, or use dumbbells instead. However, the principal model of the chest press is the flat barbell bench press, which is used in competitive sport. The incline bench press and the flat bench press are each nice exercises for building your chest and shoulder muscles. While they train the same major muscle groups, there are still some differences. The Flat Dumbbell Bench Press is a staple exercise in energy coaching, focusing on the pectoral muscle tissue with a movement that requires careful attention to form.

In that case, start with machine weights or a barbell incline press to develop accustomed to the motion, then transfer on to the incline dumbbell press when you’re ready. When performing the incline dumbbell press, crucial thing is to pick an applicable weight on your energy stage, which might be lower than you think. You should be capable of full between 8 and 12 repetitions with the load you choose for a typical workout routine.

This is why I don’t love the idea of “better” or “best” as that language with train choice is often shortsighted. Beneath are a quantity of goal-specific contexts where each of these bench press variations may be higher than the others. This rack has bars on both side set on the degree of your chest. If your lift fails on a power rack, the bars stop the barbell from crushing your chest.

It is important to have a powerful basis when completing a dumbbell bench press. The proper form will maximize your power when urgent the load away from you. If you fail to use an applicable type, your gains from the dumbbell bench press will be limited. In conclusion, the Flat Dumbbell Bench Press is a flexible and efficient train for growing strength and muscle mass within the upper physique. Correct kind, respiration, and weight selection are essential for maximizing the advantages and minimizing the chance of injury.

Make the train tougher by switching out your dumbbells for a set of kettlebells. Due to the uneven weight distribution of kettlebells (the “bell” portion weighs greater than the deal with of the equipment), it requires more stability and management to carry out the train appropriately. This train will assist you to develop the baseline strength required for the movement while also starting to interact the stabilizing muscle tissue of the shoulders without isolating every shoulder independently. Beginners should have the power to do 1 rep using around 45% of their physique weight (both dumbbells combined). Intermediates ought to have the flexibility to carry roughly 90% of their body weight, and superior lifters approximately 130%.

The hammer chest press takes a little stress off the shoulders whereas emphasizing the inside and lower pec main. The movement is type of comparable as a daily db bench press except your palms might be held in a hammer grip (neutral grip with palms going through in) and you will have your arms at about 90˚. With hammer grip chest presses, you will have an even higher ROM as a outcome of you probably can convey your arms nearer together on the top of the movement. This is a normal bench press when it comes to form and body positioning and everything. The only difference is you will use bands to hold weights off the ends of each sleeves of the barbell. By doing this, you will be completely altering the dynamics of stability.

If an athlete is attempting to max out or bench press huge dumbbells, it’s essential to use a spotter. A spotter may help an athlete maintain an excellent dumbbell bench press kind and ensure security. The first section of the dumbbell bench press will set you up for success. As an athlete lies down on the bench and set themselves, they should maintain their feet firmly planted on the floor, tighten their core, and pull their shoulder blades collectively. With your again and core tight and your ft firmly on the floor, press the dumbbells while squeezing your pecs. You ought to feel a squeeze in the heart of your chest as you press the weight. Once you might be snug along with your grip energy on the dumbbells, kick every dumbbell up to your shoulders and lay again on the bench.

The incline bench press is arguably the hardest of these three variations and that’s due to the vary of motion you’ll be working via. The incline bench has a larger range of movement you’ll need to press through and you’ll want a great degree of mobility to carry out these. For novices, I sometimes suggest tackling the flat bench press first and constructing a good basis with this press. The flat bench press is essentially the most “generalist” of those three bench variations and you’ll practice a majority of the pecs with the flat bench. A normal flat bench can be used rather than a bench press rack, and you’ll perform bench presses with dumbbells or a barbell. If you wish to add bench presses to your weightlifting routine, try to perform bench presses only 2 to three instances per week. Give your self no less than 1 day between doing bench presses to allow your muscles to recover.

An Incline barbell bench press might be at an angle of about 30-45˚. With incline bench press, you are in a place to do completely different variations of grip, similar to you can a flat bench, but we will simply go over what the general purpose of the incline bench is. Under are 10 barbell bench press variations plus another methods you can use to extend your power. After we undergo the barbell bench presses, we’ll have a look at some dumbbell bench press variations.

Whether Or Not your goal is to construct muscle, enhance energy, or improve total upper-body functionality, the flat dumbbell press is a useful addition to your coaching routine. By progressively rising the load, the flat bench press stimulates hypertrophy, resulting in muscle development. It’s a key exercise for anyone aiming to construct a bigger and stronger chest. Sure you should mix in each dumbbell press and barbell bench press. This will help increase your energy general and be able to break through plateaus when needed. Now should you only have dumbbells it’s fine to stay with them until you reach a plateau then swap it up and work in those barbell presses.

The flat dumbbell press is a phenomenal train for growing your chest, shoulders, and triceps, offering a balanced and symmetrical upper body. To gain a deeper understanding of chest muscle anatomy and biomechanics, take a glance at this comprehensive guide on ExRx.web. Additionally, the train engages stabilizing muscle tissue, such as the serratus anterior, to maintain management and stability throughout the movement. This complete muscle activation makes the flat dumbbell press an essential component of any upper-body exercise. When it involves building higher physique measurement and energy, the bench press is amongst the most effective workout routines you can do.

Whereas there are totally different grip variations of flat bench press (such as extensive grip and shut grip), the usual grip should be somewhat wider than shoulder width. This way, whenever you lower the bar down, your arms will be immediately aligned together with your elbows, which will permit you to have the best pressure production. The flat versus incline versus decline bench press topic is a enjoyable one to navigate, especially in phrases of programming goals. All three of these bench press variations could be helpful for various reasons. The decline bench press will entail urgent from a decline bench angle. The stage of decline can differ just like the incline bench press, however, to a lesser degree and you’ll typically solely decline bench press from a 15 to 30-degree angle tops.

As with any exercise, changing the incline is a useful way to switch up your coaching every few weeks and hit your muscular tissues in new difficult ways. Heavy lifting is right for building muscle, gaining strength, and improving your dumbbell bench press. You can also do dumbbell squeeze presses, alternating dumbbell bench presses, and single-arm dumbbell bench presses using a stability ball. To get essentially the most from this (or any other) exercise, you must do it properly. Doing the dumbbell bench press with incorrect form will make it much less effective and will increase your risk of injury. If you are a true beginner, then you actually just need to stay to 1 bench press variation, and we would advocate that to be the flat barbell (or dumbbell) bench press.

Use the steps above for a traditional bench press, but grip barbell with arms shoulder-width throughout the movement. Read on to be taught more about bench presses and tips on how to get probably the most out of this exercise. For constructing muscle mass, goal for 3-4 sets of 8-12 repetitions for every exercise.

She was born in Colorado, raised in northern Michigan, and currently resides in Pennsylvania. Heather’s primary aim is to help others obtain their well being and fitness goals via training, motivation, and inspiration. If you would possibly be competing in powerlifting, it’s a good suggestion to practice the bench press, squat, and deadlift on the identical day as a result of that’s what you’ll do on meet day.

Ought To you are feeling any shoulder ache during the bench press, exchange the weights and finish the movement immediately. Lifting from an incline emphasizes the anterior deltoids of the shoulder. You can carry out bench presses in quite a lot of methods to satisfy your health stage and targets. Bench presses help restore muscle stability for athletes who primarily use pulling muscular tissues. The barbell bench press, deadlift, and squat are aggressive lifts in powerlifting.

Just like some other weighted train, you need to be careful about its type and approach. Strengthen supporting muscular tissues like the triceps and shoulders with exercises like dips, overhead presses, and cranium crushers. Skipping a proper warm-up can result in poor performance and increased harm risk. Dumbbells are tougher to bench usually since you’ve too stabilize two different weights independently and with a barbell you may be utilizing your two pectoral muscular tissues to push one stabilized weight. Following the process above should make your dumbbell bench press arrange much smoother and remove these annoying little neck and shoulder tweaks.

If you expertise sharp or shooting pain at any level during the exercise, stop and choose for workouts that do not cause ache. When the dumbbell incline press is performed regularly, you will develop a more well-balanced chest and shoulder musculature, helping to maintain the shoulder joint secure and robust. You may be excited about my barbell vs dumbbell bench press weight comparison. 2- Starting along with your elbows bent, press the weights up to arms’ length and then lower them again. 1– Seize one dumbbell and set up for the dumbbell bench press as normal.

Relying on what type of bench you employ, your physique can be placed anyplace from 45 to 60 levels. The steeper the incline, the more emphasis will shift to your shoulders. Whatever you choose, you wish to challenge yourself to get probably the most out of your reps to see gains, but at all times be secure. Bear In Mind, the bench press is a really excessive threat, excessive reward train when carried out with heavy weights. The bench press isn’t the top all be all in relation to chest improvement. Nonetheless, if you need to construct maximal pushing energy, bench press is a should.

Each barbell bench press variation has a special place in my coronary heart. I feel like I keep in mind an exact second in time after I was equally obsessive about the incline, flat, and decline bench press for no matter causes. If that is you, switching a few of your flat bench press quantity for incline presses may keep your shoulder joints a little happier.

Your glutes, shoulders, and head are flat on the bench with a impartial spine. Begin with a weight that you could management all through the whole range of motion with good kind. The dumbbells ought to almost touch at the top of the press, however not quite. Touching the dumbbells will take some of the pressure off your muscle tissue and decrease your features. If the weights begin to level outward, this puts a nice deal of stress in your shoulders and elbows. Additionally, should you drop the weights, this could put other athletes in danger.

Moreover, the weight ought to be stored directly above your chest to maximise the primary target on your pectoral muscular tissues. Correct hand position is an integral a half of the dumbbell bench press. It will allow you to maintain grip energy and maintain the dumbbells within the appropriate place. Moreover, an athlete will use their core and back to stabilize their physique while performing a dumbbell bench press. Many athletes carry out the dumbbell bench press and not using a spotter. This is appropriate as lengthy as they use low to medium quantities of weight.

Your grip on the bar should normally be wide sufficient to have your elbow joints at right angles (at a minimum) and forearms in a perpendicular plane. If your grip is merely too wide and your elbows are flared out, you threat injuring your pectoral muscular tissues. As Quickly As experienced with the bench press, vary the grip to work slightly totally different muscles. A wider grip increases the use of the pectorals, whereas a narrower grip will enhance the use of the triceps. If you aren’t certain tips on how to add bench presses to an efficient fitness routine, work with an authorized private trainer.

Your physique, with its strengths and weaknesses, is unique, and simply because lifters appear to be 20–30% stronger within the flat bench press on common, it doesn’t mean that the identical essentially applies to you. How much weight you can carry in every train will rely, among different things, on your particular person body structure, making you more or less proficient at one or the opposite. Many people really feel that the incline press places less stress on their shoulder joint in contrast with the standard bench press.

The pectoralis main is a big muscle that covers the chest from the clavicle, the whole size of the sternum and the cartliages of the first six ribs near the sternum. The fibers converge and connect to the humerus almost in the identical place as the deltoid. In the shoulder girdle, the pectoralis minor and serratus anterior are the most important muscular tissues involved. The pectoralis minor is a small muscle located on the upper chest and is covered by the pectoralis main. The serratus anterior lies on the outer surface of the ribs on the sides (just below the armpits) and is covered by the scapula on the rear and the pectoralis major in front. In the elbow joint, the triceps brachii, a big muscle which covers the complete back aspect of the arm, is the only main muscle concerned. It has three sections, the lateral head on the outer floor on the again of the upper arm, the medial head on the internal aspect of the again of the upper arm, and the lengthy head in the rear of the upper arm.

Check out my blog post; http://www.annunciogratis.net/author/mahalia7407

Now establish the load of the dumbbells you utilized in the most challenging exercise in Step 2 (when you were determining your 5RM). The most difficult exercise would be the one during which you used the lightest weight. Once you have that number, plug it into the next formulation to find out your load (weight of dumbbells) for the complicated. Even circuit training — often hailed as the cardio king of the load room — seems lazy as compared. Lastly, lunges are a fantastic exercise for constructing the glutes, unilateral energy, and stability. Most of us have a stronger facet, and unilateral exercises similar to this one let you concentrate on every leg independently. To perform thrusters, merely do a full front squat and use the momentum on the concentric rep to “drive” the weight up overhead in one movement.

It is essential to notice that because the weights don’t change for any of the workouts, the “weakest” train in the complicated sequence is what finally dictates the resistance level of the dumbbells. A dumbbell complex is a kind of power circuit where you complete 2, or more workout routines with a dumbbell again to back with no relaxation without the dumbbell touching the ground. Dumbbell complexes can be utilized as a workout, or inside a exercise.

TRX suspension training is also highly adaptable for all fitness levels. Whether Or Not you’re a beginner or an advanced athlete, you can modify the depth of each train by adjusting your body place, making it an inclusive option for everybody looking for muscle-building workouts. Tabata training is a highly efficient methodology for constructing muscle and burning fat rapidly. This fashion of exercise includes short bursts of intense train adopted by transient relaxation intervals. It’s perfect for these with busy schedules looking to maximize their health outcomes.

Finally, you can even work on dumbbell deep push ups, which are great and promote a full range of movement. You can alter your physique place to target totally different areas of your chest too (i.e. place your toes up on a chair and you’re hitting your higher chest like incline bench presses). TRX suspension exercises use physique weight and gravity to help build muscle and enhance core stability. This coaching technique allows for a variety of workouts that focus on completely different muscle teams, making it a flexible addition to any health routine. You can combine and match totally different exercises to focus on specific muscular tissues or obtain various exercise targets.

“The press and jerk require not only shoulder energy however stability, particularly when using dumbbells,” Fotsch adds. This series works the entire core, including the deep abdominal muscle tissue, hips, and glutes, from a supine place. Men’s Match Membership was started with the aim of empowering males to get the most out of their lives.

In the above program, you’ll decide a weight you could perform for 10 reps on the DB Push Press and use the same load for the complete complex series. This is why your body burns fat long after you finish your workout. You burn 5 energy for each liter of oxygen you breathe to get well, and growing your demand for O2 by doing dumbbell complexes will improve your fat-burning capability.

Either method, this workout will depart you sweating, respiratory exhausting, and feeling robust. Having grasped the fundamentals of dumbbell complexes and their myriad advantages, it’s time to delve deeper. Superior strategies can amplify your outcomes, refine your physique, and elevate your fitness prowess. Here’s how you can harness the full energy of dumbbell complexes and make them an integral element of your fitness regimen. The “secret sauce” on this method is that the workout routines follow a logical order and move. The weights travel in a progressive sequence, on this case starting in an overhead place (A1- DB Push Press) and in the end ending with the weights on the bottom (A5-DB Elevated Push-Ups).

Lately, it was shown that the unstructured tail of Mcm2 can additionally be required for DDK recruitment14,15, however the mechanism remains to be unclear. As such we advise that the unstructured tail acts as an preliminary contact, which consequently turns into complemented or replaced by the Mcm2-HBRCT-Dbf4 interplay. This dual recruitment mechanism can doubtlessly explain why deletion of the Dbf4 HBRCT area is deadly in embryonic mouse cells60 and never in yeast44. A–d Three completely different structural states (I-III) derived from the same MD-(ATPγS) cryo-EM knowledge set. A Cryo-EM 3D auto-refined map (see Methods) of MD-(ATPγS) state I.

The dumbbell push press is an explosive overhead press that brings the hips and knees into play to permit for heavier dumbbells to be used. This makes it an excellent train for building muscle mass and explosive strength. This train is as compound as it will get, acting on all your joints. As such, it really does work almost each muscle in your body, but it emphasizes your quads, glutes, core, and shoulders. If you are in search of an train that can construct muscle and power while additionally burning a ton of calories, the dumbbell thruster is it.

Collectively these Dbf4-Mcm interactions place Cdc7 on the MCM2-7 double-hexamer in a unique way (Fig. 1d), which shields the kinase area from N-terminal extensions of other Mcm proteins aside from the Mcm4-N-terminal tail. Thus, the noticed kinase-substrate interaction is enhancing substrate choice for Mcm4. Substrate interplay III (SIII) includes a Dbf4 motif -M and -C connector (aa509–538), which is extremely conserved between totally different species of budding yeast (Fig. 4b-III, Supplementary Fig. 5b). Interestingly, a piece of area III (aa509–538; labelled as SCR in Fig. 1e–g) is situated in shut proximity to the Cdc7 P-loop and generates a floor along the energetic website cleft of Cdc7 immediately reverse the substrate-binding website. Kinases primarily type transient, weak interactions with their substrates involving a small region alongside the cleft of the kinase active site47. Weak interactions permit for quick release of the substrate as quickly as phosphorylation has occurred. This steady interplay presents the opportunity to characterise the large DDK-substrate interplay surface and investigate how varied structurally disordered Mcm N-termini are focused for phosphorylation.

But it’s good for novices and for folks with less than best grip energy. Grip power could be a limiting factor for some people, and a quick relaxation gives their palms and forearms a break while keeping their coronary heart rate excessive. In strength constructing, a fancy is simply a series of lifts performed one after the opposite with out stopping. Although which will seem easy, it’s a format that enables no relaxation for the weary. After the third press, deliver the dumbbells right down to a rack place with the dumbbells at your chest, both in a somewhat neutral grip or dealing with you, whichever is most comfortable. Maintain your core tight, and sit back to carry out the front squats. You do not need a health club full of equipment to build severe muscle, power, and conditioning.

F Comparability of the MD-(ATPγS) atomic model to the cryo-EM map to point out the standard of fit. EM map and atomic mannequin are coloured based on key proven in (e). The structural features of Cdc7 and Dbf4 are indicated, and a close-up view of the energetic website is proven. H Overview of the nucleotide occupancy and sort in each Mcm subunit within the MD-(ATPγS) advanced. In the G1 part of the cell cycle, the helicase complex is loaded by ORC, Cdc6 and Cdt1 onto the origin DNA. In this multi-step response, two MCM2-7 hexamers are joined collectively to type a head-to-head double-hexamer, the place each hexamers turn into related through their N-terminal interfaces and encircle double-stranded DNA (dsDNA)22,23. This helicase complex is initially inactive until DDK dependent phosphorylation of the MCM2-7 double hexamer (DH) in the course of the G1-S transition overcomes the autoinhibitory activity of the Mcm4 N-terminal tail13,24,25.

“Rowing a dumbbell utilizing one arm at a time while in a push-up position primarily works the back and biceps,” says Horton. Uncover key tips to make your again exercises safer and more effective. Observe these pointers to avoid injuries and boost your health routine. It must be robust, however the quality of the movement should stay high.

These exercises alternate between intense bursts of activity and short restoration intervals, maximizing calorie burn and muscle progress in a short amount of time. After I competed in Olympic lifting, I typically used a modified Javorek barbell complex. It was mainly to prepare my physique for heavy lifting and acted as a warm-up. However it additionally had a constructive impact on muscle mass and even conditioning.

General, that is the true definition of a full physique train. Dumbbell burpees are going to activate each single muscle in your body and they’re going to burn a ton of energy. Nevertheless, when you assume you may have what it takes to scale up the intensity of the already-brutal motion and need to add somewhat more hypertrophy potential, grab a pair of dumbbells and get to burpee-ing.

The beads have been washed with pre-RC buffer and the proteins nonetheless sure to DNA have been eluted by DNase I. The eluate was analysed by SDS-PAGE stained with silver or coomassie blue. The SDS-PAGE outcomes were used to determine DH-DDK interaction. In distinction to a Cdc7 kinase inhibitor, this mode of inhibition might enable elevated specificity for the inhibition of helicase activation. To our surprise, in the MD-(ATPγS) construction we noticed an ATPγS molecule sure to the Oligonucleotide/Oligosaccharide-Binding (OB)-fold interface of Mcm2/6, a non-canonical nucleotide-binding site (Supplementary Fig. 11a).

My favourite half about utilizing complexes for energy training is that it forces your core to be on excessive alert as your transition via multiple exercises. Most strength coaches will tell you that the easiest way capture energy positive aspects is to raise plenty of heavy weight with low reps and rest than you assume you want to. Time spent beneath said tension can only final so lengthy earlier than total failure and potential damage happens. Not solely does lifting heavy exhaust your phosphagen shops, but the neural effort it takes to coordinate the strain blasts your CNS as properly. This is why rest between units, as well as all through the week, is inspired when grinding out lifts like heavy squats and deadlifts. Second, advanced coaching, especially with high repetitions (generally 8-10 reps per exercise) has worked physique composition wonders for my shoppers and I that I have by no means witnessed with another training program, period. I personally dropped fourteen pounds of physique fats in a month on the aforementioned advanced program (while admittedly on the semi-restricted carbohydrate diet I detail here).

The session itself is quite easy, however like my Triple Squat Challenge Workout, what it lacks in complexity, it greater than makes up for in problem and effectiveness. The king of all complexes is barbell complexes as a result of you ought to use the most weight as a end result of stability and the fixed vary of movement. But they are more challenging to perform, and dumbbells are easier by comparability.

This is another good dumbbell accessory exercise for chest hypertrophy. Nonetheless, you will need good motor management to carry out it appropriately and effectively. It is very similar to a standing low to excessive cable fly, but you’ll be sitting on a bench in an incline position. When doing one arm dumbbell presses, focus on keeping your core and hips down and squared straight up.

⊕ Perform three or 4 rounds of Advanced 1, resting 60 seconds between rounds.⊗ Rest as wanted earlier than transferring on to the following complicated. When doing plank rows, I like to elevate my nonworking arm on a dumbbell so I get a full vary of motion. Stay on monitor of your health with these fast however laser-focused workouts. I don’t wish to begin sounding like an afterschool particular, so I will hold this brief. The slightly longer reply is, it depends on what type of hypertrophy you’re concentrating on. There are two typically accepted types of hypertrophy that I briefly mentioned in my Mikey and Mouth story earlier.

This effectivity helps maximize results in much less time, which is ideal for busy schedules. Incorporating bodyweight circuits into your routine might help improve flexibility and steadiness while constructing muscle. Exercises like push-ups, squats, and lunges goal a quantity of muscle teams, offering a full-body exercise that can be adjusted to swimsuit your fitness targets. Body Weight circuits are perfect for muscle constructing workouts as a result of they require no equipment and could be carried out wherever. These workout routines use your own physique weight to build power and endurance, making them a versatile choice for any fitness stage. Like barbell complexes, you can also perform dumbbell complexes to strengthen and tone muscle tissue and improve cardiovascular fitness. Barbell complicated is a high-intensity coaching that includes performing a series of exercises with out dropping the barbell.

The train is a sit up with a simultaneous overhead press. As such, it’s going to hit the core/low again (big time), chest, shoulders, triceps, biceps, and even upper back. The step-up press is great for working the hamstrings, glutes, and deltoids (the spherical muscle of your shoulder).

References:

http://010-8888-8317.kr/board_HBLF00/176845

This superior model of a pushup works a variety of muscular tissues and the shoulders while also giving your core a radical workout. For folks with shoulder tendinitis, train can significantly enhance their high quality of life by decreasing pain, increasing their range of motion, and recharging capabilities. Thanks to exercise, they can participate in engaging hobbies and work on their every day occupations with less ache. His specialty helps folks construct muscle to improve their power and common well being, with shoppers together with faculty, skilled, and Olympic athletes.

The seated dumbbell shoulder stretch is meant to assist improve mobility, shoulder, and arm energy while opening your chest cavity. This stretching routine is supposed to strengthen your shoulder muscle tissue as well as the arms. The shoulder rolls are aimed toward strengthening and stabilizing your shoulder blades so that it’s easy lifting heavy objects. It also improves mobility particularly when you’re shrugging your shoulders. Strengthening your arms and shoulder joints will assist enhance your range of motion as well as flexibility. Diagonal shoulder raises are aimed toward strengthening your chest muscular tissues in addition to the upper arms. Packing muscle onto your shoulders isn’t as easy as lifting heavy weights for a lot of reps.

And when you can goal any muscle of your body with resistance bands, the shoulders are the best to hone in on and pump them up and hammer them into development. The SFS FIVE Resistance Band Exercise Bundle has 5 enjoyable and difficult full length workouts using only resistance bands. Collectively, the 5 workouts make for the right weekly exercise routine. This adds some variety and you concentrate on preserving the core sturdy as you slowly alternate sides. Forward head posture is extremenly common in adults who sit for lengthy durations of time.

You can substitute this train with a Smith machine overhead press while training your shoulders. Whereas it is often used for various exercises similar to squats and smith machine bench presses, additionally it is a superb addition to your shoulder coaching routine as well. It’s also necessary to listen to your physique for any indicators of pain which are beyond typical muscle fatigue while performing shoulder workouts. If this happens, keep away from the train and reach out to an expert. Research exhibits performing shoulder workout routines is the best way to fight this.

It won’t be enough to totally maximize muscle development, but it ought to be sufficient to make progress. Since you aren’t doing many units, I suggest taking all your sets of push-ups and lateral raises to failure. It’s not only about muscle dimension but additionally about improving mobility and decreasing the danger of rotator cuff injuries. Gym rings shoulder workout routines target these areas effectively, selling balanced muscle improvement around the scapula and throughout the deltoids.

For this train, you will need sufficient shoulder mobility and stability, and good trunk stability and thoracic spine mobility. This was one of Arnold Schwarzenegger’s go-to workouts on shoulder day. With one arm presses, you’ll need to stabilize your core to remain standing straight along with your spine aligned. Also referred to as a pike push-up or down-dog push-up, this move is kind of a push-up in your shoulders; you’re in a pike position doing push-ups.

This is why the Farmer’s Walk is an efficient train to coach the traps; it forces your traps to engage by way of every step. The resistance and motion required in a face pull successfully activate several muscle groups in your again, together with the traps. If you’re on the hunt for lure workouts with dumbbells, look no further. Ideally, you must cycle your shoulder training from light to moderate to heavy each few weeks or even each different week. So, for these with joint issues, you don’t have to give up training, you probably can merely switch to bands for some time, or forever.

References:

steorids (https://git.pisci.eu/carmelaloughma/jawline-reshaping-for-men/wiki/Jawline-Reshaping-For-Men)

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.com/fr-AF/register?ref=JHQQKNKN

70918248

References:

https://www.arabianmatrimony.com/@halliemeister

70918248

References:

https://wzpmc.cn:3000/jestinemacgroa

70918248

References:

what are products that are consumed rapidly and regularly classified as? (https://audiofrica.com/dwightaguirre)

70918248

References:

https://freshteenclips.com/@gracielamcfarl?page=about

70918248

References:

what is in steroids (https://git.satori.love/chesterstowe49)

70918248

References:

steroid transformation 1 year; https://www.kornerspot.com/@jessieteel696,

70918248

References:

http://okbestgood.com:3000/leonardowardel

70918248

References:

anabolic steroid bodybuilding (https://git.morpheu5.net/marlalower0122)

70918248

References:

steroid side effect – https://gogs.playpoolstudios.com/wilfordpiesse6,

70918248

References:

https://git.arachno.de/gmbmary4426904

70918248

References:

How to build muscle without steroids (https://play.eccentric.etc.br/@salinajqr01766?page=about)

This is very indicative that Anavar is actually a really suppressive compound on the HPTA, necessitating the use of Testosterone in any Var cycle. Intermediate users ofOxandrolone can expect continued progress and improvements of their physiqueand efficiency. With the increased dosage and period, intermediate users mayexperience enhanced muscle development, energy features, and improved overallathletic efficiency. It is necessary to notice that particular person outcomes can varybased on elements such as genetics, food plan, training depth, and adherence tothe cycle. Additionally, it is essential to observe any potential facet effectsclosely and adjust the cycle accordingly to maintain up optimum health andwell-being. One of the most well-known anabolic steroids in the marketplace right now is Anavar, which is scientifically referred to as Oxandrolone. It was first created to treat conditions like osteoporosis and muscle loss.

Testosterone’s androgenic results can complement the fat-burning results of Anavar, albeit with some short-term water retention. Mg for mg, Anavar is technically 6x extra anabolic than testosterone (6); however, in vivo, this doesn’t translate into extra muscle positive aspects. Anavar (oxandrolone) is an oral anabolic and one of the least toxic steroids we have seen (alongside testosterone). However, anecdotally, we have seen SERMs such as Nolvadex exacerbate progesterone ranges on Deca.

Are you a woman aiming to build lean muscle or obtain a shredded look? Considering about using steroids, but concerned about their safety and effectiveness? Correct testing for HGH in athletes isn’t as simple as detecting most anabolic steroids or different PEDs, and urine testing can not be used to detect HGH. A particular test has been created to detect HGH in athletes, known as the Human Growth Hormone (hGH) Biomarkers Check, which focuses on detecting levels of IGF-1 and P-III-NP. HGH is also banned in the identical class as anabolic steroids by the World Anti-Doping Agency (WADA) and most other sporting our bodies worldwide. As A Result Of HGH is a naturally occurring protein within the physique, it’s one of the tougher PEDs to detect in doping tests. It is well worth stating that women don’t have to worry about masculine traits growing when utilizing HGH, as is the case with anabolic steroids.

HGH requires persistence to see results as a outcome of it takes many months to see its full advantages. HGH cycles are really helpful to be at least three months in period and sometimes as much as six months for max profit. Underground lab HGH comes with many risks, not the least of which is the under-dosing of the method. Anyone who has used genuine pharmaceutical-grade HGH will usually say it was well worth their investment.

Primobolan is just like Anavar in regard to its aspect effect severity, posing notably much less toxicity in comparison with steroids similar to Anadrol, trenbolone, and Winstrol. We regard Equipoise as one of many least deleterious steroids to get ripped, alongside Anavar and testosterone. We haven’t discovered Equipoise to be exceptionally androgenic, so these unwanted facet effects won’t be to the extent of testosterone, for instance. Equipoise is used among veterinarians to stimulate urge for food and bulk up horses after weight loss (3).

While Anavar is considered a gentle steroid, it still carries the chance of unwanted effects. Some widespread unwanted facet effects for both women and men embrace pimples, hair loss, and temper changes. Men may expertise testicular atrophy and decreased sperm count, whereas ladies may experience menstrual irregularities. For men, the beneficial Anavar dosage ranges from 50mg to 80mg per day. It is necessary to note that taking higher doses can improve the chance of unwanted aspect effects.

One Other concerning fact about this steroid stack is that it’s not inexpensive by all. And the toll this cycle takes in your liver is a complete one other dialogue. You should keep away from this combo cycle if you want to keep away from injury to your liver. The largest concern when using this stack is testosterone suppression. This leads to a myriad of unwanted facet effects in men (for particulars, see previous sections).

Some are usually wet compounds, which may result in joint problems when taken in excessive doses without an aromatase inhibitor (AI), leading to excess water retention that impacts the joints. Relating To the dosage and length of biking, before setting them up a number of vital indicators must be taken into account. To hold it inside normal limits, 200mgs of Deca blended with 600 mg of Testosterone Ethanate, for instance, taken for longer than weeks, is quite safe on your health. Also, based on its advantages versus health risks, Nandrolone Decanoate comes up with an inventory of mixtures you’ll need to bookmark later. By biking steroids, athletes can time their use to avoid detection throughout drug exams. Nevertheless, it’s also used by bodybuilders and athletes to burn fat and enhance their efficiency. Clenbuterol works by increasing the body’s metabolic rate, which finally ends up in a larger amount of energy being burned throughout the day.

Fat Loss and Body CompositionAnavar reveals a singular capacity to advertise fat loss while preserving lean muscle mass. Through its influence on metabolism and lipolysis, Oxandrolone aids in the breakdown of saved body fat, notably in stubborn areas. Simultaneously, it safeguards muscle tissue from catabolism, enabling individuals to achieve a extra outlined and ripped physique. Anavar can contribute to weight reduction by promoting fats loss whereas preserving lean muscle mass. It helps to enhance metabolism and enhance lipolysis, which is the process of breaking down and utilizing stored fat for energy.

The truth it is typically used by bodybuilders and health fashions, a lot of whom also use anabolic steroids, suggests to some that it may also be a steroid; nevertheless, this is not the case. Regardless Of Clenbuterol not being a legal prescription drug in the US, it is still comparatively simple to purchase there. In virtually every other nation, Clen is extensively out there and never a problematic compound to buy in pharmaceutical grade from most of the usual sources the place we can purchase anabolic steroids. Drink 1 cup of black espresso in the morning and one other late afternoon. It’s nearly like you should drive yourself to begin ingesting extra water before you are feeling like consuming extra. Once you attain a extra advanced stage with Clenbuterol, you’ll be assured in including more powerful compounds. At this stage, you should already be an skilled anabolic steroid person, because the extra substances you combine, the larger the juggling act you’ll have when coping with unwanted side effects.

Testosterone enanthate and cypionate are mostly used due to their price in addition to ease of injection. It can be utilized by each women and men and does not have any unfavorable or nasty side effects. To prime it all, it comes with a 100-day money-back assure so that you have nothing to lose. ACut is manufactured in an FDA-approved lab within the US and the UK and it mimics Anavar so as to experience all the benefits of Anavar minus its unwanted effects. As A End Result Of Anavar is a steroid that is usually well-tolerated by men, your stage of expertise is not going to play a large impact in selecting how much Anavar you should take.

References:

Rich piana steroid cycle [https://netjobsall.com/profile/vincemartell6]

Large choice lets you choose an appropriate course for every person no matter gender. Our shop steroids UK cares about its clients, their privateness, and subsequently relies on the non-public service that each buyer feel special and unique. If you buy steroids USA, the advised day by day dosage for male customers sometimes ranges from 20 to 80mg, while feminine users generally opt for portions ranging from 5 to 20mg per day. Initiation with a decrease dosage and gradual escalation is prudent, allowing for the dedication of the optimum amount that generates desired outcomes with minimal danger of undesired effects. Normal cycle durations span 6 to 8 weeks, with subsequent incorporation of suitable post-cycle remedy to reinstate the body’s innate hormone production. Post Cycle Therapy is the process of stopping a steroid cycle, shedding saved muscle mass, and re-building lean muscle.

With a concentrate on excessive standards and pharmaceutical-grade products, ZPHC Anavar provides customers an effective and reliable answer for their bodybuilding or athletic needs. The company is understood for its transparency in production, making sure you get exactly what you’re paying for. Furthermore, it’s essential to hold up a practical perspective on the advantages of Anavar.

Ideally, testosterone ranges might be measured to monitor such bridging. Professional sportspeople and amateurs alike are more and more inquiring about the utilization of legally obtainable anabolic steroids. For them, sports activities pharmacology isn’t a new notion, however it’s still unknown and untested. You won’t ever know, for certain, whether or not doping is a viable various to easily training alone till you find out about all the elements. Bodily and psychological stressors are growing shortly in sports activities as athletes compete for recognition and victory, while coaching can often push human capacities to their limits. The athlete thus begins to ponder how far they can prolong these limits. It is possible to lose 5% of body fats when doing a simple Anavar and testosterone cycle.

In the beforehand cited research, fats loss was everlasting for individuals. Thus, the hormonal lipolytic results of Anavar could additionally be preserved even when an individual is sedentary post-Anavar cycle. Our feminine sufferers have reported feeling depressed and have experienced low libido upon cycle cessation. Dave Crosland, the founder of Crosland’s Harm Reduction Providers, has additionally discovered testosterone and estrogen ranges to be deficient in females post-Anavar (24). If a person is stacking Anavar with harsh compounds, they may incorporate the above protocol. Nonetheless, if a man utilizes an Anavar-only cycle, taking one of these PCT medication alone is prone to be more than sufficient in restoring endogenous testosterone manufacturing promptly.

When integrated right into a balanced way of life, Anavar serves as a catalyst for personal growth and self-improvement. While generally well-tolerated, it’s prudent for girls to be cautious about hormonal health. When not sure in regards to the want for PCT, erring on the side of caution and implementing it can ensure the restoration of hormonal function. You also can buy injectable steroids on mega-steroids, this website is actually positive and where you presumably can typically get low cost, so we advocate you to visit the site for extra informations about that.

Learn about how celebrities use steroids and their favorites by clicking the link under. You could be stunned to learn that anabolic steroids are regularly employed in conventional medicine to effectively deal with a myriad of ailments. For this cause, we have made a comprehensive guide to assist folks like you buy Anavar online with out falling sufferer to all of the untrustworthy individuals flooding the online. Anavar (Oxandrolone) is your ultimate companion for sculpting lean, outlined muscles—without harsh unwanted side effects.

“Great stuff. Everything works as supposed, chemistry is on point. Was skeptical at first as suppose most people are, tested a pair merchandise and onerous to seek out better. About to position my 2nd order.” “Legit products! Smashing by way of PR’s and coming again for spherical two. One of one of the best if not one of the best online distributor. Extremely recommend.” The authorized status of Anavar on the market varies relying on the country and jurisdiction. In the United States, Anavar is classed as a Schedule III controlled substance under the Managed Substances Act. This implies that it’s illegal to possess or sell Anavar with no prescription from a licensed medical skilled.

When it involves effective and protected anabolic agents, Anavar for sale stays a best choice among athletes and bodybuilders. Identified chemically as Oxandrolone, Anavar 50 mg is a highly regarded oral steroid for these aiming to protect lean muscle whereas boosting power and endurance. This versatile anabolic steroid is right for slicing cycles, offering a stability between maintaining muscle mass and selling fats loss. With a low risk of androgenic unwanted side effects, Anavar 50 mg is broadly used by each female and male athletes in search of to optimize performance and achieve a lean, defined physique. The world of anabolic steroids, together with Anavar (Oxandrolone), offers important advantages for muscle growth, fat loss, and enhanced physical efficiency.

The increase in nitrogen retention will promote the anabolic atmosphere as lowered levels often lead to a catabolic state. The decrease in SHBG will yield a higher stage of free testosterone in the body, not solely providing extra of an anabolic punch but promoting a free or unbound state of all circulating anabolic hormones. As for the inhibition of glucocorticoid hormones, these are muscle losing hormones; cortisol being the most well-known. Anavar® contains 4-Androstenolone is also known as 4 androstene-3b-ol,17-one or 4-ANDRO by many in the bodybuilding group for brief. 4-Androsterone products are nice stackers, and may be stacked with virtually any compound. Both experimental and anecdotal evidence supports 4-Androstenolone’s capacity to lift testosterone ranges and improve efficiency.

First and foremost, it’s essential to emphasize the significance of purchasing Anavar from reliable and respected sources. The market is sadly flooded with counterfeit or substandard products, often posing vital dangers to health. Opting for legal alternatives is a prudent approach, as these merchandise bear stringent quality control and cling to safety standards.

References:

steroid basic structure, https://www.starfiredynamics.com/employer/anavar-steroid-results/,