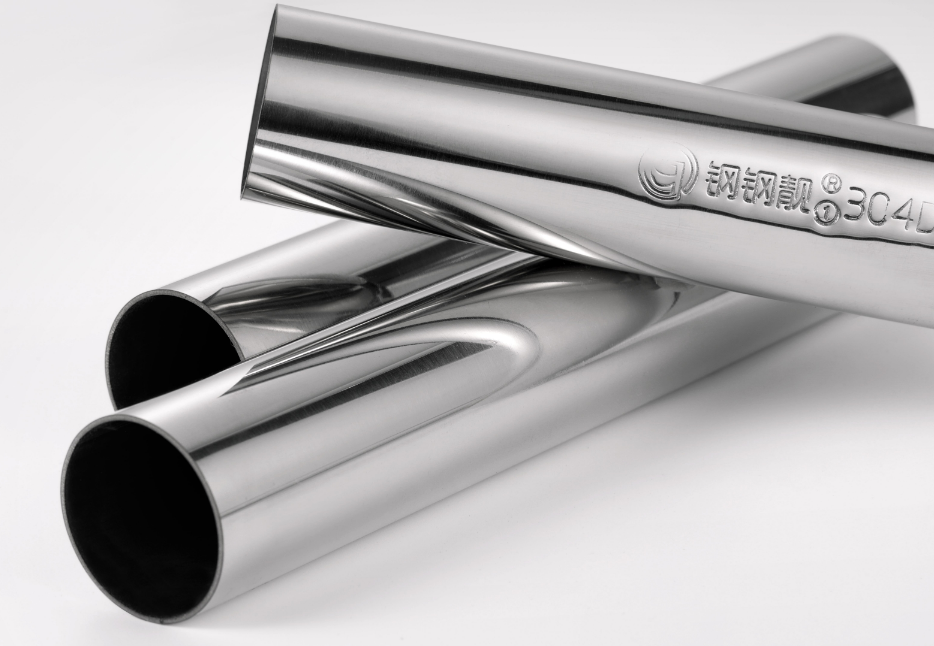

Stainless steel is a popular material for various applications due to its corrosion resistance and durability. Two of the most common types are stainless steel 304 and 304D, but what are the differences between 304 and 304D Stainless Steel? In this blog post, we will explore the similarities and differences between these two materials. So, whether you are in the manufacturing industry or just interested in stainless steel, please continue reading to learn more!

What is 304 stainless steel?

304 stainless steel is one of the most commonly used stainless steels in many industries. It is an austenitic alloy containing at least 18% chromium and 8% nickel, which gives it strong corrosion and oxidation resistance. Its high ductility and good weldability make it a popular choice for applications where strength and durability are critical.

One of the notable characteristics of 304 stainless steel is its ability to withstand extreme temperatures without losing its structural integrity. This makes it ideal for use in harsh environments such as chemical processing plants, food processing facilities, and medical equipment.

304 stainless steel has excellent hygienic properties and is suitable for kitchen utensils such as sinks, pots, pans, cutlery, and tableware. In addition, it resists stains caused by acidic foods or liquids.

Due to its versatility and excellent physical properties, such as its toughness and corrosion resistance even under high-temperature conditions, 304 stainless steel remains a widely used metal alloy in various industrial fields: automotive industry (exhaust system), construction (balustrades), aerospace industry (aircraft parts), etc.

What is 304D stainless steel?

304D stainless steel is a modified version of the popular 304 stainless steel. The “D” in its name stands for “deoxidized,” which means it has undergone a deoxidation process during manufacturing.

This process involves adding elements such as silicon and aluminum to eliminate excess oxygen in the steel, resulting in a material with improved weldability and corrosion resistance.

Compared to its predecessor, 304D stainless steel also has slightly higher contents of carbon, manganese, and sulfur. These changes enhance the machinability of this type of stainless steel without sacrificing its strength or durability.

While 304 stainless steel is still widely used in many industries, 304D stainless steel is becoming increasingly popular in applications that require high-quality welding capabilities, such as pressure vessels and piping systems.

304D stainless steel offers similar advantages to 304 stainless steel but also has some additional benefits, making it an excellent choice for certain applications.

Differences between 304 and 304D Stainless Steel

At first glance, 304 and 304D stainless steel may seem similar, but there are distinct differences between the two. The main difference lies in the carbon content in each grade.

304 stainless steel contains a maximum of 0.08% carbon, making it an excellent choice for applications that require good corrosion resistance and formability. It is commonly used in kitchen equipment, chemical processing plants, and pharmaceuticals.

On the other hand, stainless steel 304D has a higher carbon content than its counterpart – up to 0.12%. This additional carbon, compared to SS304, increases strength and hardness while reducing ductility. Therefore, it is typically used in more heavy-duty applications such as automotive components or industrial equipment.

It is important to note that while these alloys have different properties due to their varying carbon content; they still share many similarities in composition, such as the chromium-nickel ratio that provides their overall corrosion resistance.

In summary – whether you require high corrosion resistance or higher mechanical strength – understanding the differences between stainless steel 304 and its “harder” sibling can help you choose the right material for your specific application needs.

Applications of 304 and 304D Stainless Steel

Both 304 and 304D stainless steels are widely used in various industries due to their excellent properties. 304 stainless steel is commonly used in kitchen utensils, food processing equipment, chemical containers, and building decorations. It is also well-suited for medical equipment due to its good corrosion resistance.

On the other hand, when higher strength is required, stainless steel 304D is the preferred choice. With its higher carbon content compared to SS 304, it offers superior mechanical properties such as higher tensile strength and hardness. This makes it an ideal choice for heavy-duty mechanical components such as shafts, gears, springs, and bolts.

Both types of stainless steel can be found in the automotive industry, where they are used for aesthetic appeal in exhaust systems and even decorative pieces of high-end luxury vehicles.

The marine industry also extensively uses these materials due to their corrosion resistance to salt water. Additionally, both grades can withstand extreme temperatures, making them suitable for cryogenic tanks that store liquid nitrogen or oxygen.

In summary, 304 and 304D stainless steels have a wide range of applications in multiple industries due to their durability and corrosion resistance at high temperatures. They are a valuable addition to any manufacturing process that requires reliable quality assurance standards.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between 304 and 304D stainless steels. If you want to find more information about 304 and 304D stainless steels, we’d advise you to visit Sino Stainless Steel.

As a leading supplier of 304 and 304D stainless steel products across the world, Sino Stainless Steel provides customers with high-quality Stainless Steel Angles, Stainless Steel Channels, 201 Stainless Steel Strips & 304 Stainless Steel Strips, 321 Stainless Steel, 316 and 316L Stainless Steel, Stainless Steel Hexagon Bars, Hot-rolled Stainless Steel, Colored Stainless Steel Sheets, Stainless Steel Perforated Sheets, Cold-rolled Precision Stainless Steel, Stainless Steel Wire, and Embossed Stainless Steel Plates at a very competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

Elevate your palms and hold both arms together and from there, start moving your hands back with a slight bend in the elbow.

Seize every finish of the bar and hold your again straight whereas holding

the bar. You can even use a straight bar but make certain that

you are holding it with a supinated grip.

Pause on the prime after which slowly bring your hands back all the way down to the shoulder top.

Grab each the handles from each hand and lay down onto the bench.

Now start raising your hands to the perimeters

with a slight bend within the elbow and pause when your arms are parallel to the ground.

One of the best things about cable stations is the ability

to adjust the machine load increments. Every rep needs to be controlled, with a focus on intense muscle

contraction. Focus on creating your personal resistance with mild weight earlier than shifting as much as the

heavier weight plates.

The workouts are additionally suitable for anybody who wants to increase muscle mass and definition of their shoulders.

Incorporating cable shoulder workouts into your common train routine might help prevent muscle imbalances, enhance posture,

and improve athletic performance. With the

diversity and the constant tension, a cable shoulder exercise is

a powerful tool for any health enthusiast seeking to take

their shoulder coaching to the following degree.

By selecting a weight that allows you to execute each motion with control and precision, you presumably can goal your shoulder muscle tissue

successfully and safely. To execute this train, place

your self dealing with the cable machine with the handle set at shoulder height.

Pull the handle towards your face, maintaining a excessive elbow and retracted shoulder blades to target the intended muscle tissue successfully.

Exercises like the cable rear delt row give attention to the often-neglected posterior deltoids while entrance raises zero in in your

anterior delts. The unique capacity of cables

to pivot and adjust allows you to hit each muscle group from

an array of instructions that free weights merely can’t replicate.

Utilizing cables for lateral raises helps enhance shoulder stability and

power.

Pay Attention to your body; if something feels off or hurts (in a foul way), cease and examine your posture or decrease the weight.

This transfer helps make your shoulder muscle tissue sturdy and

can even make different parts of your upper body

more strong. To do a Cable Single Arm Neutral Grip Entrance Increase, stand next to the cable machine.

The lower traps are really essential for creating

stability of the scapula as we raise our arms up over our head.

Performing the face pull with this additional arm elevate helps us give them some much needed attention. So, if I

had been to attempt to do full vary of movement the place my arms are out in entrance of me getting some scapular protraction, and then I come again into the face pull,

I hit a wall. I don’t have the strength because this band obtained too hard too quickly.

How will you implement these workout routines into your exercise routine?

Embrace the importance of this guide as it can considerably impact your shoulder strength, stability, and general posture.

Executing this train with proper type and management not solely minimizes the risk of harm but also maximizes its effectiveness, selling optimal

engagement of the muscle tissue.

The shoulder muscular tissues are composed of four completely different muscular tissues, the supraspinatus,

infraspinatus, teres minor, and subscapularis. These muscles work together and

are responsible for helping to stabilize the arm

joint and move the arm. There are 5 muscular tissues under the aspect of the forearm

and 5 on the highest. The quads are the entrance a part of

the upper leg and they’re one of the largest

muscular tissues in the body. A person’s

quads are necessary in quite lots of actions corresponding to operating, leaping, and strolling, and are answerable for flexing the leg.

Gradually return to the beginning place and then repeat the motion. You can even change up

the resistance simply by changing the way you utilize the ropes generally.

Battle ropes were initially designed by a fitness trainer named John Brookfield in 2006.

Kettlebells and dumbbells have been around for a

lot longer and whenever you look at a regular workout program, you’ll most likely

see lots of them on there.

This could have an excellent impact on other coaching or

sports activities you do this require high energy output.

Once you have mastered creating waves, you possibly can transfer in several motions, corresponding to creating

circles. It is a good variation to create extra of a problem to this body weight train.

Make certain your palms don’t bang collectively, keep

your palms up excessive all through the

set.

When performing rope flow workouts, make certain to breathe accurately,

have interaction your core and glutes, and give consideration to correct type.

We want to maximize how much of our shoulder muscle

tissue we use through the exercise and minimize using all the opposite muscles, including different upper

physique muscular tissues. Here are some nice cable machine

shoulder workouts to try throughout your next workout.

The identical thing with HIIT workouts, if you have the energy, then do one,

if not, then don’t. You need to avoid overtraining,

but you additionally need to push yourself to make important adjustments and attain your objectives.

It is determined by what type of workouts you

propose to do with the battle ropes, your coaching

objectives, and what different exercises you are

doing. Then, in fact, your higher body is working as it does

with any waves variation. You are going to be shredding

through excessive calorie burn and getting a mean pump in your arms, chest, and back.

Your core, as at all times, will be working hard in tandem along with your decrease physique to stabilize all

of it.

The other essential thing to concentrate to is the place of your arms and elbows

on the end point of the motion. As An Alternative, seize it in an underhand grip together with your thumbs backward.

This offers you the external rotation of the shoulder with elevation which is what we wish.

You don’t want to be doing this, particularly should you do your face pulls as often as I’m going to advocate you

do! You’d be accumulating plenty of repetitions

in an internally rotated shoulder position with elevation.

One of the commonest errors when performing the face pull

is the inaccurate placement of the anchor level of the band or the cable.

Alternatively, you’ll be able to add a rope move session on the finish of your typical

exercise routine. If you’re new to rope circulate workout routines, you’ll

probably should make a DIY circulate rope, or buy

a branded circulate rope in order to give it a

try. If this sounds fascinating, you could need to be taught more about

the advantages of rope flow workout routines and how one can add them

to your exercise routine. Cables are an excellent piece of apparatus to target every

area of your shoulders.

As you method the upright place, your upper traps will step in to do more and more of the work.

Quality is extra essential than quantity, so focus on maintaining correct form and intensity all

through your workout. Bear In Mind to warm up before each session and funky down with some stretching

afterward to stop accidents and assist recovery. Resistance

bands are a fantastic addition to any power training routine or rehabilitation program.

They are obtainable in quite lots of sizes, lengths, and resistance levels.

They say it actually works properly, with ropes that need to be tied to the

place they want them.

As A Result Of of this, you can add a tremendous quantity

of volume to your lagging body elements. It’s also necessary to hydrate properly and

guarantee you’ve eaten something to help fuel your workout.

Wherever between 15 and 20 works greatest for me and my shoppers.

Though the method might harm at first, it’s a necessary step in therapeutic.

You should be capable of actively move the shoulder by yourself by

this point in your recovery.

For instance, 25% for lighter weights (20 to 30 reps), 50% for average loads (10 to

twenty reps), and 25% for heavy weights (5 to 10 reps).

The standing cable rear delt row with rope is a very

efficient and functional train for building muscle and power within the upper back.

Each of those movements can be carried out along with your arms working in an up and down reverse to

every other fashion (alternating) or simultaneous movement (double).

The larger you deliver the ropes up for both, the different effect it’s going to

produce. Smaller, short waves might be nice

for endurance, whereas when you start making bigger waves (or “tsunamis” one might say), you’re working power, energy and

endurance. The more durable and higher the slam, the

more energy and power comes into play. But typically speaking, waves

are nice for endurance, whereas slams are for energy and power.

Also, you might have decreased shoulder ROM when you have had shoulder surgical procedure like

a rotator cuff or labrum repair.

Shoulder active vary of motion (ROM) workouts can help improve shoulder

joint mobility. These exercises could also be prescribed when you have a shoulder situation, corresponding

to shoulder ache, that causes restricted mobility in your shoulder and arm.

Shoulder ROM exercises help you move the affected joint in all

instructions that it ought to be capable of move.

Ropes have been an integral half within the development of human historical past, as each a software

and method to amplify human power. Some historians trace the history of ropes to predating bronze, clay, steel,

and iron. While it has existed as a tool implemented

in a variety of methods in human history, its use as a device to advance human performance is a current utility.

They can help train energy and explosive actions alongside speed and agility.

Whereas the battle ropes do interact the entire physique, the arms are the primary focused muscular tissues whereas using

this piece of equipment. Cable entrance elevate targets your shoulder muscular tissues, particularly the front

parts. You stand going through away from the cable machine, ft hip-width apart.

Because you’re utilizing cables, there’s constant rigidity

in your muscular tissues all through the entire movement.

The cable shrug is a wonderful exercise to focus on the trapezius muscle on the upper back.

You can isolate the traps to additional activate the muscle,

stimulating growth. Doing shrugs with a cable machine gives you the power to perform a quantity of variations with totally

different physique angles to differ the degree of contraction within the traps.

This cable again exercise is ideal for constructing

the width of the lats. The impartial grip lat pulldown promotes

a full range of movement of the lats. Concentrate on squeezing your back muscular tissues on the bottom of the motion. Stroll into any

fitness center and you will see both the largest

guys and women using the cable machine for back workout routines in addition to newcomers who aren’t so acquainted with the world of weightlifting.

Battle ropes will improve your work capacity, endurance, and velocity, permitting you to perform better in other areas of your fitness

and in sports activities. Battle ropes will make muscle imbalances and weak muscular tissues obvious actually shortly.

What’s even better is, they will improve them shortly too, and you don’t really need

to think too much about it. Just go concerning the exercise and your weaker side

will catch up and people smaller, usually forgotten muscular

tissues like your grip, forearms, and hip flexors shall be focused it would

not matter what you do. Of course, if you want to grow specific muscular tissues, do what you have to with dumbbells

and the like, there’s nothing wrong with that. Nevertheless, if you want a quick and efficient exercise, then battle ropes are top-of-the-line coaching tools that exist for

that.

It entails quite a few muscular tissues, requiring you to rotate your waist slightly.

This is a unilateral exercise, so you have to interact your core

all through the motion. The lying cable rear delt fly

is a superb option when you have any lower again issues

or just want to reduce the quantity of stress on your decrease again. There are plenty of workouts to select from that will help you construct full-body muscular endurance while promoting fats loss at

the same time. Battle ropes not only build energy

and muscle, but they may even provide you with an excellent cardio workout.

It may be very excessive energy, and you’ll feel both your upper body and legs working onerous.

The seated wave permits you to isolate the upper physique only and

remove the strength offered by your legs.

Moreover, it’s potential to include facet, entrance, and

back lunges whereas utilizing the battle ropes to additional work out the

legs. Making positive your shoulders are warmed up means much less threat of injury

and a better chance to build power successfully.

Lift the deal with to shoulder height, then slowly decrease it back down. This

exercise keeps pressure on your shoulders, making them work

onerous. Doing this exercise retains pressure on your shoulder

muscles all through the move.

Here is my site :: list of steroids and what they do

It’s easy to lose stability should you Bench

Press inconsistently or load more plates on one side of the bar.

Bench Pressing along with your ft within the air can also be ineffective for going heavy

because you can’t interact your legs. Don’t simply push your feet into the floor whenever you Bench Press.

Drive your upper-back and glutes into the bench too. Push yourself away from

the bar instead of pushing the bar away.

Lie on the bench with a pure arch in your decrease back.

The similar arch your decrease back shows if you stand.

I should have the ability to slide my flat hand between the bench and

your lower again. Arching your decrease back helps preserving your chest

up. It increases effectiveness when you Bench Press.

You won’t have the ability to carry as much weight, however

it’s also a bit simpler on your shoulders because your

hands aren’t fixed on a straight barbell. At no level must you struggle by way of shoulder pain on this exercise.

If you discover that your shoulder hurts, first strive correcting the

errors above and make sure you’re setting your shoulders by pulling

them down and back. If this doesn’t work, then lower the

incline of the bench till you find a urgent position that’s snug.

To allow you to get essentially the most from the dumbbell bench press, we

enlisted the assistance of energy and conditioning coach and sports

activities scientist Ryan Horton. Holding a weight in every hand means

your smaller stabilizer muscle tissue must work harder as you

press. This is why you will not be capable of bench as a lot weight with two dumbbells

as you’d with a single barbell. And bear in mind, choose

the dumbbell chest press variation that feels right for you

at that moment. There’s no shame in tweaking the exercise

so it works best for your physique, fitness stage, and abilities.

Not only will this guidelines guarantee you’re doing it right,

but it’ll additionally help you with building higher physique power in your bench.

So, what I’d counsel, is just mess around with this vary

to see what feels best. Focus on contracting your chest using completely

different elbow angles to see what best prompts most of your chest fibers.

The key is to search out the candy spot that feels the most effective when it

comes to overall chest activation and comfort on your joints.

Better yet, try a continuous pressure dumbbell bench press, throughout which you keep

the non-working arm fully extended toward the ceiling between reps, suggests Henry.

“The number one good factor about doing this is that the stabilization requirement is through the freaking roof,” she provides.

Particularly, you will have to engage your entire physique in order to maintain your self from tipping over to the side as you lower one dumbbell to your chest, she says.

Not to say, your non-working arm will nonetheless should work

during it’s “break” to ensure the load stays hovering above your chest.

Harry covers news, reviews and options for Coach, Fit&Well and Live Science.

You need only a weight bench and set of dumbbells for this transfer, making it

a flexible possibility when you presumably can’t get to the

bench press stations. As they rise, allow the weights to

float closer together (some folks like to touch them

on the high of each rep, but this isn’t necessary).

Wrap your thumbs across the bar utilizing the total grip. This

will increase Bench Press energy because your arms and shoulders contract harder too

(hyper radiation). If your wrists damage, stop bending them

by gripping the bar lower in your palms.

Benching heavy dumbbells without spotter is nearly impossible.

If the load is really heavy, it will smash via your abs before it reaches

your hips. If you’re unfortunate, the bar can tear a blood vessel inside and you’ll bleed to

demise. You should be in a position to maintain the weight in the bottom for the roll of disgrace

to work. I don’t use it or suggest it as a result of it’s harmful.

I just lately uncared for to verify the safety pins before I Bench Pressed.

And I got the primary reps but then failed mid-rep.

Perform 2 to 5 total units relying on how much time you want to train. The

seated chest press machine could be a greater pressing option when you wrestle with getting up and down out of your again. Every Thing you

should find out about one of the in style power training workouts.

Naturally, there are numerous questions and misconceptions surrounding the dumbbell press.

Additionally, the athlete ought to pay attention to their hand positioning.

Their palms should be in the course of the dumbbell to achieve a balanced weight distribution. Make certain to follow my Bench Press guidelines during your weekly routine so as to see some serious positive aspects from this efficient exercise.

You’ll get more reps and Bench Press extra weight.

Resting longer increases the quantity of ATP available for your next

set. ATP is your primary energy supply for lifting weights.

While it usually plays second fiddle to the flat barbell bench, it has unique advantages.

For one, all you need is an adjustable bench and a set of dumbbells to construct a sculpted frame.

You Will also get a larger range of movement with an incline dumbbell press, which helps develop muscular stability and stability.

On the opposite hand, you probably can carry

a lot more weight with the traditional bench press, making it

higher for building strength and overall muscle mass.

For powerlifters, you actually don’t want any fluff.

I have a pair of adjustable Dumbbells in my residence gym.

However I use them to do help exercises for the Bench Press.

I don’t use them to switch the Barbell Bench Press. Because the greatest

way to extend your Bench Press is to Bench Press and

Bench Press heavy. Safety is key to Benching heavy weights with confidence with out getting harm.

Many gyms have a quantity of different chest press machines utilizing completely different

angles. Experiment to search out which of them work best for your body.

D. On an inhale, slowly lower the dumbbells again to the beginning place, pausing when the dumbbells are simply above shoulders.

But barbells force you to work from a fixed position, which could not be

perfect for guys with shoulder points or other anatomical challenges.

The weight might be easier to Bench as a outcome of you’ll

contact your chest larger. This shortens the bar path and decreases horizontal bar

motion to press it again over your shoulders.

Lie on the bench together with your upper-back tight.

Think About holding a pen between your shoulder-blades by squeezing them together.

This flattens your upper-back and increases stability when you

lie on the bench. You can push your upper-back

harder against the bench which will increase your Bench Press.

The natural tendency is to let the weights drift back over your head through the carry, so focus

on avoiding that. It could be price having somebody examine your

type when first making an attempt this move. It has the extra benefit of working your arms and shoulders

as well. The average lifter and even advanced lifters would want to stick with

1-2 bench pressing sessions per week to permit enough recovery time for muscle

tissue to grow.

If you do it right, your elbows won’t harm if you Bench

Press. The lockout will really feel more secure and you’ll be less

more probably to lose the bar. Some strong people have Bench Pressed huge weights utilizing the thumbless

grip. Others have dropped the bar on their chest regardless of Benching full grip.

However the chance of dropping the bar is greater with the thumbless grip.

It doesn’t matter if somebody has used it for years with out accidents.

When your savior is there, help him rack the bar.

Don’t release your grip and let him do all of the

work. The weight could also be too heavy for him

to carry or he will not be robust enough.

You don’t want him to fail and drop the bar in your

face.

This keeps my chest tight and saves energy for the tougher final two reps.

All The Time warmup with the empty bar if you Bench Press.

Add 10-20kg/25-45lb per set until you attain your work set.

Decrease the reps as your warmup weight will increase. There

are tons of DIY solutions for cheapskates with time.

You can put a quantity of collars in your barbell.

If you’re over-cautious, you’ll Bench at decrease intensities.

However you must Bench heavy to extend your Bench Press.

Energy Racks give you the safety and confidence

to Bench heavy. The roll of shame is like failing the Bench Press in the Power Rack, but with out one.

Situp on the bench and rise up with the bar as if Deadlifting.

Not that shameful however people usually think failing

is, thus “roll of shame”. The roll of disgrace can help you get unstuck if you fail the Bench Press without power

rack or spotter to assist you.

The lower the bar touches your torso, the additional it ends out of your shoulders.

The further the bar from you shoulders, the more durable to

Bench Press the burden. Benching with a flat chest is harder

in your shoulders. Your elbows flare when they’re 90° out at the backside of your Bench Press.

This places your upper-arms perpendicular to your torso.

In distinction, the flat bench press primarily targets the lower

chest muscle tissue (the sternal head of the pectoralis major).

The major advantage of single arm dumbbell bench presses is that you could tackle muscle imbalances.

This is also an excellent train for athletes as sports can be very unilateral, albeit

so can life generally.

You’ll discover this model, together with many others, in our article on push-up variations,

from beginner to superior. Put Together to maximize your energy with our exclusive

13-week energy training program. three, 4, and 5 day per week programming choices.

The below are commonplace rep and cargo ranges for energy, strength, hypertrophy, and endurance.

Carry Out the exercises back-to-back with no relaxation between the moves.

It’s not realistic to expect 10kg/20lb PRs on your Bench

Press. Adding that to a 100kg/220lb is a 10% improvement.

The flat dumbbell press is an exceptional exercise for creating your chest,

shoulders, and triceps, offering a balanced and symmetrical higher physique.

To achieve a deeper understanding of chest muscle anatomy and biomechanics,

check out this comprehensive guide on ExRx.web.

Moreover, the exercise engages stabilizing muscular tissues,

such as the serratus anterior, to hold up management and balance all through the

movement. This comprehensive muscle activation makes the

flat dumbbell press a very important part of any upper-body workout.

When it involves building upper body size and energy, the bench press is amongst the handiest workouts you are capable of do.

If using a flat bench, research present around a 30% improve on higher chest activation. So, if you want to goal your upper chest with out

as a lot shoulder work, flat bench reverse grip is great.

The same is true for incline, but the increase to the upper chest just

isn’t as great, contemplate the incline position already targets the higher chest extra with the standard grip.

With incline reverse grip bench press, you’ll get a few 5-10% increase in higher chest recruitment.

No, the dumbbell bench press isn’t dangerous if the athlete uses the right

type and lifts an appropriate amount of weight.

One of the primary benefits of the dumbbell bench press is the higher range of movement.

To maximize this profit, the burden must be under your chest at the backside of

the press. At the highest of the press, you need to convey the

dumbbells together.

The traditional model, this exercise permits for heavy lifting and is good

for building maximum energy and mass. Or maybe you’ve

been going to fitness center and ready to up your sport to the barbell bench press and do not

want to make any mistakes then you would possibly be undoubtedly in the best location in your answer.

Heather Jacques is a former collegiate athlete that graduated from

Grand Valley State University with a Bachelor of Science in Athletic Training.

Alongside with writing content for Carry Vault,

Heather works for one of the quickest growing sports activities vitamin corporations, Axe & Sledge Dietary Supplements,

as their product specialist. Heather is an avid lifter, snowboarder, and outdoor fanatic.

Dumbbell bench press challenges are varied targets or exams that an athlete can complete.

They are a means for athletes to push themselves to perform more within the weight room.

If you’re able to dominate the dumbbell bench press, you want to comply

with these six steps. Your elbows ought to be immediately beneath your wrists as you put together to decrease the dumbbells.

Maintaining your elbows and wrists in alignment will keep your shoulders within the appropriate place.

To set your back, flex your shoulder blades and squeeze them

collectively.

Being strong in the bench press will allow you to

be successful in all other functional push movements, to not mention in sports and in life.

The cause dumbbells are so nice is that they supply a

larger vary of motion they usually enable your arms to work

independently, which may iron out muscle imbalances. Moreover, it requires them to activate to a barely greater

diploma to stabilize.

They work several totally different muscles in your upper physique, together with

the chest, shoulders, and arms. Cortisol can also be produced when performing

the dumbbell bench press. Nonetheless, cortisol helps the

body create power by consuming tissue. Maintaining

your cortisol ranges low by resting between units of snatch-grip deadlifts is crucial.

It uses the identical type as a barbell bench press, however lifters have a higher range of

motion, so it’s simpler to beat plateaus. Selecting

the appropriate weight for a dumbbell bench press is crucial for performing

this exercise.

By lifting heavy hundreds, your bones will get denser and

stronger. Considering your strongest upper physique lift will be the bench press (without question), then there isn’t any higher exercise for higher body bone well

being than the bench press. This will keep your higher back flat and your shoulders

secure during bench presses. The squeeze of your

shoulder blades should occur even before you unrack

the bar. The third distinction that I need to touch

on on this article is the skill requirements that come together with the flat, incline, and decline bench press.

His mission is to encourage fellow “hard gainers” to rework their own our bodies and stay’s by simplifying coaching and diet to get outcomes fast.

Additionally, aim to eat a minimal of 1 gram of protein per lb of body weight.

Determine your maintenance calories utilizing the TDEE calculator and add 5-15% to determine your daily bulking energy.

This is how a lot you ought to be consuming daily to build muscle and energy.

You additionally have to be aware of its correct technique to keep away from accidents.

The bench press mimics pushing actions utilized in sports activities and day by day life, similar to throwing,

shoving, or moving heavy objects. Have you ever wondered why so many people struggle to get up from the dumbbell bench press, even after they appear robust enough

to lift? This frequent dilemma highlights the significance of bench press…

Dumbbell presses sometimes present extra flexibility in motion, which

might reduce joint strain. Nonetheless, correct form in both presses is critical for joint

health. Bench pressing can allow for heavier weights, which can be effective for building

mass, but each methods can be equally efficient with proper coaching.

Varying your routine with completely different weights, reps, and incorporating each pressing methods can help in stopping plateaus and continuously difficult your muscle tissue.

Focus on the goal muscle tissue during presses to optimize engagement.

Visualization strategies throughout dumbbell and bar presses may amplify muscle recruitment and progress.

A eager focus yields significant enhancements in type and efficacy.

These are must-have items of apparatus for trainers

and customers who wish to have extra stability and general

safety when going heavy while dumbbell pressing. They take away the necessity for spotters by providing the entire help wanted

to provoke exercise.

Nevertheless at some point you might hit a

plateau that’s if you wish to change it up and possibly start with dumbbell flat

presses then perhaps do barbell incline press and decline press.

Both the incline dumbbell press and the flat bench press are effective workout routines for

constructing a powerful, muscular chest. By understanding the

advantages and downsides of every exercise, you probably can select the one which

finest aligns with your particular person targets and skills.

The incline dumbbell press is designed to increase chest strength

and measurement, so it is typically included in a well-rounded, intermediate power training program.

If you cut up up your weekly exercises by physique part, embody this chest exercise in your higher body or chest day,

after exercises like pushups or the flat bench press. The flat bench

press is a cornerstone exercise in weight coaching and bodybuilding, famend for constructing upper body strength and muscle mass.

Progressively enhance the burden you raise with dumbbells and incorporate bench press coaching with correct approach to construct up

your power over time. Adjust the bench to a slight incline

to target higher pecs with dumbbells. Doing a chest press

on a flat bench positioned at 0-degrees targets the middle of your

pecs.

She was born in Colorado, raised in northern Michigan, and currently

resides in Pennsylvania. Heather’s primary goal is

to assist others achieve their health and health targets via

schooling, motivation, and inspiration. If you are competing in powerlifting, it’s a good idea to practice

the bench press, squat, and deadlift on the same day as a end result of that’s what you will do on meet day.

The incline bench press is arguably the toughest of these

three variations and that’s because of the range of motion you’ll be working

by way of. The incline bench has a larger range of motion you’ll

should press by way of and you’ll want an excellent level of

mobility to perform these. For novices, I usually advocate tackling

the flat bench press first and constructing a great basis with this press.

The flat bench press is the most “generalist” of those three bench variations and you’ll prepare a majority of the

pecs with the flat bench. A commonplace flat bench can be

used rather than a bench press rack, and you may carry out

bench presses with dumbbells or a barbell. If

you want to add bench presses to your weightlifting routine, try to

carry out bench presses only 2 to 3 instances per week. Give your self a minimum of 1 day between doing bench presses to permit your muscular tissues to recover.

Isolating the chest with pre-exhaustion strategies earlier than presses

can intensify muscle workload. Begin with flyes earlier than urgent movements for a complicated muscle-building strategy.

Switching between dumbbell and barbell presses can maintain muscle tissue guessing and advancing.

Periodize coaching, oscillating between volume and intensity phases for sustainable progression. Focus on maintaining your wrists straight so that they are perpendicular

to the bottom throughout the train to stop

wrist harm.

If you’re trying to construct measurement and definition in your upper chest, the incline dumbbell press is a superb choice.

Nonetheless, if you’re thinking about maximizing strength gains or concentrating on all portions of your pectorals, the flat bench press

is a better option. Additionally generally identified as the dumbbell flat bench press or the

dumbbell chest press, the dumbbell bench press is an higher body

train that primarily targets your chest and pectoral muscles.

It has the additional good thing about working your arms and shoulders as

properly. Understanding the mechanics of the flat dumbbell bench press is essential for reaping its advantages.

One Other reason why dumbbells are nice is that they allow for an even larger vary of motion,

which is part of the explanation why they have such nice muscle

activation. One of the benefits of dumbbells relates back

to the point of stability. As A Outcome Of dumbbells require extra stability, you’ll be

working your muscles differently, which is good for hypertrophy, and you’ll be better targeting your stabilizer muscular tissues to a better diploma.

No one needs to be the lifter with super-built-up higher pecs but lagging lower pecs that

lack mass and girth. When doubtful, use all three variations strategically to coach the totally different pec fiber divisions.

By pressing from different angles you’ll improve your pecs’ strength capacity and skills as an entire and be better suited to supply pressing force in a wider vary of contexts.

Whether you’re a newcomer gripping the iron for the primary

time or a seasoned fitness center veteran, these insights will gas your journey to peak bodily

kind. Let’s ignite that enthusiasm and

cost headlong into reworking your workout regimen. Carry Out the exercise

in the exact same method because the dumbbell press,

except utilizing a barbell gripped with both arms instead of individual dumbbells.

Set the bench at a 30 to 45-degree incline beneath a rack with the bar loaded.

As we talked about, dumbbells are mentioned to provide larger activation of the pecs, but not as nice of a load

can be used. So, they’re very efficient and most lifters use dumbbells as much if no more than barbells.

Often they may use barbell for one major lift (i.e.

flat bench or incline bench) after which dumbbells for the other urgent variations

or chest workouts.

You’ll restrict the amount of weight you possibly can deal

with, however it’s the easiest way to strategy the leg press for muscle constructing functions.

This three full-day plan permits you to push exhausting, each workout,

because it offers you loads of relaxation time between classes.

Three efficient exercises per week goes so much further

in boosting fitness targets than 5 to six mediocre exercises.

The bro cut up is a 6-day cut up workout that involves training each muscle group as soon as per week.

With the bro cut up, you do a quantity of workouts per physique

part to hit it from plenty of totally different angles and accumulate plenty of hypertrophic training volume.

I primarily design exercise plans and share science-based and practical info that can assist you to turn out to be stronger, practical,

and healthier. Sam Sulek follows a simple and low-volume exercise routine that involves training daily for about minutes.

The means you’ll do it’s by splitting these 12 reps into mini

‘clusters’ of 3 reps. After every cluster you’ll rest 20 seconds and maintain repping out units

of three till you full all 12.

Below is a breakdown of an optimized weekly coaching

plan to prioritize energy and muscle development while minimizing fat achieve.

(Yes, solely three days per week.) Each workout should take you about minutes,

door to door. Rest no less than ninety seconds between workout routines

similar to bicep curls and Romanian deadlifts, and up to 3-4 minutes in your

heavier sets of bench presses and squats. A good guideline is to rest lengthy sufficient to maneuver heavy weight, but not long enough to chill down.

In Week 1 you’ll perform three units of every train per exercise,

which over the course of the week provides up to 9 sets total for each bodypart, an excellent starting quantity for your

functions. With the exception of crunches for abs, you’ll do 8–12 reps per set.

One key supplement he provides to his shakes is glutamine, which

helps with every little thing from aiding your immune perform to selling digestive

health to supporting muscle restoration. The second train of the

day is a machine shoulder press. On the third set, do a drop set

to get in some extra volume. Next up is a seated dumbbell lateral increase, and you may carry out a drop

set on the second set.

Alan Ritchson begins the training week with an intense lower body workout.

He does not lean heavily in the path of one muscle or the opposite.

As A Substitute, he ensures to get a balanced training session by which he focuses on all of the

decrease physique muscle tissue like quadriceps, hamstrings, glutes and calves.

Even Bumstead does not stay at 5,000 calories year-round.

As he will get nearer to his pre-season coaching,

he tapers to between three,000 and four,000 calories per day.

Primarily aimed toward non-beginners, although all are welcome.

Really Feel free to share this article on your social media, and tell your friends

which considered one of these training splits you’re doing.

This also permits you to spend more time on every muscle,

which is another reason so many bodybuilders use this break up.

To the first point, this exercise split is based on the ‘push-pull-legs’ concept.

The aim here is to simply you some concepts on how to use

completely different coaching splits. Warming up is important to prime your body to raise

some heavy weight.

These exercises are going to take lots out of your body. Make sure you provide your physique with

the time it needs to recover between workouts by taking notice of your rest and

sleep. To do that, you could improve the dimensions of every meal, eat an additional meal per day, add a few snacks, or chug down a weight gainer shake.

It doesn’t matter HOW you create your calorie surplus as lengthy as there could be one.

You can’t expect to be on a fats loss food plan and gain muscle.

Nevertheless, if you are a beginner, you can build muscle with out worrying about bulking.

Be that as it might, you still might want to eat over your vitality upkeep stage.

In 30 days, I had put on 18 kilos (pictured below), increased the strength for ALL

of my lifts, and felt more assured than I ever had earlier than in my life.

As a extra weathered, experienced lifter although, progress is more durable to achieve.

The further away you progress out of your ‘genetic set point’, the

tougher it is to construct extra mass. To create maximum mass in simply 4-weeks you want to select the best, efficient workout routines.

If you’re requested to carry between 6-15 reps, progressive overload means choosing a weight that makes it

unimaginable to do greater than 15 reps… but simple sufficient

to crank out greater than 5. However, as a beginner this program will chew you up and

spit you out.

This is an intense muscle-building program designed for these with decent conditioning.

If you’ve been lifting for a minimum of a quantity of months and are wanting to step issues up a gear, this is for you.

It’s a rough and ready method to muscle accretion –

no real plan for food regimen, just eat, eat, eat.

However again, every person’s own needs, targets, and preferences must be taken into

account. In my expertise, I’ve found that males do greatest beginning

in the 10-12% range after which slicing once they attain 15-17%.

And girls do best beginning within the 18-20% range after which chopping when they

attain 23-25%.

You don’t have to get that close to failure on front and aspect planks.

But it’s additionally okay to think of these workout routines more like drills, a

stretching routine, or a cooldown. They’re there to teach you the means to maintain a

rigid posture beneath load. Examine that to a slicing workout, where you

may have much less vitality, and all you want to do is maintain your

muscle measurement. Sustaining muscle requires far

much less stimulation than gaining muscle, so slicing exercises could be shorter and simpler.

But whenever you follow full physique coaching you shift emphasis from muscle to

muscle which helps you to maintain energy while decreasing fatigue.

Splitting the physique over four coaching days, you’ll use a choice

of unpretentious and effective workout routines, sans complex methods and tricks.

Carry a heavy weight for the prescribed reps, rest two minutes

and do it again. When you’ve been lifting for years, you can’t add muscle mass in a short period of

time, regardless of the way you eat. That signifies that when you start pounding the calories, the pounds you add to your body shall be fat weight.

Gaining muscle and dropping fats with a year-long bulking plan requires cautious monitoring of progress.

If you favor, you can do them one after the other—”straight units.” Up to you.

You may wish to embrace some workout routines that help together

with your posture and lifting method. And you don’t have to spend greater than 5 minutes on them

every workout. You can do them during warm-ups, relaxation instances, or at the finish of your workouts.

Once you’re too robust for them, drop them out of your routine.

Notice within the exercises under that your first set calls for eight reps, your second set

10 reps and your third set 12.

They will go to a restaurant, order a major course that has around 700 energy then get dessert at the end, which provides 500 energy

to their meal. Whereas the principle course might have all been used to build muscle and function the physique, in essence consuming the dessert was the

same as consuming a slice of body fats. It’s hard to know what it feels

wish to get 2–3 reps from failure until you have lots

of apply lifting to failure. So, I recommend taking the ultimate

sets of some exercises all the method in which to failure.

Plus, the nearer you go to failure, the extra muscle development you stimulate per

set.

If you do, you’ll construct muscle, get stronger,

and most significantly, get more healthy. “Are you attempting to construct muscle mass and energy by lifting heavy weights? “Are you correcting an imbalance or rehabbing an harm with a resistance band?

” In either scenario, you can count on higher glute benefits. Finally, the place of your body means you should use your legs and back to help you raise the weight as your biceps begin to fatigue.

Then we’ll observe your progress as you go through the program, guaranteeing you get the absolute best results. This article gives you every little thing you have to start coaching for muscle progress. Feel free to ask questions within the feedback down beneath.

Nothing will change with the plan anyway, so you presumably can deload at your individual tempo. You may even change to a different certainly one of our exercise plans and just make use of the same progressive overload tactics. However, we recommend just sticking to the bulking plan beneath throughout your bulk if you are solely bulking for 3-6 months. I believe the best exercise plan for bulking is one that emphasizes consistency over complexity.

And as the holy grail of physique composition coaching, this lean muscle plan is essentially the most challenging however rewarding program you’ve ever tried. If you want us to stroll you through the process of building muscle, begin to end, with private suggestions along the way in which, try our packages. We have an unconditional 30-day refund policy on every little thing we sell. We contemplate lifting research, and we take it critically, however we additionally delve into the darkest corners of lifting lore.

You can choose dumbbell, barbell, or train machine variations utilizing the dropdown menus within the workout sheets. We additionally teach the dumbbell variations in the exercise tutorial movies. I made a tutorial video walking you thru the whole workout routine. I additionally clarify how to lift in a means that maximizes muscle growth. Traditional bodybuilders like Steve Reeves caught with full-body workouts all through their entire lifting careers.

And they let you do the biggest, best workout routines 2–3 times per week. There’s a huge amount of proof showing that high depth energy training with larger quantity ends in vital muscle mass gains [1]. Ritchson engaged in different coaching strategies like bodyweight and weight training among others to achieve practically 35 lbs of lean muscle mass over the interval of eight months.

As the pair transitioned into the muscle growth-focussed “lean bulk” phase, Thurston gradually increased Graham’s every day energy to around three,000. Whereas it’s essential to consume sufficient calories and protein in your food plan, supplements can also be useful for bulking up and supporting muscle growth. You need to follow a bulking workout plan that features compound workouts, isolation workout routines, relaxation, and restoration. As a personal trainer, I usually get requested about the best exercises to build muscle mass.

Our employees of licensed coaches, physicians, and dietitians will create a program

tailored to your needs and goals and maintain you motivated throughout your

training journey. Weight Use a weight that leaves you 1 to 2 reps wanting failure,

e.g. So, instead of pondering when it comes to “better,”

consider the benefits of every and how they can match into your overall coaching strategy.

Persevering With with the concept above, the speed at which you carry out each

rep matters as it could immediately impression the intensity you feel.

It’s not just about how heavy the load is but how onerous the set feels.

When you’re hitting those Bench Presses or Push-Ups, this is

the muscle you’re working.

Compound lifts are good for constructing muscular tissues normally, but it’s

important to do isolated actions that work with particular muscle

teams to make your muscles stronger. It’s a dynamic movement that

challenges your core, shoulders, and upper chest uniquely.

The dumbbell incline all over the world, also identified

as the incline crossover twist, is an advanced train that takes chest training to a whole new level.

Using a stability ball as a substitute of an inclined bench adds instability

to the exercise, which forces the recruitment of many

stabilizer muscles, especially in your core.

If you’d like to train with Barbell Medication, attain out to us to get

a customized fitness program delivered right

to your inbox. We welcome the opportunity to learn extra about your individual

training goals and expectations and help you obtain them.

You’ll feel the burn quicker and with far less weight, but you’ll see strength gains notably faster.

For muscle growth, working at intensities that convey you near, but not all the time to, failure can be helpful.

The flooring press emphasizes the upper chest and triceps greater

than a regular bench press, because of the shorter range of motion.

The greatest lower chest workout routine will embody effective exercises to target the abdominal head of the sternal area.

This is somewhat more sophisticated, because it makes use ofsuper sets, large

units and exercises not on our list above, as we

attempt toincorporate some additional muscle groups into our chest workout.

This isn’t simply lifting weights; this is about

partaking the best muscle tissue and doing it successfully.

It’s easy to let different muscular tissues leap in and take over however

keep the concentrate on the shoulders. Now that you know

where the deltoid heads are, you’re going to

have a much easier time activating and contracting them throughout the following efficient

workouts. The muscular tissues on the outer a part of your shoulders, known as lateral deltoids, start from a particular level in your shoulder blade known as

the acromion process. It’s simply as essential (more so) to know how the muscle fibers work

as it is to study efficient shoulder workouts for them.

A shoulder workout with cables also can tackle

muscle imbalances and cut back the danger of shoulder damage.

Set a seated bench directly between 2 cables facing away from

the machine. Set up in a break up stance with one foot in entrance of the opposite to remain balanced.

Keep a slight bend in your elbows as you squeeze your chest to raise your

arms in front of you. Muscle fibers from this complete vary come together into one single

tendon that inserts on the entrance of your higher arms.

The Smith machine decline bench press eliminates some want

for shoulder stability in the course of the train, allowing the lifter to isolate the lower chest muscles better.

The decline cable chest press is a variation of the decline dumbbell bench

press. Throughout dumbbell incline bench presses, the resistance is directly downward, and your triceps brachii

take over a lot of the force from your chest at the top of

the press. During the standing dumbbell fly, the hand, and arm transfer through

an arc whereas the elbow stays at a continuing angle. The angle of the adjustable bench in this variation puts extra pressure in your lower chest

muscles than a flat bench press would. The Incline Bench Press train focuses on the upper

chest and helps construct a massive chest. The incline angle also

allows for greater activation of the anterior deltoids (front shoulder muscles).

Working out your chest targets two main muscle groups,

the pectoralis main and the pectoralis minor. The pectoralis main is the bigger of the 2 and sits on high of its smaller

pectoralis minor counterpart. Chest workout routines

prolong to target peripheral muscular tissues such as the serratus anterior,

deltoids, and subclavius. Strengthening the peripheral

chest muscular tissues is essential for stabilizing joints and bigger muscle teams.

For instance, doing a single arm cable fly won’t only work your chest muscle tissue, but

in addition your core muscle tissue.

Return to the starting position beneath management

and repeat for the desired variety of reps. You’ll really feel

the distinction as cables pressure every portion of your chest to work independently, carving out that sought-after

separation between your collar bone and rib cage. Picture chiseled traces across your chest –

every cable movement brings you nearer. Getting its

name from the rhombus (quadrilateral shape) the rhomboids are comprised of two muscles; the rhomboid major and minor.

The primary perform of the rhomboids is to help in the motion of the

scapula.

As you progress to the intermediate level, improve to

3-4 sets and goal for reps. Superior lifters can push further with 4-5

sets at reps. Adjust the cable machine settings primarily based in your peak and degree,

permitting for consistent resistance by way of both the reducing and lifting phases.

Keep your shoulders relaxed and retract your shoulder

blades as you carry out each exercise to avoid pointless strain.

Nevertheless, gym-goers who’ve been coaching for any size of time will know the worth

of the cable machine in carving out a giant chest. A cable crossover machine could be expensive and can take up plenty of area in your gym.

They can also be more difficult to use if you’re trying to isolate

smaller muscle groups. Standing cable flys help you develop a lean chest, and by mixing in some low

to excessive and high to low variations, you presumably can target all of the

different muscle teams.

A sluggish and steady tempo increases muscle fiber activation and promotes higher muscle power

and growth. With palms dealing with ahead and elbows barely bent, deliver your arms collectively in entrance of your chest.

Hold for a short moment before slowly returning to the starting position.

The latissimus dorsi is the biggest and widest muscle within the back and the largest muscle in the complete higher body.

Ensure proper type and control for damage prevention and maximize advantages.

Including this train in a chest exercise can contribute to general

chest improvement and strength. Incorporating the cable standing neutral grip fly into your workout

routine is significant for total chest improvement and strength.

The impartial grip (palms dealing with each other) hones in on the inner chest muscular tissues,

promoting balanced growth throughout the entire chest

region. It’s essential to prioritize kind

and management to ensure maximum effectiveness whereas performing this train. With Dumbbell Flys, you get a relaxation at the peak of the movement, when the

weights are directly over your chest and supported by your arms and shoulders.

Cable Flys, nevertheless, don’t have any “support point”, so your chest muscles are regularly beneath tension through the

entire movement.

The distinctive mixture of passion for my area

and the continuous quest for progress fuels my drive to break new floor.

Incorporating movements like weighted pushups or press ups

using cables allows a number of muscle teams to work simultaneously which is perfect for thorough compound exercise routines.

Chest workouts on cables require stability from varied muscle tissue together with abs

and exterior obliques; this promotes strong core growth throughout every train session. Begin with lighter weights or resistance levels, performing 2-3 units of repetitions for every train. Making

Certain that shoulder blades are retracted accurately and elbows

don’t lock throughout repetitions additional contributes to a safe training surroundings on the cable machine.

Emphasize controlled movement over pace to keep

each set effective—and most importantly—safe.

This train effectively isolates and activates your decrease chest

muscle tissue whereas also partaking your shoulders and triceps for stability and

support. Executing this exercise successfully and constantly can result in increased strength and definition in your higher chest.

It also helps enhance shoulder stability and overall upper body muscle stability, making it a useful addition to any

upper body workout routine. The dip scored 69% for total pec stimulation in one of many two studies

charted above, but the third study rated weighted dips the very best of all

exercises for lower pec stimulation.

Manish is a NASM-certified fitness and nutrition coach with over 10 years of experience in weight lifting and fats loss health teaching.

He makes a speciality of gym-based coaching and has plenty

of knowledge about train, lifting approach, biomechanics, and extra.

These approaches are wonderful for maximizing exercise efficiency by introducing

variations that problem completely different aspects of muscle efficiency without

extending workout length. Adjusting these durations based on personal needs is

essential as it ensures optimal balance between muscular problem and sufficient recovery.

Listening to your physique and maintaining proper type throughout

each set are equally necessary when modifying relaxation durations.

Rest intervals between units ought to be customized to align along with your health degree and objectives.

Like flat dumbbell press, incline dumbbell press lets you increase the range of

motion you’d normally use on barbell bench press. In 2025, consciousness of harm charges from improper fly kind has become increasingly essential, with studies indicating that poor method can result in shoulder accidents.

By avoiding these widespread pitfalls, you can significantly scale back your risk of injury and successfully enhance

your upper physique power with a chest fly workout. Using

the fly machine can assist in creating lean body mass and bone density, together with boosting your base metabolic rate.

This means progressively increasing the load or resistance of your workout routines over time

to stimulate muscle progress and power features. In addition to this straightforward routine, incorporating other efficient cable workout

routines like unilateral cable press or low cable

fly can present even larger selection in muscle stimulation.

To carry out this exercise, lie along with your head and shoulder blades supported by an train ball whereas holding

onto two cables hooked up to a excessive pulley system.

Interact your abdominals as you press up in the course of

the ceiling until each of your arms are absolutely extended before slowly decreasing the weights down again with management.

To perform this exercise accurately, stand with one foot slightly in entrance of the other and grasp a single-handle attachment hooked up to a low pulley with one hand.

Use your core to stabilize your body as you begin by bringing the deal

with in the direction of your midline until it’s near shoulder height

earlier than slowly reducing again to starting position.

For instance, unilateral cable press targets one side of the chest at a time, providing an intense contraction for greater activation of

the pectoral muscle tissue.

Lower chest exercises profit well being

and wellness by promoting core engagement, strength coaching,

and correct posture. Firstly, core engagement is crucial for creating stability while performing bodily actions.

The added stability prevents damage and encourages athletes to

work out using the correct type. Secondly, decrease

chest exercises promote energy coaching, which will increase the number of exercises athletes can carry out with out damage.

Thirdly, decrease chest exercises enhance posture,

which leads to a larger lung capability, and fewer back and shoulder pain. In addition, the fixed tension throughout the vary of

motion supplied by cable machines, such as cable crossovers, offers a extra important stimulus for general muscle growth.

The neutral grip can result in greater triceps engagement than the standard grip.

You can nonetheless use an incline bench to do that train, but you’ll want

to adjust the bench to get a good contraction. The decrease chest is doubtless considered one of the more durable areas to train due to the

dearth of variations obtainable and the limited vary of

movement. It is carried out on a decline bench, which is

set at a downward slope of around 30 to 45

degrees.

Design your working set based on your fitness objectives, or do that workout.

Complete three units of each of those moves beneficial by Gardner, Gagliardi and

Ezechibueze, doing 10–12 reps of every train. “Commit five to 10 minutes to this period of lighter exercise”, Gagliardi stated.

Start by setting the cable machine to a excessive position with handles hooked up.

Stand in between both pulleys and seize the handles with a neutral grip, palms facing each other.

Transferring from the security benefits of cable pec workout routines, let’s delve into how they excel

in muscle activation. Cable machines offer a constant pressure on your pectoralis major, which

is key for stimulating development and energy.

Engage your core throughout the exercise while maintaining

stability and management during both phases of movement.

The lats, rhomboids, trapezius, rear deltoids, and spinal erectors are underneath pressure throughout this exercise, serving to to

build not solely a stronger again, however stronger deadlifts and again squats.

If you have to use your entire physique to twist and rock the burden up then the dumbbell is simply too heavy.

The most popular different to Barbell Rows is probably the One Arm

Row. The Only Arm Dumbbell Row is great if you have dumbbells

however no barbell or if you would like a rowing motion that allows for extra low back support.

Bent Over Barbell Rows are top-of-the-line exercises

for constructing a bigger and stronger again. Using a barbell permits you to

work heavy and bent rows will problem your complete again from prime to bottom.

Suspension trainer rows utilize suspension trainers to target

the back muscular tissues and enhance back strength and stability.

Start in your weaker side and match the work along with

your dominant arm to even out muscular imbalances. If you don’t have access

to a landmine system, you possibly can place a barbell in the

corner of a room and use towels or mats to keep away from damaging your

walls. If you battle to grip the end of the barbell, use

lifting straps to secure it in place.

The seated cable row provides an excellent stretch for the lats

and trapezius and in addition allows you to use some pretty heavy

weight. With repeated, heavy use this could contribute to deterioration of your spinal discs

and, eventually herniation on the sacral degree. Since I simply gave you

the 16 best one arm dumbbell row alternatives,

it’s up to you to choose which ones you wish to try. To round out the one arm dumbbell row

options to a traditional row, here’s one other method to make lighter weight feel heavier.

In terms of general effectiveness and security, the one arm dumbbell row

is among the best workouts you are capable of do. You goal a number

of muscle tissue in your upper again and aren’t putting your

lower again into any sort of vulnerable place. One arm dumbbell row alternatives may

give your training a breath of contemporary air to keep things fun and attention-grabbing.

Combined with the higher loading capacity of the Yates row, one can see

why it’s thought-about to be a more superior motion than the standard bent over row.

To carry out a repetition of the T-bar row, both affix a T-bar deal with and landmine equipment to reverse

ends of a barbell or just load a T-bar machine. In Any Other Case, the T-bar row and bent

over row are much the identical in that they work the posterior deltoids, trapezius,

the various rotator cuff muscular tissues and the elbow flexors to an analogous diploma.

In addition, the barbell row isn’t quite as efficient as the lat pulldown for training the lats.

Technically, the Yates row is extra of a barbell row

variation than it’s another. Nonetheless, the explanation I’m including it on this list is principally as a end result

of the upright torso position signifies that it’s not as onerous on the

spinal erectors as common bent-over rows. This means the lower again goes to be concerned to a

higher extent than the chest-supported row.

If you have access to cables, you can also do a seated cable row since they’re very similar.

Since the single-arm dumbbell row is a compound movement,

carry out it close to the beginning of a back-focused exercise.

You can also carry out this exercise with a kettlebell if you don’t have

entry to dumbbells. Fortunately there are many barbell row options you can do to construct and strengthen your

back. We’ve put together our definitive record of

the top 10 bent-over row alternate options below!

Additionally, the angled grip and impartial wrist position put less stress on the wrists and

elbows. Novices getting into row weightlifting ought

to stick to the seated cable row. It’s probably the most beginner-friendly

alternative, and you’re least more doubtless to injure yourself when performing it.

The one-arm dumbbell row is a bent-over row substitute focusing on the latissimus dorsi, traps, rhomboids, and

biceps for bodybuilders. It won’t allow you to use as much weight as the bent-over row, so it’s not the most effective for powerlifters.

Similar to the barbell row, the gorilla row targets the identical muscle teams with the

added benefit of intensified core and spine stability work.

What units this exercise apart, aside from the distinctive position, is the incorporation of alternating dumbbells in each

hand. As one arm executes a row, the opposite engages in a urgent motion against the load on the

ground. This alternating motion not solely

enhances core stability but also promotes shoulder mobility.

The underhand barbell row allows one to lift extra weight and move by way of higher vary of motion, which is why it is a revered bodybuilding t-bar

row alternative. They are an ‘easier’ version of the T-Bar row and a

useful substitute to incorporate in your program

extra frequently. Seated cable rows carefully mimic the

motion pattern of T-Bar rows, especially should you

use the narrow grip deal with attachment and

keep your elbows tucked in near the body.

Various workouts can goal different angles and supply a different vary of motion, which may

additional problem the muscular tissues and lead to better general energy and

growth. To execute the barbell row accurately one must be sustaining a impartial spine and squeezing the shoulder blades together throughout the motion. This will

ensure good posture and keep away from injuries such as chronic back pain. Emma

loves constructing her own useful energy and fitness exterior of work with numerous training types, from weightlifting to calisthenics,

yoga, and dancing. She advocates for the powerful potential of exercise

to improve bodily, mental, and emotional health and well-being.

For more detail, try our article on the muscles labored by barbell rows.

So the upper and center back will be the true limiting factor for this exercise in comparability

with your lower again, core, or forearms. As they squeeze their

lats, the handles must be pulled in direction of the

shoulders by bending the elbows in the path of the perimeters of the torso.

Named after long-time Mr. Olympia legend Dorian Yates, the Yates row is just as distinct amongst its friends due to its extra vertical torso orientation and historically underhand grip.

In addition, the bent over row is characterised by a wider than shoulder-width pronated hand orientation, of which isn’t

the most effective for recruitment of the biceps brachii.

I’m personally an enormous fan of unilateral workout routines, however it would

not be right to incorporate one instead for a bilateral

motion. Individuals who lack shoulder mobility

may also struggle to get a full range of motion on this exercise.

Hear to your physique and experiment with a variety of workouts to find your personal list of greatest movements.

If you’re really lucky, your T-Bar Row machine will be one

which also includes chest assist. It provides stability and allows for centered strength training of particular muscle groups, making it easier

to target and isolate muscular tissues for growth. Nevertheless,

it might be particularly beneficial for beginners as a result

of it is easier to hold up proper technique

than rows with a barbell or dumbbell.

Barbell rows load your lats and again muscles with heavy weights while strengthening your core and

hamstrings. Bent-over barbell rows trigger some lifters

to expertise decrease back ache. Others lack the core stability or grip power to

get essentially the most out of this train.

You can do bodyweight rows anywhere you’ll find a stable horizontal bar, such as at a playground or out of doors fitness center.

Using the help of a bench to anchor your physique

as you row one arm at a time minimizes pressure on the lower again. If you

prefer a visible demonstration, this video tutorial is a good way to study seated cable rows.

They are an excellent foundational again exercise for building muscle and power.

The Helms Row is a bilateral dumbbell rowing train that is carried out together with your upper chest supported on the end of

a bench. The bent-over barbell row is a superb t bar row various and may be

performed using both an overhand or underhand grip.

By incorporating the barbell row into your exercise routine you possibly can successfully strengthen and develop the muscles in your upper again, enhancing your general posture and upper physique energy.

Moreover, the barbell row activates the biceps and forearm muscular tissues as secondary movers.