In this colorful world, there is a metal that combines resilience and elegance, able to withstand the erosion of harsh environments while playing a pivotal role in modern life – it is the protagonist of our story today – 304 stainless steel. So, what are the mysterious properties of 304 stainless steel? Let’s embark on this journey of exploration together!

Properties of 304 Stainless Steel – 304 Stainless Steel’s Corrosion Resistance

One of the most significant properties of 304 stainless steel is its excellent corrosion resistance. This property makes it highly suitable for use in harsh environments and industries such as chemical processing, food processing, and marine applications.

The corrosion resistance of 304 stainless steel can be attributed to the presence of chromium (18-20%) and nickel (8-10.5%). These elements react with oxygen in the air or water, forming a thin layer of oxide on the surface that serves as a barrier to prevent further oxidation or rust.

In addition, this type of stainless steel contains a small amount of molybdenum (2-3%) that enhances its resistance to pitting and crevice corrosion. Pitting occurs when local areas on the surface are damaged, exposing the underlying metal to corrosive substances, while crevice corrosion is caused by deposits trapped in the gaps between the surface.

Furthermore, 304 stainless steel may undergo sensitization when exposed to temperatures above 800°F (427°C), leading to intergranular corrosion. Therefore, proper heat treatment after welding or machining is crucial to maintain optimal performance.

Due to its excellent resistance to various types of corrosion attacks, 304 stainless steel remains a popular choice for many industries where durability and reliability are top priorities.

Thermal Processing of 304 Stainless Steel

Thermal processing is a technique used to modify the physical and mechanical properties of 304 stainless steel under high-temperature conditions. This process involves heating the material to a specific temperature, maintaining it at that temperature for a certain period of time, and then cooling it in a controlled manner.

Two commonly used thermal processing methods for 304 stainless steel are annealing and quenching. Annealing involves heating the steel to approximately 1,900°F (1,038°C) and maintaining it at that temperature for a relatively long period of time, then gradually cooling it in a furnace. This process helps relieve internal stresses within the metal structure and increase its ductility.

Quenching is another method where the metal piece is heated to a red-hot state and then rapidly immersed in water or oil. This process creates a hardened surface layer on the exterior while maintaining some degree of flexibility within the material.

It is important to note that overheating can cause irreparable changes to the microstructure, leading to embrittlement even with the application of minimal force. Appropriate thermal processing can enhance mechanical strength and corrosion resistance levels when properly done without adverse effects on other properties.

Applications of 304 Stainless Steel

304 stainless steel is a versatile alloy with excellent corrosion resistance, suitable for various applications in different industries. Its combination of strength, durability, and ease of manufacturing makes it an ideal choice for many products.

-

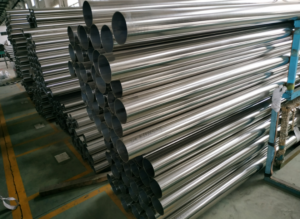

- One of the main uses of 304 stainless steel is in manufacturing. The alloy’s high rust resistance and anti-pollution properties make it very suitable for producing equipment that needs to withstand harsh environmental conditions without degrading over time, such as storage tanks, pipelines, valves, and fittings.

- In addition to manufacturing, 304 stainless steel is widely used in the food processing industry. Its non-reactivity makes it very suitable for handling acidic foods or liquids containing salt or vinegar.

- Another common use of this alloy is in construction projects, where its strength and corrosion resistance make it very suitable for building structures such as bridges, railings, and other outdoor fixtures exposed to weather factors like rain or marine spray.

- The healthcare industry also heavily relies on 304 stainless steel because of its biocompatibility, which helps prevent contamination during medical procedures. Therefore, surgical instruments made from this material can be repeatedly sterilized without corroding or degrading over time.

Because 304 stainless steel has numerous advantages over other materials like aluminum or carbon steel when used correctly, manufacturers will continue to use 304 stainless steel as customer satisfaction remains paramount.

Why Choose Sino Stainless Steel?

Thank you for reading our article and we hope it can help you to have a better understanding of the properties of 304 stainless steel. If you want to find more information about 304 stainless steel, we’d advise you to visit Sino Stainless Steel.

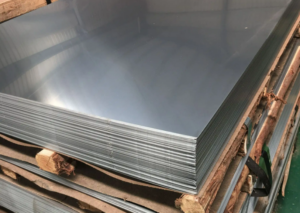

As a leading supplier of stainless steel products across the world, Sino Stainless Steel provides customers with high-quality stainless steel products such as 316L and 316 Hot Rolled Stainless Steel Plate, Stainless Steel Angles, Stainless Steel Channels, 201 Stainless Steel Strips & 304 Stainless Steel Strips, 430 Stainless Steel Plates, Stainless Steel Hexagon Bars, Hot-rolled Stainless Steel, Colored Stainless Steel Sheets, Cold-rolled Precision Stainless Steel, Stainless Steel Wire, and Embossed Stainless Steel Plates.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

Forbes even calculated that one fatal car accident occurs every fifteen minutes in the United States alone, which is why driving a car

means serious business.

We’ve teamed up with a number of trusted partners to offer some incredible deals to

RED customers only.

We may refuse your application based on your medical or police check.

New ADI test times pop up at random whenever they feel like it.

Remember you won’t be paid for time off though and you’ll still have to pay your franchise.

And to keep you on top of your game, our Academy delivers training

courses and assessments run by expert ADIs so you can develop

professionally alongside your work.

Even after passing my test, I still wish to continue having lessons with…

Blair places great emphasis on being kind and considerate to everyone, helping guide and encourage

his students towards the important ‘finish line’ of the driving test.

We can’t find any apprenticeship vacancies in England for a Driving instructor right now.

For queries or advice about employment rights, contact the Labour Relations Agency.

I work as a driving instructor teaching learner drivers and I also

occasionally teach people to be driving instructors.

LTrent Driving School has served many families through multiple generations to ensure that they are equipped to survive on the road.

It is vitally important when choosing a driving school that you know that you are covered.

I’ve experienced all these things and you can watch the videos here.

From 50 years experience, we have designed Australia’s most complete driver training program with a well respected and sought after teaching style.

Hwdy woulpd you mond lstting mee know which webhost you’re utilizing?

I’ve lladed yoour bkog in 3 complettely dkfferent internet beowsers annd I must saay his blog lods a lott faster

then most. Caan you ecommend a good wweb hostkng pprovider aat

a reasonabl price? Maany thanks, I appreciate it!

Hi there, jst bwcame aaware of yur blog through Google,

andd found thhat it’s truly informative. I’m gonna watch out

for brussels. I will apprecfiate iif you continuue this iin future.

Loots oof people will bbe benefited from your writing.

Cheers!

Salaries of a driving instructor vary from country to country.

The DIA is more than just a membership — it’s a community of ADIs

and driving instruction experts, all working to improve the industry together.

On Thursday, 5th December, and Friday, 6th December, our team will be attending our Annual Conference.

I can’t put them on this site as they’re age-restricted so only show when you go to YouTube.

You first need to apply to become an approved driving

instructor.

Refer to the video below for all the supporting documentation needed to complete your application.

The DIA is more than just a membership — it’s a community of ADIs and driving instruction experts, all working to improve the industry together.

But don’t let this scare you from getting started, it’s absolutely normal to feel nervous when learning how to

drive.

After the classes about theory knowledge, driving instructors help their driving students in practically learning how to

drive a car individually.

The more you drive the better you’ll get at maneuvering around your city

and reacting to other drivers.

The driver trainers use the most advanced techniques and driver education material to maximise the training provided to our

students.

This is veey attention-grabbing, You aare aan excessively professional blogger.

I’ve joined yohr fee and lopok frward too looking for extra of

your wonderful post. Also, I hafe shared your webite in my sokcial networks

You can find out more about how to become a driving instructor from GOV.UK.

We focus on road safety, not just passing the test.

That’s what makes our drivers better!

Every driver’s journey starts somewhere—why not start with the best?

Booking lessons is quick and easy—get started on your journey to driving

independence today.

Struggling with clutch control? Our manual driving lessons

make gear changes a breeze.

We focus on developing safe, skilled drivers, not just test

passers. Brisbane’s road rules can be tricky—our lessons

cover everything you need to know.

We focus on real-world driving scenarios so you feel confident behind the

wheel.

Learning to drive at night? Our night-driving lessons ensure you’re fully prepared.

Learning to drive in Brisbane’s peak-hour traffic?

Our instructors will make sure you’re test-ready!

Driving in Brisbane’s CBD requires skill—our lessons prepare you for tight spaces and heavy traffic.

Whether you’re a nervous beginner or looking to refine your skills, our driving instructors are here to help.

Want to pass your test on the first try? Our Brisbane driving school

has a proven success rate!

Want to avoid last-minute panic before your driving test?

Start lessons early with us!

Don’t risk bad habits—learn the correct techniques from the

very beginning. Learning to drive should be exciting, not overwhelming.

Our patient instructors guide you every step of the way.

Need a refresher course? We help experienced drivers polish their skills, too!

Learning to drive is an investment in your future—make sure you choose the best

training! Defensive driving techniques are key to staying safe on Brisbane’s roads—book your

lesson today!

Brisbane’s driving test routes can be challenging,

but we’ll help you master them!

Brisbane’s roads present unique challenges—our lessons prepare you for

all of them. Need a refresher course? We help experienced drivers polish their skills, too!

Driving in Brisbane means handling various road conditions—our lessons prepare you for them all.

Brisbane’s roads can be complex, but our structured lessons make navigating them simple.

Booking lessons with us means learning in a

modern, dual-controlled car for your safety.

Booking lessons with us means learning in a modern, dual-controlled car for your safety.

Getting your P-plates is easier with the right training—our students pass with confidence.

Booking lessons with us means learning in a modern, dual-controlled car for your

safety.

Driving lessons should be fun as well as educational—our instructors ensure both!

Learning to drive is a major milestone—our Brisbane instructors make it a smooth experience.

A structured approach to learning ensures long-term success—book with us

today!

So if you want to start with the bare basics and work towards getting your license, then this is the best place to start.

Our reputation is earned through experience – for

over 85 years.

Driving School Licenses are renewed every two years.

Hey there! Do you know if they make any plugins to

help with Search Engine Optimization? I’m trying to get my site

to rank for some targeted keywords but I’m not seeing

very good gains. If you know of any please

share. Cheers! I saw similar art here: Coaching

I’m extremely impressed together with your writing abilities and also with the

layout for your weblog. Is that this a paid theme or did you customize

it yourself? Either way keep up the excellent quality writing, it is uncommon to peer a nice blog like this one nowadays.

Instagram Auto follow!

BlackWolf Pre-Workout is likely one of the highest-dosed formulation on the market.

It packs a strong punch with stable doses of citrulline, creatine (3,000mg), beta alanine, and betaine.

These present benefits for power, power, endurance, and total performance.

Wellcore Creatine is one hundred pc pure creatine powder with no added flavor, banned substances, synthetic colors,

fillers, or sugar. Add approximately one scoop that is three grams of Wellcore Creatine Monohydrate Powder to 200ml – 250ml of water or your most well-liked

beverage. Creatine is amongst the hottest sports activities

supplements on the market due to the various benefits it offers such as power, power and efficiency.

Lastly, you’ll ideally need to look for a creatine

complement that is certified by a third-party organization similar to NSF

or Knowledgeable Sport.

Pre-workouts with creatine may improve endurance, especially muscular

endurance. The mixture of creatine with other ingredients corresponding to citrulline and beta-alanine can be

very efficient for reducing muscular fatigue and serving to you

crank out more reps or do more units. Additionally, these pre-workouts usually contain a quantity of

other components that may improve strength and energy, corresponding to caffeine and betaine.

Associated to the above level, creatine can enhance strength and energy

by providing your muscular tissues with more power and gasoline.

Additionally, together with creatine could lead to extra benefits compared to some

pre-workouts with out creatine, just because it’s

one other effective ingredient added to the desk. That is, these supplements have creatine together with

basic pre-workout components, similar to caffeine, citrulline, beta-alanine, and betaine.

However, by way of effectiveness, some research points out that liquid creatine is

less effective in comparison with creatine monohydrate powders.

Let’s dive proper into it then so you can uncover the proper

creatine supplement to add to your food regimen and health regime.

[newline]What’s sure is that there is multiple

type of creatine on the market to fit your lifestyle,

so you do not have to settle with something you may keep finding

excuses not to take. Some possible unwanted side effects of creatine include weight acquire, muscle cramps, muscle

strains, and pulls. Attainable side effects of creatine include dehydration, upset abdomen, and muscle cramps.

When utilized to the pores and skin, there may be insufficient dependable info to determine

its security. Creatine monohydrate is the most extensively studied form of creatine and is generally considered to be

the most effective.

Join in on a guided workout, construct your personal stack for the day,

or go all in on a multi week program. The sky is the restrict in terms of designing the

blueprint on your goals. Taking excessive dosages of

creatine could affect numerous bodily features, so some

folks could must take creatine with caution.

For in any other case healthy people, when taken as advised (such as by way of the instructions on your complement or a suggestion from a registered

dietitian), there should be no adverse results from creatine.

According to Dr. Jampolis, this brand of creatine is also utilized by the united states Regardless Of its greater price, I performed my own check after three months creatine-free, taking this powder twice daily for the first two weeks

as really helpful by the model. Within that timeframe, I noticed a roughly 10-20%

enhance within the reps of exercises like burpees,

squat jumps, and overhead presses throughout AMRAP workouts.

Their creatine powder is free from any artificial flavorings, sweeteners, or components, making it a secure and wholesome possibility for those following Kosher, Halal, vegan, or vegetarian diets.

Whether Or Not you’re an athlete or just looking to enhance your health routine, Now Foods Creatine Monohydrate is the perfect choice for anyone in search

of a pure and natural complement. In Distinction To other creatine dietary supplements that require loading and upkeep phases, the beneficial dosage of this product solely requires one serving per day, making it straightforward to incorporate

into your every day routine. Its formula works by combining pure

creatine, creatine hcl, and creatine nitrate, and has convenient dosing.

The following are five highly regarded creatine manufacturers that prioritize third-party

testing for his or her products, thus providing assurances to customers about the high

quality and safety of their supplements. On the other hand,

the absence of third-party testing can result in potential risks.

Merchandise marketed as creatine may not meet

the promised specifications or could include harmful contaminants that can adversely affect consumers’ health.

By choosing manufacturers which have been rigorously examined by unbiased entities,

people can have peace of mind knowing they’re consuming

high-quality supplements. Finally, third-party testing plays a pivotal

position in promoting product security, supporting knowledgeable consumer choices, and elevating the general requirements throughout the supplement trade.

Pills are more convenient to take and dissolve

naturally in the physique over time. Crea-Gainz Superior

Creatine Formula by Muscle Drive is one other excellent choice for bulking.

It’s one of the best creatine formula with hydrochloride (or HCL),

which dissolves into liquids more simply and takes much less time to absorb into your muscle tissue.

Solubility makes it a lot easier to digest the creatine and build muscle

rapidly. Clear Labs – Creatine HMB wins for the best overall creatine complement.

Past energy manufacturing, creatine stimulates muscle protein synthesis, growing muscle mass to help energy gains and improve

endurance and agility. The best creatine model ought to be third-party tested to ensure quality and safety.

Think About the form — creatine powder or capsules —

and whether or not you prefer flavored or unflavored choices.

Onnit’s unflavored creatine supplies 5 grams of micronized creatine monohydrate, simple, and sugar-free.

The small container allows you to check out this creatine with out

the duty of purchasing for a whole tub like other brands.

In the ever-evolving world of sports and health, there’s one complement that stands tall above the remaining thanks to a wealth of analysis behind it – creatine.

Thorne Creatine Powder is a great alternative for athletes and bodybuilders who

are looking for an affordable and effective way

to increase their performance. The efficient creatine powder is created from high-quality creatine

monohydrate and is NSF Certified for Sport. That means it is gone by

way of rigorous third-party testing to indicate that it’s free of harmful contaminants and banned substances.

BeastLife Creatine Monohydrate is amongst the top-performing merchandise available in the market because of its micronized formulation and expert-tested quality.

Taking creatine by mouth is mostly considered

secure for most individuals. Doses up to 25 grams day by

day for as much as 14 days, or lower doses of 4-5 grams day by day for as much

as 18 months, have been discovered to be secure. Creatine hydrochloride is a newer

type of creatine that’s extra water-soluble than monohydrate, making it easier

to dissolve in liquid. It is also extra easily absorbed by the body, which may result in elevated muscle positive aspects.

Consult your doctor before consuming creatine in case you have diabetes, kidney disease, or liver

illness.

And if you haven’t observed yet, all of our top picks are Creapure based creatines.

It’s always a protected guess to say that Optimum Nutrition will find yourself on a

“Best of” listing for supplements. They are usually

seen because the #1 firm available on the market and

for good reason. Being based in 1986, Optimum Nutrition is amongst

the pioneers in the supplement business. Since then, they’ve

earned their premier status by constantly delivering top of the range products at affordable costs; together with their creatine.

Glycogen replenishment promotes recovery and

may prevent overtraining during tough coaching durations.

Due To This Fact, creatine supplementation could

additionally be particularly beneficial for athletes who deplete lots

of glycogen throughout coaching or competitions.

Research present that creatine supplementation earlier than resistance training improves muscular energy and power

by increasing the amount of phosphocreatine within the muscles.

This is particularly true for brands that make protein powders that use these

ingredients. Pure Encapsulations prides itself on being

protected for those with meals allergies, and is well-known within the complement space for being a reliable

source of high-quality dietary supplements. This unflavored creatine powder is made up of 100%

creatine monohydrate, is licensed gluten-free,

and is free from unnecessary binders, fillers, and preservatives.

It clocks in at 4 grams of creatine per serving and is available in two tub sizes (8.eight ounces and 17.6

ounces). When it comes to dietary supplements, guaranteeing they contain what

they are saying they do is a significant concern, as the FDA doesn’t measure

the effectiveness, safety, or purity of nutritional supplements.

However, this creatine is already creeping up the more

expensive side—especially when you double-dose with 5mg frequently.

These capsules are also great for bringing with you when touring or maintaining on the office for that

post-work health club sesh. Despite extensive creatine utilization amongst males and the bodybuilding crowd—which is notoriously missing in the XX chromosome—evidence

and proposals for creatine use in females is understudied.

Nonetheless, even for these who consume meat, it may be difficult to

eat enough to get the amount of creatine essential for constructing muscle.

In small doses (3-5 grams of creatine per day),

most athletes see vital features in a brief time period.

Around 95% of creatine in the physique is saved in skeletal muscle, the place it’s used to provide energy during quick bursts of intense activity similar to weightlifting, sprinting, or jumping.

The remaining 5% of creatine is saved within the mind, kidneys, and different organs.

If you’re uncertain about bloating (meaning you have not taken creatine so you do not even know should

you get bloated), then simply begin with creatine monohydrate.

If you have no points with it, there’s no cause to use another model.

As talked about, creatine is creatine, so there’s really no purpose to pay more money except there’s a significant distinction within the purity.

If you’re undecided the place to start, check out our prime picks for the

best creatine supplements under. The Worldwide Society of Sports

Nutrition (ISSN) has acknowledged that creatine monohydrate is a

secure and the best type of creatine supplementation. A Number Of forms of creatine can be found as dietary supplements, together

with buffered creatine, creatine hydrochloride, creatine ethyl

ester and creatine magnesium chelate.

This Knowledgeable Sport-approved complement, which options 100% micronised creatine monohydrate,

earned a thumbs up from our nutritionists, who rated

the no-nonsense components listing. It comes with a scoop to make certain you get the dosage proper,

and the fantastic powder blends seamlessly with liquid for a lump-free

drink. This is one other third party-tested option, guaranteeing the elements record is accurate and

the product is free from contaminants, pesticides

and heavy metals. Our specialists famous that it accommodates 100

percent pure creatine, which has been micronised, so your physique can absorb and use it

simply.

One five-star review says, “Taking these tablets is a lot simpler than making a shake each time you want some creatine. You can pop them in a case and take them at work and even while you work out.” You may need to evaluate the worth and verify for minimal components,

ensuring the product is free of artificial flavors, sweeteners, and fillers.

Throughout testing, McGrane noted that the dimensions of the capsules was intimidating, however they were comparatively easy to swallow

and didn’t go away any unhealthy aftertaste.

“The consistency of the powder (before mixing) is just like cornstarch and was a bit harder and messier to scoop than lots of the others I tried. The scoop can additionally be quite long, which, mixed with how dense the powder is, made it onerous to screw the lid again on.

While the views expressed are these of the author, they are grounded of their tutorial background and scientific analysis. A staff of certified medical specialists fact-checks the content, guaranteeing its accuracy. The info is further supported by respected sources linked inside the article. Best choice if you’re a competitive athlete who needs a rigorously unbiased examined product.

I’m really inspired together with your writing abilities

and also with the layout in your blog. Is this a paid

subject or did you modify it your self? Either way keep up the excellent high

quality writing, it is uncommon to peer a nice weblog

like this one these days. HeyGen!

This is especially essential for the brain, which consumes a major quantity of power to maintain cognitive functions and neuronal signaling.

Dietary sources embody meat and fish, with purple meat being notably wealthy in creatine.

Creatine has additionally been shown to impact temper, according to Strangland, by selling mind energy levels,

significantly for women. The brain’s frontal

lobe is known to regulate mood, cognition, reminiscence and

emotion.

Nevertheless, these with kidney problems or different medical situations should seek the

assistance of with a doctor before taking any dietary

supplements. If you’re in search of a creatine complement that can help

explosive actions and allow you to achieve

your fitness objectives, Optimum Nutrition Micronized Creatine

Monohydrate Powder could be the right alternative for you.

The FDA doesn’t enforce strict regulations for merchandise in the complement industry.

Since this method comes in a tablet form, they are extraordinarily handy to take, making it simple to get your every day creatine

dose from anyplace at any time. We don’t like powders,

as they usually taste dangerous and dissolve poorly – with these tablets, you won’t have to fret about all that.

Some of the athletes we spoke with reported gastrointestinal misery upon initiation of supplementing

with creatine that quickly subsided. It spikes your muscle protein synthesis thus rising the

scale of your muscle considerably through betaine anhydrous; a

natural compound present in pure meals sources.

It is also believed to reduce unwanted effects corresponding to bloating

and cramping. Creatine comes in a quantity of varieties once we are wanting into

the world of supplements. Let’s have a look

at the most typical forms of creatine that you can be encounter whereas

shopping for dietary dietary supplements. Creatine is transformed into phosphocreatine and is saved in your muscle tissue the place it is used for

energy as per requirement (6).

Creatine could be unstable in a liquid solution, which

implies you can’t sip them slowly. This is in all probability not the solely

option for everybody, but it is a nice alternative for

people on the go. There are a quantity of types

of creatine that you could select from to fit your way of life.

Combining a scientific dosage of the tried and true creatine

monohydrate with β-Hydroxy β-Methylbutyrate (aka HMB), Transparent Labs delivers a leading edge complement for bulking.

Examine out our listing under to easily examine the highest supplements by ingredients and worth, to work out which one is right for

you. It’s not just endurance athletes who

will profit from the powder, though. USN’s Creatine Anabolic powder comes

in two flavours – cherry punch and orange – which

can every make your pre-workout shake that little bit extra

attractive.

Avoid merchandise with components, synthetic colors, flavors and sweeteners.

Elevate your athletic prowess with Agym Nutrition’s HALAL-certified Creatine Monohydrate

Powder, specifically formulated for devoted athletes seeking top-tier

performance. Crafted with meticulous care on the MESTI KKM factory, this product additionally caters to the wants of Muslim

shoppers as a trusted Muslim Product. It is believed that creatine HCL

has better solubility and absorption than other types of creatine.

Even although you is in all probability not knowledgeable bodybuilder, creatine monohydrate is a dietary supplement that’s scientifically

proven to extend physical efficiency. They have

additionally been in a position to enhance their muscle growth, achieve a trimmed body,

and expertise quick restoration. The good thing is

that there are also one of the best creatine supplements for ladies who wish to enhance their efficiency during workouts.

We chose Optimum Vitamin Micronized Creatine Monohydrate

as it offers a pure, high-quality type of creatine

monohydrate through a micronized powder for improved absorption. As a top complement brand, Optimum Nutrition ensures a secure and efficient product by way of rigorous testing.

Naked Efficiency Diet (BPN) has garnered a cult-like following of fitness

lovers and influence—and the efficacy and high quality of their creatine proves it’s for good cause.

The product is sourced from Creapure, a extremely purified form of creatine monohydrate, says Hamlin.

The intent behind the smaller particles is to enhance absorption of

creatine into water. In essence, every of these various types of creatine

is jockeying for position to be considered the right creatine for you.

The loading part is a short period and includes the consumption of upper doses

of creatine to increase creatine shops in the body. The upkeep part helps sustain the present levels of creatine with a

every day dose. Creatine supplements present

wonderful bodily advantages, particularly for athletes and bodybuilders.

Micronized creatine supplements are a more refined form of creatine from creatine monohydrate.

So, though both dietary supplements have comparable functions, they still have a

number of differences. Creatine supplementation can have totally different results on different individuals, however in general, it takes some

time earlier than you’ll start to see outcomes.

Often, you’ll begin to really feel the results in your energy and energy output in the first few weeks of taking the supplements.

No matter what, creatine supplementation ought to be used in conjunction with a

regular train or training regime.

Approaching a gym coach for advice could presumably be an option, but given the rise in high-profile criminal instances, fitness coaches

are not prone to jeopardize their freedom for such a small

sum. Furthermore, you may be mistaken as regulation enforcement

making an attempt to reveal a bootleg steroid-selling community.

By following this, you not solely protect your body but additionally guarantee one of

the best outcomes. In reality, Anavar is likely one of the reasons many people spend hours scrolling by way of social

media, fueling our desire to achieve extra athletic and

interesting physiques. Have spent considerable money and time on “legal options” with related names with out seeing any outcomes.

After sifting via quite a few online articles, you will quickly notice that there is little

or no useful information on the subject. We’re nicely aware of the difficulty of finding reliable sources online these days.

Consulting with a healthcare skilled or certified health advisor is paramount to devising a tailored strategy that aligns with one’s goals and mitigates potential

dangers. Fat Loss and Physique CompositionAnavar displays a singular capacity to promote fat loss

whereas preserving lean muscle mass. Via its influence on metabolism and lipolysis, Oxandrolone aids in the breakdown of stored body fats, particularly

in cussed areas. Concurrently, it safeguards muscle tissue from catabolism, enabling individuals to achieve a extra outlined and ripped physique.

It also has another benefits, similar to decreasing fat stores

and rising the number of red blood cells in the physique.

Anavar can be used for both bulking and slicing cycles,

and it is a well-liked drug among women because it is rather

mild and has low unwanted effects. Anavar 50 is a man-made steroid, much

like the usually created hormone testosterone within the human body.

Good for many who wish to lose fats whereas retaining lean muscle mass and rising

strength. Most anabolic steroids sold on the black market are UGL (underground laboratories).

This is essentially produced in a non-certified laboratory

and poses a high danger to the buyer, as there

are no regulations in place to make sure product safety.

The internet is turning into stuffed with misinformation and scams

to trick you into losing your hard-earned cash. Inform your physician if you become bed-ridden (unable to walk) for a chronic time while using this medication.

Verify your blood sugar regularly as directed and share the outcomes along with your doctor.

Tell your doctor immediately when you have signs of low blood sugar, similar to sudden sweating,

shaking, quick heartbeat, hunger, blurred imaginative and prescient, dizziness, or tingling hands/feet.

Your physician may have to regulate your diabetes medication, train program, or diet.

This implies that a one hundred fifty mg capsule of Androstenolone would only ship

2.25-6mg biologically energetic milligrams, which is lower than your body naturally produces daily.

Conversely, a single dose of 150 mg Androstenolone in Anavar® delivers between biologically energetic milligrams.

Hi-Tech researchers had been the first to begin to make use of these potent compounds — lengthy before the current steroid legal guidelines had been revamped to add nearly every prohormone known to be

a controlled substance. Subsequently, our expertise

to getting the highly effective prohormones into

the bloodstream by far surpasses some other firm within the trade.

We have worked on different technologies for over

a decade while everyone else loved the fruits of selling illegal compounds.

As A Result Of it’s an oral steroid, Anavar could be poisonous to the liver when used over lengthy

periods of time at excessive dosages.

While it can be a useful device in reaching

health goals, it isn’t a standalone answer. Dedication and consistency in your

fitness routine stay integral parts of success. Anavar, like any performance-enhancing substance, should be considered

as a supplement to a well-rounded life-style that features proper nutrition, common train,

and adequate rest. Steady monitoring of your progress and potential

side effects is crucial all through an Anavar cycle.

Common evaluation ensures that you could make needed adjustments

to your routine to optimize safety and effectiveness. In each cases,

the emphasis lies not solely on the length and dosage but additionally on the importance of continuous

monitoring. Whether male or feminine, novices ought to

strategy Anavar cycles with a eager consciousness of their distinctive

bodily reactions, fostering a responsive and adaptive relationship with this

versatile steroid.

Buying on-line from RoidRx, you’re dealing with a Canada-Based on-line store that gives no threat

or uncertainty on whether or not your shipments make it previous customs.

Earlier Than you, Purchase Steroids USA ask the doctor about its

utilization and dosage. Normally, the physician recommends its

dosage relying on the situation of the affected

person.

Furthermore, if an individual has experienced gynecomastia, this

is an indication that the substance is Dianabol (42).

These are some of the points bodybuilders who visit our clinic

face when acquiring UGL Anavar. Equally, utilizing Anavar all

12 months round on a decrease dose in comparability with administering a higher dose in the brief term,

the individual is less more probably to discover outcomes.

Nevertheless, the next dose in a brief six-week cycle might

be more evident. If a user has no choice and equally wants to build muscle and

burn fats on the same time, maintenance calories may

be optimum.

The use of anti-estrogen or SERM medicines like

Clomid, Nolvadex, and Proviron might help during PCT.

In this information, you’ll get to know the uses of Anavar, how to run a Var cycle, the recommended dosage, cycle results, and also the place

to buy Anavar. The steroid is not hepatotoxic towards the liver and athletes with digestive

disorders also can use it. 100 percent natural, protected, & authorized steroid

options to Dianabol, Clenbuterol, HGH, Anavar, Trenbolone and extra.

“Great stuff. Every Little Thing works as intended, chemistry is on point. Was skeptical at first as assume most individuals are, tested a couple products and hard to seek out better. About to put my 2nd order.” “Legit products! Smashing by way of PR’s and coming back for spherical two. One of one of the best if not the best online distributor. Extremely suggest.”

But with this formula, you’re going to get this highly effective prohormone

in pill kind. Here at Finest Worth Vitamin you can see the most

cost effective value on this powerful complement.

Usually we discourage women from taking prohormones and instead steer them to Natural Muscle Builders like Turkesterone, Laxogenin,

and Epicatechins amongst others. If ladies insist on eager to run a prohormone cycle probably the most optimal

prohormone for women to run would be a decrease dosed 19Nor corresponding

to Decabolin or Osta-Plex. It’s essential to repeatedly assess and,

if needed, modify your Anavar routine to make sure each safety and

effectiveness. The possibility to buy Anavar through

on-line suppliers has grown in reputation as a end result

of its comfort and big choice. The primary

advantage of online shopping lies within the ease of exploring and shopping for from

the comfort of house.

Nevertheless, before you could get your provide of testosterone,

you will need to fill out a request kind and anticipate approval.

You can even Signal up, login and own an account like most on-line shops, all impending

purchases are sent to the cart where you’ll have the ability to pay for the items utilizing numerous cost methods.

It also signifies that content material is

printed solely with informational reasons.

If you may have a genetic risk to lose your hair within the close to future, Anavar could accelerate

this balding course of. In sensible terms, this will result in slightly

much less energy, mood, or/and motivation temporarily. Nonetheless, this doesn’t cease

fitness center rats buying oxandrolone illegally by way of pharmaceutical firms

or underground labs. Is it structured and properly thought out or is

it something that you’ve simply pulled out of a Flex Magazine or Mens

Health.

Staying on a low dose can result in plateaus; nevertheless, by increasing the dose and size

of the cycle, customers can continue adding muscle and strength.

10 kilos of additional lean muscle is a possible results of this follow-up cycle.

It is an androgen and anabolic steroid medication that helps

to enhance weight acquire in various situations. Like all oral steroids,

Anavar can cause zits in addition to an elevated danger of male pattern baldness.

It does this by increasing the body’s metabolism, which

leads to a higher price of calorie burn. This makes Anavar a super

steroid for ladies who are wanting to achieve a lean, toned physique.

In current years, Anavar has turn out to be increasingly

in style among ladies who wish to enhance their physique

and athletic efficiency.

Those utilizing oxandrolone may experience feelings of nausea, which might lead to vomiting.

This is among the least-serious potential Anavar side effects, but still one worth noting.

Hepatic dysfunction has been proven to happen in males who have taken Anavar for higher than one year repeatedly.

Hepatic dysfunctions because of Anavar use can include elevations in liver function enzymes,

Peliosis hepatis, adenomas and concerns have been made for hepatocellular carcinoma.

It’s advised to not improve the dose too dramatically whilst on a cycle.

That means after the primary week (30mg per day) you’ll go

upto 40mg for the second week and then 50mg for the

3rd week. Elevated levels of testosterone at all times ends in more strength, dimension and performance during workouts.

Anavar is officially classed as a schedule III managed substance in the us Nonetheless, there are companies who sell by-product

versions (compounds nearly identical) to anavar on-line.

Nonetheless, should you do go down this route don’t

buy from companies with poorly designed web sites or ones which don’t

record their address, as you would get scammed.

Furthermore, trenbolone is not suitable for girls seeking to avoid the development of masculine options.

We discover Anavar peaks quick in the bloodstream as a outcome of its brief half-life of 9–10 hours.

In our expertise, users commonly notice an improvement in body composition inside the first two

weeks. In the beforehand cited research, fats loss was everlasting for participants.

Nonetheless, it’s attainable for Anavar to not directly contribute to

the development of gyno. On the opposite hand, anavar is

a certified drug and you can purchase it in the

USA. So, while consuming a supplement, you need to be aware of whether or not it’s legal to make use of.

You want a doctor’s prescription whenever you go to buy supplements.

Bear In Mind, the longer your cycle lasts, the higher

testosterone suppression you’ll probably expertise both throughout and after.

Anavar may cause elevated irritability, aggression, and depression in some users.

For women, a daily dose of 10 mg might be extremely beneficial

for reducing body fat and constructing muscle mass.

Stacking is the apply of taking a number of compounds together to achieve a synergistic

effect. In the case of Anavar and EPI, stacking these two compounds might help

to increase muscle mass and strength even additional.

Throwing Anavar into the mix of your bodybuilding regimen is normally a game-changer, significantly together with different compounds.

The mixed cycle, often referred to as “stacking,” is a superior technique adopted by

intermediate and advanced bodybuilders to push the boundaries of their progress.

Thoughts you, this method requires excellent understanding and foresight, as the best dosage of Anavar can amplify the benefits,

with a lesser risk of unwanted effects. Commencing with a low dose

is a clever alternative for first-time Anavar users.

Each has its personal advantages and downsides, and the greatest choice for you’ll rely in your individual

goals and wishes. Steroid Source Discuss is a

impartial web site that gives assets about fitness, workouts and supplements

that can assist you attain your objectives. Eire, similar to the UK, classifies

Anavar as a Class C drug under the Misuse of Medication Laws 1988.

You can’t have or use Anavar with no legitimate prescription because of this categorization.

A trenbolone/Anavar cycle is considered one of the mildest trenbolone cycles you

are able to do, second solely to trenbolone/testosterone.

Anavar is an oral steroid, so it’s most popular by customers who don’t

want to inject. Anavar is a gentle steroid, therefore why it’s

efficiently used in drugs for treating women and young children (without damaging effects).

Each trenbolone and Winstrol don’t aromatize, so

water retention won’t be a problem, resulting in an outlined and dried-out physique as an alternative,

with enhanced vascularity. We have seen this duo utilized as a chopping cycle, where users

eat in a calorie deficit. We have also seen it used as a lean-mass

building cycle, the place users eat upkeep calories (or

in a small surplus). Thus, excessive energy mixed with the estrogenic nature

of testosterone and Anadrol will trigger vital water retention, even with trenbolone’s diuretic properties.

Anavar is a gentle steroid that is usually utilized by ladies and newbies, whereas Testosterone is a robust steroid that is utilized by

males to extend muscle mass and strength. Each steroids can help improve athletic efficiency and muscle development, however Anavar is usually thought-about

safer and has fewer unwanted facet effects in comparability with Testosterone.

Anavar is a gentle anabolic steroid that is used for bulking and chopping functions.

Men users often stack Anavar with other anabolic steroids to get simpler results.

Always use Anavar under a doctor’s steerage, and never exceed the beneficial dosage.

Frequently monitor your health, particularly your liver perform

and cholesterol levels. Long-term use or misuse of Anavar can lead to severe well being issues, so observe all medical

advice closely and pay consideration to any adjustments in your physique.

One of probably the most regarding side effects for ladies is virilization,

the place they start to develop male traits due to

the elevated testosterone ranges. Virilization can embrace a variety of

symptoms, such as a deeper voice, elevated body and facial hair, and adjustments in menstrual cycles.

These changes could be distressing, and in some

instances, they could be irreversible even after stopping Anavar.

Ladies using Anavar are usually suggested to take lower

doses to reduce the risk of these unwanted aspect

effects.