Stainless Steel Suppliers

When was stainless steel invented?

Stainless steel is a ubiquitous material in our modern world, used in everything from surgical instruments to skyscrapers. But have you ever wondered when this versatile alloy was first invented?

The answer might surprise you. The ship’s engineers used a new type of steel that was highly resistant to corrosion, which allowed it to withstand the harsh conditions of the ocean. Little did they know that this steel would revolutionize the industry and become one of the most important materials in our daily lives.

So, when was stainless steel invented? Let’s explore the fascinating history of this material.

Who invented stainless steel?

The invention of stainless steel is attributed to Harry Brearley, a metallurgist from Sheffield, England. In 1913, he was tasked with finding a way to prevent gun barrels from corroding. After extensive experimentation, Brearley discovered that adding chromium to steel made it highly resistant to corrosion, thus inventing what we now know as stainless steel.

While Brearley is credited with inventing stainless steel, he was not the only one working on the problem. Several other scientists, including Leon Guillet in France, were also experimenting with adding chromium to steel around the same time.

The invention of stainless steel revolutionized the industry and opened up new possibilities for manufacturing. Today, stainless steel is a ubiquitous material used in a wide range of applications, from kitchen appliances to skyscrapers.

Stainless steel suppliers play a critical role in the industry, providing raw materials to manufacturers and ensuring a steady supply of stainless steel products. The demand for stainless steel continues to grow, with increasing demand from industries such as automotive, aerospace, and construction.

In conclusion, while there were several scientists working on the problem of corrosion-resistant steel, Harry Brearley is widely credited with inventing stainless steel. His discovery opened up new possibilities for manufacturing and has had a lasting impact on industry and society as a whole.

What is the composition of stainless steel?

Stainless steel is a versatile and widely used material that is known for its corrosion resistance, durability, and strength. It is an alloy made up of various elements, including iron, carbon, chromium, and nickel, among others. The precise composition of stainless steel varies depending on the specific grade, but the most common grades are austenitic, ferritic, and martensitic.

Austenitic stainless steel, which is the most widely used type, is made up of iron, carbon, and high levels of chromium and nickel. The high levels of nickel and chromium give it excellent corrosion resistance, making it suitable for use in a wide range of applications, including food processing equipment, medical devices, and automotive parts.

Ferritic stainless steel, which contains lower levels of nickel and higher levels of chromium than austenitic stainless steel, has good corrosion resistance but lower ductility and toughness. It is commonly used in automotive exhaust systems and appliances.

Martensitic stainless steel contains higher levels of carbon than austenitic and ferritic stainless steel, giving it greater hardness and strength. However, it has lower corrosion resistance than the other two types, making it more suitable for applications where strength is more important than corrosion resistance, such as in cutting tools and knives.

In addition to these three main types of stainless steel, there are also duplex and precipitation hardening stainless steels, which have unique properties and applications.

Stainless steel suppliers offer a wide range of grades and types of stainless steel, each with its own specific composition and properties. It is important to select the appropriate grade and type of stainless steel for each application to ensure optimal performance and longevity.

How is stainless steel made?

Stainless steel is an alloy made up of iron, chromium, nickel, and other elements, with a minimum of 10.5% chromium content by mass. The exact composition of stainless steel can vary depending on the specific grade and intended application.

Stainless steel is typically made through a process called melting and casting. First, the raw materials, including scrap metal, iron ore, chromium, nickel, and other alloying elements, are melted in a large electric furnace. The resulting molten metal is then refined to achieve the desired chemical composition and remove any impurities.

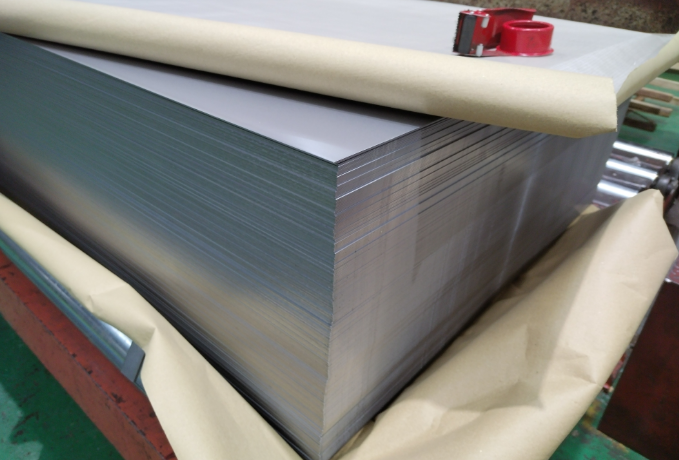

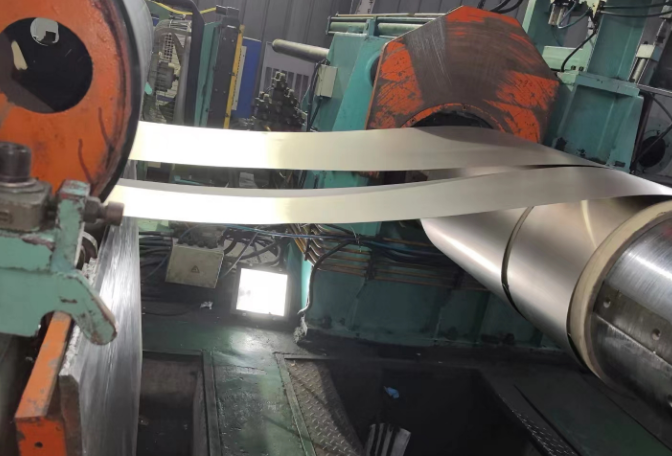

Once the molten metal has been refined, it is cast into various shapes and forms, including bars, sheets, plates, and coils. These forms are then sent to stainless steel suppliers who process and fabricate them into finished products for a variety of industries, including construction, automotive, aerospace, and medical.

There are also other methods for producing stainless steel, including powder metallurgy and electroslag refining, which are used to create specialized alloys with unique properties.

Regardless of the production method, the quality and consistency of stainless steel rely heavily on the expertise and experience of the stainless steel suppliers involved in the process. The use of advanced technology and quality control measures, such as spectroscopy and X-ray fluorescence, can help ensure the desired composition and purity of the final product.

Overall, the process of making stainless steel is complex and requires careful attention to detail at every step. The resulting alloy offers a wide range of benefits, including high strength, corrosion resistance, and aesthetic appeal, making it a popular choice for a variety of applications.

What is the future of stainless steel?

Stainless steel is a ubiquitous material that is used in a wide range of industries, including construction, automotive, aerospace, and healthcare. As the demand for durable, corrosion-resistant, and visually appealing materials continues to rise, the future of stainless steel looks bright.

One area of growth for stainless steel is in the automotive industry, where it is increasingly being used for lightweight components to improve fuel efficiency. Additionally, the growing popularity of electric vehicles is expected to boost demand for stainless steel due to its high electrical conductivity.

In the construction industry, stainless steel is being used more frequently for facades, roofs, and interior fittings due to its durability and aesthetic appeal. It is also being used for sustainable building applications, such as solar panels and green roofs, due to its corrosion resistance and ability to withstand harsh weather conditions.

In the healthcare industry, stainless steel is a preferred material for medical devices and equipment due to its biocompatibility and ease of cleaning. With the aging population and growing demand for medical care, the use of stainless steel in healthcare is expected to increase.

Moreover, the development of new grades of stainless steel with improved properties, such as increased strength and corrosion resistance, is also driving growth in the industry. Stainless steel suppliers are constantly investing in research and development to create innovative materials that can meet the evolving needs of their customers.

In conclusion, the future of stainless steel looks promising as it continues to be a material of choice across various industries. With ongoing innovation and development, stainless steel will continue to offer solutions to the challenges faced by industries today and in the future. As stainless steel suppliers continue to work towards meeting the needs of their customers, the possibilities for stainless steel applications are endless.

What are the properties of stainless steel?

Stainless steel is a highly versatile and popular metal alloy that is used in a wide range of applications, from household appliances to industrial equipment. It is known for its unique properties, which make it highly resistant to corrosion, staining, and heat damage, as well as its durability and strength.

One of the key properties of stainless steel is its high resistance to corrosion. This is due to the presence of chromium in the alloy, which forms a thin, passive oxide layer on the surface of the metal that protects it from environmental factors such as oxygen and moisture. This makes stainless steel ideal for use in environments where corrosion is a concern, such as marine and chemical processing industries.

Stainless steel is also highly resistant to staining and discoloration. This is due to the alloy’s composition, which includes elements such as nickel and molybdenum, that prevent the metal from reacting with acids or other substances that may cause discoloration or staining.

In addition to its corrosion and staining resistance, stainless steel also has excellent heat resistance, making it ideal for use in high-temperature applications such as industrial ovens and furnaces. It is also highly durable and strong, with a high tensile strength and resistance to wear and tear.

Other properties of stainless steel include its excellent formability and workability, which allow it to be easily shaped and molded into various forms and sizes. It is also highly hygienic, making it ideal for use in medical and food processing industries, where cleanliness and sanitation are essential.

Overall, stainless steel’s unique combination of properties make it a highly desirable material for a wide range of applications. Stainless steel suppliers continue to develop and refine the alloy to meet the needs of various industries and applications, ensuring its continued popularity and success.

What are the different types of stainless steel?

Stainless steel is a versatile material used in a variety of applications, from construction to medical equipment. There are several types of stainless steel, each with different properties and characteristics.

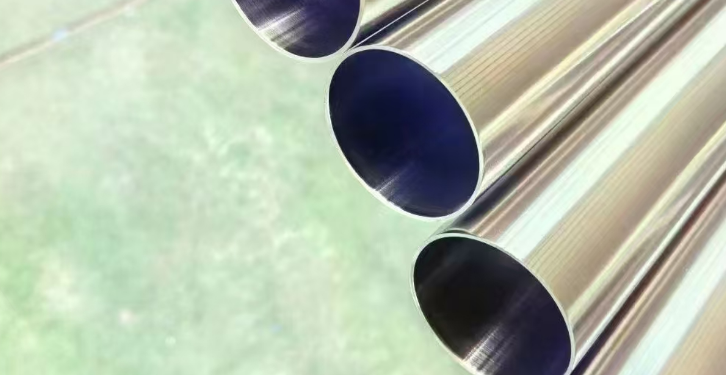

One of the most common types of stainless steel is Austenitic stainless steel, which contains high levels of chromium and nickel. This type of steel is highly corrosion-resistant and is commonly used in kitchen equipment, medical equipment, and piping.

Another type of stainless steel is Ferritic stainless steel, which is composed of iron and chromium. This type of steel is magnetic and has a lower level of corrosion resistance compared to Austenitic stainless steel.

Martensitic stainless steel is another type that is composed of chromium, carbon, and sometimes nickel. It has a high level of strength and is commonly used in knives, scissors, and turbine blades.

Duplex stainless steel is a mix of Austenitic and Ferritic stainless steel, providing a balance of strength and corrosion resistance. It is commonly used in chemical processing, oil and gas, and marine applications.

Precipitation-hardening stainless steel is a type that is heat-treated to increase its strength. It is commonly used in aerospace applications, such as aircraft components.

Stainless steel suppliers offer a wide range of options to meet the needs of various industries. Each type of stainless steel has its own unique properties and applications. By understanding the differences between them, manufacturers can choose the best type for their specific needs.

In summary, the different types of stainless steel include Austenitic, Ferritic, Martensitic, Duplex, and Precipitation-hardening stainless steel. Each type offers unique properties and characteristics, making stainless steel a versatile material used in various industries. Stainless steel suppliers can help manufacturers choose the best type of stainless steel for their specific applications, ensuring optimal performance and longevity.

What industries use stainless steel?

Stainless steel is a versatile material that has a wide range of applications across various industries. Its unique combination of properties such as corrosion resistance, strength, durability, and aesthetic appeal make it a popular choice in many industrial applications.

One of the primary industries that use stainless steel is the construction industry, where it is used in the construction of buildings, bridges, and other structures. Stainless steel’s strength and durability make it ideal for these applications, especially in areas where corrosion is a concern.

Another industry that utilizes stainless steel is the automotive industry, where it is used for parts such as exhaust systems, trim, and grilles. Stainless steel’s resistance to corrosion and heat makes it a popular choice for these applications.

The medical industry also relies heavily on stainless steel, which is used for surgical instruments, medical implants, and equipment such as MRI scanners. Stainless steel’s biocompatibility, corrosion resistance, and sterilization properties make it an excellent choice for these applications.

The food and beverage industry also uses stainless steel extensively due to its non-reactive and non-toxic properties. Stainless steel is used to manufacture equipment such as food processing machinery, tanks, and piping systems.

Other industries that use stainless steel include the aerospace industry, where it is used for aircraft components, and the marine industry, where it is used for boat parts and offshore oil rigs.

Stainless steel suppliers play a crucial role in providing high-quality stainless steel materials to these industries. With the increasing demand for stainless steel in various applications, stainless steel suppliers are constantly innovating to provide new and improved materials with better properties and performance.

In conclusion, stainless steel is a versatile material that is used across various industries for its unique combination of properties. With the increasing demand for high-performance materials, the future of stainless steel looks promising, and it is expected to continue to be a popular choice in various industrial applications.

How has stainless steel changed over time?

Stainless steel is a type of steel that has been widely used for more than a century. Since its invention in the early 20th century, stainless steel has undergone significant changes in terms of composition, manufacturing processes, and applications.

The initial creation of stainless steel involved adding chromium to steel to make it more resistant to rust and corrosion. Later, other elements such as nickel, molybdenum, and nitrogen were added to improve its properties. These additions resulted in the development of different grades of stainless steel, each with unique properties and applications.

In the mid-20th century, the introduction of duplex stainless steel revolutionized the industry. Duplex stainless steel contains a balanced combination of austenite and ferrite, resulting in improved strength and corrosion resistance. This development has enabled new applications, such as in offshore oil and gas production.

In recent years, advancements in technology have further enhanced the properties of stainless steel. For example, the development of high-performance alloys has made it possible to manufacture stainless steel components that can withstand extreme conditions such as high temperatures, high pressure, and aggressive environments.

The applications of stainless steel have also evolved over time. It is now used in a wide range of industries, from construction and architecture to medical devices and aerospace. In the automotive industry, stainless steel is used in exhaust systems, fuel tanks, and other critical components due to its corrosion resistance and durability.

Overall, stainless steel has come a long way since its invention in the early 1900s. Its unique properties and versatility have enabled it to become a crucial material in various industries. With ongoing research and development, it is expected that stainless steel will continue to evolve and find new applications in the future.

Stainless steel suppliers play a crucial role in the evolution of stainless steel. They provide the raw materials, manufacturing processes, and technical expertise necessary to produce high-quality stainless steel products. With the support of stainless steel suppliers, manufacturers can continue to push the boundaries of what is possible with this remarkable material.

What is the market size of stainless steel?

Stainless steel is a widely used material in various industries, including construction, transportation, and manufacturing. According to a report by Grand View Research, the global stainless steel market size was valued at USD 111.4 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2021 to 2028. The market is driven by the increasing demand for stainless steel in developing economies such as China, India, and Brazil.

The growth of the stainless steel market can be attributed to various factors such as the increasing use of stainless steel in the construction sector for building facades, roofing, and cladding, as well as in the manufacturing sector for the production of automotive parts, appliances, and industrial equipment. In addition, the rising demand for stainless steel in the oil and gas industry for pipelines, storage tanks, and drilling equipment is also contributing to the growth of the market.

Stainless steel suppliers are also introducing new and innovative products to cater to the diverse requirements of various industries. For instance, high-performance stainless steel grades such as duplex and super duplex stainless steel are being developed for use in harsh environments such as offshore oil and gas platforms and chemical processing plants.

However, the stainless steel market faces challenges such as the fluctuating prices of raw materials such as nickel and chromium, which are key components of stainless steel. In addition, the availability of substitutes such as aluminum and carbon fiber composites can also pose a threat to the growth of the market.

In conclusion, the stainless steel market is expected to grow in the coming years, driven by the increasing demand for stainless steel in various industries and the introduction of new and innovative products by stainless steel suppliers. However, the market also faces challenges that need to be addressed to ensure sustainable growth.

Conclusion

In conclusion, stainless steel has become a vital material in modern society due to its unique properties and versatility. Since it was first invented in the early 20th century, it has undergone various changes, improvements, and advancements. The invention of stainless steel revolutionized the manufacturing industry and paved the way for numerous applications that would have been impossible with other materials.

As we have seen, the properties of stainless steel make it a perfect fit for a wide range of industries, including construction, automotive, medical, and aerospace. The different types of stainless steel available today allow for even more specialized applications and can withstand the most challenging environments.

Furthermore, as environmental concerns increase, the ability to recycle stainless steel has become more important than ever. Stainless steel can be recycled endlessly without losing its properties, making it a sustainable and eco-friendly choice.

The market size for stainless steel continues to grow as its applications and demand increase. The emergence of stainless steel suppliers has helped make this material more accessible to industries of all sizes, ensuring that its benefits can be enjoyed by everyone.

In summary, the invention of stainless steel has had a significant impact on our lives and will continue to do so in the future. As technology and science advance, we can only expect even more advancements in the field of stainless steel, making it an exciting time for manufacturers, suppliers, and consumers alike.

Get A Free Quote

Table of Contents

Related Posts

Protective Measures for Stainless Steel in Water Environments

Stainless steel, as an extensively utilized alloy material, finds applications across numerous working scenarios. However, it is crucial to emphasize that when stainless steel is

Performance Characteristics and Applications of 303 Stainless Steel

303 stainless steel, as a type of stainless steel containing sulfur and selenium, not only exhibits high machinability and resistance to high-temperature sticking but also

Properties, Characteristics and Applications of 416 Stainless Steel

As an outstanding martensitic stainless steel, 416 stainless steel boasts a unique chemical composition that endows it with superior magnetic properties, good corrosion resistance, ease

Advantages of Hot Rolling Process in Stainless Steel Manufacturing

Stainless steel, a ubiquitous metallic material, finds extensive applications across various sectors such as construction, food processing, and healthcare. Enhancing the reliability and durability of

5 Methods to Enhance the Strength of Austenitic Stainless Steel

Stainless steel, as a crucial and widely utilized steel type, enjoys extensive applications in civil and industrial sectors due to its high corrosion resistance, excellent

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com