Stainless Steel Suppliers

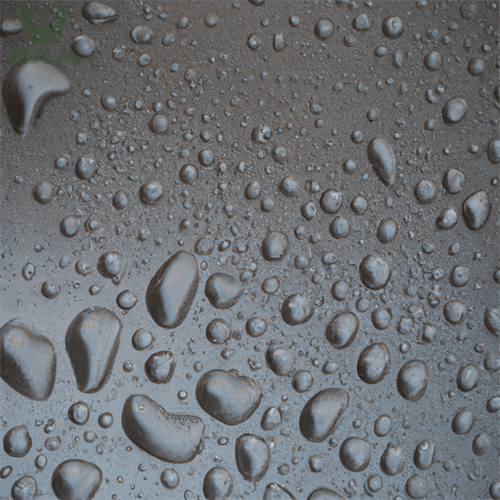

Is stainless steel waterproof?

Water is a powerful force of nature, capable of wearing away mountains over time. So it’s natural to wonder if stainless steel, a popular material in many industries, can hold up against water.

To answer this question, let’s consider the story of the Titanic. Despite being known as “unsinkable,” the Titanic met its tragic fate due to a lack of proper waterproofing. But would the outcome have been different if stainless steel had been used in the ship’s construction?

The answer maybe yes for that stainless steel is waterproof. It is a corrosion-resistant metal alloy that can withstand exposure to water and other liquids without rusting or corroding. However, it is important to note that stainless steel may still be susceptible to staining or discoloration in certain environments or if exposed to harsh chemicals for extended periods.

Let’s explore the properties of stainless steel and its ability to withstand water.

Table of Contents

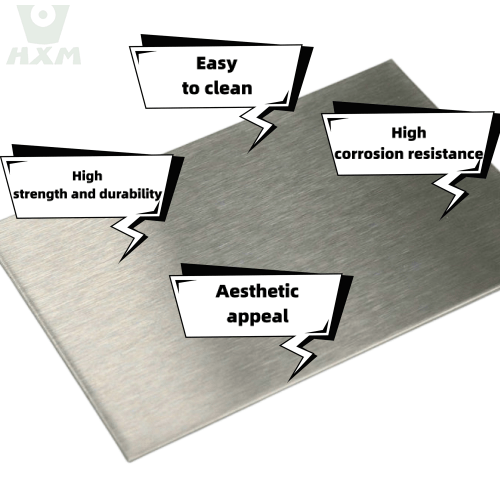

Stainless steel is a widely used metal alloy known for its exceptional durability, corrosion resistance, and strength. Its unique properties make it suitable for a variety of applications, including construction, manufacturing, and transportation. However, one question that often arises is whether stainless steel is waterproof.

The water resistance of stainless steel is a crucial factor to consider in various industries where exposure to moisture is common. The ability of stainless steel to resist water penetration is essential for ensuring its longevity, reducing maintenance costs, and preventing potential damage or failure of equipment. Therefore, understanding the water resistance of stainless steel is crucial for engineers, manufacturers, and designers.

Stainless steel is an alloy composed of iron, carbon, and at least 10.5% chromium. The addition of chromium enhances its corrosion resistance, making it resistant to rust and staining. There are different types of stainless steel, classified based on their composition, microstructure, and properties.

The purpose of this article is to explore the water resistance of stainless steel and its properties. We will examine the definition of water resistance and waterproofness, the properties of stainless steel, the effect of surface finish on water resistance, and applications of stainless steel in wet environments. By the end of this article, readers will have a better understanding of whether stainless steel is waterproof and its suitability for use in wet environments.

Stainless steel suppliers play a critical role in providing high-quality stainless steel materials for various applications. In the following sections, we will discuss the water resistance of stainless steel and its properties in detail.

II. Water resistance vs. Waterproof

Water resistance refers to the ability of a material to resist the penetration of water to some degree, but not entirely. Waterproofness, on the other hand, refers to the complete resistance of a material to water penetration.

Examples of waterproof materials include rubber, Gore-Tex, and polyurethane. These materials are commonly used in outdoor gear such as jackets, boots, and tents to keep the wearer or contents dry.

A. Explanation of the water resistance of stainless steel

Stainless steel is not completely waterproof, but it is highly resistant to water penetration. This is due to its unique composition, which includes at least 10.5% chromium. The chromium in stainless steel reacts with oxygen in the air to form a thin, invisible layer of chromium oxide on the surface of the metal. This layer acts as a barrier, protecting the underlying metal from corrosion and water penetration.

Stainless steel can be made even more water-resistant by using specific surface finishes, such as electropolishing or passivation. These finishes create an even more protective layer of chromium oxide on the surface of the metal.

Stainless steel is a popular material for use in wet environments, such as in marine or food processing applications, due to its high water resistance. Stainless steel suppliers often advertise their products as being water-resistant or waterproof, depending on the specific application and level of protection needed.

Overall, while stainless steel is not completely waterproof, it is highly water-resistant and can be made even more so with specific surface finishes. Its unique composition and protective layer of chromium oxide make it a popular choice for use in wet environments where water resistance is crucial.

III. The Composition of Stainless Steel

.png)

A. Composition of stainless steel

Stainless steel is an alloy composed of iron, carbon, and other elements such as chromium, nickel, and molybdenum. The amount of these elements and the specific composition determine the properties of stainless steel, including its water resistance. Different grades of stainless steel have different compositions, making them suitable for various applications.

One of the most notable properties of stainless steel is its high resistance to corrosion.

This is due to the presence of chromium in the alloy, which reacts with oxygen to form a thin layer of oxide on the surface of the steel.

This oxide layer, also known as a passive layer, protects the steel from further corrosion and enhances its water resistance.

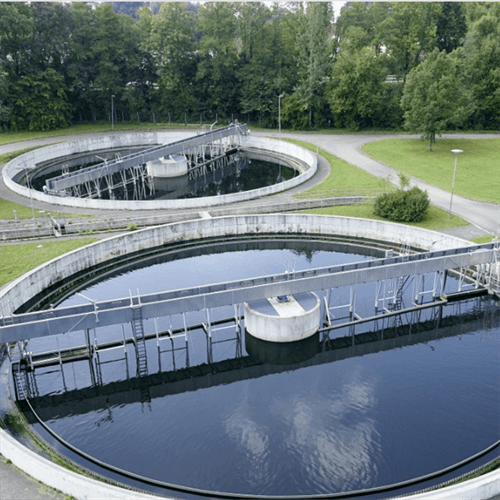

The corrosion resistance of stainless steel plays a crucial role in its water resistance. Since stainless steel is highly resistant to corrosion, it is less likely to rust or deteriorate when exposed to water or other liquids. This makes it a suitable material for applications that require high water resistance, such as in marine environments, water treatment plants, and food processing facilities.

Stainless steel suppliers offer a range of corrosion-resistant stainless steel grades, including austenitic, ferritic, and martensitic grades. These grades have varying levels of corrosion resistance and mechanical properties, making them suitable for different applications.

In addition to its corrosion resistance, stainless steel has several other properties that contribute to its water resistance. It has high strength and durability, making it resistant to impact and deformation. It is also resistant to heat and fire, making it suitable for high-temperature applications. These properties make stainless steel a versatile material for a wide range of applications that require water resistance.

In conclusion, the properties of stainless steel, including its composition and corrosion resistance, play a crucial role in its water resistance. Stainless steel suppliers offer a range of grades and surface finishes that enhance its water resistance, making it suitable for various applications in wet environments. Understanding the properties of stainless steel is essential when choosing a material for applications that require high water resistance.

IV. The effect of surface finish on water resistance

Stainless steel is available in various surface finishes, including polished, brushed, matte, bead-blasted, and patterned finishes.

Each finish has a different appearance and texture and is suitable for different applications.

The surface finish of stainless steel plays a critical role in its water resistance properties. A smooth surface finish will provide better water resistance than a rough one, as it minimizes the surface area where water can accumulate and corrode the stainless steel. Pitting corrosion can occur on stainless steel surfaces with a rough finish, causing cracks and crevices that can collect water and lead to further corrosion. Surface contaminants can also impact the water resistance of stainless steel by promoting corrosion.

There are several methods that stainless steel suppliers can use to enhance the water resistance of stainless steel surfaces. Electropolishing is a process that smooths and cleans the surface of stainless steel, reducing the risk of pitting corrosion and enhancing water resistance. Passivation is another process that creates a protective layer on the surface of stainless steel, preventing corrosion and improving water resistance. Chemical treatments are also available that can enhance the water resistance of stainless steel surfaces by removing surface contaminants and promoting corrosion resistance.

In conclusion, the surface finish of stainless steel plays a crucial role in its water resistance properties. Stainless steel suppliers should carefully consider the surface finish of their products to ensure optimal water resistance for various applications. Electropolishing, passivation, and chemical treatments are effective methods to enhance the water resistance of stainless steel surfaces.

V. Applications of Stainless Steel in Wet Environments

A. Examples of Industries That Use Stainless Steel in Wet Environments

- Food and Beverage Industry:

Stainless steel is extensively used in the food and beverage industry, particularly in the processing and packaging of food and beverages. It is preferred due to its corrosion resistance, durability, and ease of cleaning. - Chemical Industry:

The chemical industry employs stainless steel due to its resistance to chemical corrosion and high-temperature environments. It is used in chemical processing equipment, reactors, storage tanks, and pipelines. - Marine Industry:

Stainless steel is commonly used in the marine industry due to its resistance to seawater corrosion. It is used for components such as propellers, shafts, and fasteners.

B. Specific Applications of Stainless Steel in Wet Environments

- Water Treatment Plants:

Stainless steel is used in water treatment plants due to its resistance to corrosion from chlorides and other chemicals found in water. It is used in equipment such as pipes, valves, and tanks. - Swimming Pools:

Stainless steel is often used in swimming pools because it is resistant to corrosion from chlorine and other chemicals used to sanitize the water. It is used for pool ladders, handrails, and diving boards. - Medical Equipment:

Stainless steel is used in medical equipment, particularly in environments where cleanliness and hygiene are critical, such as operating rooms and laboratories. It is used for equipment such as surgical instruments, storage cabinets, and sinks.

C. Importance of Water Resistance in These Applications

Durability:

Stainless steel’s water resistance is crucial in applications where durability is essential. In wet environments, water can accelerate the corrosion process and shorten the lifespan of materials. Stainless steel’s resistance to water ensures its durability in these environments.Safety:

In applications such as swimming pools and marine environments, safety is crucial. Stainless steel’s resistance to corrosion ensures that the components will not fail or weaken over time, reducing the risk of accidents and injury.Hygiene:

In applications such as food processing and medical equipment, maintaining a high level of hygiene is essential. Stainless steel’s smooth surface and resistance to corrosion make it easy to clean and disinfect, reducing the risk of contamination.

There are many stainless steel suppliers worldwide that offer a range of products and services, including custom fabrication and finishing. When selecting a supplier, it is important to consider factors such as the supplier’s experience, reputation, and quality control processes. Working with a reputable supplier can help ensure that the stainless steel used in wet environments meets the necessary standards for durability, hygiene, and safety.

While stainless steel is highly water-resistant, it is not entirely waterproof. Moisture can still penetrate the surface and cause damage over time. To enhance the water resistance of stainless steel, various surface finishes can be applied, such as electropolishing or passivation. Coatings, such as PVD coatings, can also be used to enhance the water resistance of stainless steel.

Working with a knowledgeable supplier can help ensure that the appropriate surface finish or coating is used to enhance the water resistance of stainless steel in specific applications.

Overall, the water resistance of stainless steel is essential in many applications, particularly those in wet environments. Working with a reputable supplier and understanding the appropriate surface finishes and coatings can ensure that stainless steel meets the necessary standards for durability, hygiene, and safety in these environments.

VI. Conclusion

Stainless steel is a versatile material with excellent corrosion resistance and a high degree of water resistance. It is important to distinguish between water resistance and waterproofness, as these terms have different meanings and implications for the suitability of materials in wet environments. The properties of stainless steel that contribute to its water resistance include its composition, which typically includes chromium and nickel, as well as its ability to form a passive oxide layer on the surface that further protects against corrosion. The surface finish of stainless steel also plays a critical role in its water resistance, with certain finishes being more effective than others.

The thesis of this paper is that stainless steel is a highly suitable material for use in wet environments due to its inherent water resistance and corrosion resistance. By understanding the properties of stainless steel, the effects of surface finish on water resistance, and the various applications of stainless steel in wet environments, designers and manufacturers can make informed decisions about using this material in their products.

As the demand for products that can withstand exposure to water and other corrosive substances continues to grow, the use of stainless steel is likely to become even more prevalent. Stainless steel suppliers have a crucial role to play in ensuring that the material they provide is of high quality and meets the specific requirements of their customers. Designers and manufacturers, on the other hand, need to consider the intended application of their products and select the appropriate grade of stainless steel, surface finish, and other features to ensure optimal water resistance and durability.

Overall, stainless steel is a valuable material for use in wet environments, offering a unique combination of water resistance, corrosion resistance, and strength. By taking advantage of the properties of stainless steel and understanding its limitations, manufacturers can create products that are designed to last in even the harshest of conditions.

Get A Free Quote

Related Posts

Protective Measures for Stainless Steel in Water Environments

Stainless steel, as an extensively utilized alloy material, finds applications across numerous working scenarios. However, it is crucial to emphasize that when stainless steel is

Performance Characteristics and Applications of 303 Stainless Steel

303 stainless steel, as a type of stainless steel containing sulfur and selenium, not only exhibits high machinability and resistance to high-temperature sticking but also

Properties, Characteristics and Applications of 416 Stainless Steel

As an outstanding martensitic stainless steel, 416 stainless steel boasts a unique chemical composition that endows it with superior magnetic properties, good corrosion resistance, ease

Advantages of Hot Rolling Process in Stainless Steel Manufacturing

Stainless steel, a ubiquitous metallic material, finds extensive applications across various sectors such as construction, food processing, and healthcare. Enhancing the reliability and durability of

5 Methods to Enhance the Strength of Austenitic Stainless Steel

Stainless steel, as a crucial and widely utilized steel type, enjoys extensive applications in civil and industrial sectors due to its high corrosion resistance, excellent

:+86-13012867759

:+86-13012867759  :export86@sino-stainless-steel.com

:export86@sino-stainless-steel.com