Stainless Steel Suppliers

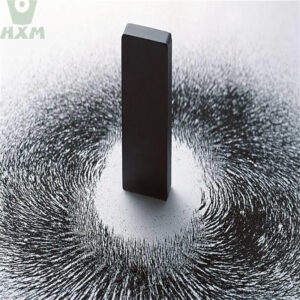

Does a magnet stick to stainless steel?

Imagine this: You’re at a fancy dinner party, dressed to impress in your best suit or dress. As you reach out to grab your champagne glass, you notice a strange phenomenon. The magnet on your watch band is inexplicably drawn to the stainless steel tableware. Is it just a fluke, or can magnets really stick to stainless steel? The question remains, does a magnet really stick to stainless steel? Let’s investigate.

The answer to this question is not a simple yes or no. While some types of stainless steel are magnetic and will attract a magnet, others are not magnetic and will not.

The magnetic properties of stainless steel depend on its composition and the presence of other elements such as nickel, manganese, and chromium. Understanding the magnetic properties of stainless steel can be useful in a variety of applications, from identifying different types of stainless steel to checking the quality of a stainless steel product.

In this article, we’ll explore the properties of stainless steel and its relationship with magnetism. You might be surprised to learn that not all stainless steel is created equal when it comes to magnetism.

What makes stainless steel non-magnetic?

Stainless steel’s non-magnetic properties come from its unique atomic structure. The addition of elements such as nickel, manganese, and nitrogen to the steel alloy disrupts the alignment of iron atoms, preventing them from forming a magnetic field.

The crystal structure of stainless steel is also important, with certain types of austenitic stainless steel having a face-centered cubic structure that inhibits magnetic attraction. Overall, the non-magnetic properties of stainless steel are important for many applications, particularly those involving sensitive equipment that can be affected by magnetic fields.

Can some types of stainless steel be magnetic?

Yes, some types of stainless steel can be magnetic, while others are non-magnetic. Magnetic properties in stainless steel depend on the alloy’s chemical composition, especially the addition of ferromagnetic elements like nickel, chromium, and manganese.

Austenitic stainless steel, which is the most common type, is generally non-magnetic due to its high nickel content. Ferritic and martensitic stainless steel, on the other hand, contain lower nickel content and may exhibit some magnetic properties.

The magnetic properties of stainless steel have various applications, such as in magnetic resonance imaging (MRI) machines, where magnetic susceptibility is important, and in certain types of tools and equipment that require magnetic properties. Understanding the magnetic properties of stainless steel is essential for proper material selection and application.

How can you tell if stainless steel is magnetic or not?

Stainless steel is generally non-magnetic, but some types of stainless steel can be magnetic. To determine whether a particular piece of stainless steel is magnetic or not, there are a few methods you can use.

One method is to use a magnet and see if it sticks to the stainless steel. If the magnet sticks, the stainless steel is likely magnetic. However, if the magnet does not stick, it does not necessarily mean that the stainless steel is non-magnetic, as some non-magnetic types of stainless steel can still be slightly magnetic.

Another method is to perform a spark test using a grinding wheel. If the sparks produced during the grinding process are short and red in color, the stainless steel is likely non-magnetic. However, if the sparks are longer and more yellow in color, the stainless steel is likely magnetic.

It is important to note that the magnetic properties of stainless steel can be influenced by factors such as the composition of the alloy, the manufacturing process, and any heat treatment that the steel has undergone. Therefore, it is always best to consult with a materials expert or refer to the manufacturer’s specifications to determine the magnetic properties of a particular type of stainless steel.

What is the difference between magnetic and non-magnetic stainless steel?

The main difference between magnetic and non-magnetic stainless steel lies in their composition. Magnetic stainless steel contains high levels of ferrite, a magnetic iron compound, while non-magnetic stainless steel is usually made up of austenite, which is non-magnetic. The presence of ferrite in magnetic stainless steel makes it susceptible to corrosion and rust, while non-magnetic stainless steel is more resistant to corrosion and rust.

In terms of physical properties, magnetic stainless steel has lower ductility and is more prone to cracking compared to non-magnetic stainless steel. Magnetic stainless steel also tends to be harder and more brittle, which can make it more difficult to work with in certain applications.

It’s important to note that not all types of stainless steel are magnetic. For example, austenitic stainless steels such as grades 304 and 316 are typically non-magnetic, while ferritic and martensitic stainless steels such as grades 430 and 420 are magnetic.

Understanding the differences between magnetic and non-magnetic stainless steel is important when selecting the right type of stainless steel for a particular application. It’s also important to take into account factors such as corrosion resistance, strength, and workability when making this decision.

Does the grade of stainless steel affect its magnetic properties?

Yes, the grade of stainless steel can affect its magnetic properties. Austenitic stainless steels, which are the most common type of stainless steel, are non-magnetic. However, other types of stainless steel such as ferritic and martensitic grades are magnetic due to their crystal structure.

Ferritic stainless steels have a body-centered cubic crystal structure, while martensitic stainless steels have a body-centered tetragonal crystal structure. The amount of magnetic attraction will also depend on the alloying elements present in the stainless steel.

For example, adding nickel to stainless steel can help make it more non-magnetic. It’s important to note that while magnetic properties are often associated with lower quality or lower corrosion resistance in stainless steel, this is not always the case. Magnetic stainless steel can still be highly corrosion resistant and used in various applications, such as in the automotive and construction industries.

How does temperature affect the magnetism of stainless steel?

Stainless steel can exhibit varying degrees of magnetism depending on its composition and microstructure. Generally, austenitic stainless steel (grades such as 304 and 316) are non-magnetic, while ferritic and martensitic stainless steels (grades such as 430 and 420) are magnetic. However, the magnetism of stainless steel can also be affected by temperature.

As temperature increases, the magnetic properties of stainless steel can change. For example, at high temperatures, austenitic stainless steel may become partially magnetic due to the formation of martensite. On the other hand, ferritic and martensitic stainless steels may become less magnetic as the temperature increases.

The Curie temperature is the temperature at which a material loses its magnetic properties. For most grades of stainless steel, the Curie temperature is above room temperature, meaning that they remain non-magnetic at normal operating temperatures. However, some ferritic and martensitic stainless steels have a low Curie temperature, which can cause them to become magnetic at room temperature and below.

Overall, it is important to consider the grade and temperature of stainless steel when evaluating its magnetic properties.

What are the benefits of using non-magnetic stainless steel in certain applications

Non-magnetic stainless steel offers several benefits in certain applications. For example, it is often used in industries where magnetic interference can cause issues, such as electronics and medical equipment. In addition, non-magnetic stainless steel is ideal for use in environments with high temperatures or corrosive substances, as it is highly resistant to corrosion and oxidation.

Another benefit is that non-magnetic stainless steel is easy to weld, allowing for strong and durable connections. Additionally, it is aesthetically pleasing and often used for decorative purposes in architecture, interior design, and household appliances.

Moreover, non-magnetic stainless steel is durable and long-lasting, making it a cost-effective choice for applications that require a material with high strength and longevity. Overall, the benefits of non-magnetic stainless steel make it a popular choice for a wide range of industries and applications.

Can magnetic particles stick to stainless steel surfaces?

Yes, magnetic particles can stick to stainless steel surfaces. This is because stainless steel is not completely non-magnetic, and even the non-magnetic types can still have some magnetic properties. The presence of iron in the stainless steel can cause it to attract magnetic particles.

In addition, stainless steel surfaces can also become magnetized through exposure to external magnetic fields, such as those from machinery or equipment. This magnetization can cause magnetic particles to stick to the surface.

To prevent magnetic particles from sticking to stainless steel surfaces, the surface can be treated with a passivation process that removes any iron particles or other contaminants that could cause magnetization. Additionally, anti-magnetic stainless steel alloys can be used for applications where the attraction of magnetic particles is a concern.

Can the magnetism of stainless steel be affected by its surface finish?

Yes, the surface finish of stainless steel can affect its magnetic properties. Generally, a smoother surface finish will result in a lower magnetic response, while a rougher surface finish will result in a stronger magnetic response.

This is because a smoother surface finish reduces the number of microscopic imperfections in the steel that can create areas of magnetic polarization. Additionally, a smoother surface finish can help reduce the amount of iron that is exposed at the surface of the steel, which can also contribute to magnetic response. Conversely, a rougher surface finish can increase the amount of iron exposed at the surface, leading to a stronger magnetic response.

It’s important to note, however, that surface finish is just one factor that can affect the magnetic properties of stainless steel, and other factors such as the steel’s composition and processing can also play a role.

Conclusion

In conclusion, the magnetism of stainless steel is a complex topic that requires understanding the composition and grade of the material, as well as external factors such as temperature and surface finish. Non-magnetic stainless steel is often preferred for certain applications, such as medical and aerospace industries, where magnetic interference can be detrimental.

While some types of stainless steel can be magnetic, others are designed to be non-magnetic, and the grade of stainless steel can affect its magnetic properties. It is important to note that magnetic particles can still stick to stainless steel surfaces, and the magnetism of stainless steel can be affected by factors such as temperature and surface finish.

Understanding the magnetism of stainless steel can be beneficial in selecting the appropriate material for a specific application, as well as ensuring that magnetic interference is minimized. Overall, the properties of stainless steel make it a versatile material for various applications, and its magnetism should be considered when selecting the appropriate grade and finish for a particular use case.

Get A Free Quote

Table of Content

Related Posts

Protective Measures for Stainless Steel in Water Environments

Stainless steel, as an extensively utilized alloy material, finds applications across numerous working scenarios. However, it is crucial to emphasize that when stainless steel is

Performance Characteristics and Applications of 303 Stainless Steel

303 stainless steel, as a type of stainless steel containing sulfur and selenium, not only exhibits high machinability and resistance to high-temperature sticking but also

Properties, Characteristics and Applications of 416 Stainless Steel

As an outstanding martensitic stainless steel, 416 stainless steel boasts a unique chemical composition that endows it with superior magnetic properties, good corrosion resistance, ease

Advantages of Hot Rolling Process in Stainless Steel Manufacturing

Stainless steel, a ubiquitous metallic material, finds extensive applications across various sectors such as construction, food processing, and healthcare. Enhancing the reliability and durability of

5 Methods to Enhance the Strength of Austenitic Stainless Steel

Stainless steel, as a crucial and widely utilized steel type, enjoys extensive applications in civil and industrial sectors due to its high corrosion resistance, excellent

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com