Stainless steel, a term synonymous with durability and resilience, has been a material of choice for a wide range of applications due to its exceptional corrosion resistance. This corrosion resistance, which is a fundamental property of stainless steel, is attributed to the unique metallurgical structure and composition of the alloy. In this article, let’s take a close look at stainless steel corrosion resistance.

Stainless Steel Corrosion Resistance – An Overview

1. Composition and Structure

Stainless steel is primarily composed of iron, with additions of chromium, nickel, and other elements that enhance its properties. The key to its corrosion resistance lies in the chromium content, which typically ranges from 10.5% to 30% by weight. Chromium forms a thin, invisible, and adherent layer of chromium oxide on the steel’s surface, known as the passive film. This film acts as a barrier, preventing further corrosion by blocking the ingress of oxygen and other corrosive agents.

Nickel is another significant addition to stainless steel, particularly in austenitic grades. It stabilizes the austenitic structure, which is non-magnetic and has a high ductility. Nickel also enhances the corrosion resistance of stainless steel, particularly against chloride-induced stress corrosion cracking.

Other elements, such as molybdenum, titanium, and nitrogen, are added to further improve the corrosion resistance of stainless steel, especially in specific environments.

2. Types of Stainless Steel

There are several types of stainless steel, each with its unique composition and corrosion resistance characteristics. The most common types are austenitic, martensitic, ferritic, and duplex.

Austenitic stainless steels, such as 304 and 316, are the most widely used due to their excellent corrosion resistance, ductility, and weldability. These alloys have a high chromium and nickel content, which gives them their non-magnetic and corrosion-resistant properties.

Martensitic stainless steels, on the other hand, have a higher carbon content and are magnetic. They are less corrosion-resistant than austenitic stainless steels but offer superior strength and hardness.

Ferritic stainless steels have a lower chromium content and are also magnetic. They exhibit good corrosion resistance but are less ductile and weldable than austenitic stainless steels.

Duplex stainless steels combine the properties of austenitic and martensitic stainless steels, offering both high strength and excellent corrosion resistance.

3. Stainless Steel Corrosion Resistance Mechanisms

The corrosion resistance of stainless steel is primarily due to the passive film that forms on its surface. This film is self-repairing, meaning it can regenerate itself when damaged, maintaining its protective properties. However, certain environments and conditions can affect the stability of the passive film, leading to corrosion.

Chloride ions, for example, can penetrate the passive film and initiate pitting corrosion, a localized form of corrosion that can lead to the failure of stainless steel components. Other factors that can affect the corrosion resistance of stainless steel include temperature, pH, and the presence of oxidizing agents.

4. Improving Stainless Steel Corrosion Resistance

There are several methods to improve stainless steel corrosion resistance, including:

- Selecting the appropriate grade of stainless steel for the specific application and environment.

- Using surface treatments, such as pickling and passivation, to remove contaminants and enhance the formation of the passive film.

- Employing protective coatings, such as paints or polymer films, to further isolate the steel from corrosive agents.

- Regular maintenance and inspection to identify and address corrosion issues promptly.

Conclusion

Stainless steel corrosion resistance is a result of its unique composition and metallurgical structure. Understanding the factors that can affect this resistance and implementing appropriate measures to mitigate them is crucial in ensuring the longevity and performance of stainless steel components in various applications.

Thank you for reading our article and we hope it can help you to have a better understanding of the stainless steel corrosion resistance. If you are looking for stainless steel products suppliers online now, please don’t hesitate to contact Sino Stainless Steel.

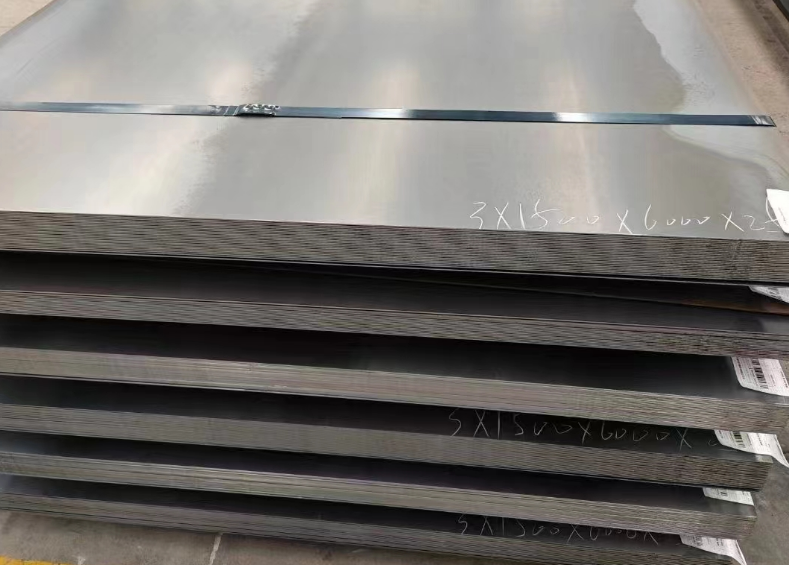

As a leading supplier of stainless steel products from Shanghai, China, Sino Stainless Steel offers customers high-quality stainless steel pipes, stainless steel strips, stainless steel coils, stainless steel plates, stainless steel sheets, stainless steel bars, and stainless steel tubes at an extremely competitive price.

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com

I don’t know whether it’s just me or if everybody else encountering issues with your blog.

It appears like some of the written text within your posts are running off the screen.

Can somebody else please provide feedback and let me know

if this is happening to them as well? This may be a problem

with my web browser because I’ve had this happen previously.

Thank you